Professional Documents

Culture Documents

Ecp 12076042

Uploaded by

VigneshVickeyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ecp 12076042

Uploaded by

VigneshVickeyCopyright:

Available Formats

Modelling and Simulation of the Coupled Rigid-flexible Multibody

Systems in MWorks

Xie Gang1, Zhao Yan1, Zhou Fanli*2, Chen Liping1

1

CAD Center, Huazhong University of Science and Technology, Wuhan, China, 430074

2

Suzhou Tongyuan Software & Control Tech. Co. Ltd, Suzhou, China, 215123

{xieg, zhaoy, zhoufl, chenlp}@tongyuan.cc

teed. Therefore, stress and deformation of machine

Abstract

components have to be predicted in the design pro-

cess.

Aiming to the design challenge of modern mecha-

tronic products, this paper presents a method to sim- The increasing computational power of current com-

puter enables to model a multibody system as 3D

ulate the coupled rigid-flexible system in MWorks.

Firstly, the component mode synthesis (CMS) tech- deformable body using the finite element method.

The flexible multibody dynamics is the subject con-

nique is introduced and the Craig-Bampton method

is adopted to build the flexible-body model. The cerned with the modeling and analysis of constrained

general flexible-body model named FlexibleBody is deformable bodies that undergo large displacements

developed based on the standard MultiBody library and rotations. DLR® FlexibleBodies Library [1, 2] pro-

in Modelica, which describes the small and linear vides the general flexible model so that users can

deformation behavior (relative to a local reference simulate the elastic deformation of flexible-body in a

frame) of a flexible-body that undergoes large and modal synthesis way, in which the standard input

non-linear global motion. In the model, the modal data (SID) [3, 4] file should be offered by a third-party

neutral file (MNF) is introduced as a standard inter- software. In SID file, Guyan reduction and Ritz ap-

face to describe the constraint modes. Secondly, the proximation are adopted. The Rayleigh–Ritz method

[4]

model is used to construct a library of boom system chooses an approximate form for the eigenfunc-

of concrete pump truck and the simulations covering tion with the lowest eigenvalue. In the Guyan reduc-

the expanding and folding process are carried out tion method [4], a set of user-defined master nodes are

based on both the rigid multibody and the coupled retained and the remaining set of slave nodes are re-

rigid-flexible system models. Finally, the influence moved by condensation. Only stiffness properties are

to dynamics performance of the boom system is ana- considered during the condensation, and inertia cou-

lyzed and the conclusion is drawn. The method in pling of master and slave nodes are ignored. Based

this paper provides an effective approach to build on an improved Craig-Bampton method [5-8],

unified model and simulate flexible-body in multi- MSC.ADAMS® adopts the modal neutral file [9],

domain engineering systems. which can be exported by some finite element soft-

Keywords: rigid-flexible system; concrete pump ware, to drive the animation of the flexible body.

truck; MWorks The MNF is a binary file that contains the location of

nodes and node connectivity, nodal mass and inertia,

mode shapes, generalized mass and stiffness for

1 Introduction mode shapes. The mode shapes in modal neutral file,

which contain the interface constraint modes, are

Much industrial equipment is mechatronic and con- revised effectively after modal truncation. So the

tains high-speed, lightweight, and high-precision Craig-Bampton method is more accurate and has

mechanical system. In these mechanical systems one been widely used in engineering [10-14]. But the soft-

or more structural components often need to consider ware, just like ADAMS, mainly focuses on modeling

the deformation effects for design analyses. The in- and simulation of the pure mechanical system and

tegrated design and simulation of the mechatronic lacks support of multi-domain physical systems. In

systems with flexible bodies make the multidiscipli- order to model and simulate the mechatronic prod-

nary challenge. When designing such a mechatronic ucts composed of mechanical, electronic, hydraulic,

system, the performance requirements must be satis- and control engineering systems, the co-simulation

fied and the strength of the system must be guaran-

DOI Proceedings of the 9th International Modelica Conference 405

10.3384/ecp12076405 September 3-5, 2012, Munich, Germany

Modelling and Simulation of the Coupled Rigid-flexible Multibody Systems in MWorks

should be performed with other software such as 2.1 Theoretical Background

Matlab/Simulink®,

LMS.AMESim®,

etc.

In this paper, the FlexibleBody model is developed In this paper, only small, linear body deformations

based on the component mode synthesis (CMS) and relative to a local reference frame are considered,

the improved Craig-Bampton method [9, 11]. An exter- while that local reference frame indicates large, non-

nal C function MNFParser is programmed to get the linear global motion.

mode shapes data in the model. The finite element The discretization of a flexible component into a fi-

analysis (FEA) results can then be incorporated into nite element model represents the infinite number of

a part model by superimposing the flexible-body de- degree of freedom (DOF) with a finite element. The

flection on the motion of rigid-body. The postproces- basic premise of modal superposition is that the de-

sor tool in MWorks [15] is also improved to support formation behavior of a component with a very large

the nephogram animation of the deformation. As an number of nodal DOF can be captured with a much

example, a boom system library of the concrete smaller number of modal DOF. This reduction in

pump truck is developed. And the simulations cover- DOF is called modal truncation.

ing the expanding and folding process are carried out The linear deformations of the nodes of this finite

based on both the rigid multibody and the coupled element mode, u , can be approximated as a linear

rigid-flexible system models. The simulation results combination of a smaller number of translational

are compared and it shows the coupled rigid-flexible mode shapes matrix [9], ΦT T 1 , T 2 , , TM .

system is more conformable with the actual boom M

system. u ΦT q+ΦT q T 1q1 + +TM qM =Ti qi (1)

i 1

Where ΦT and q are the truncated mode shapes ma-

2 The Flexible-Body Model trix and the truncated modal coordinates respectively.

M is the number of mode shape, and

q q1 , q2 , , qM is the modal coordinates.

T

To build the model of flexible-body based on CMS,

the mode shapes data in MNF is provided by third- Similar to equation(1), as the body deforms, every

party finite element analysis (FEM) software. So the node rotates through small angles relative to its ref-

MNF file needs to be parsed. Then the equations of erence frame. These angles are obtained using a

coupled elastic deformation and rigid body are estab- modal superposition [9].

lished. To animate the deformation of flexible-body, M

the postprocessor needs to have the ability to show θ ΦR q ΦR q Ri qi (2)

i 1

nephograms. The whole process in MWorks is

shown in Figure 1. Where ΦR R1 , R 2 , RM is the slice of rotational

CAE software: Ansys,

Nastran, etc.

mode shapes matrix.

MNF file

In the studies referring to [3, 4], the eigenvectors of

an unconstrained system be used. Eigenvectors are

Multi-domain FlexibleBody

MNF file name found to provide an inadequate basis in system level

Modeling modeling. To improve the accuracy of the system

Parameters MnfParser

model, the CMS [3] techniques are adopted, the most

Parse MNF file

Variables general methodology is Craig-Bampton method [5].

Initial algorithm

Calculate Invariants

and Damping

The Craig-Bampton method [5, 6] allows the user to

Coefficient select a subset of DOF which are not to be subject to

Mworks

Initial Equations

Computation

Equations

modal superposition. These boundaries DOFs (or

Mass, Inertia tenser,

Node coordinate, etc.

attachment DOFs) are preserved exactly in the

deformation nephograms Craig-Bampton modal basis. There is no loss in reso-

Import geometry file

lution of these DOF when higher order modes are

truncated [7, 8].

PostProcessor Color legend bar

The system DOF in Craig-Bampton method are par-

Render nephograms titioned into boundary DOF, uB , and interior DOF,

u I . Two sets of mode shapes are defined, as follows

Figure 1: Development process of flexible-body in [9]

MWorks :

Constraint modes: These modes are static shapes

obtained by giving each boundary DOF a unit dis-

placement while holding all other boundary DOF

406 Proceedings of the 9th International Modelica Conference DOI

September 3-5, 2012, Munich Germany 10.3384/ecp12076405

Session 3D: Mechanic Systems II

fixed. The basis of constraint modes completely

spans all possible motions of the boundary DOFs,

with a one-to-one correspondence between the modal

coordinates of the constraint modes and the dis-

placement in the corresponding boundary DOF,

qC uB .

Fixed-boundary normal modes: These modes are

obtained by fixing the boundary DOF and computing

an eigensolution. There are as many fixed-boundary

normal modes as the user desires. These modes de-

fine the modal expansion of the interior DOF. The Figure 2: The position vector to a deformed point P

quality of this modal expansion is proportional to the on a flexible body

number of modes retained by the user. The instantaneous location of a point that is attached

The relationship between the physical DOF and the to a node, P , on a flexible body, B , is the sum of

Craig-Bampton modes and their modal coordinates is three vectors, showing in Figure 2.

illustrated by the following equation. rp x s p u p (5)

u I 0 qC

u B Where

Φ IN q N

(3)

u I Φ IC x is the position vector from the origin of the ground

Where I , 0 are identity and zeros matrices, respec- reference frame to the origin of the local body refer-

tively. ΦIC is the physical displacements of the inte- ence frame of the flexible body.

rior DOF in the constraint modes. ΦIN is the physi- s p is the position vector of the undeformed position

cal displacements of the interior DOF in the normal of point P with respect to the local body reference

modes. qC is the modal coordinates of the constraint frame of body B .

modes. qN is the modal coordinates of the fixed- u p is the translational deformation vector of point P ,

boundary normal modes. the position vector from the point’s undeformed po-

The generalized stiffness and mass matrices corre- sition to its deformed position. It is also expressed in

sponding to the Craig-Bampton modal basis are ob- the local body coordinate system. The deformation

tained via a modal transformation. vector is a modal superposition, uP ΦTPq . Where

ΦTP is the slice from the modal matrix that corre-

2.2 FlexibleBody Model sponds to the translational DOF of node P .

The general flexible-body model based on CMS is

The governing differential equation of flexible-body developed according to the following processes.

[9, 15]

, in terms of the generalized coordinates is: (1) Defining the parameters: MNF file name, mass,

T T

1 M ψ inertia, mode shape, set of selected mode, etc.

Mξ Mξ ξ ξ Kξ f g Dξ λ Q (4)

2 ξ ξ (2) Setting the variants and default values: modal

Where, coordinates and first-order derivate, second-

order derivate, velocity, acceleration, etc.

ξ,ξ, ξ are the generalized coordinates of the flexible-

(3) Configuring the initial algorithm: Call

body and their time derivatives. MNFParser function (refer to 2.3 MNF File Par-

x ψ q

T

ξ x y z qi ,i 1,

T

,M

ser) to get the mass, inertia, mode shape, stiff-

ness matrix, invariants, damping coefficient, etc.

M is the mass matrix.

(4) Setting the initial equations: just like the equa-

K is the generalized stiffness matrix.

tions in Body model in Multibody library.

f g is the generalized gravitational force.

(5) Describing the equations: Force and torque bal-

D is the modal damping matrix. ance equation, and equation (4) are defined.

Ψ is the algebraic constraint equations. With modal coordinates, the deformation of the

λ is the Lagrange multipliers for the constraints. flexible-body equation (1) , (2), (4) and (5).

Q is the generalized applied forces. This approach consists of the Body model in Multi-

Body library. The general FlexibleBody model is

shown in Figure 3.

DOI Proceedings of the 9th International Modelica Conference 407

10.3384/ecp12076405 September 3-5, 2012, Munich, Germany

Modelling and Simulation of the Coupled Rigid-flexible Multibody Systems in MWorks

100% critical damping for modes with frequen-

cy above 1000.

The MNFParser also provides nodes coordinates and

element faces of the FE model to the postprocessor

for rendering deformation nephograms.

