Professional Documents

Culture Documents

V4i4 1287

Uploaded by

waris rOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V4i4 1287

Uploaded by

waris rCopyright:

Available Formats

Verma Akanksha; International Journal of Advance Research, Ideas and Innovations in Technology

ISSN: 2454-132X

Impact factor: 4.295

(Volume 4, Issue 4)

Available online at: www.ijariit.com

Powder metallurgy: Advanced techniques and applications

Akanksha Verma

akankshaverma067@gmail.com

Institute of Engineering and Technology, Lucknow, Uttar Pradesh

ABSTRACT

In this paper, a brief review about the advancement in powder metallurgy process along with their applications as well as

problems faced during the research is discussed. The main objective of this paper is to accentuate the applications of advanced

powder metallurgy technology in various fields and also to encourage the readers to understand and write more papers on such

issues. Advanced Powder Metallurgy is also known as metal injection moulding (MIM) technology helpful for forging complex

shaped components with a low investment of money. Therefore, a forming technology applied to form new materials by diffusion

of different metals as well as ceramic powders as raw ingredients through sintering (temperature below the melting point) is

known as powder metallurgy. The most advantageous thing of this process is that the powder can easily be shaped directly into

the end product and also possesses a significant degree of freedom in the composition of materials, properties, microstructure

and thermal processing. Powder Metallurgy provides such properties that cannot be achieved by the melting process.

Advancement in Powder Metallurgy technique is a standard allusion for the engineers in the metal forming industries that use

powder metallurgy with a research interest in the field.

Keywords— Metal injection moulding, Diffusion of metals, Sintering, Complex shaped components, Thermal processing

1. INTRODUCTION

Powder metallurgy is a general metal forming technique applied to produce dense and precision components. It is regarded with the

production of metal powders and commensurates them to the desired shape. In this kind of technique, the particulate materials are

bonded to semi-finished and finished products. On the other hand, direct laser forming (DLF) technique is another advanced powder

processing technique. Steps in the process of powder metallurgy are shown in the following given figure:

Fig. 1: Powder metallurgy process

© 2018, www.IJARIIT.com All Rights Reserved Page | 425

Verma Akanksha; International Journal of Advance Research, Ideas and Innovations in Technology

2. PRINCIPLES OF POWDER METALLURGY

The long-established powder metallurgy process involves the blending of the metal powders and other constituents by compaction

and sintering to obtain desired size and shape. The two stages of compaction are fused into a single step in hot pressing. Some of

the problems occurred during die-compaction and compaction of sintering in traditional powder metallurgy technique can be

overcome by newly developed isostatic compaction method.

3. MATERIALS AND PROCESSES IN POWDER METALLURGY

3.1 Titanium:- Hot Isostatic pressing (HIP), Injection moulding

3.2 Superalloy and steel:- Spray Forming

3.3 Aluminide, Nickel:- Reaction sintering and Extrusion

3.4 Iron alloy:- Powder Forging

3.5 Stainless steel:- Cold isostatic pressing (CIP)

3.6 Solidified aluminum alloy:- Complete densification method

4. APPLICATIONS OF POWDER METALLURGY

4.1 Gears, bearings and connecting rods (for automobiles)

4.2 Produce cutting/abrasion resistant tooling materials such as cemented carbide tip and moulding

4.3 Porous materials such as filters and implants for living bodies

4.4 Materials for pantograph contact strips

4.5 Sensor rings

4.6 Aircraft structuring

4.7 Fine jewellery/accessories

4.8 Cutting Tools and Dies

4.9 Anticorrosive component

4.10 Dynamic membranel filter

5. FUTURE DEVELOPMENTS

5.1 Structural parts: To enhance the strength of sintered materials, nickel and molybdenum have been mixed to achieve the high

hardness. As the chromium is the most effective element for the improvement of hardness and strength of steel and because Cr

is not so expensive, we can obtain high-strength materials at very low cost.

5.2 Magnetic parts: Recently, we are seeking to initiate the new applications of magnetic materials to support the enhancement in

the demand for electric cars. This will be done by improving magnetic properties and advancing the techniques for development

of net shaping methods in order to produce cores that are more difficult to be formed.

5.3 Next-Generation High-Performance parts: For the continuous advancement of Powder Metallurgy industry, the trend

towards reaching higher relative density levels should be emphasized. There has been an increasing trend in the usage of high-

density Powder Metallurgy steels over the last decades. To maintain the future development of Powder Metallurgy and

competitiveness with the other manufacturing processes, reaching full or near-full density is a key factor.

5.4 Powder Lamination 3D:- Ti powder laser forming is now an advanced method to improve the relative density and accuracy

of the product.

6. CONCLUSION

After studying the whole research paper, in the end, we come to the conclusion that, in recent, metal injection moulding (MIM) and

powder lamination 3-D printing are brought as new powder forming techniques. Producing large products is still difficult because

of deformation due to their own weight during the debinding process and long processing time. If these problems are resolved then

the scope of application is expected to be greatly expanded. Contrarily, metallic powder lamination 3D printing has just come into

the trend with the efficiency of forming complicated structures and shapes on the outer as well as the inner side. The roughness of

the side surfaces and entire dimensional accuracy need to be improved. Some of the problems are associated with the volume

production but this powder metallurgy technique is different and unique from a manufacturing point of view. Now, at last, based on

the whole study the further advancement and development is needed to be very much upgraded

7. REFERENCES

[1] Introduction and materials used in powder metallurgy by Hideshi MIURA (Professor, Department of Mechanical Engineering,

Kyushu University) NTN TECHNICAL REVIEW No.82(2014)

[2] Applications of powder metallurgy by Hideshi MIURA (Professor, Department of Mechanical Engineering, Kyushu

University) NTN TECHNICAL REVIEW No.82(2014)

[3] Future developments by Tadayuki Tsutsui, Hitachi Powdered Metals Co., Ltd.(Review Paper), Technical report no. 54

© 2018, www.IJARIIT.com All Rights Reserved Page | 426

You might also like

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationFrom EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationNo ratings yet

- Lecture 1 IntroductionDocument22 pagesLecture 1 IntroductionguruNo ratings yet

- Powder Metallurgy Process and ApplicationsDocument32 pagesPowder Metallurgy Process and ApplicationsChandan KumarNo ratings yet

- Kem 682 239Document8 pagesKem 682 239Mehdi DjaghloulNo ratings yet

- Rapid CastingDocument23 pagesRapid CastingquarkenNo ratings yet

- Introduction To Powder Metallurgy A ReviDocument7 pagesIntroduction To Powder Metallurgy A ReviFerry SetiawanNo ratings yet

- Mould Design Analysis of Casted Natural Fibre-Metal Matrix CompositesDocument7 pagesMould Design Analysis of Casted Natural Fibre-Metal Matrix CompositesIndra XenoNo ratings yet

- Emg 4102 CN 1Document3 pagesEmg 4102 CN 1MaxwellNo ratings yet

- Singh 2020Document13 pagesSingh 2020BornJustForDead AmenNo ratings yet

- Powder Metallurgy ThesisDocument5 pagesPowder Metallurgy ThesisPurchaseCollegePapersCanada100% (3)

- Rapid Casting Solutions - A ReviewDocument24 pagesRapid Casting Solutions - A ReviewAlex BurdeNo ratings yet

- Optimization of Process Parameters in SheetDocument24 pagesOptimization of Process Parameters in SheetThiru MoorthyNo ratings yet

- An In-Depth Review of Direct Metal Additive ManufacturingDocument9 pagesAn In-Depth Review of Direct Metal Additive ManufacturingGet SazzidNo ratings yet

- Chapter 1 Powder Metallurgy - JRJDocument99 pagesChapter 1 Powder Metallurgy - JRJK. K. TUTORIALS TECH CLUB100% (1)

- 316L Muchos Resultados FFF Tensile StrengthDocument10 pages316L Muchos Resultados FFF Tensile StrengthJuan JimenezNo ratings yet

- Introduction To Powder MetallurgyDocument19 pagesIntroduction To Powder Metallurgyabhichegg22No ratings yet

- 10.1007@s40516 019 00094 yDocument37 pages10.1007@s40516 019 00094 yTrương Bảo TínNo ratings yet

