Professional Documents

Culture Documents

Valmet Dewatering Elements Polyethylene

Uploaded by

Ammar MalikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valmet Dewatering Elements Polyethylene

Uploaded by

Ammar MalikCopyright:

Available Formats

Valmet Dewatering Elements

Polyethylene

Experts from Valmet’s Wet End Solutions group will evaluate and recommend

improvements to optimize your forming section configuration. Our cost-effective

approach maximizes the utilization of your existing forming and press equipment

to optimize the performance of the wet end section of your machine.

Benefits

• All basic designs available to match any

application, regardless of OEM

• Developed to give optimum wear and

durability across a wide range of operating

conditions

• All Polyethylene components are made close

to you for fast turn-around

Valmet combines expertise in drainage optimization Materials in order of wear resistance:

with a comprehensive range of polyethylene • Valmet Dewatering Element Poly 1000* - A virgin

dewatering elements to suit all positions and machine UHMW of the highest molecular weight commercially

configurations. available. An economical alternative, and often the

best place to start.

Polyethylene materials

• Valmet Dewatering Element Poly 2000 - Valmet

Whether you need conventional or specially designed

Dewatering Element Poly 1000 with molybdenum

components, Valmet’s Service experts have many years

disulfide and cross-linking for better wear and

of experience serving the Pulp and Paper Industry,

impact properties.

helping to select and produce all types of drainage

• Valmet Dewatering Element Poly 5000 - Our standard

components.

SiO2 filled material for abrasive applications. Proven

Our polyethylene materials are formulated and

to extend life and non-abrasive to wires or felts.

developed to deliver optimum performance across a

wide range of operating conditions. • Valmet Dewatering Element Poly 6500 - A special

blend of fillers for the toughest applications.

• Valmet Dewatering Element Poly 7000 - A special

blend of fillers for the toughest applications.

• Valmet Dewatering Element Poly 8000** -

Recommended case by case for special applications.

Polyethylene Application Guidelines

Former Applications - Foils, Lo Vacs, Hi Vacs Press Applications - Uhle Strips and Covers

Brown Brown Brown Brown

UHMW-PE Fine Paper Fine Paper Fine Paper Fine Paper

Color Paper Paper Paper Paper

Material WetApp’s DryApp’s WetApp’s DryApp’s

WetApp’s DryApp’s WetApp’s DryApp’s

Black/

Poly 1000* X X X X X X X X

White

Poly 2000 Dark Blue X X X X X X X X

Poly 5000 Light Blue X X X X X X

Poly 6500 Light Gray X X X X X X

Poly 7000 Light Gray X X X X X X

Black /

Poly 8000** Recommended case by case

White

*1000=Poly S

**8000=Poly D/EVO2

Valmet Dewatering Element Poly 1000 was earlier known as CW1000, Valmet Dewatering Element Poly 2000 was earlier known as

CW2000, Valmet Dewatering Element Poly 5000 was earlier known as CW5000, Valmet Dewatering Element Poly 6500 was earlier

known as CW6500, Valmet Dewatering Element Poly 7000 was earlier known as CW7000, Valmet Dewatering Element Poly 8000 was

earlier known as CW8000

© Valmet Corporation, MON01301 V2 EN 10/2022.

For more information, contact your local Valmet office. www.valmet.com

e-mail: napaper.service@valmet.com

Specifications in this document are subject to change without notice.

Product names in this publication are all trademarks of Valmet Corporation.

You might also like

- Polyrib Catalogue PDF NEW PDFDocument16 pagesPolyrib Catalogue PDF NEW PDFsekarNo ratings yet

- Produktguide 2 Vibraflex Vibrasetex UK Interactive-1Document2 pagesProduktguide 2 Vibraflex Vibrasetex UK Interactive-1Alexander EssNo ratings yet

- PTV - Datasheet Screw in Vents - ENDocument4 pagesPTV - Datasheet Screw in Vents - ENBala SakthiNo ratings yet

- Muntajat Data Sheet (Booklet)Document34 pagesMuntajat Data Sheet (Booklet)VivekNo ratings yet

- Fibre 04.2017Document28 pagesFibre 04.2017ary RAHMANSYAHNo ratings yet

- Millad NX8000Document1 pageMillad NX8000Bhavesh GandhiNo ratings yet

- 11 Insulating Materials PDFDocument24 pages11 Insulating Materials PDFidlemineNo ratings yet

- Eco-Friendly Plywood Products for Safety and DurabilityDocument28 pagesEco-Friendly Plywood Products for Safety and DurabilityShanu SinghNo ratings yet

- BN20 e PreDocument59 pagesBN20 e PreTuan DinhNo ratings yet

- Bondller Electrical Insulation Tape Product Catalog 2023Document16 pagesBondller Electrical Insulation Tape Product Catalog 2023europe toyotapeNo ratings yet

- 2fd9c443-8a5c-41e2-9aad-48cdd9dc151dDocument2 pages2fd9c443-8a5c-41e2-9aad-48cdd9dc151dmelsabaeNo ratings yet

- Optiflo: Technical Information B-RI 18Document8 pagesOptiflo: Technical Information B-RI 18Akshai RedwalkerNo ratings yet

- ELFTEX 570-EnglishDocument2 pagesELFTEX 570-EnglishLeandro EsvizaNo ratings yet

- ADSHEL production specifications guideDocument17 pagesADSHEL production specifications guideDiamond MC TaiNo ratings yet

- ARHICTEC Brochure 2017Document2 pagesARHICTEC Brochure 2017Mahendra Singh BudhathokiNo ratings yet

- Elastomer Selection Guide: Rubber-Covered RollsDocument2 pagesElastomer Selection Guide: Rubber-Covered RollsÂm Thầm Ném GạchNo ratings yet

- Featherlite CatalogueDocument13 pagesFeatherlite CatalogueRaviKiran EdaraNo ratings yet

- Amberlite™ Hpr2800 H Ion Exchange Resin: Product Data SheetDocument4 pagesAmberlite™ Hpr2800 H Ion Exchange Resin: Product Data SheetsamarthNo ratings yet

- Polyfusion 4 50 EngDocument11 pagesPolyfusion 4 50 EngAlexandros GiannikosNo ratings yet

- QUOTATION PUTTING GREEN 10mmDocument1 pageQUOTATION PUTTING GREEN 10mmNick DivinagraciaNo ratings yet

- Aquafilteruae 800 GPDDocument1 pageAquafilteruae 800 GPDoffpageseodigitalmarketingNo ratings yet

- Sell Sheet Optal XP en FinalDocument2 pagesSell Sheet Optal XP en Finalalguna54No ratings yet

- Crane-Ropes-Usha-Martin-Catalogue - 2020Document18 pagesCrane-Ropes-Usha-Martin-Catalogue - 2020Deni SuhayaNo ratings yet

- ABS Sheet Solutions: Key CharacteristicsDocument2 pagesABS Sheet Solutions: Key CharacteristicsKevinGarciaNo ratings yet

- Selection Chart - Lamination SLDocument1 pageSelection Chart - Lamination SLayman emmadNo ratings yet

- Ytron: Process TechnologyDocument9 pagesYtron: Process TechnologySofia KhalifmanNo ratings yet

- Crane Ropes - Usha Martin 1Document18 pagesCrane Ropes - Usha Martin 1Sanjeeb SinhaNo ratings yet

- SupaGard ENG TEXDocument2 pagesSupaGard ENG TEXivan tejoNo ratings yet

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Combo EbroDocument5 pagesCombo Ebroamolsinha1No ratings yet

- Warco Filters ™: High Capacity Filter Vessels Process - Pipeline - PiggingDocument4 pagesWarco Filters ™: High Capacity Filter Vessels Process - Pipeline - Piggingakaalj qhseNo ratings yet

- Continental Belting Profile GLASSDocument2 pagesContinental Belting Profile GLASSdeepak6569No ratings yet

- Auger Compactor - ENDocument4 pagesAuger Compactor - ENEugene Jin LeowNo ratings yet

- Resistant To Acids and High Thermal Loads: High-Performance Fume CupboardsDocument5 pagesResistant To Acids and High Thermal Loads: High-Performance Fume CupboardsAbdul RBed IsaNo ratings yet

- General Products Catalouge - 2019 EditionDocument29 pagesGeneral Products Catalouge - 2019 EditionShaziaNo ratings yet

- SGG Aspira CatalogueDocument16 pagesSGG Aspira CatalogueOCTOPUS TRADERSNo ratings yet

- IDS 302 1001 002 General Purpose MEK BlackDocument3 pagesIDS 302 1001 002 General Purpose MEK BlackFarid DiazNo ratings yet

- Smart ReologyDocument42 pagesSmart ReologyMarisol Martinez MaldonadoNo ratings yet

- PEL1Document36 pagesPEL1Usman IslamNo ratings yet

- Arbothane 1245SL 1Document3 pagesArbothane 1245SL 1Jake BarlowNo ratings yet

- Pre-Qualification (Tic)Document32 pagesPre-Qualification (Tic)Ajay RanganathanNo ratings yet

- IPRO Rate1 List DemmyDocument10 pagesIPRO Rate1 List DemmyRollson LasradoNo ratings yet

- PMMA Resist - Product InformationDocument8 pagesPMMA Resist - Product InformationMałgosiaSikora-JasińskaNo ratings yet

- Interpon D1000 Sable TDSDocument2 pagesInterpon D1000 Sable TDSRashid MohammedNo ratings yet

- Thermal Products Session-2 Dtd 19th May’20Document8 pagesThermal Products Session-2 Dtd 19th May’20Sachin KothariNo ratings yet

- Bird Proof Purlins: - Not Giving Birds A Leg To Stand OnDocument2 pagesBird Proof Purlins: - Not Giving Birds A Leg To Stand Onrizwan qadeerNo ratings yet

- CLEAN EQUIPMENT FOR FLOORSDocument40 pagesCLEAN EQUIPMENT FOR FLOORSpambudi 24No ratings yet

- TRIBOX Thermoplastic Enclosure - 2021Document16 pagesTRIBOX Thermoplastic Enclosure - 2021VBANo ratings yet

- Spec Sheet Potato Peeler Pi 20Document2 pagesSpec Sheet Potato Peeler Pi 20voldemort.bilalNo ratings yet

- Cargo Waste Bin Series Catalog LaunchDocument10 pagesCargo Waste Bin Series Catalog LaunchCharan ReddyNo ratings yet

- Snobrite Kaolin 2Document1 pageSnobrite Kaolin 2Đặng Hoàng YếnNo ratings yet

- Nido Edge Dock Leveler - ND-DL-10Document5 pagesNido Edge Dock Leveler - ND-DL-10Web AdminNo ratings yet

- Manhole Covers Sri Lanka - Gratings - Water Pump Manufacturer - Manholes Convers For Roads - Edna GroupDocument2 pagesManhole Covers Sri Lanka - Gratings - Water Pump Manufacturer - Manholes Convers For Roads - Edna GroupIeeeChannaNo ratings yet

- 312 DatasheetDocument1 page312 DatasheetGregory Alan Francisco IINo ratings yet

- PARALOID™ Thermosetting Acrylic Resins: For Conventional Solids and High Solids CoatingsDocument22 pagesPARALOID™ Thermosetting Acrylic Resins: For Conventional Solids and High Solids CoatingsDewiNo ratings yet

- Spray Droplet Size Standard S-572: Robert E. WolfDocument37 pagesSpray Droplet Size Standard S-572: Robert E. WolfIvana BaraćNo ratings yet

- Nuoer pptDocument32 pagesNuoer pptr.b.sons007No ratings yet

- SINIAT Plasterboard Installation Guide v8 2021julyDocument78 pagesSINIAT Plasterboard Installation Guide v8 2021julysivaramNo ratings yet

- GC Sheet Drain JoiningDocument6 pagesGC Sheet Drain JoiningVgkBharadwajNo ratings yet

- Headbox Seals Replacement - FlyerDocument1 pageHeadbox Seals Replacement - FlyerAmmar MalikNo ratings yet

- Valmet Dewatering Elements PolyethyleneDocument2 pagesValmet Dewatering Elements PolyethyleneAmmar MalikNo ratings yet

- Valmet Doctor Blade Carbon VE - FlyerDocument1 pageValmet Doctor Blade Carbon VE - FlyerAmmar MalikNo ratings yet

- Valmet Dewatering Elements PolyethyleneDocument2 pagesValmet Dewatering Elements PolyethyleneAmmar MalikNo ratings yet

- Double DoctorDocument1 pageDouble DoctorAmmar MalikNo ratings yet

- Hose Replacement Services For BTF HeadboxDocument1 pageHose Replacement Services For BTF HeadboxAmmar MalikNo ratings yet

- Headbox Dilution Control System Testing - FlyerDocument1 pageHeadbox Dilution Control System Testing - FlyerAmmar MalikNo ratings yet

- Double DoctorDocument1 pageDouble DoctorAmmar MalikNo ratings yet

- Slice Lip Replacement - FlyerDocument1 pageSlice Lip Replacement - FlyerAmmar MalikNo ratings yet

- FiberLean Brochures A4 Paper Solutions 2021 Low Res-1Document1 pageFiberLean Brochures A4 Paper Solutions 2021 Low Res-1Ammar MalikNo ratings yet

- Headbox Condition Testing - FlyerDocument1 pageHeadbox Condition Testing - FlyerAmmar MalikNo ratings yet

- End PortionDocument1 pageEnd PortionAmmar MalikNo ratings yet

- FiberLean Brochures A4 Paper Solutions 2021 Low Res-5Document1 pageFiberLean Brochures A4 Paper Solutions 2021 Low Res-5Ammar MalikNo ratings yet

- FiberLean Brochures A4 Paper Solutions 2021 Low Res-2Document1 pageFiberLean Brochures A4 Paper Solutions 2021 Low Res-2Ammar MalikNo ratings yet

- FiberLean Brochures A4 Paper Solutions 2021 Low Res-3Document1 pageFiberLean Brochures A4 Paper Solutions 2021 Low Res-3Ammar MalikNo ratings yet

- FiberLean Brochures A4 Paper Solutions 2021 Low Res-4Document1 pageFiberLean Brochures A4 Paper Solutions 2021 Low Res-4Ammar MalikNo ratings yet

- Admission Application Form-10Document1 pageAdmission Application Form-10Ammar MalikNo ratings yet

- Admission Application Form-1Document1 pageAdmission Application Form-1Ammar MalikNo ratings yet

- Admission Application Form-9Document1 pageAdmission Application Form-9Ammar MalikNo ratings yet

- Admission Application Form-8Document1 pageAdmission Application Form-8Ammar MalikNo ratings yet

- Admission Application Form-6Document1 pageAdmission Application Form-6Ammar MalikNo ratings yet

- Admission Application Form-5Document1 pageAdmission Application Form-5Ammar MalikNo ratings yet

- Cross Section of SPRDocument1 pageCross Section of SPRAmmar MalikNo ratings yet

- Admission Application Form-5Document1 pageAdmission Application Form-5Ammar MalikNo ratings yet

- Admission Application Form-2Document1 pageAdmission Application Form-2Ammar MalikNo ratings yet

- 2019-04-04 18 - 16 - 44Document1 page2019-04-04 18 - 16 - 44Ammar MalikNo ratings yet

- Crscent FormerDocument1 pageCrscent FormerAmmar MalikNo ratings yet

- January 2019 Paper 2Document16 pagesJanuary 2019 Paper 2Anderson AlfredNo ratings yet

- Oracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1Document86 pagesOracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1EttoreNo ratings yet

- Overflow The RPC Marshalling Buffer For Both RCE and LPE: DescriptionDocument13 pagesOverflow The RPC Marshalling Buffer For Both RCE and LPE: DescriptionPetro BondarNo ratings yet

- 20a Solar Power Controller ManualDocument8 pages20a Solar Power Controller ManualVeilleur De ConscienceNo ratings yet

- Carbohydrates: Organic Vs Inorganic CompoundsDocument16 pagesCarbohydrates: Organic Vs Inorganic CompoundsTsu Wei Chua100% (5)

- Dumpstate - Log 2020 03 23 21 37 39 12783Document4 pagesDumpstate - Log 2020 03 23 21 37 39 12783Nurlan JakenaiNo ratings yet

- Actuator BrochureDocument6 pagesActuator BrochureCarlos Ramirez100% (1)

- Torrcon Users ManualDocument17 pagesTorrcon Users ManualAgustin100% (1)

- Supreme Roa02Document1 pageSupreme Roa02MUDI SOBARHADINo ratings yet

- 07 Rr410208 Computer Aided Design of Electrical MachinesDocument4 pages07 Rr410208 Computer Aided Design of Electrical MachinesandhracollegesNo ratings yet

- Chem 123 Problem Set 1Document4 pagesChem 123 Problem Set 1Stuart BrookesNo ratings yet

- Operation and Maintenance Manual IC-80-3L 4X2Document75 pagesOperation and Maintenance Manual IC-80-3L 4X2gabri1992No ratings yet

- UsxrefDocument57 pagesUsxrefgmawoyoNo ratings yet

- 1 General Physics PDFDocument39 pages1 General Physics PDFHakim Abbas Ali PhalasiyaNo ratings yet

- Blast Furnace Simulation Using DEMDocument18 pagesBlast Furnace Simulation Using DEMDaniel NasatoNo ratings yet

- Config Et Use Rslogix500Document76 pagesConfig Et Use Rslogix500Fogape TitiNo ratings yet

- Hypothesis (: Independent Variable (What Dependent Variable (What Controlled Variables (ThoseDocument2 pagesHypothesis (: Independent Variable (What Dependent Variable (What Controlled Variables (ThoseSarah AlbishahNo ratings yet

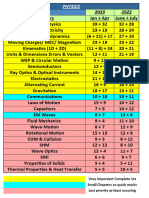

- Priority List JEEDocument3 pagesPriority List JEE6r5x5znb8bNo ratings yet

- Ac App ExercisesDocument2 pagesAc App ExercisesLynn N David100% (1)

- LQ 310 PDFDocument2 pagesLQ 310 PDFRana WahyudiNo ratings yet

- Jee 2024Document7 pagesJee 2024Sangeeta YadavNo ratings yet

- Final Report - HVACDocument10 pagesFinal Report - HVACBenny BennyNo ratings yet

- Beer Lambert LawDocument4 pagesBeer Lambert LawasjawolverineNo ratings yet

- Configurable Controller User's ManualDocument22 pagesConfigurable Controller User's ManualFabio Nelson CubidesNo ratings yet

- CSV Aug09 PDFDocument43 pagesCSV Aug09 PDFtreda23No ratings yet

- OutlineDocument88 pagesOutlineLorrayne Zhen T. CarabidoNo ratings yet

- An Empirical Study of C++ Vulnerabilities in Crowd-Sourced Code ExamplesDocument14 pagesAn Empirical Study of C++ Vulnerabilities in Crowd-Sourced Code ExamplesThadeus_BlackNo ratings yet

- Weighted mean calculationDocument230 pagesWeighted mean calculationAkshay RajNo ratings yet

- Java Project Final-3Document39 pagesJava Project Final-3Shubham PradhanNo ratings yet

- Multiple Organ Failure Post Injury, Pathophysiology and Prevention of ARDS in Trauma PatientDocument37 pagesMultiple Organ Failure Post Injury, Pathophysiology and Prevention of ARDS in Trauma PatientDipo Mas SuyudiNo ratings yet