3 Modeling and Simulation of the

Coupled Rigid-flexible Boom Sys-

Figure 3: Icon of the FlexibleBody model tem

The FlexibleBody model encapsulates the complexi- The concrete pump truck has become a kind of in-

ty of details into a black box that we can use modu- dispensable machinery equipment in construction

larly without considering the detailed implementa- industry. It pumps concrete continuously sent by

tion at the top level. concrete mixer truck to the pouring site. The boom

system is generally composed of mechanical, hy-

2.3 MNF File Parser draulic and control subsystems, and the multi-

domain modeling and simulation is necessary for the

The mode shapes data are needed to build the flexi- design and validation of this system. The modeling

ble-body model with modal synthesis method, and and simulation process of boom system in MWorks

the MNF is adopted to express these data, which is is shown in Figure 4.

generated by CAE software such as ANSYS®, NAS- Multi-domain Library

Concrete Pump

· Mechanical system

TRAN® etc. Truck Arm System

· Hydraulic system

Modeling · Control system

Modal neutral file is a platform-independent binary

file. The information in a MNF includes geometry · Set algorithm, simulation time,

(locations of nodes and node connectivity), nodal Compile & Simulate

·

tolearance

Compile

mass and inertia, mode shapes, generalized mass and · Simulate

stiffness for mode shapes, which is listed in Table 1.

·

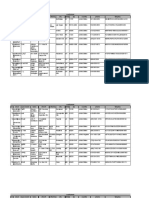

Table 1: Information in MNF PostProcessor

·

View Animation

View Plots

Block information

date, program name and version, title, Compare

· Input Experiment Data

Header Simulation Result

· Superimpose test data on plots

MNF version, units and Experiment

mass, moments of inertia, center of

Body properties

mass Model Verification

Interface points Reduced stiffness and mass matrices

Interface modes User requests the number of modes Rigid-flexible · Define Flexible Bodies

Coupling Dyanmics · Rigid-flexible Coupling Dynamics MNF File of Arm

Constraint modes Interface constraint modes Simulation Analysis

According to its data structure, an external C func- Design of · Design Sensitivity Studies

tion “MNFParser” is programed to parse the MNF Experiment & · Design of Experiments

Optimization · Optimization

file and to obtain the quality, inertia tensor, eigen-

values, modal shapes matrix, etc.

To reduce the simulation time, the nine inertia invar- Figure 4: The modeling and simulation workflow of

iants [9] are calculated beforehand from the N nodes booms system of concrete pump truck

of the finite element model based on each node’s

3.1 Library of Boom System

mass, undeformed location coordinates in the com-

ponent modes.

The hierarchical multi-domain library of boom sys-

And the default damping coefficients are calculated

tem is developed based on the standard Modelica

according to the modal frequency.

library and the hydraulic library developed by Su-

1% damping for all modes with frequency low-

zhou Tongyuan Software & Control Technology

er than 100.

Company. Its structure is shown in Figure 5.

10% damping for modes with frequency in the

100-1000 range.

408 Proceedings of the 9th International Modelica Conference DOI

September 3-5, 2012, Munich Germany 10.3384/ecp12076405

Session 3D: Mechanic Systems II

system model can be conveniently constructed by

Platform

dragging and dropping based on the library.

Concrete Booms

Pump Truck 3.2 Simulation of Rigid Boom System

Mechanics

Boom Link Mechanism

System

Pipeline The booms of concrete pump truck must expand and

fold regularly while working. The working loads

Hydraulic Special Valves

should be analyzed to ensure the safety. The control

High Volume system should also be designed to satisfy the casting

Pump

needs.

Control

… ... The hierarchical structure of the boom system model

is established based on the MultiBody library, shown

Figure 5: Structure of the booms library in Figure 6.

The boom system library includes mechanics, hy-

draulic, and control subsystem library. The boom

Mechanical system

Derricking cylinder

Chassis model

Control system

Hydraulic system

Figure 6: Hierarchical model of the booms system

Base on the system model, the various working con- ity of control system can also be analyzed. For ex-

ditions can be simulated by modifying the parame- ample, the expanding and folding process of the

ters of the control and hydraulic systems, and the boom_4 is simulated and the result is shown in Fig-

work loads of each boom, flow quantity and pressure, ure 7.

impact loads in the hydraulic system and the reliabil-

DOI Proceedings of the 9th International Modelica Conference 409

10.3384/ecp12076405 September 3-5, 2012, Munich, Germany

Modelling and Simulation of the Coupled Rigid-flexible Multibody Systems in MWorks

Boom_5

Boom_4

Displacement of flange_b in Cylinder_4

Cylinder_4

Trajectory of

CM in Boom_5

Force of flange_b in Cylinder_4

Flow of port_B in Cylinder_4

Figure 7: The expanding and holding process of the boom_4

3.3 Simulation of the Coupled Rigid-flexible

Boom System

There will be a large elastic deformation on each (a) Boom_1

boom in the actual working process. This not only

has a great impact on the casting work, but also re-

duces the safety performance of the system. So it is

necessary to take the elastic deformation into consid-

eration for improving the accuracy of the system (b) Boom_2

model.

3.3.1 Modal Analysis of the Booms

The modal neutral files of booms are needed to per- (c) Boom_3

form the coupled rigid-flexible dynamic analysis. So

it’s necessary to take modal analysis for each boom.

We use the ANSYS software to compute the modals. (d) Boom_4

The analysis workflow is as follow:

(1) Inputting the material parameters: The elastic

modulus, Poisson's ratio, and density are set to

FE model. The material properties determine the (e) Boom_5

spring stiffness and damping. Figure 8: FE model of booms

(2) Meshing the model: The solid45 element is se-

lected to mesh the solid geometry. And the We set twenty modes to extract for each boom. Then

mass21 element is selected to mesh the key we can get fifty modes in the MNF. The modes from

points set up on the central axis of the hinge first to sixth are rigid modes, approximately to zero.

hole. Because there are five fixed interface points in each

(3) Configuring the rigid region: The rigid regions boom, and thirty constraint modes of six degrees of

are established about the interface node and freedom are extracted. We choose a sufficient num-

nodes on the cylinder faces respectively. ber of modes to represent the boom so that the fre-

(4) Generating the MNF: Run the ADAMS macros, quency range is able to deactivate eigenmodes based

choose the interface nodes, specify the mode on the frequency or the energy criterion. Some natu-

order numbers to expand, then generate modal ral frequencies of the booms are listed in Table 2.

neutral file of each boom.

The finite element models of booms are shown in

Figure 8.

410 Proceedings of the 9th International Modelica Conference DOI

September 3-5, 2012, Munich Germany 10.3384/ecp12076405

Session 3D: Mechanic Systems II

Table 2: Natural frequency of booms mechanical system is converted from the rigid multi-

Nat. body to the coupled rigid-flexible system.

Boom_1 Boom_2 Boom_3 Boom_4 Boom4

Freq. Replaced by FlexibleBody model with respective parameters

1-6 0 0 0 0 0

7 25.8302 35.5842 33.0956 49.3527 8.7492

8 36.3539 48.4689 49.3527 22.1214 11.1239

9 52.8219 76.9397 49.3527 53.6334 23.7672

10 74.1143 89.2075 49.3527 60.5197 30.3335

11 75.6471 90.2372 49.3527 81.8889 47.3777

12 81.2592 94.7992 49.3527 85.3635 56.8012

… … … … … …

Figure 9: The coupled rigid-flexible mechanical system

3.3.2 Replacement of the FlexibleBody Model 3.3.3 Simulation of Coupled Rigid-flexible

The rigid parts of booms shown in Figure 6 are re- Boom System

placed by FlexibleBody model with respective pa- The expanding and folding process of boom_5 is

rameters, as shown in Figure 9. So the model of the simulated, as shown in Figure 10.

Flexible

Boom_5

Cylinder_5

Displacement of flange_b in Cylinder_5

Flexible

Boom_4

Force of flange_b in Cylinder_5

Trajectory of

CM in Boom_5

Deformation of Boom_5

Figure 10: The process of expanding and folding boom_5

The modal coordinates of each boom are show in

Figure 11. The modal coordinates q[1] - q[6] are cor-

responding to 7th - 12th modes respectively. Obvious-

ly, the value of modal coordinate q[1] is the biggest

one in each boom. It indicates that the 7th mode con-

tributes most energy to the flexible-body. And the

values of other modal coordinates are smaller and

smaller, indicating less energy contribution. The var-

iation tendency is complied with the modal superpo-

sition theorem and energy criterion [11].

(a) Boom 1

DOI Proceedings of the 9th International Modelica Conference 411

10.3384/ecp12076405 September 3-5, 2012, Munich, Germany

Modelling and Simulation of the Coupled Rigid-flexible Multibody Systems in MWorks

(a) t= 10.44s

(b) Boom 2

(b) t = 12.84s

(c) Boom 3

(c) t = 100.20s

Figure 12: Nephograms of the deformation in booms

The obvious vibration can be found in simulation

result of the coupled rigid-flexible dynamics. And in

the actual working process, the vibration does exist

in the expanding or the holding process. The impact

on hydraulic and control system can be analyzed for

the elastic deformation of each boom. So compared

(d) Boom 4 with a rigid model, the coupled rigid-flexible model

has higher accuracy, and is more close to the actual

system.

3.4 Simulation Comparation between Rigid

and Coupled Rigid-flexible Boom System

3.4.1 Comparation of Simulation Results

The Figure 13 shows the simulation results, in com-

parison coupled rigid-flexible multibody with rigid

multibody, of boom_3 ~ boom_5 expanding and

(e) Boom 5 holding together.

Figure 11: Modal coordinates of booms

With the powerful post-processor in MWorks, the

deformation color contour of boom_4 and boom_5

are shown in Figure 12.

412 Proceedings of the 9th International Modelica Conference DOI

September 3-5, 2012, Munich Germany 10.3384/ecp12076405

Session 3D: Mechanic Systems II

Rigid boom system Coupled rigid-flexible boom system

Figure 13: Comparation of rigid system and coupled rigid-flexible system

-4

x 10

12

Rigid system

10 Rigid-flexible system

8

flow (m3/s)

-2

0 50 100 150 200 250

time (s)

Figure 14: Flow in hydraulic cylinder port_A of boom_4

5

x 10

8

6 Rigid system

Rigid-flexible system

4

2

force (N)

-2

-4

-6

-8

-10

0 50 100 150 200 250

time (s)

Figure 15: Force in flang_b of boom_4

DOI Proceedings of the 9th International Modelica Conference 413

10.3384/ecp12076405 September 3-5, 2012, Munich, Germany

Modelling and Simulation of the Coupled Rigid-flexible Multibody Systems in MWorks

Figure 14 shows the flow in hydraulic cylinder system, especially at the reversing point: the former

port_A of boom_4. Figure 15 shows the force in changes gently, but the latter changes dramatically,

flange_b of boom_4. There are obvious differences which are due to elastic deformation of flexible

between rigid and the coupled rigid-flexible boom booms.

6.952

Rigid system

6.95 Rigid-flexible system

6.948

length (m)

6.946

6.944

6.942

6.94

6.938

0 50 100 150 200 250

time (s)

Figure 16: Length of boom_4

9.22

Rigid system

9.21

Rigid-flexible system

9.2

9.19

length (m)

9.18

9.17

9.16

9.15

9.14

0 50 100 150 200 250

time (s)

Figure 17: Length of boom_5

Figure 16 and Figure 17 show the length of boom_4 tion. Moreover, the coupled rigid-flexible system is a

and boom_5 respectively. The length of the rigid strong nonlinear system, especially integrated with

boom is a constant value, while the length curve of hydraulic and control subsystem.

the flexible boom is shown a relatively evident fluc- Although introducing great number of variables and

tuation, especially when the motion state changed, equations, component mode synthesis saves time and

deformation peak appears. The maximum force of processing resources by breaking up a single large

each hinge point is larger than the rigid body simula- problem several reduced-order problems via sub-

tion results, when boom system changes the motion structuring.

state.

The calculation time for coupled rigid-flexible boom

system is more than double for rigid boom system in

3.4.2 Comparation of Calculation Efficiency

the test cases. There are several influence factors for

The finite element method is apt for discretizing the calculation time.

arbitrary complicated geometry. But with gigantic

(1) The number of nodes. Too many DOFs can

nodes in large scale and complex system, the compu-

mean unacceptably long computation time.

tation is heavy. FEA is too inefficient for system lev-

el modeling and is incapable of analyzing large mo- (2) The number of modes. If a mode does not con-

tribute to the response of the flexible component

414 Proceedings of the 9th International Modelica Conference DOI

September 3-5, 2012, Munich Germany 10.3384/ecp12076405

Session 3D: Mechanic Systems II

during a simulation, it could be disabled to save DLR FlexibleBodies Library. Proceedings

computation time. 8th Modelica Conference, Dresden, Germany,

(3) The modal damping coefficients. The bigger March 20-22, 2011: 121- 132.

modal damping coefficient is helpful to control [3] O. Wallrapp: Standardization of Flexible

the integration step by suppressing the resonance Body Modeling in Multibody System Codes,

response respect to the corresponding natural Part 1: Definition of Standard Input Data,

frequency. Mechanics of Structures and Machines

22(3):283-304, 1994.

[4] P. Koutsovasilis, V. Quarz, M. Beitelschmidt.

4 Conclusions Standard input data for FEM-MBS coupling:

importing alternative model reduction meth-

By introducing the CMS technique and the improved ods into SIMPACK. Mathematical and Com-

Craig-Bampton method, the FlexibleBody model has puter Modelling of Dynamical Systems, 2009,

been constructed based on the standard MultiBody 15(1): 51-68.

library in this paper. The boom system of concrete [5] R. Craig, M. Bampton. Coupling of substruc-

pump truck is modeled and simulated in MWorks, tures for dynamic analysis. Amer. Inst. Aero.

which is composed of a coupled rigid-flexible mech- Astro. J. 1968, 6(7): 1313-1319.

anism, a hydraulic and a control subsystem. Numeri-

cal results are compared and discussed with respect [6] S. Rubin. Improved component-mode repre-

to efficiency and accuracy. sentation for structural dynamic analysis

The FlexibleBody model can be easily incorporate Amer. Inst. Aero. Astro. J., 13 (8) (1975), pp.

flexibility into system models. This optional add-on 995–1006.

module interface with several commercial finite ele- [7] R. R. Craig. Coupling of substructures for

ment applications to accurately define component dynamic analyses: an overview, in: Struc-

flexibility, and it has an easy-to-use interface that tures, Structural Dynamics and Material Con-

allows engineers to quickly convert rigid parts to ference, 41st AIAA/ASME/ASCE/AHS/ASC,

flexible ones. Atlanta, 2000, AIAA-2000-1573.

The simulation process is illustrated by boom system [8] D. J. Daniel, J. Rixen. A dual Craig-Bampton

of concrete pump truck applications. However, it can method for dynamic substructuring. Journal

be applied to design any mechanical system such as of Computational and Applied Mathematics,

classical or compliant mechanisms, deformable 2004, 168(1-2): 383-391.

structures and more general to solve most mechani- [9] ADAMS. Theoretical Background. MSC.

cal dynamics problems. Software Corporation, 2003: 1-30.

http://ti.mb.fh-

osna-

ACKNOWLEDGEMENTS brueck.de/adamshelp/mergedProjects/flex/fle

x_gen/flextheory.pdf.

The paper is supported by Major National Science & [10] Dimitri Metaxas, Eunyoung Koh. Flexible

Technology Specific Project (No. 2011ZX02403- multibody dynamics and adaptive finite ele-

005), The National Basic Research Program of China ment techniques for model synthesis and es-

(973 Program) (No. 2011CB706502). timation. Comput. Methods Appl. Mech. En-

grg. 1996, 136: 1 – 25.

[11] Takehiko Eguchi. Improvement of compo-

References nent mode synthesis model for vibration

analysis of hard disk drives using attachment

[1] Andreas Heckmann, Martin Otter, Stefan

modes. Microsyst technol, 2007, 13: 1085-

Dietz, et al. The DLR FlexibleBodies library

1092.

to model large motions of beams and of flex-

ible bodies exported from finite element pro- [12] Frédéric Bourquin. Analysis and comparison

grams, The Modelica Association. Modelica of several component mode synthesis meth-

2006: 85-95. ods on one-dimensional domains. Numer.

[2] Andreas Heckmann, Stefan Hartweg and In- Math. 1990, 58: 11 – 34.

go Kaiser. An Annular Plate Model in Arbi- [13] Polarit Apiwattanalunggarn, Steven W. Shaw,

trary Lagrangian-Eulerian Description for the Christophe Pierre. Component Mode Synthe-

DOI Proceedings of the 9th International Modelica Conference 415

10.3384/ecp12076405 September 3-5, 2012, Munich, Germany

Modelling and Simulation of the Coupled Rigid-flexible Multibody Systems in MWorks

sis Using Nonlinear Normal Modes. Nonlin-

ear Dynamics, 2005, 41: 17 – 46.

[14] Ulf Sellgren. Component Mode Synthesis –

A method for efficient dynamic simulation of

complex technical systems. Department of

Machine Design, the Royal Institute of

Technology, Sweden, 2003: 1-27.

[15] Zhou Fanli, Chen Liping, Wu Yizhong, et al.

MWorks: a Modern IDE for Modeling and

Simulation of Multi-domain Physical Sys-

tems Based on Modelica. The Modelica As-

sociation, Modelica 2006: 725-731.

