Professional Documents

Culture Documents

Harrington MARINE ENGINEERING-62314451

Harrington MARINE ENGINEERING-62314451

Uploaded by

Sunil S I Shipping0 ratings0% found this document useful (0 votes)

69 views964 pagesOriginal Title

Harrington_MARINE_ENGINEERING-62314451

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

69 views964 pagesHarrington MARINE ENGINEERING-62314451

Harrington MARINE ENGINEERING-62314451

Uploaded by

Sunil S I ShippingCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 964

MARINE

ENGINEERING

Written by

a Group of Authorities

EDITOR

ROY L. HARRINGTON

Newport News Shipbuilding

Published by

THE SOCIETY OF NAVAL ARCHITECTS AND MARINE ENGINEERS

601 Pavonia Avenue, Jersey City, NJ. 07306

ISON 0.999779-10-4

© Copyright 1992 by

‘The Society of Naval Arcitects and Marine Enginwers

Lary of Congress Catalog Card No, 92-62243

Printed in the United States of Amica

| Foreword

Beginning with the 1989 edition of Principles of Naval Architecture, the Society of Naval

Architects and Marine Engineers lias maintained a program of publishing significant treatises on

the subjects of naval architecture, marine engineering, and shipbuildinyc. Three companion texts arc

dedicated to these subjects, namely, Principles of Naval Architertu v, Marine Engineering, and

Ship Design and Construction, AS the base of technology has evolvedt with the passage of time,

teach of these texts has Been periodically revised and updated. Marini: ENGINEERING Was originally

published in two volumes in 1942 and 1944, and was subsequently revised in 1971

In accordance with Society policy, a Control Committee was formed 19 establish the overall

guidelines and direction for this text: The members of the Control Committee were:

William 6. Buitock John C. Maxharn

Allen Chin Perry W. Nelson

Steven H. Cohen Michael G. Parsons

Allen E. Crout Michael Pets

John M. Dabbar ‘Alan L: Rowen

José Ferenia, Jr John K, Stuart

Robert M, Freeman Joseph Tirattn

Richard Frey Jon §. Tucker

Paul R. Geiger William Watson

John P. Hackett John A. Youngquist

Joseph D, Hamilton

Several factors make this edition particularly noteworthy. The techinical editor, Roy L. Harrington,

is the same very qualified marine engineer who, more than 20 years ago, edited the 1971 revision,

‘Two chapter authors, Everett A. Catlin and Chester L. Long, authored corresponding chapters in,

the earlier edition. The Society's T&R Program, through the Ship's Machinery Committee, played

a major role in the development of the book and in the chapter reviews. And, finaly, less than four

years elapsed from the formation of the Controt Committee until publication, which was completed

fas the Society began its Centennial Celebration. The completion of this work within the original

time schedule is a remarkable achievement to the credit of the authors and the leadership and

persistence of the technical editor.

‘THOMAS P. MACKEY

Chairman, Marine Engineering Control Committee

| Preface

More than twenty years have passed since the previous edition of Maine ENGINEERING was

published. During that period. many changes have occurred in the body of technology that is

collectively known as “marine engineering.” Most of the changes have been of an evolutionary

nature; as examples, diesels have continued to supplant steam turbines for most ship propulsion

applications in the commercial arena, and gas turbines have become more firmly established as

propulsion engines, particularly for warships of the frigate class.

Because of the evolutionary nature of the technology changes, the coverage of some subjeets has

been reduced in comparison with that in the previous edition (e.g., Boilers and Combustion), but the

coverage of other subjects has been expanded substantially. Noise Control, for example, has been

given a more thorough treatment; Chapter 1% is dedicated to that subject. In addition, the introduc:

tory chapter has beer. broadened to include several topics, such us Design for Production, that have

been given an increased emphasis since publication of the previous edition.

‘The purpose of this second revision remains the same 2s that for eurlier editions, that is, to provide

a basic understanding of marine engineering principles to persons who are nominally second-year

engineering students.

During the process of allocating the various topics to the most appropriate chapters for coveraze,

the introductory chapter became the repository for subjects which, for a variety of reasons, could

not suitably be published as stand-alone chapters. Notwithstanding the diverse subjects covered,

however, the chapter has been shaped into a remarkably coherent theme.

The selection of the units of measure to be used in the text was the result of much deliberation,

‘The advocates of both English and SI units held strong positions; therefore, the chapter authors

‘were permitted to select the units used in each respective chapter, with ST units recommended where

there was no strong preference. The use of dual units was considered; however, to avoid nsmerous

uplications throughout the text and to improve the clarity of the material presented, the use of

‘only one type of units, along with a conversion table at the end of the text, was considered preferable.

‘To ensure that the text was factual and accurately represented the consensus of the marine

industry, each chapter was subjected to 2 series of reviews. The manuscripts prepared by the

authors were generally reviewed within their respective organizations and then were reviewed by

the technieal editor, the Control Committee for the preparation of the text, and selected members

of the marine industry who were recognized authorities in each particular discipline. The Society is

deeply indebted to this last group, as they often transformed good manuscripts into excelient

manuseripts.

Several members of the Control Committee made outstanding contributions to the development

of the book. The assistance provided by Perry W. Nelson, Professor Alan L. Rowen, John Young.

uist, and Richard A. Frey (and Michael Petz, who succeeded him as deputy director of the NAVSEA

Machinery Group) was of particular value. John S. Tucker not only served as an active member of

the Control Committee, but he and his colleagues at NASSCO also insisted upon completing the

Electrical Systems chapter for Walter Schmid, the principal author, who became terminally ill.

‘With few exceptions it would be improper to suggest chat the chapters were prepared by only

the authors indicated. In several cases, the contributions of those who assisted were as large as

that of the author. Professor Alan Rowen is particularly appreciative of the figures in Chapter 8

that were provided by Seaworthy Systems, Inc.; ASEA Brown-Boveri, Ltd.; Colt Industries, Fair-

banks Mosse Engine Division; Krupp Mak Maschinenbau GmbH; MAN-B&W Diesel A/S; and New

Sulzer Diesel, Ltd. Thomas Mackey notes that Ivar Krogstad, Samuel E. Bevins, and Doug Brooke

made extraordinary contributions in the preparation of Chapter 18. Henry J. Cassee acknowledges

the contributions made by Edward Marino, Harold Mcallister, Douglas Whittaker, and Scott Jackson

in preparing the figures for Chapter 22.

An accurate listing of all who assisted in the preparation of this text would include many names,

Hundreds of people made direct contributions by assisting with the preparation of manuscripts,

supplying reference material, reviewing manuscripts, and providing illustrations; and hundreds

more made indirect contributions. For fear of omissions, no attempt has been made to enumerate

all who contributed. This text is, indeed, the result of an industry effort.

Roy L. Harrincton

Technical Editor

| Table of Contents

Chapter 1 BASIC CONCEPTS

JAMES A. PALMER, Vice President, Engineering, Newport News Shipbuildiny

Page Page

1. Introduction 1 4. Other Design Considerations of Note.

2 The Ship Design Process 4 worthy Significance 4

5 Development of Main Propulsion System 12 5. ‘Tests and Trials a

Chapter It THERMODYNAMICS AND HEAT ENGINEERING

036 FEMENIA, Professor and Chairman, Engineering Department, State University of New

‘York Maritime College

Page Page

1. Review of Fundamentals 46 5. ‘Thermodynamics of Steam Cycles a

2. Heat Transfer in Boilers 52 6. Diesel Engine Thermodynamics 81

3, Internal Thermodynamics of the 7. Gas Turbine Thermodynamics :

Steam Turbine 57 8 Waste Heat from Diesel and Gas

4. External Thermodynamics of the Steam ‘Turbine Engines 86

‘Turbine 63

Chapter II DIESEL ENGINES

ALAN L. ROWEN, Mandell and Lester Rosenblatt Professor of Marine Engineering, Webb

Institute of Naval Architecture

Page Page

1. Introduetion ...... 5 91 7. Engine Components fe iG

2 Thermodynamic Analysis 97 8 Engine Control : 321

3. Performance Characteristics of 9, Waste-Heat Recovery and Utilizay

Diesel Engines 100 tion; Steam Systems... 128

4, Fuel Characteristics, Injection, and 10. Support Systems 128

Combustion ‘i 106 11. Installation, Operation, and Main:

5. Engine Matehing and Selection 10 tenance Practices sees 187

6. Moments, Forces, and Vibration ng

Chapter IV GAS TURBINES

DAN A. GROGHAN, Director, Internal Combustion and Gas Turbine Engines Division, Naval

Sea Systems Command

Page Page

1. Introduetion 146 5. Compressor Design 165

2. Arrangement and Structural De 6, Turbine Design and Construction im

tails 154 7. Combustion Systems 15

3. Accessories 159 8 Bearings, Seals, and Lubrication 119

4 Controls 161

Chapter V ROILERS AND COMBUSTION

EVERETT A. CATLIN, Marine Engineer (retired), The Babcock & Wilcox Company

Page Page

1, Classification of Marine Steam 3. Boiler Design 200

Generators. 184 4. Boiler Operation 228

2. Considerations in the Selection of a

Boiler 196

Chapter VI STEAM TURBINES

WILLIAM G CATLOW, Manager, Mechanical Design, Navy and Small Steam

‘Turbine Department, General Blectrie Company

Page Page

1. Arrangements and Cycles 282 7. Casings and Packings 265

2. Turbine Performance... 240 8. Lubrication and Bearings 2 269

8. Turbine Stage Design < - 248 9. Main Propulsion Turbine Oper-

4 Turbine Control 251 ation 22

5. Rotors and Blades 256 10. Auxiliary Turbines 221.211 214

6. Nozzles, Diaphragms, and Station-

ary Biading : ceo 264

Chapter VII NUCLEAR MARINE PROPULSION

KYLE I, HARRINGTON, Lieutenant, U. 8. Navy

Page Page

1. Fundamental Principles... 219 8. Nuclear Propulsion Applications ...... 294

2. Reactor Design Considerations 285

Chapter VIII ELECTRIC PROPULSION DRIVES

JOHN A. BEVERLEY, Navy and Marine Systems Engineering, General Electric Company

Page Page

1. Basic Considerations .... 804 8 Alternating-Current Propulsion-

2 Direet-Current Propuision- Drive Systems vos aud

Drive Systems... 0... 809 4. Ship Applications 2 322

Chapter IX REDUCTION GEARS

GARY P. MOWERS, Manager, Gear Engineering, General Electric Company

Page Page

1, Introduction 825 3 Gear Design 382

2. Tooth Design Factors 328 4. Applications STI 46

Chapter X PROPELLERS. SHAFTING, AND SHAFTING

SYSTEM VIBRATION ANALYSES

CHESTER L. LONG, Engineering Director, Newport News Shipbuilding

Page Page

1, Introduction j 3536, Propellers. 384

2 Arrangement Considerations 356 1 Torsional Vibration 391

3. Shafting Loads : 358 8 Longitudinal Vibration 403

‘L Shafting Design 18639. Whirling Vibration 208

5. Bearings 35

Chapier XI BEARINGS AND LUBRICATION

JAMES F. DRAY, Program Manager, Mechanical Technology, Ine

Page Page

1. Review of Fundamentals 412 3, Lubrication Systems 431

2 Bearings 420

Chapter XII FUELS AND FUEL TREATMENT

MATTHEW F. WINKLER, Vice President, Seaworthy Systems, Inc.

Page Page

1. Marine Petroleum Fuels 4982. Propulsion Fuel-Oil Systems a9

Chapter XIII NOISE CONTROL

MICHAL L, FoWELL, Manager, Ship Silencing, Newport News Shipbuilding

Page Page

1. Noise-Control Pundamentals 462 2, Noise-Control Techniques 469

Chapter XIV PUMPS, COMPRESSORS, BLOWERS, AND EJECTORS

‘ WILLIAM 5. SEMBLER, Manager, Marine and Navy Engineering, Dresser Pump Di

Page

1. Pumps soe 4BL 8. Blowers

2 Compressors 529 4. Bjectors

Chapter XV MAIN AND AUXILIARY CONDENSERS

ROBERT J. FOSTER, Project Manager, Delaval Condenser Division, Imo Industries Ine.

Page Page

1, General Characteristies $52 8, Surface Condenser Performance 516

2 Condenser Design 558 4 Performance Predictions from Design

Geometry 580

Chapter XVI HEAT EXCHANGERS

RICHARD 4. MANCUSO, Vice President, Engineering, Struthers Wells Corporation

Page Page

1. Introduction . 590 4. Shelland-Tube Heat Exchanger Mechan-

2. Shelland-Tube Heat Exchanger Ar ial Design... siz

rangements| : 592 5, Plate Heat Exchangers and Conipact

3. Shelkand-Tube Heat Exchanger Heat Exchangers... 615

‘Thermal and Hydrodynamic Design... 600 6. Heat Exchanger Appliestions 613

Chapter XVII DESALINATION PLANTS

FRANK J. 7ARAMBO, Manager, Marine Produets Mechanical Equipment Company

Page Page

1, Desalination Plant Designs 636 2, Distilling Plant Design Considerations . 655

Chapter XVIII HULL MACHINERY

‘THOMAS P. MACKEY, President, Hyde Products, Inc.

Page Page

1. General Design Considerations ....... 667 4. Winches, Capstans, Cargo-Handling

2 Steering Gears S68 Equipment, and Hlevators -. 681

3. “Anchor Windlasses . TILL) 682 5. Maneuvering Devices 708

6. Ship Roll Stabilization TL) r08

Chapter XIX ELECTRICAL SYSTEMS

WALTER E. SCHMID, Manager, Electrical Engineering, National Steel and Shipbuilding Co.

Page Page

1. Introduction 716 8. Interior Communication Systems 156

2. Power System [TIT 9. Navigation Systems 762

8. Power Sources and Conversion... 124 10. Exterior Communication Systems 18%

4. Power Distribution wlltllll 730° 11 Degaussing. 769

5. Electric Plant Control + T8112. Blestromagnetic Environmental

6 Electrical Power Consuming Systems Effects - . 72

and Equipment ‘i - 142 18. Shipboard Cabling =. 7

7. Lighting System 00000007 152

‘Chapter XX PIPING SYSTEMS

HENRY 3. C4SSEE, Director, Auxiliary Systems Division, M. Rosenblatt & Son, Ine.

Page Poge

J. Piping Sytem Design Development ... 782 3. Machinery Plant Support Systems .... 207

2 Piping Design Details LL) 189 4) Ship-Serviee Systems ..... 826

Chapter XX

HEATING, VENTILATION, AIR CONDITIONING,

AND REFRIGERATION

JOBL L. KRINSKY, Director, HVAC Life Support Division, Naval Sea Systems Command

Page Page

1. General. : 846 3. Distributive Systems... 88

2. The Design Process 859

Chapter XXTT CONSTRUCTION MATERIALS

MATERIALS STAFF, Materials Division, David Taylor Research Center

Page Page

i. Introduction S13. 4. Behavior of Metals at Elevated Tempera

2 Corrosion of Metals 913 ‘ures . ea

3. Fatigue 9215, Composite Materials 926

Units of Measure Conversion Table

Index . .

8. Survey of Select Material Applications . 931

941

943

4. A. Palmer |

CHAPTER |

Basic Concepts

Section 1

Introduction

1.1. Historical Perspective. In or about 1712, ‘Thomas

Neweomen, an enterprising blacksmith from Dartmoor,

England, suecessfully developed a rudimentary steam en

fine for pumping water out of mines. This engine con

sisted essentially of a single-acting piston working in a

‘vertical open-topped cylinder. The piston was packed with

hemp since the state of the metalworking art was very

primitive, and a tolerance of about one-sixteenth inch out,

‘of round or “the thickness of a thin sixpenee” was about

the best that could be expected. The piston was connected

to one end of a rocker arm by a chain without a piston rod

or guide, The differential working pressure was derived

primarily from the vacuum that was ereated below the

piston by water spray into the steam space at the end of

the upstroke. The steam and water valves were worked

by hand. Some 64 years later, radical improvements were

made by James Watt, whose name is more frequently

associated with the early development of the steam en-

«gine. In the course of time, numerous other improvements,

followed, of which the most important was probably the

double-acting inverted vertical engine, which proved to

have so many advantages thatit continues te have applica-

tions.

Accounts of the work of men such as Newcomen, Watt,

‘and others in connection with the invention and develop-

ment of steam engines are truly exciting [1,2,9}: Despite

the earlier development of steam engines, their applica-

tion to the propulsion of ships was not seriously under-

taken until about 1784. Attempts to adapt steam engines

to ship propulsion were carried out almost simultaneously.

in America, Scotland, and France. At least seven reason-

ably practical steamboats were developed by 1807. In that

year Robert Fulton inaugurated the first commercially

successful use of steam marine propulsion in the small,

paddle-wheel vessel Clermont [1]. The wooden-hulled

Clermont operated up the Hudson River from New York

to Albany, a distance of 10 miles, in about 32 hours.

Although paddle-wheel vessels were promptly adopted

for river serviee, twelve years elapsed after the launching

of the Clermont before the steamer Savannah made the

first ocean voyage from America to Europe. Notable, how-

ever, is that even in this instance the machinery was not

"Numbers in brackets refer to references at the end of the text

‘operated continuously during the outbound leg of the trip

and the inbound leg was made under sail

‘The introduction of the screw propeller in 1887 was

revolutionary development, but this development also did

not immediately lead to the demise of sails or paddle

wheels. As late as 1860 the speed of the best clippers still

exceeded that of any steamship, and the greater part of

the work at sea continued to be accomplished under sail.

‘The Great Eastern was an exception. It was an iron-

dulled vessel, almost 700 ft long and of 22,000 tons bur-

den, with both a screw propeller at the stern and two side

paddle wheels, as well as sails arrayed on six masts. The

sails, however, were little used.

By 1898, when the Society of Neval Arvhitects and Ma-

rine Engineers was founded, a screw propeller, driven by

a triple-expansion reciprocating steam engine, had be-

come the predominant means of propulsion for seagoing.

ships. Paddle wheels were still used on river and excursion

steamers, Steam was almost universally produced by

Scotch (fire-tube) boilers, and coal was the common fuel.

‘The steam turbine and diesel engine were yet to debut.

‘The decade from 1893 to 1908 was a period rich in ma-

rine engineering development. The early reciprocating

steam engine reached the point of development of the six-

cylinder quadruple-expansion engines of 10,000 indicated

horsepower supplied with steam at 200 psi by Scotch boil-

‘ers. The use of electric power generated by steam engine

driven “dynamos” at 100 to 112 volts was increasing rap

idly. Watertube boilers, which would eventually replace

the Scotch boiler on the seas, had become established in

England, France, and the United States.

By the end of the 19th century, ship's propulsion plants

had hecome sufficiently reliable to assare the delivery of

cargo to any port in the world, put often at great cost to

their crews. Mechanical ventilation had not been devel

‘oped, und those who shoveled coal commonly developed

black lung. Steam leaks were chronic, and in warmer cli:

‘mates the risk of heat exhaustion was accepted by those

who worked in machinery spaces. Large, exposed recipro

cating mechanisms endangered the life and limb of eare-

less crew members; and, in time, members of the machin-

ery space erew hecame progressively deaf because of the

exposure to excessive noise.

2 MARINE ENGINEERING

‘The development by Sir Charles A. Parsons of the first

successful application of the steam turbine to marine pro-

pulsion was another important milestone in marine engi-

‘neering. This was accomplished aboard the Turbinia, a

‘small vessel about the size of a torpedo boat. The rotative

speed of the Turbinia’s three series turbines was about

2000 rpm, and they were coupled directly to relatively

primitive serew propellers in a tripleshaft arrangement.

Parsons had been dismayed on his earliest trials to dis

cover that his first propellers “bored a hole in the water,”

developing disappointingly low driving thrast, a phenome-

non now recognized as eavitation. After further develop.

mental work, however, this new prime mover was success

fully adapted to the requirements of marine propulsion.

In what mast certainly be considered one of the earliest

efforts at model tank testing of propellers, Parsons inves-

tigated the subject of cavitation and succeeded in rede

signing his propellers. Three per shaft were ultimately

employed and in 1897, at a naval review of the British

fleet at Spithead, England, the Twrbinia astounded the

British admirals by steaming past smoothly at a speed of

84 knots, belching smoke like an angry bull tossing dust.

Lord Kelvin described this development as “the greatest

advance made in steam engine practice since the time of

James Watt” [4].

Before 1893, there were a number of attempts to de-

velop internalcombustion engines that involved fuels

ranging from gunpowder to gas. One of these was of a

radically different type, in which the combustion air

charge was compressed to a pressure and temperature

above the ignition point of the fuel. This engine was pat-

ented in 1892 by Dr. Rudolf Diesel, a German engineer.

Serious difficulties had to be overcome with the diesel

engine, and development proceeded slowly. Not until i

teen to sixteen years later was suecessful commercial

diesel engine of 25 hp produced. Once this had been

achieved, however, progress became rapid. In a few years

many firms in Continental Europe were actively building

diesel engines with as much as 500 hp per eylinder, and

experimental engines developing 2000 hp per cylinder

‘were under test.

‘The challenge to the coal-fired, low-pressure reciprocat-

ing steam engine came from the steam turbine and the

diesel engine at about the same time, at the turn of the

century. World War I caused a greater emphasis to be

placed on marine engineering developments for military

applications, while in the merchant marine arena the mass

production of proven designs was emphasized. However,

advances in the design of steam turbines and diesel en-

gines were made. These developments continued after

the war, and were spurred on by the constraints of the

Washington Treaty, by the rapid development of diesels

for railroad use and for submarine propulsion, and by the

realization thatthere would be a growing requirement for

merchant ships of standard design. The advantages of

cil, as fuel, became increasingly apparent. The use of oil

reduced erew requirements and made fuel storage and

handling an easier task. During the same period, the supe-

rior economy and performance of steam turbines and die-

sel engines, when compared with reciprocating steam en-

ines, became recognized. These trends in ship propulsion

continued during World War TT, and by the end of the

war new applications of reciprocating steam engines for

propulsion applications were rare.

‘The next major development in marine engineering bis

tory hegan a few years after World War II. Under the

direction of Admiral Hyman G. Rickover, the submarine

Nautilus, the world’s first nuclear-powered ship, put to

sea on January J7, 1955 and transmitted the historie mes-

sage “underway én nuclear power.” Nuclear propulsion

enabled the Nautilus to establish many records, inlading:

distance, speed, time traveled submerged, and passage

under the geographic North Pole, which she achieved in

1958. The Nautilus's pressurized-water reactor devel

oped about 15,000 hp and was highly successful

Nuclear propulsion revolutionized the design of subma-

rines by allowing them to remain underwater for extended

periods of time. For surface ships, however, nuclear pro-

Pulsion has received mixed reviews. The U.S. Navy has

successfully used nuclear propulsion for aircraft carriers,

starting with the Enterprise in 1962, Nuclear propulsion

provides aircraft carriers with an unlimited range and

the ability to carry more aviation fuel and weapons than

conventionally powered carriers. Nuclear propulsion has

also been used for cruisers; however, when compared with

asturbine propulsion, the advantages provided—with an

inereased range being the most significant—are not offset

by the higher acquisition cost.

