Professional Documents

Culture Documents

TEC Brochure

Uploaded by

jose05olivera96Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TEC Brochure

Uploaded by

jose05olivera96Copyright:

Available Formats

Tubing Encapsulated Cable

HARSH ENVIRONMENT DOWNHOLE SOLUTIONS

Artwork courtesy of Roxar

Linking the oil and gas industry from end to end

Tubing Encapsulated Cable (TEC) -

As tough as the people who use it

Tubing Encapsulated Cable (TEC) is the answer to the challenges of harsh environmental conditions associated

with recovery of oil and gas through reservoir management.

TEC uses welded stainless steel and nickel alloy tubing to protect TEC configurations are available with an almost infinite combination

electrical and optical components from the pressure and corrosive of components in splice-free custom lengths.

effects of the downhole environment. Polymeric encapsulation pro-

vides additional mechanical protection. And Draka is the only manu- Standard encapsulation sizes (11 mm x 11 mm square and 0.41 inch

facturer that produces and controls all TEC components including round with flatpack and multiple tube construction) are available to

fiber / copper cores, hydraulic control / chemical injection lines and meet almost any downhole requirements.

in-house encapsulation.

Composite cables utilizing various combinations of electrical and

Draka’s wide selection of copper and fiber components allow produc- optical components are available to match specific downhole needs.

tion of the industry’s most sophisticated instrumentation cables. Please contract a Draka sales engineer to learn more.

Since first introducing TEC for the oil and gas industry in 1985, Draka has

continually improved and optimized this product for new generations of

downhole gauges and tools for increasingly hotter and deeper wells.

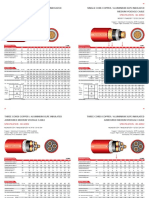

Sample constructions

18 AWG single conductor Incoloy tube

Square encapsulated

A) 18 AWG (7 x 0.39 mm) tinned copper

O.D. 0.046 in (1.16 mm) nom.

B) Natural T-01 (FEP) insulation

O.D. 0.098 in (2.49 mm) nom. A B C DE

C) Red P-06 (polypropylene) filler

O.D. 0.180 in (4.57 mm) nom.

D) Alloy 825 tube

Wall thickness 0.035 in (0.89 mm) nom.

O.D. 0.250 in (6.35 mm) nom.

E) Yellow square profile CP-1 (polypropylene)

0.433 in (11 mm) square

16 AWG twisted pair Incoloy tube, galvanized steel bumper

Flatpack encapsulated

A) 16 AWG solid bare copper

O.D. 0.510 (1.29 mm) nom.

B) Black and white T-01 (FEP) insulation

O.D. 0.079 in (2.01 mm) nom. A/B

C D

C) Natural T-17 (ETFE) filler A/B

0.181 in (4.60 mm) nom.

D) Alloy 825 tube

Wall thickness 0.035 in (0.89 mm) nom.

O.D. 0.250 in (6.35 mm) nom. E

E) Stranded galvanized steel rope

O.D. 0.313 in (7.9 mm) nom.

(7 x 2.64 mm) construction F

F) Rectangular profile CP-1 (polypropylene)

0.906 x 0.472 in (23 x 12 mm)

Tubing options

TEC is selected based on well conditions such as pressure, tempera- Draka has over 25 years of downhole cable design experience coupled

ture and corrosiveness of the well fluid. The tubing is composed of with extensive metallurgy expertise. Please consult with Draka’s engi-

an alloy matched to the application. It is then longitudinally welded, neers to discuss the correct tubing alloys for specific applications.

eddy current tested and drawn to finished size. Complete test data is

available for every tube.

Mechanical Characteristics for Cold-worked 316L and A825 Alloy TEC

Diameter Wall Thickness 316L Minimum Collapse A825 Minimum Collapse Minimum Bend Radius*

Inches Inches PSI PSI inches

.125 (1/8) 0.022 23,882 25,209 0.75

.250 (1/4) 0.028 16,371 17,281 1.50

.250 (1/4) 0.035 19,688 20,781 1.50

.250 (1/4) 0.049 26,173 27,627 1.50

.375 (3/8) 0.035 13,783 14,549 2.25

.375 (3/8) 0.049 18,739 19,780 2.25

Calculations based on minimum yield strength of 120,000 psi.

All TEC tubing is oversized welded and drawn.

Tubing can be custom printed with a variety of data including part number, serial number, sequential length and purchase order number.

