0% found this document useful (0 votes)

632 views4 pagesValmet Hydrocyclone Cleanpac 700 MCD Brochure

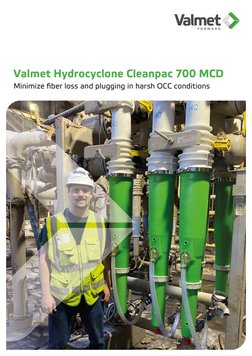

The Valmet Hydrocyclone Cleanpac 700 MCD cleaner combines proven hydrocyclone designs with new dilution technologies to minimize fiber loss and plugging in recycled fiber mills. It introduces dilution water at key points to reduce fiber consistency and increase throughput while lowering fiber losses up to 2 tons per day.

Uploaded by

javier bravo zarorCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

632 views4 pagesValmet Hydrocyclone Cleanpac 700 MCD Brochure

The Valmet Hydrocyclone Cleanpac 700 MCD cleaner combines proven hydrocyclone designs with new dilution technologies to minimize fiber loss and plugging in recycled fiber mills. It introduces dilution water at key points to reduce fiber consistency and increase throughput while lowering fiber losses up to 2 tons per day.

Uploaded by

javier bravo zarorCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd