0% found this document useful (0 votes)

2K views53 pagesTroubleshooting Loesche Vertical Roller Mill

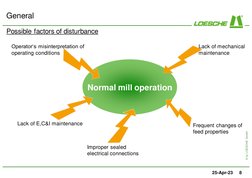

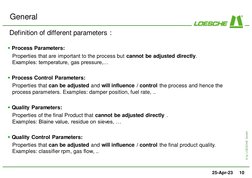

The document provides an overview of training on troubleshooting a Loesche vertical roller mill (VRM) for a cement plant in India. It discusses various process parameters of the VRM like gas flow, mill outlet temperature, differential pressure, and presents potential issues to monitor for each parameter. The training covers general operation and optimization of the VRM, as well as procedures for responding to alarms and process disruptions. Key points emphasized are the importance of maintenance, automated controls, and understanding how adjusting control parameters can impact product quality and mill operations.

Uploaded by

BhaiyaLalYadavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views53 pagesTroubleshooting Loesche Vertical Roller Mill

The document provides an overview of training on troubleshooting a Loesche vertical roller mill (VRM) for a cement plant in India. It discusses various process parameters of the VRM like gas flow, mill outlet temperature, differential pressure, and presents potential issues to monitor for each parameter. The training covers general operation and optimization of the VRM, as well as procedures for responding to alarms and process disruptions. Key points emphasized are the importance of maintenance, automated controls, and understanding how adjusting control parameters can impact product quality and mill operations.

Uploaded by

BhaiyaLalYadavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd