Professional Documents

Culture Documents

Modelling and Analysis of Flow Through An Inlet Duct in An Electrostatic

Uploaded by

Myo Myint MaungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modelling and Analysis of Flow Through An Inlet Duct in An Electrostatic

Uploaded by

Myo Myint MaungCopyright:

Available Formats

IJSRD - International Journal for Scientific Research & Development| Vol.

5, Issue 02, 2017 | ISSN (online): 2321-0613

Modelling and Analysis of Flow through an Inlet Duct in an Electrostatic

Precipitator

Mitendra Sulakhe1 Sanjay Gupta2

1

M. Tech Student 2Assistant Professor

1,2

Department of Computer Engineering

1,2

CCET Bhilai (C.G), India

Abstract— Electrostatic Precipitator (ESP) are well accepted precipitators have several advantages when compared with

and widely used for air pollution control due to reasonable other control devices.

collection efficiency, low pressure-drop, and low capital and

operating costs. The objective of the present work is to

improve the flow distribution in the duct. In this present

work, CFD analysis of flow through the ESP inlet duct has

been performed using ANSYS FLUENT, in order to

improve the efficiency of duct. The analysis for path lines,

velocity contours, pressure distributions for various cases

involving no guide vane and with guide vanes has been

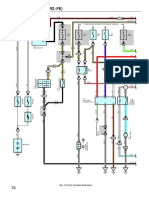

done. Fig. 1: ESP working principle

Key words: ESP, Electrostatic Precipitator

I. INTRODUCTION

An Electro Static Precipitator (ESP) is a particle control

device that uses electrical forces to move the articles out of

the flowing gas stream and onto collector plates. The

particles are given an electrical charge by forcing them to

pass through a corona, a region in which gaseous ions flow.

The electrical field that forces the charged particles to the Fig. 2: Overview of Electrostatic Precipitator

walls comes down electrodes maintained at high voltage in They are very efficient collectors, even for small

the centre of flow lane. Once the particles are collected on particles. Because the collection forces act only on the

the plates, they must be removed from the plates without re- particles, ESPs can treat large volumes of gas with low

entering them into gas stream. This is usually accomplished pressure drops. They can collect dry materials, fumes, or

by knocking them loose from the plates, allowing the mists. Electrostatic precipitators can also operate over a

collected layer of particles to slide down into a hopper from wide range of temperatures and generally have low

which they are evacuated. Some precipitators remove the operating costs. Possible disadvantages of ESPs include

particles by intermittent or continuous washing with water. high capital costs, large space requirements, inflexibility

Electrostatic precipitators are used in large power plants, with regard to operating conditions, and difficulty in

cement plants, incinerators, various boiler applications, controlling particles with high resistivity. Disadvantages of

chemical factories, sugar mills, etc., ESP’s are well accepted ESPs can be controlled with proper design. An improvement

and widely used for air pollution control due to reasonable of flow distribution in the duct through optimization can be

collection efficiency, low pressure-drop, and low capital and achieved by placing guide vanes in the inlet duct. In this

operating costs. The performance of modern ESP’s would present work, CFD analysis of flow through the ESP inlet

be expected to be better than 99.9% particulate removal duct is to be performed without guide vanes and with guide

efficiency while incurring less than 100 Pa pressure drop. vanes, in order to reduce the pressure drop, reduce

Although commercially available ESP’s for large scale turbulence as well as achieve uniform distributions among

industrial gas cleaning exhibit slight variations in design the streams and minimize erosion of duct walls caused due

characteristics, component, and mechanical cleaning style, to high velocity. Reducing erosion of the duct walls results

all achieve gas cleaning quite simply by the use of in the reduction of leakages in the ducts. Reduction of

electrostatic forces acting on airborne solid particles to pressure drop across the duct saves the power consumption.

promote their attraction to and eventual collection on The ESP inlet duct consists of an inlet and two outlets. In

charged electrodes. ESP inlet duct is one through which flue this paper Modeling and analysis of ESP inlet duct has been

gases enter electrostatic precipitator from air pre-heater. The performed using CAD software ANSYS 15.0 CFX.

design of ESP inlet duct is very important that the collection

efficiency and the power consumption will be affected II. LITERATURE REVIEW

Collection of particles by electrostatic precipitation involves

the ionization of the stream passing though the ESP, the Bhasker [3, 4] has done flow simulation in inlet ducts with

charging, migration, and collection of particles on several guide vanes used in electrostatic precipitator (ESP)

oppositely charged surfaces, and the removal of particles analyzed to understand the flow pattern at its exit location.