*The bending radius indicated is in a static condition after final training at the termination. All bending must be performed using a tubing bender to ensure that the bending radius is

uniform. While deploying into or out of the well, the minimum bending radius should be as large as possible.

Over 25 Years of TEC Experience

1985 Shell Oil purchased first TEC

1987 Introduced first TEC using 825 Incoloy alloy tubing

1988 Redesigned TEC to allow longer welded lengths

1988 Introduced heavier wall tubing for operation at increased pressures

1992 Introduced encapsulated tubing to provide enhanced mechanical protection

1994 Introduced first orbitally-welded splices for longer welded lengths

1998 Introduced roll-reduced tubing for enhanced mechanical properties

1999 Introduced first two-conductor cable

2003 Introduced first copper-fiber hybrid cable

2004 Manufactured the longest TEC to date – 40,000 ft (12,200 m)

2005 Introduced first multi-pair copper cable

2008 Introduced first Fiber In Metal Tube (FIMT) hybrid cable

Electrical and Fiber Options

Electrical Components

TEC Style TEC 100 TEC 150 TEC 175 TEC 200 TEC 250 TEC 300

Temperature range -10 to +100°C -10 to +150°C -100 to +175°C -100 to +200°C -100 to +250°C -100 to +300°C

Filler* PP PP FEP FEP PFA Proprietary

Fluoropolymer

Insulation* PP FEP FEP FEP PFA Proprietary

Fluoropolymer

* See the Encapsulation, Insulation and Filling Materials chart on the next page for abbreviations

Copper conductors can be specified from a wide selection of configurations:

8 - 28 AWG conductors

Up to 32 conductors

Single, pair, triad and quad configurations

Solid or stranded conductors

Bare or tinned, silvered or nickled copper

Maximum Electrical Conductor Resistance @ 68 °F (20°C)

Conductor AWG Conductor Conductor Solid Bare Copper Stranded (7 strands) Bare Copper

Outside Diameter Outside Diameter

inches mm Ohms / kft Ohms / m Ohms / kft Ohms / m

18 0.0403 1.02 6.52 21.4 6.66 21.8

17 0.0453 1.15 5.15 16.9 5.27 17.3

16 0.0508 1.29 4.10 13.5 4.18 13.7

15 0.0571 1.45 3.24 10.6 3.31 10.9

14 0.0641 1.63 2.57 8.45 2.62 8.62

13 0.0720 1.83 2.04 6.69 2.08 6.82

12 0.0808 2.05 1.62 5.31 1.65 5.43

11 0.0907 2.30 1.29 4.22 1.32 4.30

10 0.102 2.59 1.019 3.34 1.039 3.41

9 0.114 2.90 0.808 2.65 0.825 2.71

8 0.128 3.25 0.641 2.10 0.654 2.14

Optical Components

TEC Style TEC 100 TEC 150 TEC 175 TEC 200 TEC 250 TEC 300

Fiber Coating* Acrylate Mid-temp Silicone-coated Silicone Coated Polyimide Polyimide

Acrylate or Polyimide or Polyimide

Fiber Types SM, SM, SM, SM, SM, SM

50 or 62.5 MM 50 or 62.5 MM 50 or 62.5 MM 50 or 62.5 MM 50 or 62.5 MM 50 or 62.5 MM

Buffer Type Polymeric loose tube Polymeric loose tube 304 stainless steel FIMT 304 stainless steel FIMT 304 stainless steel FIMT 304 stainless steel FIMT

316L and A825 available 316L and A825 available 316L and A825 available 316L and A825 available

Optical fibers can be specified in configurations of up to 12 fibers

*Carbon-coated fiber available upon request

TEC components can include

Optical signal and sensing fibers

Copper signal and power conductors

Encapsulation Options

Flatpacks

Flatpacks can include copper and fiber components, hydraulic control Draka helps take the guesswork out of well completions. Our engi-

and chemical injection lines as well as mechanical components for neers will work with you to optimize the selection of tubing alloys and

crush resistance and additional longitudinal strength. Individual com- wall thicknesses, crush-resistant bumpers and flatpack encapsulation

ponents and tubes can be color-coded and custom printed to ease materials to meet the exact requirement of your wells.

installation. Draka TEC production is entirely vertically integrated to

provide fast delivery, tight quality control, and the widest variety of

configurations.

Completion Fluid Environment

TEC Style TEC 100 TEC 150 TEC 175 TEC 200 TEC 250 TEC 300

Brine HDPE PP FEP, ETFE or FEP PFA Proprietary

PE TPO-PP ECTFE Fluoropolymer

Petroleum-based Nylon Nylon FEP, ETFE or FEP PFA Proprietary

ECTFE Fluoropolymer

Petroleum ETFE or ETFE or FEP, ETFE or FEP PFA Proprietary

and brine ECTFE ECTFE ECTFE Fluoropolymer

Encapsulation, Insulation and Filler Materials

Abbreviation Generic Name Trade Name Minimum installation temperature of encapsulation materials

ECTFE Ethylene Chlorotrifluoroethylene Halar® -60°C

ETFE Ethylene Tetrafluoroethylene Tefzel® -60°C

FEP Fluoronated Ethylene Propylene Teflon® FEP -100°C

HDPE High Density Polyethylene -- -40°C

PFA Perfluoroalkoxy Teflon® PFA -100°C

PA Polyamide Nylon -40°C

PP Polypropylene -- -10°C

PVDF Polyvinylidene Fluoride Kynar® -20°C

TPO-PP Thermoplastic polyolefin Santoprene® -20°C

Flatpack components can include

TEC with fiber and electrical conductors

Hydraulic control lines for controlling of downhole valves

Fluid injection lines for enhanced oil / gas recovery or corrosion / scaling inhibition

Bumpers of stranded galvanized steel cable for crush protection

Linking the oil and gas industry from end to end

Draka

111 Chimney Rock Road | Bridgewater, NJ 08807 | Tel +1-732-469-5902 | Fax +1-732-469-6363

For sales and technical information, contact: 1-866-786-8823 or 1-732-469-5902

www.prysmiangroup.com

You might also like

- Ej 2021 q1 IssueDocument82 pagesEj 2021 q1 IssueReab SimanthNo ratings yet

- Part-04 05 ESP CablesDocument42 pagesPart-04 05 ESP CablesHazem Kolieb100% (1)

- Credit Card NCC BANKDocument1 pageCredit Card NCC BANKKazi Foyez AhmedNo ratings yet

- Kumpulan 100 Soal TOEFL Written ExpressiDocument8 pagesKumpulan 100 Soal TOEFL Written ExpressiPuji AmbarNo ratings yet

- Cabletec Metal Braids Bonding Leads CatalogDocument28 pagesCabletec Metal Braids Bonding Leads CatalogРоман ДяченкоNo ratings yet

- Manual Bomba KoomeyDocument95 pagesManual Bomba KoomeyDiego De JesusNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Raychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingDocument4 pagesRaychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingGIBUNo ratings yet

- Guayas 5-16 y 7-32 CamesaDocument2 pagesGuayas 5-16 y 7-32 CamesaPaul Buenaño100% (2)

- MV Cables Data Sheet - SampleDocument5 pagesMV Cables Data Sheet - SampleAvoor KhanNo ratings yet

- Recommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsDocument43 pagesRecommended Practice For Precast Prestressed Concrete Composite Bridge Deck PanelsAnonymous Gd0PTUQNo ratings yet

- Middle East Technical UniversityDocument13 pagesMiddle East Technical Universityiremnur keleş100% (1)

- Electrical Downhole Cable: ApplicationsDocument3 pagesElectrical Downhole Cable: ApplicationsAndrea VarasNo ratings yet

- 9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCDocument2 pages9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCwaynecruzz29No ratings yet

- TMC - Crouse Hinds - TMC3 TerminatorDocument2 pagesTMC - Crouse Hinds - TMC3 TerminatorJFPA2012No ratings yet

- TMCX ConnectorsDocument5 pagesTMCX ConnectorsGregory StewartNo ratings yet

- Untitled Extract PagesDocument11 pagesUntitled Extract PagesMohammedIrfanNo ratings yet

- Retropod (Deep Water) : Technical DatasheetDocument1 pageRetropod (Deep Water) : Technical DatasheetReza AbadiNo ratings yet

- KEC - Instrumentation-Cables PDFDocument8 pagesKEC - Instrumentation-Cables PDFbharatsehgal00No ratings yet

- TMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofDocument2 pagesTMCX Connectors For Jacketed Metal Clad Cable: Explosionproof, Dust-IgnitionproofFernando TovarNo ratings yet

