Professional Documents

Culture Documents

Valmet Uhle Box Cover

Uploaded by

javier bravo zaror0 ratings0% found this document useful (0 votes)

40 views1 pageValmet Uhle Box Cover

Original Title

Valmet Uhle Box Cover (4)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentValmet Uhle Box Cover

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views1 pageValmet Uhle Box Cover

Uploaded by

javier bravo zarorValmet Uhle Box Cover

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Valmet Uhle Box Cover

Cost saving felt conditioning solution

The perforated Valmet Uhle Box Cover is an effective and straight-forward

solution to increase dewatering and reduce energy consumption in press

section.

Efficient dewatering at a lower vacuum

level

The more effective dewatering performance of a per-

forated Valmet Uhle Box Cover stems from the long

dwell time in the suction area. The surface geometry

of the perforation pattern improves water removal at a

lower vacuum level. The cover provides stable support Valmet Uhle Box Cover can be applied in two ways:

for the felt over the entire suction area; there is no

‘diving’ into slots as with conventional covers. Felts Case 1 – Increase dewatering at the existing

run longer. vacuum level by replacing conventional Uhle box

cover with the perforated one

• Increased dewatering

• Improved runnability

• Improved profiles

• Lower friction

Case 2 – Modify the existing vacuum

system and replace conventional Uhle box cover

with the perforated one

• Vacuum load reduction

• Lower friction - lower press drive load

-> cost savings

The more effective dewatering performance of a perforated

Valmet Uhle Box Covers combined with Valmet

cover stems from its large open area and more uniform

vacuum system study and modification give an

vacuum effect.

opportunity to achieve considerable production cost

savings.

Results: increased dewatering

Valmet Uhle Box Cover was installed in the pick-up

felt loop of a 7-m-wide containerboard machine.

The target was to increase dewatering and improve

runnability. Vacuum air load level remained on the

earlier level

© Valmet Corporation, SER13185 V3 EN 07/2017.

2 x Uhle box with 1 x Valmet Uhle

slotted cover Box Cover

Pick-up felt

1,090 l/min

The pick-up felt moisture profile with Valmet Uhle Box cover Uhle box 830 l/min

30% increase!

is very even when compared to slotted cover. Water removal dewatering

efficiency is also better. Run time of each felt the same. 36 kPa

Vacuum level 50 kPa

Production machine results. 28% decrease!

For more information, contact your local Valmet office.

valmet.com/solutionfinder, e-mail: paper.service@valmet.com

Specifications in this document are subject to change without notice.

Product names in this publication are all trademarks of Valmet Corporation.

You might also like

- Eliteline: Premium Cargo Protection. Premium Environmental ResponsibilityDocument6 pagesEliteline: Premium Cargo Protection. Premium Environmental Responsibilityfran namiuchiNo ratings yet

- Department Editor: Kate Torzewski: Packed ColumnsDocument1 pageDepartment Editor: Kate Torzewski: Packed ColumnshvananthNo ratings yet

- Lamella Gravity SettlerDocument2 pagesLamella Gravity SettlerIwan Kenichiwa100% (1)

- Eriez Deslime Flotation PosterDocument1 pageEriez Deslime Flotation PosterAshvani SahuNo ratings yet

- Mueller Co Series 2361 RWGV FormDocument1 pageMueller Co Series 2361 RWGV FormLarry Wayne Sumpter, JrNo ratings yet

- High Performance TraysDocument4 pagesHigh Performance Traysahmed mohamedNo ratings yet

- HYDAC Optimicron Vs BetamicronDocument2 pagesHYDAC Optimicron Vs BetamicronLe DuNo ratings yet

- W2P Membrane DiffuserDocument1 pageW2P Membrane DiffuserAngirishNo ratings yet

- Dome 3 PDFDocument2 pagesDome 3 PDFDinesh ChouguleNo ratings yet

- Flexicon Flexible Screw Conveyor AdDocument1 pageFlexicon Flexible Screw Conveyor AdRamon CastroNo ratings yet