416 Proceedings of the 9th International Modelica Conference DOI

September 3-5, 2012, Munich Germany 10.3384/ecp12076405

You might also like

- Electronic Fundamentals Module-4 EASA Part-66Document90 pagesElectronic Fundamentals Module-4 EASA Part-66SK88% (58)

- Electronic Fundamentals Module-4 EASA Part-66Document90 pagesElectronic Fundamentals Module-4 EASA Part-66SK88% (58)

- AD881357 - Wheeled AmbhibiousDocument434 pagesAD881357 - Wheeled AmbhibiousVigneshVickeyNo ratings yet

- RADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintDocument392 pagesRADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintLafayers100% (2)

- Pearson Knowledge Management An Integrated Approach 2nd Edition 0273726854Document377 pagesPearson Knowledge Management An Integrated Approach 2nd Edition 0273726854karel de klerkNo ratings yet

- Customer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyDocument37 pagesCustomer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyAgus ChandraNo ratings yet

- Robotics: Dynamic Modeling of Planar Multi-Link Flexible ManipulatorsDocument26 pagesRobotics: Dynamic Modeling of Planar Multi-Link Flexible ManipulatorsJackNo ratings yet

- 58 MelnikovDocument13 pages58 MelnikovMayurNo ratings yet

- In-Cylinder CFD Simulation Using A C++ Object Oriented Toolkit SAE2004Document11 pagesIn-Cylinder CFD Simulation Using A C++ Object Oriented Toolkit SAE2004AghajaniNo ratings yet

- CSTR LMPC Vs NMPCDocument6 pagesCSTR LMPC Vs NMPCgverma9461No ratings yet

- A Simulink Environment For Simulation and Control of Flexible Manipulator SystemsDocument6 pagesA Simulink Environment For Simulation and Control of Flexible Manipulator SystemsselvamNo ratings yet

- A - Simplified - Flexible - Multibody - Dynamics - For - A - Main Landing GearDocument11 pagesA - Simplified - Flexible - Multibody - Dynamics - For - A - Main Landing GearSoma VargaNo ratings yet

- Dynamics of In-Line Six-Cylinder Diesel Engine With Rubber DamperDocument10 pagesDynamics of In-Line Six-Cylinder Diesel Engine With Rubber DamperkspetsnazNo ratings yet

- IMSD2018 Full Paper 206Document17 pagesIMSD2018 Full Paper 206Mahmoud KaramNo ratings yet

- On the Use of Lagrange Multiplier State-Space SubsDocument29 pagesOn the Use of Lagrange Multiplier State-Space SubsacarrascotaberaNo ratings yet

- Machine Tools Mechatronic AnalysisDocument10 pagesMachine Tools Mechatronic AnalysisAndrisan CatalinNo ratings yet

- Permanent Magnet Synchronous Motor Parameter Identification Using Particle Swarm OptimizationDocument8 pagesPermanent Magnet Synchronous Motor Parameter Identification Using Particle Swarm OptimizationSrinivas KamarsuNo ratings yet

- Taniguchi 2001Document14 pagesTaniguchi 2001sajbberNo ratings yet

- Dynamic Model of Flexible Link Manipulators With Translational and Rotational JointsDocument7 pagesDynamic Model of Flexible Link Manipulators With Translational and Rotational JointsVanHieu LuyenNo ratings yet

- Equivalent Circuit Synthesis of Multiport S Parameters in PoleResidue FormDocument9 pagesEquivalent Circuit Synthesis of Multiport S Parameters in PoleResidue FormYassir Ait lahcenNo ratings yet

- Dynamics Modelling of Suspended Mobile Manipulators: An Explicit Approach With VerificationDocument9 pagesDynamics Modelling of Suspended Mobile Manipulators: An Explicit Approach With VerificationAli BelhocineNo ratings yet

- Ling 2016Document12 pagesLing 2016Ho Nhat LinhNo ratings yet

- Tpel 2016 2628783Document12 pagesTpel 2016 2628783Vivek PatelNo ratings yet

- Planarmultibody A Modelica Library For Planar Multi-Body SystemsDocument8 pagesPlanarmultibody A Modelica Library For Planar Multi-Body Systemssudhansu samalNo ratings yet

- Application of Dynamic Optimisation To The TrajectDocument18 pagesApplication of Dynamic Optimisation To The TrajectadeshinexxNo ratings yet

- Multibody System Simulation With SimmechanicsDocument24 pagesMultibody System Simulation With SimmechanicsSonny Jason ANo ratings yet

- Paper 11Document7 pagesPaper 11api-282905843No ratings yet

- Research Article: Model Reduction of The Flexible Rotating Crankshaft of A Motorcycle Engine CranktrainDocument10 pagesResearch Article: Model Reduction of The Flexible Rotating Crankshaft of A Motorcycle Engine CranktrainDavide MaranoNo ratings yet

- Paper 10Document6 pagesPaper 10Daniel G Canton PuertoNo ratings yet

- Robustness Analysis For Rotorcraft Pilot Coupling With Helicopter Flight Control System in LoopDocument8 pagesRobustness Analysis For Rotorcraft Pilot Coupling With Helicopter Flight Control System in LoopMuhammad Mazhar BashirNo ratings yet

- Superquadrics and Model Dynamics For Discrete Elements in Interactive DesignDocument13 pagesSuperquadrics and Model Dynamics For Discrete Elements in Interactive Design1720296200No ratings yet

- Computers and Geotechnics: Bin Wang, Philip J. Vardon, Michael A. Hicks, Zhen ChenDocument9 pagesComputers and Geotechnics: Bin Wang, Philip J. Vardon, Michael A. Hicks, Zhen ChenKTMONo ratings yet

- Gence Li 1993Document12 pagesGence Li 1993Luis CarvalhoNo ratings yet

- An Investigative Model For Wimax Networks With Multiple Traffic SummaryDocument14 pagesAn Investigative Model For Wimax Networks With Multiple Traffic SummarySalman ZahidNo ratings yet

- Modelling Short-And Open-Circuit Faults in Permanent Magnet Synchronous Machines Using ModelicaDocument7 pagesModelling Short-And Open-Circuit Faults in Permanent Magnet Synchronous Machines Using ModelicaAbir HezziNo ratings yet

- 1 s2.0 S0957415809001585 MainDocument17 pages1 s2.0 S0957415809001585 MainLeila JoudiNo ratings yet

- Efficient Solution Algorithms For Factored MdpsDocument70 pagesEfficient Solution Algorithms For Factored MdpsĐạt Hoàng LễNo ratings yet

- Convex Optimization With Abstract Linear OperatorsDocument9 pagesConvex Optimization With Abstract Linear OperatorsjohanNo ratings yet

- tmp79F5 TMPDocument10 pagestmp79F5 TMPFrontiersNo ratings yet

- Fast Algorithms For Digital Computation of Linear Canonical TransformsDocument35 pagesFast Algorithms For Digital Computation of Linear Canonical TransformsActivities with Arnav GoelNo ratings yet