- L2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Document3 pagesL2B2AT-Canare Corp. - Two-Conductor Shielded Cables - Two-Conductor Shielded Cables (Single) Aluminum Foil Shield (L-2B2AT)Antonius Patra100% (1)

- OS1LTSTA12UBKDocument2 pagesOS1LTSTA12UBKShimahNo ratings yet

- Tubing PDFDocument20 pagesTubing PDFTheEdgeNo ratings yet

- Especificaciones Técnicas: Specifications Physical DimensionsDocument1 pageEspecificaciones Técnicas: Specifications Physical DimensionsGianny Daniela Torres TelloNo ratings yet

- FTC 2022 PRESENTATION - CompressedDocument16 pagesFTC 2022 PRESENTATION - CompressedclaudioNo ratings yet

- Trimdek 1015Document6 pagesTrimdek 1015Shital ChaudhariNo ratings yet

- Nyfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesNyfgby 2 X (1.5-300) MM 0.6/1 KVBagus Arief WibowoNo ratings yet

- Data Sheet Junction Boxes 8118 121-807 GBDocument3 pagesData Sheet Junction Boxes 8118 121-807 GBSivagurunathan SpNo ratings yet

- Tdoct2014b EngDocument2 pagesTdoct2014b Engmahmoud abuelmgdNo ratings yet

- Lida Tubular Anodes PDFDocument4 pagesLida Tubular Anodes PDFVCNo ratings yet

- NYFGb YDocument5 pagesNYFGb YMuhammad Adrianto LubisNo ratings yet

- Leader Cable - 132kVDocument8 pagesLeader Cable - 132kVTeo Yi LinNo ratings yet

- Central Loose Tube Armoured External Cable: ComplianceDocument2 pagesCentral Loose Tube Armoured External Cable: CompliancenajiruddinshaikNo ratings yet

- Brosur NYRGbY SNI IECDocument5 pagesBrosur NYRGbY SNI IECMuhammad YusufNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- Technical Specification - Grounding - WP4Document6 pagesTechnical Specification - Grounding - WP4nnNo ratings yet

- PROD - Cable TerminationsDocument5 pagesPROD - Cable TerminationsAnaNo ratings yet

- Loose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJDocument5 pagesLoose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJPetyo GeorgievNo ratings yet

- N1P 1.5 P1T2 BLK LDocument2 pagesN1P 1.5 P1T2 BLK LRijo RajanNo ratings yet

- T2XDocument3 pagesT2XMarius CANJANo ratings yet

- Appleton TMC TMCX BrochureDocument4 pagesAppleton TMC TMCX Brochurefernando magneNo ratings yet

- Pt. Alsun Suksesindo: Roofin G System InsulatedDocument6 pagesPt. Alsun Suksesindo: Roofin G System Insulatedindra pramudiaNo ratings yet

- BS 1057Document8 pagesBS 1057drg gocNo ratings yet

- Kabelindo Power MVDocument2 pagesKabelindo Power MVAndrewNo ratings yet

- Katalog Power MV 1core 20 KV PDFDocument2 pagesKatalog Power MV 1core 20 KV PDFHafidz BandungNo ratings yet

- Resistance WireDocument16 pagesResistance Wirets01759No ratings yet

- Arc701 S70016Document1 pageArc701 S70016Radient MushfikNo ratings yet

- RE2YYDocument2 pagesRE2YYmathan_aeNo ratings yet

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDocument4 pagesDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyNo ratings yet

- Mixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDocument5 pagesMixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDotty RoseNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- NYFGbY - SNI - IEC-pvc-sfwa-pvc Kmi1Document4 pagesNYFGbY - SNI - IEC-pvc-sfwa-pvc Kmi1Saung KuringNo ratings yet

- High-Performance Wire and Cable FullCatDocument47 pagesHigh-Performance Wire and Cable FullCatHaleppsNo ratings yet

- Product CAT CST - DatasheetDocument15 pagesProduct CAT CST - Datasheetfaisalardy20No ratings yet

- SECTION 16640 Cathodic Protection (Boiler Plant/Outside Steam Distribution) Part 1 - General 1.1 DescriptionDocument7 pagesSECTION 16640 Cathodic Protection (Boiler Plant/Outside Steam Distribution) Part 1 - General 1.1 Descriptionno nameNo ratings yet

- N2Xfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesN2Xfgby 2 X (1.5-300) MM 0.6/1 KVfasa9009No ratings yet

- Power CablesDocument8 pagesPower Cableslam2660% (1)

- Ab Cable GTPDocument17 pagesAb Cable GTPNaresh Ch MahapatraNo ratings yet

- 1 Wire Ropes, Elements and DefinitionsDocument6 pages1 Wire Ropes, Elements and DefinitionsDiego RodriguezNo ratings yet

- RE2YKRY KMI VendorDocument2 pagesRE2YKRY KMI VendorArthurNo ratings yet

- Kabel Katalog Airfield LightingDocument10 pagesKabel Katalog Airfield LightingHimawan Sigit NugrohoNo ratings yet

- N2XSEYBY - Cu XLPE CTS DSTA PVCDocument3 pagesN2XSEYBY - Cu XLPE CTS DSTA PVCabhi boyzNo ratings yet

- Copper Steel Earthing RodDocument3 pagesCopper Steel Earthing RodArnold StevenNo ratings yet

- Brosure Kabel NA2XSYDocument5 pagesBrosure Kabel NA2XSYcandra handarsenNo ratings yet

- Defining Submission PhasesDocument1 pageDefining Submission Phasesmohan krishnaNo ratings yet

- Chapter 4Document6 pagesChapter 4Rocel Marie LopezNo ratings yet

- Cambridge IGCSE: BIOLOGY 0610/42Document20 pagesCambridge IGCSE: BIOLOGY 0610/42Ashtav ArunNo ratings yet

- Speech Act Approach (Revised)Document15 pagesSpeech Act Approach (Revised)Udiana Puspa DewiNo ratings yet

- Cultural Anthropology: Appreciating Cultural Diversity by Conrad Kottak - 15e, TEST BANK 0078035007Document16 pagesCultural Anthropology: Appreciating Cultural Diversity by Conrad Kottak - 15e, TEST BANK 0078035007jksmtnNo ratings yet

- Research 3 Quarter 3 LESSON-2-HYPOTHESIS-TESTINGDocument29 pagesResearch 3 Quarter 3 LESSON-2-HYPOTHESIS-TESTINGRaven Third-partyAccNo ratings yet

- Europass Curriculum Vitae: Personal InformationDocument2 pagesEuropass Curriculum Vitae: Personal InformationNatasa BudisinNo ratings yet

- Ranger R2 DatasheetDocument2 pagesRanger R2 DatasheetRocky VNo ratings yet

- GRM 1Document55 pagesGRM 1Mady RadaNo ratings yet

- ThesisDocument153 pagesThesisMarius BrătanNo ratings yet

- Cultural Product Innovation Strategies Adopted by The Performing Arts IndustryDocument33 pagesCultural Product Innovation Strategies Adopted by The Performing Arts IndustryMateo FemopaseNo ratings yet

- Drill HolesDocument304 pagesDrill HolesJorge Luis Zegarra OtoyaNo ratings yet

- Q1-L1 - English 10 Activity No. 1.4Document2 pagesQ1-L1 - English 10 Activity No. 1.4Thal S. GayakNo ratings yet

- Nicol, Abigial, Komal - Maths Finial SbaDocument14 pagesNicol, Abigial, Komal - Maths Finial SbavanessajageshwarNo ratings yet

- Climate Change Scheme of Work For KS2Document13 pagesClimate Change Scheme of Work For KS2Zoe AlsumaitNo ratings yet

- Chapt 11 Cost-Volume-Profit AnalysisDocument32 pagesChapt 11 Cost-Volume-Profit AnalysisJumry Al-ashiddiqiNo ratings yet

- IGS System-1Document11 pagesIGS System-1manojNo ratings yet

- Politeness in Friends TV Series Does It Represent American Value?Document7 pagesPoliteness in Friends TV Series Does It Represent American Value?Dieu LinhNo ratings yet

- IoDocument1 pageIopamminorNo ratings yet

- Fire FightingDocument18 pagesFire FightingkennyNo ratings yet

- What Does Fire Hazards Mean?Document2 pagesWhat Does Fire Hazards Mean?Karima HijaraNo ratings yet

- ScorecardDocument15 pagesScorecardKarthik KadambiNo ratings yet

- Ejece 455Document7 pagesEjece 455E-dot ProjectNo ratings yet

- LG Machine SpecDocument1 pageLG Machine SpecMohd AffiqNo ratings yet