- DVC 99straightwayDocument2 pagesDVC 99straightwayMohamed ElmakkyNo ratings yet

- Ash Conveying SystemsDocument1 pageAsh Conveying SystemsTrishul Nath PallayNo ratings yet

- V2 enDocument5 pagesV2 endharmeshkher7265No ratings yet

- VE-p-20090511 ELÉTRICADocument6 pagesVE-p-20090511 ELÉTRICATiago OliveiraNo ratings yet

- Catalog Z SeriesDocument16 pagesCatalog Z SeriesTeuku Rizki Muda KeulanaNo ratings yet

- New PROTEGO® Flame Arrester UnitDocument2 pagesNew PROTEGO® Flame Arrester UnitAlejandro BorsaniNo ratings yet

- 315SKBroch 1591 07 14ENG PDFDocument8 pages315SKBroch 1591 07 14ENG PDFJan HendriksNo ratings yet

- Bosch Rexroth Axial Piston Pump CatalogDocument10 pagesBosch Rexroth Axial Piston Pump CatalogTiagoNo ratings yet

- Hemipleat Filter Technology: High Performance FiltrationDocument6 pagesHemipleat Filter Technology: High Performance Filtrationherysyam1980No ratings yet

- Warman WGR Pump BrochureDocument8 pagesWarman WGR Pump BrochureJOKO WIKARNANo ratings yet

- The Benefits of Using Die-Formed Packing Rings and Sets: by Ralf Vogel, ESA MemberDocument2 pagesThe Benefits of Using Die-Formed Packing Rings and Sets: by Ralf Vogel, ESA Membermoorthymech1979No ratings yet

- TDS Conbextra GP1 India PDFDocument4 pagesTDS Conbextra GP1 India PDFvikash singh tomarNo ratings yet

- 401 Arctic Seal Flyer MalarkeyDocument1 page401 Arctic Seal Flyer MalarkeyHoeNo ratings yet

- 2001 01 26 Vanhala e PDFDocument3 pages2001 01 26 Vanhala e PDFLuis CaballeroNo ratings yet

- Technical Information Kalmar Container Handler, DRF.: Reachstackers 42 - 45 TonnesDocument12 pagesTechnical Information Kalmar Container Handler, DRF.: Reachstackers 42 - 45 TonnesIlija MiosevicNo ratings yet

- High Pressure Cast Steel: Sempell Dewrance Parallel Slide Gate ValvesDocument20 pagesHigh Pressure Cast Steel: Sempell Dewrance Parallel Slide Gate ValvesbagusNo ratings yet

- Valmet Hydrocyclone Cleanpac 700 MCD BrochureDocument4 pagesValmet Hydrocyclone Cleanpac 700 MCD Brochurejavier bravo zarorNo ratings yet

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37Document16 pagesKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37el_apache10No ratings yet

- Brush Seals FlyerDocument2 pagesBrush Seals FlyerSofiane HalimiNo ratings yet

- GSD General Service Centrifugal Pump Brochure EN Oct18Document4 pagesGSD General Service Centrifugal Pump Brochure EN Oct18rafaelberaldiNo ratings yet

- SKF Mudblock Cassette Seals: A New Generation of Radial Shaft Sealing Units For Off-Highway, Oil-Lubricated ApplicationsDocument6 pagesSKF Mudblock Cassette Seals: A New Generation of Radial Shaft Sealing Units For Off-Highway, Oil-Lubricated ApplicationsMurray PeartNo ratings yet

- SKF Mudblock Cassette Seals: A New Generation of Radial Shaft Sealing Units For Off-Highway, Oil-Lubricated ApplicationsDocument6 pagesSKF Mudblock Cassette Seals: A New Generation of Radial Shaft Sealing Units For Off-Highway, Oil-Lubricated ApplicationsDiego PatiñoNo ratings yet

- EutecticCanada Booth1355 CdpWearPlate.613ad64c7ea94Document4 pagesEutecticCanada Booth1355 CdpWearPlate.613ad64c7ea94JLVriverNo ratings yet

- CIP Dry Bag SistemiDocument2 pagesCIP Dry Bag SistemiBala SundaramNo ratings yet

- Drum DryerDocument13 pagesDrum DryerFAiz100% (1)

- Drum Dryer PDFDocument13 pagesDrum Dryer PDFNiken SitoresmiNo ratings yet

- Pump GSD BDocument4 pagesPump GSD BfzamudiolNo ratings yet

- Document Lamella Gravity Settler 1796Document2 pagesDocument Lamella Gravity Settler 1796fitomoh624No ratings yet

- DC100 Conformal Coating Drying Cabinet Technical Brochure 160209Document2 pagesDC100 Conformal Coating Drying Cabinet Technical Brochure 160209Lee HitchensNo ratings yet

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37 - IsoDocument18 pagesKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37 - IsoktexNo ratings yet

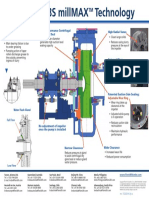

- 00millMAXSlurryPumpJuly2016Cutaway PDFDocument1 page00millMAXSlurryPumpJuly2016Cutaway PDFPatricio AcuñaNo ratings yet

- 00 Mill MAXSlurry Pump July 2016 CutawayDocument1 page00 Mill MAXSlurry Pump July 2016 CutawayPatricio AcuñaNo ratings yet

- Brochure Super Pump II 11Document2 pagesBrochure Super Pump II 11kend starNo ratings yet

- Fixed Dummy Blocks: PurposeDocument2 pagesFixed Dummy Blocks: PurposeAlson LeeNo ratings yet

- Headbox MX06 Coating - FlyerDocument1 pageHeadbox MX06 Coating - FlyerAmmar MalikNo ratings yet

- Valmet Take-Off DeviceDocument2 pagesValmet Take-Off DevicenotengofffNo ratings yet

- IMTPDocument16 pagesIMTPDHAVALESH AMNo ratings yet

- Cono RC CedarapidsDocument8 pagesCono RC CedarapidsJesus DugarteNo ratings yet

- SealBond Mexico CsDocument2 pagesSealBond Mexico CshalimNo ratings yet

- Ball Mill For Cement GrindingDocument5 pagesBall Mill For Cement GrindingJorge SilvaNo ratings yet

- MAX LOCK Lost Circulation Material SLSH PDFDocument2 pagesMAX LOCK Lost Circulation Material SLSH PDFmehranNo ratings yet

- DeGrussa Mine Performance CavTube Column PDFDocument2 pagesDeGrussa Mine Performance CavTube Column PDFAllen GaoNo ratings yet

- Bearing Arrangement For A Drum-Displacer™: Examples of Application Engineering WL 13 516 EADocument2 pagesBearing Arrangement For A Drum-Displacer™: Examples of Application Engineering WL 13 516 EAArief WicaksonoNo ratings yet

- ENERGY STAR Guide Petroleum Refineries 20150330Document7 pagesENERGY STAR Guide Petroleum Refineries 20150330rameshkarthik810No ratings yet

- Dowsil 2400 Silicone Assembly SealantDocument2 pagesDowsil 2400 Silicone Assembly SealantLEONARDONo ratings yet

- FST Technical Manual 2015 Sec07 DiaphragmsDocument31 pagesFST Technical Manual 2015 Sec07 DiaphragmsAbdessamad AyadNo ratings yet

- Telescopic Loading Bellows With Built-In Dust Filter: BellojetDocument6 pagesTelescopic Loading Bellows With Built-In Dust Filter: BellojetCarlos Manuel Pinto GuerraNo ratings yet

- FLEX LOCK V Liner Hanger System SLSHDocument1 pageFLEX LOCK V Liner Hanger System SLSHHemza BelhouaneNo ratings yet

- Cat G.E.T. Solutions For Hydraulic Mining ShovelsDocument26 pagesCat G.E.T. Solutions For Hydraulic Mining ShovelsComex LimaNo ratings yet

- Manual de Limpieza Con SHMPDocument2 pagesManual de Limpieza Con SHMPAlexis Jara VidalNo ratings yet

- Ocp For CanteenDocument4 pagesOcp For CanteenSharif Khan0% (1)