Exploratory applications of nuclear propulsion for com-

mercial ships by the United States in 1959 (Savannah),

Germany in 1968 (Otto Hahn), and Japan in 1974 (Mfutsu)

failed to establish commercial opportunities for nuclear

propulsion, Nuclear propulsion was, however, proven to

be advantageous by the Russian ieebreaker Lenin in 1960,

and other nuclearpowered icebreakers have subse.

quently been built.

‘The historical developments noted in the foregoing, as

well as many others, were magnificent concepts and

achievements, especially when viewed against the tech-

nologies and materials available at the time. No effort has

been made here to inchide the full roster of great names

and pioneering events in marine engineering. However,

additional material concerning the early days in marine

engineering, which conveys an indication of the ingenuity

of the early practitioners, can be found in references

166.

1.2 Marine Engineering Defined. ‘The concept that

motivated the majority of the early advances in marine

‘engineering was quite simple, namely, to develop «system

to overcome the vagaries of the wind and the inadequacy

‘of muscle power in the propulsion of ships. In the early

history of marine engineering, the concepts formed and

the decisions made, although frequently ingenious, were

of sufficiently narrow scope that a single individual could

become intimately familiar with all facets of the undertak-

ing. The success of the early developments depended to a

large extent upon intuitive perception and upon chance.

BASIC CONCEPTS 3

However, the accumulation of advances that have been

made subsequently have caused the field of marine engi

neering to become highly sophisticated.

From a functional pointof view, a ship is a most complex

vehicle which must be reliably self-sustaining in its ele-

ment for extended periods of time. A ship is perhaps the

most multipurpose of vehicles, having more built-in fune:

tions than does any other vehicle type. As a part of 2

transportation or military system, the ship contains a

greater variety of components than any other vehicle

"The design of a ship's mechanical, electrical, and struc:

tural systems is further complicated by the fact that they

must. be compatible with the marine environment. Ship:

board design constraints include space and weight limita.

tions, which can be particularly severe in the case of

weight- and space-sensitive vessels such as subinarines,

‘and high-impact shock, which is a major design consider-

ation for naval combatants, In addition, other constraints

imposed by the marine environment range from hostile

pitch and roll conditions resulting from violent seas, to

the corrosive nature of seawater and its atmosphere. A

comprehensive description of the marine environment, as

it influences the design of shipboard systems, is included

in reference 6.

Marine engineering is, therefore, not as simply catego-

rized as, for example, civil, mechanical, electri, or chet

ical engineering. It is an integrated engineering effort

comprising parts of many engineering disciplines directed

to the development. and design of systems of transport,

warfare, exploration, and natural resource extraction that

have only one thing in common, namely, that they operate

in, or upon the surface of, « body of water.

‘The division of responsibilities between naval architects

and marine engineers is seldom sharp, and it differs from

one activity to another. In any event, each needs some

familiarity with the diseiplines typically used by the other.

Marine engineers are, in general, principally responsible

for the engineering systems, including the main propul-

sion plant, the powering and mechanical aspects of ship

functions ‘such as steering, anchoring, cargo handling,

‘weapon systems, heating, ventilation, air conditioning,

electrical power generation and distribution, and interior

and exterior communications.

Naval architects are, in general, primarily concerned

with the hydrodynamie and hull form characteristics of

the ship, the structural design of the hull, the maneuver-

ability characteristies of the vehicle, and its ability to sur-

vive and endure in the marine environment. Naval archi-

tects, assisted in appropriate areas by marine engineers,

are responsible for the overall exterior and interior ar-

rangement of the ship. In addition, naval architects gener-

ally are charged with the responsibility for the overall

aestheties of the design, including the interior decorations

and the pleasing quality of the architecture.

Some aspects of the design of marine vehieles are diff

cult assign as the exclusive province of a naval architect

‘or a marine engineer. The design of propellers or propuls-

ors is one of these, being in the minds of some a hydrody-

namie device in the domain of a naval architect, and in the

minds of others an energy conversion device, similar to

‘pumps, and thus in the domain of a marine engineer. Hull

vibration, excited by the propelier or by the main propul-

sion plant, is another such area, The development of the

most effective means of achieving a desired ship's speed

also requires trade-offs between naval architects and ma-

rine engineers, with due regard for the vessel's intended

use. Noise reduction, shock hardening, and the dynamic

responce of structures or machinery in general are ust-

all the joint responsibility of both a naval architect and

‘ marine engineer. Cargo handling, carge pumping sys-

tems, environmental control, habitability, hotel services,

and numerous other such aspects of ship design involve

joint responsibilities and require lose interaetion between

naval architects and marine engineer.

‘The traditional distinetions between naval architecture

and marine engineoring have been replaced by broader

concepts of systems engineering and analysis. The multi

disciplined nature of marine engineering and naval archi

tecture has eaused their definitions to evolve continuously

and to assume new dimensions.

1.3 Marine Vehicle Applications and Limitations. The

ranges of feasible characteristics for marine vehicles de-

pend upon their intended use. Some of the charactetisties

are based upon economic comparisons with alternative

modes of transportation, whereas others are derived from

the laws of physies. Marine vehicles are primarily used in

the following ways:

(@) As a link in a transportation system. In this

application, the payload, speed, turnaround time, and

‘number of vessels involved in the trade are the primary

variables. These factors must be considered principally in

relation to initial and operating costs.

(0) As a mobile naval base. Seaborne bases for war

fare systems are included in this group. In this instance,

the design of the ship is subordinated to the military sys-

tem and weapon requirements, except for inescapable es

sentials such as seaworthiness and habitability. Payload

and speed in this case are generally defined in terms relat-

ing to military effectiveness and the successful accom-

plishment of the mission.

(0) As a special-purpose vehicle or platform. ‘There

remain many diversified craft which have litte in eommon

beyond the fundamentals of naval architecture and ma-

rine engineering, and are, therefore, difficult to eatego-

ize. Oceangoing tugs, salvage vessels, oceanographic re-

search ships, submersibles, offshore vessels, dredging

vessels, yachts, ferryboats, towboats, pushers, barges,

hydrofoil craft, and surface-effect ships are examples of

such craft.

Often, depending upon the application, payload and

speed may be the predominant considerations in the selec-

tion of the type of vehicle employed and may either favor

or rule out some types of marine vehicles. Figure 1 is a

comparison of alternative means of transportation and

shows the feasible ranges of speed for various types of

vehicles.

In general, size restrictions are less stringent for ships

than with the alternative modes of transportation. Geo-

retrically similar ships of different scales float at the

same proportionate draft since hoth the amount of water

4 MARINE ENGINEERING

AA ey oer

nisirs Ewmtee] ||

coo tox wen | | | |

a

wit Lo Lid

Fig 1 Specife power veut speed for vorius vehies

Jisplaced (the buoyancy or displacement) and the weight

of the ship tend to vary as the tifbe of the seaie

In general, displacement ships are less weight sensitive

than the alternative modes of transportation. Fixed-wing

aireraft, hydrofoil craft, planing boats, and surface-offect

vehicles in general are weight sensitive and size limited

Such eraft derive their support while in motion from lift

ing surfaces of various types; consequently, when geo-

rmetrically sintilar but larger versions of a prototype are

considered, the weight of the craft, including its payload,

increases approximately as the cube of the scale ratio

vehile the area of the lifting surface increases only as the

square of the seale, As a result, the pressure loading on

the lifting surface increases directly with the scale

‘As may be evident from Fig. 1, the displacement type of

vessel, while generally unlimited in size, has very definite

limitations with regard to the speed at which it can be

efficiently driven, The speed limitations for ships are most

appropriately expressed in terms of the so-called speed:

length ratio. Reference 7 contains a comprehensive treat-

‘ment of this subject.

‘The most spectacular growth in the size of ships has

been in tankers. Many tankers built in the early 1950's

were in the eargo deadweight range of 20,000 to 30,000

tons, and they were appropriately called supertankers be-

cause they were twice the sizeof the T-2 tankers of World

War II vintage. However, these “‘supertankers” have

been ectipsed by later generations of tankers that are yet

another order of magnitude larger in size. Some of the

larger tankers became feasible when the natural limita-

tions imposed by harbor depths were avoided by the use

of pipelines to offshore unloading terminals.

Section 2

The Ship Design Process

21_Definition of Ship Design Requirements. ‘The de-

ign of a ship is predicated upon its mission, as indicated

above. But mission considerations can lead the details

of the processes used to design commercial ships, naval

surface combatants, and submarines, as examples, in

strikingly different ways. Consequently, e comprehensive

review of the design processes used for the various types

‘of ships would be extensive in scope. To simplify this

presentation and maintain a focus upon the underlying

‘principles, the examples used in the following discussion

fare commonly oriented to commercial applications,

‘The theoretical problem of optimizing a transport sys

tem would appear to be simply that of maximizing the

mathematical product of payload times mean effective

speed from point to point, while at the same time minimiz-

ing initial costs and yearly operating costs. However, anal-

yses of typical transport missions usually include other

{factors that put a great premium on higher speed. These

include flexibility, or the ability to be in the right place at

the right time with the right payload. The great increase

in the speed of communications in recent decades has

placed a higher premium on speed; however, higher

speeds entail higher transportation costs. Higher trans-

portation costs are in part the result of increased power

requirements, which entail both additional eapital ex-

penses (¢.g,, propulsion plant rating) and operating ex-

penses (eg., fuel consumption). Other contributions to the

increased costs of higher speeds are the increased first

costs and reduced payload capacity of higher-speed vehi

cles. To obtain feasible resistance characteristics for

higher-speed ships, their lines must be finer and have

‘more curvature, which tends to increase the eost of build-

ing the ships and to decrease their cargo capacity (8], As

a result of these factors, aircraft usually transport most

of the people, special equipment, and precious commodi-

ties for which speed is of great importance, while ships

continue to carry the larger portion of the heavy commodi-

ties and bulk cargoes in both military and nonmilitary

services.

Ship design requirements are defined in terms that re-

— |

BASIC CONCEPTS 5

late the ship to the overall mission objectives. Ship design

requirements for both commercial and naval applications

are established in a similar manner. Cargo ships, for ex

ample, must form an effective link in the cargo transpor

tation system, but there is generally no uniquely superior

or one best way in which this might be achieved. For most,

applieations, many different combinations of ehip speod,

ship size, and numbers of ships may be used to transport

a given amount of cargo at a given rate from one point to

another.

In addition to a time schedule for the movement of

cargo, the ship design requirements must also include a

statement of other aspects of the mission that influence

the principal features of the ship. An example isthe inter

faces that must he established for integrated general

cargo transportation systems in which eargo is packed in

‘containers thet may then be transported by trucks, ships,

barges, and trains, in any combination, before being deliv-

ered and unpacked, Effective provisions for the loading,

storage, and discharge of cargo are important ship design

considerations,

‘The constraints imposed by the intended application,

and by the limitations relating to payload and speed,

largely determine a feasible range of the basic ship design

requirements, The basic ship design requirements spect

fied for a merehant ship are broadly stated design eriteria

for the following typical characteristies:

+ Payload (cargo or passenger capacity and de-

scription)

+ Sustained sea speed and endurance

+ Limits to overall ship dimensions length, beam, and

draft) for operation in the intended service

+ Loading-discharging methods and capacities

+ Number of holds, tanks, or other cargo spaces for

balanced service

+ Crew or manning requirements/level of automation

¢ Hotel requirements such as heating, ventilation, air

conditioning, galley, public spaces, power, and

lighting

+ Special requirements for navigation and eommuniea-

tions

+ Mancuverability requirements (steering, handling,

and mooring)

+ Reliability and logistics support objectives

‘A more detailed discussion concerning the factors to be

considered when establishing the basic ship design re-

quirements is presented in reference 9

2.2. The Ship Design Procedure. The broad ship design

requirements, which are necessary to ensure that the ship

can support the overall mission objectives, mast be trans-

lated into specific ship performance capabilities by marine

engineers and naval architects. Inputs from other per-

spectives, such as owner preferences, must also be consid-

cred, Indepth analyses that may involve many diseiplines

are required to provide confidence that the ship design

requirements will support the mission objectives. The

analysis of these criteria, which leads to a synthesis of

‘mission requirements and constraints, takes the form of

an iterative process entailing suecessive steps of reassess

ment and adjustment. Most ship design requirements are

interdependent and cannot be analyzed without consider-

ing the others. Investigations may demonstrate that some

of the basic ship requirements are not feasible, and a

change in the overall strategy is necessary. In the event

of such a change, al of the ship design requirements nust

hhe reevaluated to ensure that a balanced set of ship desir

requirements is maintained

The procedure used by marine engineers and naval ar

chitects to translate the ship design requirements inte

specific ship design criteria is often described as a design

spira! [10], The traditional method of ilustrating the ship

design procedure represents the process as a reiterative

series of engineering. and design activities that proceed

through progressively more definitive phases and spiral

inward to a solution. Figure 2 isa variation on this theme

in which a set of concentric circular beads is used to repre

sent the successive stages of engineering activity. As the

ship design develops and progresses through the inner

stages, the feasible range of each decision becomes more

restricted and the engineering analyses become progres:

sively more detailed,

‘The ship design process is generally considered to prog:

ress through four stages, namely, conceptual design,

preliminary design, contract design, and detail design.

Each of these design stages is represented in Fig. 2 by

band of engineering activity that is separated from other

bands of activity by an approval of the preceding stage

or by some other authorizing action. The design stages

are shown separated because there is no assurance that

design conditions can be developed that will satisfy all of

the requirements established for any stage. Instead, in

some cases, no amount of analysis and reassessment will

result in a ship design that satisfies the established erite-

ria and is acceptable to those with the authority to initiate

the next stage. The authorization to provesd to a subse-

quent stage is normally in the form of a formal approval

or contract award. These authorisations are significant

events because not only do they constitute the acceptance

and conclusion of that stage, but they also initiate the

authorization to expend the resources required to execute

the next stage. While the conceptual design stage may be

performed by a small group of people for a few hundred

‘mar-hours, each subsequent stage may entail an order-

‘of-magnitude increase in engineering effort. The award

of a ship construction contract is normally the authoriza-

tion to proceed with the detail design stage.

As indicated by Fig. 2 the ship design process begins

with a definition of the ship design requirements. Based

‘upon the required payload delivery schedule, limiting hull

dimensions (e.g, draft restrictions), and other stipulations

stated as the ship design requirements for commercial

ships, the hull form and dimensions of eandidate ship de-

signs can be determined. From these, with further modifi

cations and compromises, the most economical ship design

may be established by using procedures such as those

outlined in reference 9. However, before the dimensions,

6 MARINE ENGINEERING

form, and characteristies of a candidate ship can be estab-

lished, as-yet unknown secondary data concerning the ma-

chinery space, fuel consumption, and other engineering

Features must be available. To overeome this seemingly

impossible situation, and to permit the analysis to proceed,

the unknown characteristics must be initially approxi:

mated and later refined as the analysis progresses. Esti-

‘mates that are based on sophisticated and time-consuming:

analytical procedures may not be warranted during the

formulative phases of a design analysis because the sup-

porting data may change and nullify the results obtained.

Parametric studies of similar ship designs, and other over-

all methods of comparison, are generally adequate, and

‘are more appropriate for early approximations. Of course,

as the design analysis progresses and the supporting data

become more firm, increasingly rigorous analytical proce-

dures become appropriate.

During the conceptual design stage, feasibility studies

are conducted, usually by a small group of people, to

identify alternative ship configurations that might satisty

the ship design requirements. This study effort may re-

quire the development of an array of alternative design

configurations that involve various combinations of the

‘number and size of ships and ship speed, specialized hull

forms, and optional propulsion and machinery concepts.

Al of the ship features indicated on Fig. 2 may not be

‘analyzed to the same depth for each candidate ship config-

uration, since reasonable approximations for some fea-

tures may be adequate for the intended purpose. How-

ever, during the conceptual design stage, the number of

alternstive configurations is narrowed to those with com-

binstions of principal characteristics that have the great-

est potential for satisfying the cost and performance eri-

teria

‘The products of the conceptual design stage generally

{nelude: hull dimensions and propulsion power require-

‘ments; general arrangement drawings and an interior al-

location of space by function (e.g., machinery rooms,

cargo or combat systems volume, crew accommodations);

‘an estimate of total manning requirements; a high-level,

light-ship weight estimate (ie,, the weight of the steel,

outfitting, and machinery); an’ estimate of construction

costs; and similar high-level characteristics. The concep-

tual design serves as a basis to determine the viability

of the overall ship acquisition program and to identify

candidate alternative concepts, such as optional types of

propulsion plants to be evaluated in the preliminary de-

sign stage, which follows.

‘The conceptual design stage may continue for any num-

ber of iterations around the band indicated on Fig. 2

In fact, the ship design requirements may prove to be

impracticable as initially specified, in which event the anal-

ysis would be curtailed during this stage. If, instead, an

‘acceptable, balanced conceptual ship design is developed

‘and approved, then authorization to proceed with the pre-

liminary design stage may be given,

‘The preliminary design stago entails more detailed

analyses and, therefore, requires a much greater engi

neering and design effort than does the conceptual design,

‘Trade-off studies are made during the preliminary design

BASIC CONCEPTS 7

slage to evaluate the relative merits of the various alter

rative ship systems, Once a reasonably definitive prelimi-

nary design has been developed, a tentative listing of the

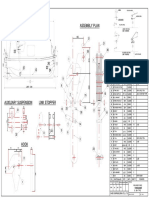

machinery components may be developed. Tables 1 and 2

list types that were prepared for a 42,000-dwt products

tanker. In addition, preliminary sketches that depiet the

arrangement of major components and the larger and

more important auxiliary units may be prepared. Many

aspects of the ship design remain tentative during this

stage, and it is essential that each member of the design

team maintain clase communications with all others. F

example, changes in the hull form or dimensions may

result ina required change in the rating of the propulsion

plant or plant configuration. Daring the preliminary de

sign stage, the ship design is developed to the extent

necessary to ensure that it is technically sound and can

meet all of the ship design requirements. When an accept-

able preliminary ship design has been confirmed and ap-

proved, the development of a contract design may be av-

thorized,

While the basic design characteristics of the ship are

generally defined. at the completion of the preliminary

design stage, the design and performance parameters are

not developed in sufficient detail to serve 2s a basis for a

construction contract. During the contract design stage,

the objective is to develop the ship design in sufficient

detail to permit a shipbuilder to have a clear understand:

ing of the significant ship features and to estimate accu:

rately the cost of building the ship. This requires fuli

definition of the ship's features and is a major engineering

effort. For merchant ships, the invoked requirements of

the classification societies, euch as the American Bureau

of Shipping or Lloyd's Register of Shipping, as well as

the requirements of the regulatory bodies, such as the

United States Coast Guard and the Public Health Serviee,

establish minimum requirements. The General Specifica’

tions for Building Ships for the U.S. Navy (11] provide a

corresponding base for naval ships. Contract designs are

usually performed by shipyards that have engineering

departments sufficiently large and experienced, or by in-

dependent design agents.

Some details of a ship design are not readily described

in words; examples are hull lines, space arrangements,

and piping schemes. In such eases, contract drawings or

contract guidance drawings may be prepared. Contract,

drawings deseribe precisely the design desired by the

owners, and the shipbuilder must deliver a design that

conforms to that described; hull lines are often specified

in this way. Contraet guidance drawings, on the other

hand, are usually not contractually obligatory but only

illustrate a design that is acceptable to the owner. The

shipbuilder is expected to closely analyze contract guid-

ance drawings and consider design alternatives to ensure

that the design is proper. The contract design products

typically inelude a set of contract specifications and draw-

ings, the results of preliminary model tests, alist of ma-

chinery and equipment (including estimated ratings), and

2 contract weight estimate,

Ship specifications deseribe the work to be done and

the performance expected; and they define standards of

design, construction, materials, and workmanship. The

preparation of a contract design package requires a thor:

‘ough knowledge of the ship, the ability to diseriminate

between the essential and the trivial, a habit of thorough-

nessand aecursey, and a talent for clear, enncise presenta

tion, A contract, design package is developed in sufficient

detail to fully define the ship; however, unessential re-

strietions must be avoided, so @ to eccommodate accept-

able alternative approaches that are compatible with con

struction procedures found to be most effective by the

shipbuilder,

Design standards, which may be either a fully specified

design for companents that are used repeatedly, ora para

metric definition of elements that with variations have

‘multiple applications, are effective supplements to ship

Standards are well known and accepted by

sstry, and they avoid the necessity for redundant,

specification words. Descriptions of systems must state

the essential system characteristies and may include spe:

cific descriptions of equipment where essential, Citing a

specific manufacturer’s product could avoid the necessity

for a long, detailed description; but doing so has the unde-

sired effect of limiting competition. 4 preferred practice

is to add the words “or equal.” Thus: “The distilling plant,

shall be an 8000 gpd, double-effect, XYZ Co. unit, or

equal.” With this specification wording, the owner would

be obligated to accept the XYZ Co. unit, if offered, but

other, comparable designs would also be considered

‘To complete the contract design phase, severai itera-

tions around the contract design band indicated on Fig. 2

are required, until all aspects of the ship's characteristics

are proven to be mutually compatible. The significant ship

characteristies desired must be accurately reflected in the

contract design package beeause subsequent corrections

might disrupt other design work previously completed.

This could necessitate a contract change with the ship-

builder, usually incurring additional expenses.

‘The detail design stage is initiated after the completion

and approval of the contract design package, and usually

begins immediately after the award of a construction eon-

‘tract. The detail design is usually conducted by the ship-

builder, butit may be performed by an independent design

agent. During this stage, working drawings and oth

data required to construct the ship are developed. As ind

cated by Fig. 2, this is the final design stage, and all of

the major design decisions (such as the selection of the

types and ratings of machivers} have already been made

and confirmed as satisfactory. However, a large volume

of engineering and design work remains to be done to

‘ensure that distributive systems can accomplish their in-

tended functions, that individual eomponents are techni

cally adequate, that stress levels are within acceptable

limits, that acoustic objectives are met, that regulatory

body and classification society rules are satisfied, and that

uhambiguous instructions are available to the construc.

tion tradesmen (usually in the form of working drawings

and supporting data). To the extent that the preceding

stages of the design process have been accomplished prop-

erly, the detai) design phase is a relatively straightfor-

ward, but nonetheless challenging, process.

MARINE ENGINEERING

Table 1

sige concie

Pp ae

‘elit Me

mt

se

a

‘aoar ome

wt uy

oo

loeeat la fn

“Tien

‘eg

arranged fo ential mutardrirn 9

‘item Sonplance wih reustarybody euiements

Pert tt

Sa.

EERE ES cn nee

erga 5 Gi

a

2

EPS stl cently tin ee

IE an satcnee

Serta te htc

aoe wna

ee arte oe OO

Ene, 2

betnntll 2

Derue ors

eg a ta te oe

a 2

Seri ae pore wd

paeageaa 8

aie hh Te

VSS aes 8

Peed wsupertare, Ae pes cd

Toe Saroe

ga ee ant

see cet,

Sooo

aay f

‘Poekoil exp cS ene

al tees

‘i

2a espe

Woe heater

ti

cog EW mt

hte ry ier

met

Mpeg nine

List of machinery for @ 42,000-dwt products tonker

een

ieee |

ESE wr e

eee ss

Labegt oat ie

‘Pair mole eee wiht enue et

“Si inte eh

area om, oi

ia a =

ee 8

He og ens

Soret tacger cae en a a

fees, SI

eles, id

omearmt ,

omer ens a

a8 a

ear Bute ‘3

ae ee =

Scuittegir se mme

EERE ence 7

meee ~

a e

g

i

i

ggumeme

et seernar

sald ge

Bins deen

argc eerie

gente powers

pot

Dagon gm sete

tewicare

anae

BASIC CONCEPTS

Tobie 1

SEL EREAET erro

on g

cc ien &

Peron ne z

SES te eke or heart?

eo is

EEE Ene n+

ieee 7

eae eee

sak

ocean =

Bre. 3

Ae Nem te Basa ee ee

Cote ne A ow

See a -

unter gent nen AMADOR ag

Seema in WG 2

KS enmnnae

BEES. wv *

Eeeeinen inom ae

eae’ ce

a si

BERS ve ¢

ites ew ;

cra

a a

(cont

Pree

=a

Seagerane estes

ago eine

sete

Arco wit ering

ie

Mooring wishes)

Hong cranes

a odig ee

‘ieee

eater

°

oe %

‘alin eer so ie ato

Sane :

Mee use ne mtr 6

ae

Ceca papers

ror ow ac, e

EEE SE ra epee ut

Wonrewortattner

‘steer se rat bp 180

Powe Aurene Banas

‘pe bare se nl Seo font

Se

a wn

Stott ym %

SELL 2

eer ene

bite tre ter nb He

ESE eel ong vm ent ne

mam tl one heya winch oe ccs en

ctor.

Figeeickears

Fe EE wee mm it an

gece

rc ran a a

me ad

ae a

emcee on

eee =

Seeneaecerntateemie

se 2

‘Bids oes tom central sytem

Beer os

ae &

EEE rnin =

10

MARINE ENGINEERING

Table 2 Pump list for « 42,000-dwt products tanker

% Se eas ere

& = a

Thar code dem eta

te

2 cin Pg Se

a

ee on SE ow wt

2 ives situ aT Ot

5 om Eco ym Bn

2 cali on BE owt Bin

ae

2 pnp a re Pe

2 eerombigeaniaiat wees Taye aa

= a

1 teromtigssone wees BT pw ets RE

=

oe or a er

ee

2 ny a er

= ay

2st wo BE ew

a

regedit cts waka

ee

Ler oe EE ww tt

a

2 pew a

=

1 twa oe ry eet

ee

1 deat ow aw oe ae

2 mane way etme

2 ‘camshaft lubeoil supply, rotary! — Lo 35 C 3 10ip He

1 drab ee ee es

2 hal et wey tl

2 taint a er es

2 tla eee a er

2 tate wey EE mms mk tint

_—, wr HE mma

2 tmpmeptattatetety muy So ae

2 ant detail weary SET rose

+ Wlaioesmy way SET nas

2 mike Lone many Eww

2 RL nomete mar SET okt

2 SPro wm a a ee ee

EE a ey ca cai, AB thr 2.6 caine du

Impeller. Bre, NAIBre Impeller, NiAlBre Ally 20, E-Monet feotor? duet tron steel

See pele AA SSS

* Casing: Bra, NiAlBra, CuNi Stainless steel, AISI 316

feet. EE MNS ae ig at

ae ee. Ie

Shite 410416 SS.

BASIC CONCEPTS n

23 Specific Morine Engin

turning to the ship design process illustrated by Fig. 2,

marine engineers are usually assigned the responsibil

of translating the broadly defined ship design require

‘ments and cost objectives into specific requirements for

the various shipboard systems. Such requirements typi:

cally fit the following scheme of classification:

Main Propulsion System

‘Type and number of propulsors

Shaft power

Proyelier diameter and speed

‘Type of propulsion plant

‘Automation objectives

Puet consumption objectives

Noise objectives

Space and weight objectives

Auxiliary Ship Systems

Eleetrie plant

Steam

Fuel handling and treatment

Lubricating-oil

Heating, ventilation, and air conditioning

Firefighting, bilge, and ballasting

Pollution control

Seawater

Fresh water

Hull Machinery Systems

Steering gear

Bow or stern thrusters

Anchor handling

‘Mooring

Ship stabilization

Cargo Systems

‘Tanker systems, such as eargo and ballast pip-

ing and pumps, tankecleaning provisions,

and inert-gas provisions

Cargo handling

‘Naval-Ship Combat Support Systems

‘Weapon elevators

Aireraft elevators

‘Aireraft catapults

‘Torpedo handling

Underway replenishment

Military Electronics

‘Command and control

Weapon directors

Tactical data

Electronic countermeasures

Communications and Navigation Systems

Interior communications

Exterior communications

Navigation

‘The requirements specified for these representative

systems must ensure a compatibility with the marine envi

ronment. Among the factors to be considered are the

ship's motion (piteh and roil) as well as trim and lst, possi

ble exposure tu seawater and a salt atmosphere, and a

serviee life that often exceeds 30 years.

24 Equipment Procurement. Shipbuilders custom

arily purchase from ether manufacturers much of the

machinery and equipment required to construet a ship;

however, the extent of the equipment purchased varies

with the policy, facilities, and staff of the shipbuilder.

During the 1930s, the larger shipyards manufactured a

very high percentage of the equipment used to construct

their ships, Two factors especially helped make this poliey

feasible: ships were generally of a lower power level a

much less sophisticated in their design, and there was a

preference by shipyard management to maintain control

over their work. By the 1940s, however, the continual

escalation in the complexity of equipment, and the econo-

mies derived from specialization and standardization, re

sulted in a continuing decline in the percentage of the

equipment manufactured by shipbuilders. As a conse

‘quence, many shipyards purchase substantially all ma-

chinery components except for those of high volume (2g.

piping system elements) that some shipyards have elected

to develop a specialized capability to produce.

Some shipyards have maintained the technical and pro-

duction capabilities necessary to manufacture a great ma-

jority of ship components, however, the components can

often be purchased from syecialty manufacturers at

lower cost. Nevertheless, a much broader manufacturing

capability must still be maintained by shipyards, because

in eritieal produetion situations the shipbuilder often be

comes the manufacturer of last resort. This may occur if,

for example, labor disputes, business faitures, or design

deficiencies ‘prevent. a manufacturer from meeting an

‘equipment delivery date. In such an event, the cost of the

‘component, itself, may become of secondary importance

as itis overshadowed by the costs that would be incurred

in delaying the ship.

With the exception of standard components, purchased

equipment is usually built in compliance with a special

purchase order that satisfies the ship requirements. Ma-

rine engineers play important roles in the procurement

process, They provide technical direction for the develop-

ment. of detailed procurement, specifications that define

the important equipment characteristies, ineluding the

features, duty, construction, materials, manufacturing

standards, and test requirements. This responsibility re-

quires a comprehensive analysis of total systems (e.g.,

propulsion plant, piping, ventilation, and electrical) to es-

tablish the performance requirements for specific compo-

nents.

Ensuring the functional adequacy of a design is a major

responsibility of marine engineers. The development of

piping diagrams is an important example of a marine engi-

neer's work. Piping diagrams present, in @ convenient,

usable form, the pertinent requirements of the specifica-

tions and regulatory bodies; they usually also show, in

12 MARINE ENGINEERING

clementary form, the piping connections between the var

ous units, the types of valves and regulating devices, and

the equipment ratings as well as their sizes, materials, and

pressure standards, Many major design decisions must be

made to support the development of diagrams; however,

the preparation of diagrams facilitates an early identifica

tion and resolution of design problems that would becoine

inereasingly disruptive to correct as the design prog:

ressee. Piping and other system diagrams, which are illus

trated in Chapter 20, reflect functional characteristies

only and do not explicitly deseribe the arrangement of a

system.