- Matrix Methods in Structural Mechanics Lecture NotesDocument33 pagesMatrix Methods in Structural Mechanics Lecture NotesEyuel ZebeneNo ratings yet

- Paper Electrical Journal Bratislava 4 - 120-02Document9 pagesPaper Electrical Journal Bratislava 4 - 120-02EndritShalaNo ratings yet

- Upscale1 PDFDocument8 pagesUpscale1 PDFPondok HudaNo ratings yet

- Dynamixel MX ModelDocument7 pagesDynamixel MX ModelMaximNo ratings yet

- FE Simulation of HoneycombDocument5 pagesFE Simulation of HoneycombManoj KumarNo ratings yet

- Ruzlaini Ghoni (cd7272) - Chap 3Document5 pagesRuzlaini Ghoni (cd7272) - Chap 3Vignesh RamakrishnanNo ratings yet

- Reduced-Order Models For MEMS ApplicationsDocument34 pagesReduced-Order Models For MEMS ApplicationsCazimir BostanNo ratings yet

- Recursive dynamics solver (ReDySim) efficiently simulates multibody systemsDocument6 pagesRecursive dynamics solver (ReDySim) efficiently simulates multibody systemsJorge Renato Chirinos QuiñonezNo ratings yet

- A New Self-Healing DSTATCOM For Volt-VAR and Power Quality ControlDocument8 pagesA New Self-Healing DSTATCOM For Volt-VAR and Power Quality ControlMahutaNo ratings yet

- Modal AnalysisDocument10 pagesModal Analysislrodriguez_892566No ratings yet

- Iowtc2022 98217Document10 pagesIowtc2022 98217Quién SabeNo ratings yet

- Model Order ReductionDocument21 pagesModel Order Reductionhaider aliNo ratings yet

- Fractional Order Sliding Mode Control Based Chaos Synchronization and Secure CommunicationDocument6 pagesFractional Order Sliding Mode Control Based Chaos Synchronization and Secure CommunicationPRITAM PARALNo ratings yet

- The Complementarity Class of Hybrid Dynamical Systems: W.P.M.H. Heemels and B. BrogliatoDocument39 pagesThe Complementarity Class of Hybrid Dynamical Systems: W.P.M.H. Heemels and B. BrogliatoLeonora C. FordNo ratings yet

- Control and Control Theory For Flexible RobotsDocument8 pagesControl and Control Theory For Flexible RobotsGIYEONGNo ratings yet

- Advanced FRF Based Determination of Structural Inertia Properties - WhitepaperDocument13 pagesAdvanced FRF Based Determination of Structural Inertia Properties - Whitepapermanzoni1No ratings yet

- Dynamic Analysis of A Car Chassis Frame Using The Finite Element MethodDocument10 pagesDynamic Analysis of A Car Chassis Frame Using The Finite Element MethodNir ShoNo ratings yet

- Robot 6 DofDocument5 pagesRobot 6 DofMiguel PérezNo ratings yet

- Sciendo: Nonlinear PD Plus Sliding Mode Control With Application To A Parallel Delta RobotDocument8 pagesSciendo: Nonlinear PD Plus Sliding Mode Control With Application To A Parallel Delta RobotĐức QuangNo ratings yet

- Message Flow Graph SemanticsDocument37 pagesMessage Flow Graph SemanticsFrruftdrNo ratings yet

- An Overview of Feature-Based Methods For Digital Modulation ClassificationDocument7 pagesAn Overview of Feature-Based Methods For Digital Modulation ClassificationHayder HadiNo ratings yet

- On Projection-Based Algorithms For Model-Order Reduction of InterconnectsDocument23 pagesOn Projection-Based Algorithms For Model-Order Reduction of InterconnectsKb NguyenNo ratings yet

- A Review of Subdomain Modeling Techniques in Electrical Machines Performances and ApplicationsDocument7 pagesA Review of Subdomain Modeling Techniques in Electrical Machines Performances and ApplicationsFaiza OuiddirNo ratings yet

- Neural-Network-Based Terminal Sliding-Mode Control of Robotic Manipulators Including Actuator DynamicsDocument9 pagesNeural-Network-Based Terminal Sliding-Mode Control of Robotic Manipulators Including Actuator DynamicsngothientuNo ratings yet

- Mechanical Properties of Nanostructured Materials: Quantum Mechanics and Molecular Dynamics InsightsFrom EverandMechanical Properties of Nanostructured Materials: Quantum Mechanics and Molecular Dynamics InsightsNo ratings yet

- The Mimetic Finite Difference Method for Elliptic ProblemsFrom EverandThe Mimetic Finite Difference Method for Elliptic ProblemsNo ratings yet

- Module2 Heat TransferDocument20 pagesModule2 Heat TransferPatranNo ratings yet

- Unit1: Electrical Resistance Strain GaugesDocument29 pagesUnit1: Electrical Resistance Strain GaugesZaid MohammedNo ratings yet

- Experimental Stress Analysis Jan 2016 (2010 Scheme)Document1 pageExperimental Stress Analysis Jan 2016 (2010 Scheme)VigneshVickeyNo ratings yet

- Unit1: Electrical Resistance Strain GaugesDocument15 pagesUnit1: Electrical Resistance Strain GaugesVigneshVickeyNo ratings yet

- Adam FunctionDocument130 pagesAdam FunctionLai PhamNo ratings yet

- Topic Wise Tests for Mechanical EngineeringDocument5 pagesTopic Wise Tests for Mechanical EngineeringVisakh RadhakrishnanNo ratings yet

- Problems Chapter 7: Plane StressDocument1 pageProblems Chapter 7: Plane StressVigneshVickeyNo ratings yet

- Module2 Heat TransferDocument20 pagesModule2 Heat TransferPatranNo ratings yet

- CCRT Indian Culture NotesDocument1 pageCCRT Indian Culture NotesVickram JainNo ratings yet

- Sources of Torsional VibrationDocument3 pagesSources of Torsional VibrationVigneshVickeyNo ratings yet

- ATCDocument25 pagesATCVigneshVickeyNo ratings yet

- Faa 8083 30 - ch11 PDFDocument30 pagesFaa 8083 30 - ch11 PDFShankar NayakNo ratings yet

- Ethesis Vishwajeet (108me038) PDFDocument55 pagesEthesis Vishwajeet (108me038) PDFNaveen KrishnaNo ratings yet

- AD CEAD Robo PresentnDocument12 pagesAD CEAD Robo PresentnVigneshVickeyNo ratings yet

- Paper Torsional Vibration Calculation Issues With Propulsion SystemsDocument38 pagesPaper Torsional Vibration Calculation Issues With Propulsion Systemsgatheringforgardner9550No ratings yet

- XDocument6 pagesXVigneshVickeyNo ratings yet

- Guidelines for Preventing Torsional Vibration ProblemsDocument48 pagesGuidelines for Preventing Torsional Vibration ProblemsPrashanth KumarNo ratings yet

- AD830268 - Automotive AssyDocument519 pagesAD830268 - Automotive AssyVigneshVickeyNo ratings yet

- CA Sample ChapterDocument12 pagesCA Sample ChapterVigneshVickeyNo ratings yet

- A Critical Review Ofthe State-Of-The-Art inDocument40 pagesA Critical Review Ofthe State-Of-The-Art inDiego PillcoNo ratings yet

- AD783697 - Military ElectricalsDocument597 pagesAD783697 - Military ElectricalsVigneshVickeyNo ratings yet

- AD830290 - Artillery AmmuntionDocument92 pagesAD830290 - Artillery AmmuntionVigneshVickeyNo ratings yet

- ADA180439 - Tracked Vehicle Endurance TestingDocument10 pagesADA180439 - Tracked Vehicle Endurance TestingVigneshVickeyNo ratings yet

- AD889588 - Environment ControlDocument192 pagesAD889588 - Environment ControlVigneshVickeyNo ratings yet

- ADA180439 - Tracked Vehicle Endurance TestingDocument10 pagesADA180439 - Tracked Vehicle Endurance TestingVigneshVickeyNo ratings yet

- DARCQM-R 319 - 6 US Aberdeen Proving Groundvtsteap-Mt-M) Aberdeen Proving Ground, MarylandDocument13 pagesDARCQM-R 319 - 6 US Aberdeen Proving Groundvtsteap-Mt-M) Aberdeen Proving Ground, MarylandVigneshVickeyNo ratings yet

- 07 FSM PDFDocument25 pages07 FSM PDFnew2trackNo ratings yet

- Block Ice Machine Bk50tDocument6 pagesBlock Ice Machine Bk50tWisermenNo ratings yet

- Squidpy: A Scalable Framework For Spatial Omics Analysis: ArticlesDocument14 pagesSquidpy: A Scalable Framework For Spatial Omics Analysis: ArticlesXin XuNo ratings yet

- Bee Unit-IiDocument98 pagesBee Unit-IiHemant Ingale100% (1)

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyGautam PaulNo ratings yet

- Universiti Teknologi Mara Odl Test 1: Confidential 1 EM/ MAY 2020/MEM603Document4 pagesUniversiti Teknologi Mara Odl Test 1: Confidential 1 EM/ MAY 2020/MEM603000No ratings yet

- The World in Which We Believe in Is The Only World We Live inDocument26 pagesThe World in Which We Believe in Is The Only World We Live inYusufMiddeyNo ratings yet

- BIGuidebook Templates - BI Logical Data Model - Data Integration DesignDocument12 pagesBIGuidebook Templates - BI Logical Data Model - Data Integration DesignShahina H CrowneNo ratings yet

- G8 - Light& Heat and TemperatureDocument49 pagesG8 - Light& Heat and TemperatureJhen BonNo ratings yet

- Travel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteDocument1 pageTravel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteMark Levin Munar100% (1)

- Vedic Maths - India's Approach To Calculating!Document4 pagesVedic Maths - India's Approach To Calculating!padmanaban_cse100% (2)

- Tda7266 PDFDocument9 pagesTda7266 PDFRenato HernandezNo ratings yet

- Unit 3 Nis 22620Document6 pagesUnit 3 Nis 22620Komal JadhavNo ratings yet

- Agricrop9 ModuleDocument22 pagesAgricrop9 ModuleMaria Daisy ReyesNo ratings yet

- How to Critique a Work in 40 StepsDocument16 pagesHow to Critique a Work in 40 StepsGavrie TalabocNo ratings yet

- The Effect of Electronic Word of Mouth On Sales A Meta-Analytic Review of Platform Product and Metric FactorsDocument52 pagesThe Effect of Electronic Word of Mouth On Sales A Meta-Analytic Review of Platform Product and Metric FactorsHoda El HALABINo ratings yet

- CSR of DABUR Company..Document7 pagesCSR of DABUR Company..Rupesh kumar mishraNo ratings yet

- Economics Not An Evolutionary ScienceDocument17 pagesEconomics Not An Evolutionary SciencemariorossiNo ratings yet

- Dyno InstructionsDocument2 pagesDyno InstructionsAlicia CarrNo ratings yet

- LPDocument5 pagesLPHeizyl ann VelascoNo ratings yet

- QP 7721-Sobha-B+g+8-2town-Pahse IiDocument2 pagesQP 7721-Sobha-B+g+8-2town-Pahse IirajatNo ratings yet

- ks20201 Sample Questions Psycholinguistics Module3Document6 pagesks20201 Sample Questions Psycholinguistics Module3Anurag TiwariNo ratings yet

- Cooler Catalogue PDFDocument12 pagesCooler Catalogue PDFCărunta-Crista CristinaNo ratings yet

- Blood Smear PreparationDocument125 pagesBlood Smear PreparationKim RuizNo ratings yet

- EPFO Declaration FormDocument4 pagesEPFO Declaration FormSiddharth PednekarNo ratings yet

- BrochureDocument2 pagesBrochureNarayanaNo ratings yet

- Envision Math 8.1 - Use Models To Multiply A Whole Number by A Fraction PracticeDocument2 pagesEnvision Math 8.1 - Use Models To Multiply A Whole Number by A Fraction PracticeMerlin D SilvaNo ratings yet