- Additive Manufacturing of Titanium Alloys: January 2018Document20 pagesAdditive Manufacturing of Titanium Alloys: January 2018nick amirNo ratings yet

- 12 Bhaskar Chandra Kandpal Jatinderkumar Hari SinghDocument9 pages12 Bhaskar Chandra Kandpal Jatinderkumar Hari SinghFerry SetiawanNo ratings yet

- Powder MetallurgyDocument24 pagesPowder MetallurgyNitin Gupta100% (1)

- Sankhla2021 Stircasting Processing MethodDocument23 pagesSankhla2021 Stircasting Processing Methodashok_abclNo ratings yet

- 10 46519-Ij3dptdi 947650-1805818Document9 pages10 46519-Ij3dptdi 947650-1805818ÖyküNo ratings yet

- A Review of Issues in Photochemical Machining: July 2014Document6 pagesA Review of Issues in Photochemical Machining: July 2014TiếnNo ratings yet

- Manufacturing ProcessesDocument136 pagesManufacturing ProcessesArijit GhoshNo ratings yet

- POWDERMETTRALUGYDocument9 pagesPOWDERMETTRALUGYNeel PatelNo ratings yet

- Ijesit201402 64Document10 pagesIjesit201402 64lamrabet abdelkaderNo ratings yet

- A Review of Soft Computing Techniques in Materials Engineering PDFDocument17 pagesA Review of Soft Computing Techniques in Materials Engineering PDFqoriNo ratings yet

- Design and Analysis of IS513CR2 Using FEADocument34 pagesDesign and Analysis of IS513CR2 Using FEAakhilesh vaibhavNo ratings yet

- Manufacturing Technology-1Document23 pagesManufacturing Technology-1Pratham DakoriaNo ratings yet

- 8 IjetstDocument5 pages8 IjetstAviator 167onNo ratings yet

- Evaluation On Mechanical Properties of Coated RHA-TIO2-LM24 Aluminium Alloy CompositeDocument13 pagesEvaluation On Mechanical Properties of Coated RHA-TIO2-LM24 Aluminium Alloy CompositeIJRASETPublicationsNo ratings yet

- Matecconf Ti2019 07008Document6 pagesMatecconf Ti2019 07008shaiksha47No ratings yet

- A Review On Machining of Metal Matrix Composites UDocument23 pagesA Review On Machining of Metal Matrix Composites UAlina JumoleaNo ratings yet

- Powder Metallurgy Thesis PDFDocument4 pagesPowder Metallurgy Thesis PDFlisaolivenorthlasvegas100% (1)

- Processing Techniques, Microstructural and Mechanical Properties of Additive Manufactured 316L Stainless Steel: ReviewDocument14 pagesProcessing Techniques, Microstructural and Mechanical Properties of Additive Manufactured 316L Stainless Steel: Reviewvasundhara singhNo ratings yet

- Riview HVOFDocument4 pagesRiview HVOFscribd_anjirNo ratings yet

- MEC207Document4 pagesMEC207Senthil Muthu Kumar TNo ratings yet

- Scale 1 2 3 4 5 Level: Titanium Alloy For Medical ApplicationDocument10 pagesScale 1 2 3 4 5 Level: Titanium Alloy For Medical ApplicationFirdaus AsryNo ratings yet

- A Review On Properties of Aerospace Materials Through Additive ManufacturingDocument18 pagesA Review On Properties of Aerospace Materials Through Additive ManufacturingkrishnaNo ratings yet

- Current Trends in Welding Processes and Materials: Improve in EffectivenessDocument12 pagesCurrent Trends in Welding Processes and Materials: Improve in EffectivenessRoberto Antonio PerezNo ratings yet

- 2012 - On Selective Laser Melting of Ultra High Carbon SteelDocument11 pages2012 - On Selective Laser Melting of Ultra High Carbon SteelSachin SinghNo ratings yet

- Effect On The Mechanical Properties of Sintering Process of Aluminium Alloys (#651528) - 914969Document7 pagesEffect On The Mechanical Properties of Sintering Process of Aluminium Alloys (#651528) - 914969kahramanNo ratings yet

- Cutting Tools and Machining Research Progress ReportDocument3 pagesCutting Tools and Machining Research Progress ReportShweta YadavNo ratings yet

- Report Sheet Metal Blanking 1hhDocument28 pagesReport Sheet Metal Blanking 1hhDino DanielNo ratings yet

- PM Process for Manufacturing Metal PartsDocument44 pagesPM Process for Manufacturing Metal PartsAkshay RajanNo ratings yet

- AE 2253 Production Technology Lesson Plan for Aeronautical Engineering Sem IVDocument2 pagesAE 2253 Production Technology Lesson Plan for Aeronautical Engineering Sem IVGiridharan SharmaNo ratings yet

- FINAL MCW-17ME35A - Notes PDFDocument108 pagesFINAL MCW-17ME35A - Notes PDFAMOGHNo ratings yet

- Data 1Document12 pagesData 1ssc.shumailkhan.191167No ratings yet

- Paperpublished STM 2023-Versão1Document11 pagesPaperpublished STM 2023-Versão1Filipe PossamaiNo ratings yet

- Finite Element Modeling of Chip Formation in Orthogonal MachiningDocument45 pagesFinite Element Modeling of Chip Formation in Orthogonal MachiningSuresh ReddyNo ratings yet

- 3D Printing of MetalDocument172 pages3D Printing of MetalSaimul HossainNo ratings yet

- Parameter Optimization of Metal Injection Moulding: A ReviewDocument15 pagesParameter Optimization of Metal Injection Moulding: A ReviewKresna Dwi PutrantoNo ratings yet

- Ductility of Ti-6Al-4V Alloy Produced by SLMDocument10 pagesDuctility of Ti-6Al-4V Alloy Produced by SLMFrancesco Di SimoneNo ratings yet

- Review of Hard Turning and Hard Milling: ArticleDocument7 pagesReview of Hard Turning and Hard Milling: ArticleĐạt Phan ThànhNo ratings yet

- Review of Metal Additive Manufacturing MethodsDocument8 pagesReview of Metal Additive Manufacturing MethodsJoe JoeyNo ratings yet

- Hybrid Stir Casting ProcessDocument5 pagesHybrid Stir Casting ProcessSquakx BescilNo ratings yet

- Deep Drawing Analysis of Angular Dies for Anisotropic MaterialsDocument10 pagesDeep Drawing Analysis of Angular Dies for Anisotropic MaterialsSumairNo ratings yet

- Paperpublished STM 2023-Versão3Document11 pagesPaperpublished STM 2023-Versão3Filipe PossamaiNo ratings yet

- Effect of Post-Treatment On Local Mechanical Properties of Additively Manufactured Impellers Made of Maraging SteelDocument18 pagesEffect of Post-Treatment On Local Mechanical Properties of Additively Manufactured Impellers Made of Maraging SteelJimmy the ReverendNo ratings yet

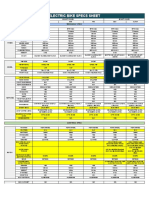

- Electric Cycle Specs - Specs SummaryDocument2 pagesElectric Cycle Specs - Specs Summarywaris rNo ratings yet

- Solar Bicycle ProjectDocument25 pagesSolar Bicycle ProjectSAI KIRAN79% (14)

- Solar CycleDocument26 pagesSolar Cyclewaris rNo ratings yet

- 1st Phase Seminar On Plastic Welding: Vinktesh Raman 1601298316 Guided by Manas Ranjan SethiDocument19 pages1st Phase Seminar On Plastic Welding: Vinktesh Raman 1601298316 Guided by Manas Ranjan Sethiwaris rNo ratings yet

- Friction Welding: Presented by MD Mujtaba Hussain 1601298324 MECH-2Document11 pagesFriction Welding: Presented by MD Mujtaba Hussain 1601298324 MECH-2waris rNo ratings yet

- Fundamentals of Nuclear Engineering - (5.1 Choice of Coolant) PDFDocument1 pageFundamentals of Nuclear Engineering - (5.1 Choice of Coolant) PDFJagdeep SekhonNo ratings yet

- ME Lab 1 Exp 7 Bomb CalorimeterDocument18 pagesME Lab 1 Exp 7 Bomb CalorimeterJAMAL HALIBAYNo ratings yet

- PDF 13 1Document141 pagesPDF 13 1TsihatesfaNo ratings yet

- EllinghamDocument19 pagesEllinghamJuan Ignacio GonzálezNo ratings yet

- Poly Vinyl ChlorideDocument2 pagesPoly Vinyl ChlorideGłfghh GhklNo ratings yet

- Lutetium (Lu) Chloride: Radiopharmaceutical Precursor, SolutionDocument6 pagesLutetium (Lu) Chloride: Radiopharmaceutical Precursor, Solutionshadab0123No ratings yet

- Technetium-99 Behavior in The Terrestrial Environment - Field Observations and Radiotracer ExperimentsDocument8 pagesTechnetium-99 Behavior in The Terrestrial Environment - Field Observations and Radiotracer ExperimentsMissoft waresNo ratings yet

- Ezeh Amara's Project1Document16 pagesEzeh Amara's Project1Amara EzehNo ratings yet

- Bends Requirement As Ibr & AsmeDocument3 pagesBends Requirement As Ibr & AsmeSimbu ArasanNo ratings yet

- Basic Plant Processes (Laboratory)Document70 pagesBasic Plant Processes (Laboratory)anon_228573261No ratings yet

- Amino + Nitro Compounds Class XII NotesDocument62 pagesAmino + Nitro Compounds Class XII NotesAditya BhattNo ratings yet

- Downstream Petroleum Sector and Fuel Quality StandardsDocument7 pagesDownstream Petroleum Sector and Fuel Quality Standardssanjayshah99No ratings yet

- Aluminium vs. Upvc - Doc (An Intro of Reality)Document2 pagesAluminium vs. Upvc - Doc (An Intro of Reality)Harsh BhaiNo ratings yet

- Worksheet ElectrolysisDocument3 pagesWorksheet ElectrolysisTeena SheikhNo ratings yet

- Material Safety Data Sheet: Production IdentificationDocument6 pagesMaterial Safety Data Sheet: Production IdentificationFarmaceuticaNo ratings yet

- Sir Gerobel Narrative Report in ChemistryDocument19 pagesSir Gerobel Narrative Report in Chemistryangelo aquinoNo ratings yet

- Pdo SP 1211Document71 pagesPdo SP 1211MuddasarNo ratings yet

- HYDROCAL 1011 Genx P English - R02 03.2019Document4 pagesHYDROCAL 1011 Genx P English - R02 03.2019caiorazecNo ratings yet

- 1 s2.0 S0165993621003095 MainDocument11 pages1 s2.0 S0165993621003095 MainSebastian CasadiegoNo ratings yet

- Inv Chem 1Document24 pagesInv Chem 1Animesh kanjilalNo ratings yet

- 26 - Improved Forged Crankshaft Performance Utilizing Deep RollingDocument23 pages26 - Improved Forged Crankshaft Performance Utilizing Deep RollingandypressNo ratings yet

- Cilindipine Final EditedDocument46 pagesCilindipine Final EditedM PriyankaNo ratings yet

- 1 Au NPs Thin Films Fabricated by Electrophoretic Deposition Method For Highly Sensitive SERS Application Odi YesDocument7 pages1 Au NPs Thin Films Fabricated by Electrophoretic Deposition Method For Highly Sensitive SERS Application Odi Yesben0706No ratings yet

- Engineering Properties of Drill Pipe CasingDocument14 pagesEngineering Properties of Drill Pipe Casingchar_lynNo ratings yet

- ColumnsDocument15 pagesColumnsAnonymous UOrBDcCJua0% (1)

- H-Industrial Pumps Part 2Document28 pagesH-Industrial Pumps Part 2yerinNo ratings yet

- Test Bank For Biochemistry A Short Course 2nd Edition John L Tymoczko DownloadDocument36 pagesTest Bank For Biochemistry A Short Course 2nd Edition John L Tymoczko Downloadcorduroy.rugousf1xrwe100% (43)

- Chlorimet 2 (N-7M) and Chlorimet 3 (CW-6M)Document6 pagesChlorimet 2 (N-7M) and Chlorimet 3 (CW-6M)gullenariNo ratings yet

- CadDocument8 pagesCadRamesh Babu GarlapatiNo ratings yet