Production schedules usually require equipment pur

chase orders to be placed before the design of systems

has heen completed; therefore, the equipment ratings as

specified often inclade a prudent margin that is based

mainly on the marine engineer's experience.

‘The purchasing agent uses the procurement specifica

tions to obtain price quotations from prospective manufac-

turers, whose products are evaluated for their technical

acceptability by marine engineers. After a purchase order

has been placed, the detaiied plans developed by the manu-

facturer are reviewed to confirm that the design complies

with the system and purchase order requirements. When

this compliance has been confirmed, the release for manu

facture is authorized. The shipbuilder's marine engineers

foliow the progress of the equipment through the produc-

tion process and may work with the manufacturer in the

resolution of any production problems. A marine engineer

usually will travel to the manufacturer's plant to inspect

the completed equipment ani observe the completion tests

before itis transported to the shipbuilder for installation,

Section 3

Development of Main Propulsion System

3.1 Overall Considerations. The basic operating re-

quirement for a main propulsion system is to propel the

vessel at the required sustained sea speed for the range

(or endurance) required and to provide stopping, backing,

and maneuvering capabilities. All of these operations

‘must be accomplished reliably, and the operation and on-

board maintenance requirements of the propulsion sys-

tem must be within the capabilities of the crew. Finally,

the main propulsion system must fulfill all of the basic

operating requirements ata cost within that allocated

during the preliminary studies of the ship system; other-

wise the preliminary studies must be reevaluated.

Before a main propulsion plant can be designed, the

power required for sustained operation and endurance

rust be tentatively determined. However, there is an in-

terdependent relationship involved: the space and weight

requirements for the propulsion plant vary withthe power

rating and can have a significant effect on the ship contig:

uration, while the dimensional and form characteristics of

the hull and its approximate displacement are required to

establish an estimate of the propulsive power required. It

is apparent that marine engineers must coordinate their

activities with those of naval architects from the earliest

conceptual design stage,

3.2 Propulsion Power Profile. Except for short peri-

cos when approaching or departing port, most merchant

ships operate at a high pereentage of rated power. Oces-

sionally, the operating schedule may include periods of

‘operation at reduced speed, but seldom at speeds below

that corresponding to about one-half power. Conse-

quently, for merchant ships economical operation at the

sustained sea speed corresponding to the intended trade

route is of primary importance.

‘The situation with naval ships is entirely different. The

power plants for naval ships must be designed to satisfy

the highest speed requirements projected for them, but

the maximum power capability provided is seldom used.

During the mejority of the life of a naval ship, the ship is

operated at cruising speeds, which correspond to approxi-

mately 60% of maximum speed or about 20% of the propul

sion plant rating. Consequently, good economy at the

cruising speed is of major importance because the fuel

consumption at this speed may control the range of the

ship during many operations.

‘The power requirements for special-purpose vessels,

such as towboats and icebreakers, are clearly established

by extremes in the towing and ieebreaking modes of oper

ation, but free-route operations must also be given cansid-

eration,

‘The design of @ power plant must fully reflect the op-

erating profile of a ship. This means that for ships which

‘must have a very high power capability, but only for rare

and brief periods, the acceptable component service lives

for full-power operation may be relatively low, and the

acceptable rate of fuel consumption at full power may be

high. Economy measures, such as waste-heat recovery,

‘would generally not be ‘considered for the maximum

power condition. On the other hand, economy would be

given major emphasis for the more extensively used, low-

er-power, cruising mode of operation.

33. Determination of Ship Resistance. The general

subject of ship resistance falls within the domain of naval

architecture as opposed to marine engineering. For this

reason, @ detailed treatment of the subject is presented in

reference 7; but for completeness purposes, some of the

considerations involved warrant a brief review.

‘The most reliable means of determining the resistance

of a ship is to construct a seale model of the underwater

portions of the ship and conduct model resistance tests in

4 towing tank. However, because of the time and cost

BASIC CONCEPTS, 13

invelved, and because the ship dimensions and hull form

are subject to frequent adjustment during the preliminary

design stage, model testing is generally postponed to &

later design stage. For preliminary purposes, sufficient,

accuracy can generally be obtained from an approximate

assesiment of the ship's resistance that is based on a

Published series of test results derived from systemati

cally varied hull forms, using tentative values that have

been established for the ship payload, sustained sea speed,

and principal dimensions. Wwo such test series that can

be used to assess the resistance of fine to moderately

full-form displacement hulls are known as the Taylor's

Standard Series [12]. and Series 60 [13]. These systematic

series are weli known and widely used; however, other

series data have Leen developed thst are applicable to

specifie types of hull forms. Reference 14 is one such

series that relates to full hull forms.

Although series test data can be used to estitiate the

resistance of ships in a straightforward manner, the pro-

cess requires estimates to be developed for the major

hnull characteristics. Ifthe accuracy of an estimate is fess

{important than the rapidity with whieh it ean be made,

statistical method may be used. Reference 15 is an illus-

tration of a statistical method. By averaging plots of a

substantial number of actual designs, an approximate sta-

istical technique was developed to estimate the weight,

displacement, speed, power, and other principal character-

istics of a wide variety of cargo ships and tankers. Marine

design activities commonly summarize their data on ex-

isting designs in a similar form to permit approximate

parametric investigations to be made rapidly

3.4. Selection of the Propulsor. Once the ship speed

requirements and resistance have been tentatively estab-

lished, the next step is to select the type of propulsor. As

indicated by Fig. 3, some types of propulsors are inher

cently more efficient than others for particular applications

[16]. Figure 8 shows that relatively slow but high-powered

vessels such as trawlers and tugs have inherently lower

propeller efficiencies, but improved efficiencies are

achievable by using, propellers in nozzles. For higher-

speed ships, however, contrarotating propellers are seen,

to be more efficient.

‘The selection of the propulsor may not be a simple pro-

cess, because in order to establish the type of propulsor,

it may be necessary to at least tentatively select the type

‘of main propulsion machinery. For example, the gain in

efficiency offered by selecting contrarotating propellers

or other complex propulsors must be traded off against

the advantage of simplicity provided by conventional main

propulsion machinery and shafting arrangements.

Similarly, the selection of the number of propulsors

may also involve a tradeoff. In general, vessels may be

single, twin, triple, or quadruple serew. That is to say, the

total power required to propel @ vessel may be distributed

(usually equally) among as many as four propulsors. From

the point of view of initial and operating costs, fewer

Propellers are preferred; however, the magnitude of the

ower requirement, or the constraints on the propeller

diameter, may force the selection of a multiple-serew ar.

rangement to avoid an excessive propeller loading and

the attendant ewvitation that could otherwise result. In

addition, there may be other factors in a given case, such

as reduced vulnersbility or improved maneuverability,

that may favor the use of multiple propellers,

Several systematic series of fixed-pitch propellers have

been model tested, and the resulting data have been pre-

sented in a form that is convenient for design selection

purposes. Of these, probably the most suitable for design

approximations is the Troost B Series of three, feur, five,

six, and severrbladed propellers, although there are

others that may be used [17]. In the usual ease, the maxt

mum propeller diameter that will allow adequate propeller

submergence for the operating draft of the vessel, allow

ample tip clearances, and aiso adapt to the stern configu:

ration of the vessel S0 a8 to minimize propeller-blade-fre-

quency excitation forces, would be the propeller selected.

A study must be made of the trade-off between the

propeller zotative speed required to achieve a maximum

propulsive efficiency and the constraints on propeller ro-

tative speed that are imposed by size, weight, and cost

considerations of the prime mover or transmission. The

propeller rotative speed that is necessary to achieve a

maximum propulsive efficiency (usually in conjunction

with the largest propeller that ean be accommodated by