- Bca Be Sac ChecklistDocument6 pagesBca Be Sac Checklistfbb055926No ratings yet

- Utility IPCRFDocument7 pagesUtility IPCRFLarry ZanteNo ratings yet

- Particularly Sensitive Sea Areas (Pssas) and Marine Environmentally High Risk Areas (Mehras)Document10 pagesParticularly Sensitive Sea Areas (Pssas) and Marine Environmentally High Risk Areas (Mehras)Polaris BridgemanNo ratings yet

- Biosecurity in Aquaculture, Part 2: Recirculating Aquaculture SystemsDocument12 pagesBiosecurity in Aquaculture, Part 2: Recirculating Aquaculture SystemsMohanad Dheyaa Taha TahaNo ratings yet

- Group13 Project Final Practice 2Document34 pagesGroup13 Project Final Practice 2THEOPHILUS ATO FLETCHERNo ratings yet

- Veena Tutorials™: Answer The FollowingDocument1 pageVeena Tutorials™: Answer The FollowingSaahil LedwaniNo ratings yet

- AMB PFD Belt Press NBD-M100Document1 pageAMB PFD Belt Press NBD-M100Bimoaji PribadiNo ratings yet

- PJSIR Series A: Physical Sciences Vol. 56, No. 1, January-February, 2013Document15 pagesPJSIR Series A: Physical Sciences Vol. 56, No. 1, January-February, 2013Syed Umair AnwerNo ratings yet

- SCPW - What Are Wetland CentresDocument24 pagesSCPW - What Are Wetland CentresAaron Julius M. LeccionesNo ratings yet

- Kemp 02Document52 pagesKemp 02KatrinaDocsNo ratings yet

- Aker Arctic Shuttle Tanker 70000DWTDocument2 pagesAker Arctic Shuttle Tanker 70000DWTscrible2989No ratings yet

- Chapter 18 Air PollutionDocument47 pagesChapter 18 Air PollutionnavalepeiNo ratings yet

- Listening and Speaking 2unit 7 Student Book Answer KeyDocument3 pagesListening and Speaking 2unit 7 Student Book Answer KeyNguyễn Thanh TúNo ratings yet

- Surface Preparation and Painting FinalDocument45 pagesSurface Preparation and Painting FinalthanghanvicoNo ratings yet

- IRC 78-2014 Ammendment (Nov-2017)Document20 pagesIRC 78-2014 Ammendment (Nov-2017)avisek_basu33% (3)

- Sea2 4040 PDFDocument1 pageSea2 4040 PDFMd. Suruz ZamanNo ratings yet

- BWT AdvisoryDocument80 pagesBWT AdvisoryInder MukhopadhyayNo ratings yet

- 02 08 2013 Drip Design ImpDocument65 pages02 08 2013 Drip Design ImpanbugobiNo ratings yet

- Faecal Sludge Management in Rural Areas: SBM (Grameen) Phase IiDocument12 pagesFaecal Sludge Management in Rural Areas: SBM (Grameen) Phase IihinduNo ratings yet

- Jet Lube 21 Oilfield SdsDocument11 pagesJet Lube 21 Oilfield SdsERDNo ratings yet

- Hydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCDocument1 pageHydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCJeff L DjambakNo ratings yet

- Rubber Wastewater Treatment ProcessDocument2 pagesRubber Wastewater Treatment ProcessStan MacapiliNo ratings yet

- General Planning and Development Model PDFDocument194 pagesGeneral Planning and Development Model PDFEijnuj PitzNo ratings yet

- Singapore WaterDocument45 pagesSingapore WaterkergabNo ratings yet

- Toilet: BID 303 Interior and Furniture TechnologyDocument42 pagesToilet: BID 303 Interior and Furniture TechnologyDarshi PatelNo ratings yet

- The Comparison Study For The Models of Reservoir Release Rule For Irrigation. Case Study: Sutami ReservoirDocument8 pagesThe Comparison Study For The Models of Reservoir Release Rule For Irrigation. Case Study: Sutami ReservoirNanisNo ratings yet

- Bina MAMPAN Full VersionDocument32 pagesBina MAMPAN Full VersionAhmad NorhanifNo ratings yet