from the collection surfaces. In dry ESPs the particulate is The geometry of inlet duct has refined with guide vanes

removed by rappers which vibrate the collection surface. placed at several locations. The domain of duct geometry

Wet ESPs use water to rinse the particles off. Electrostatic around guide vanes were decomposed with several volumes

All rights reserved by www.ijsrd.com 1152

Modelling and Analysis of Flow through an Inlet Duct in an Electrostatic Precipitator

(IJSRD/Vol. 5/Issue 02/2017/315)

and filled with hexahedral elements. The resulting Without

1 24363 5636

computational grid has been used in fluent solver to predict Guide vane

its flow pattern in the duct. Simulation for the specified With 6 Guide

conditions predicted uneven flow distribution in the ESP 2 29318 6817

vanes

inlet duct. Due to large flow recirculation and turbulent Table 1: Details of Elements and Nodes of the

losses in the duct, non-uniform averaged mass flow rates Computational Domain

were noticed at duct exit locations. Simulation results In this research the CAD model has been generated

suggested that the improvement of flow distribution in the using ANSYS 15.0 software and the model has been

duct through optimization can be tried by placing more validated with the base paper (Reference 1) for following

guide vanes in the inlet duct. In order to ensure that the two cases:-

results obtained from fluent are meaningful and in right Case A Inlet Duct without Guide vanes

direction, in the absence of measurement data, simulation Case B Inlet duct with six guide vanes.

was benchmarked with other industry standard commercial

flow solvers. A. Case A- ESP Inlet Duct without Guide Vane

Seralathan S. et al [1] presented a paper in which Using the CAD software ANSYS 15.0 ESP Inlet Duct

CFD analysis of flow through the ESP inlet duct is model without guide vanes has been generated. The

performed by placing the guide vanes, in order to reduce the computational model view of ESP inlet duct without vane is

pressure drop, reduce turbulence as well as achieve uniform shown in Fig 3.

distributions among the streams and minimize erosion of After generating computational model meshing has

duct walls caused due to high velocity. Reducing erosion of been done using triangular surface element shown in Fig 4.

the duct walls results in the reduction of leakages in the The boundary conditions are same for all the cases

ducts. Reduction of pressure drop across the duct saves the as mentioned earlier. Fig 5 shows the velocity distribution

power consumption [Ref. 8]. The ESP inlet duct consists of flow through the inlet duct of ESP.

an inlet and two outlets. The simulation studies involving

the flow through the ESP inlet duct is performed using

commercial code, FLUENT 6.3 using structured hexahedral

mesh. The path lines, velocity contours, pressure

distributions for various cases involving no guide vane and

six guide vanes are analyzed. The ESP inlet duct with six

guide vanes shows lesser pressure drop with uniform

distributions across the duct. The numerical analysis of the

flow through ESP inlet duct has been performed involving

various cases – no guide vane and six guide vanes.

Reduction of pressure drop around 30 % in the proposed Fig. 3: Computational model view of ESP inlet duct without

model with six guide vanes as compared to the existing guide vane

layout of duct without guide vanes, which in turn results in The computational fluid analysis of CAD model

saving of power consumption in inlet draught fan and has been done using ANSYS 15.0 CFX for calculation of

improves the performance of ESP. Going through the pressure drop. The velocity at the outlet of ESP inlet duct is

literature it has been observed that in duct designing, increased compared to the inlet section. At first, velocity

different methods has been applied to improve the efficiency increases and there is stagnation at the corner of the duct and

of duct. This improvement may be in the form of reduction then gradually increases again.

in pressure, making smooth the streamline through the duct

or reducing the turbulence of flow.

III. NUMERICAL VALIDATION OF MODEL

The modeling of the inlet duct of ESP is done using ANSYS

15.0. Triangle surface mesh is generated and used in the

simulation studies to create the fluid domain. Table 4.1

shows the number of elements and number of nodes for the

present model using ANSYS 15.0 Workbench. Analysis has

been done using CFX and meshing is done with triangle

surface elements type. The entire domain is in the stationary Fig. 4: Meshing of CAD model of Inlet duct without Guide

frame of reference. The boundary conditions specified are vane

mass flow rate at the inlet and static pressure at the outlet. A high velocity zone at the sharp edge is noticed

The velocity at inlet is 6 m/s. The walls are defined no slip and velocity decreases sharply and then increases. Therefore

condition. The monitoring parameter is pressure for the there is non- uniform distribution of velocity of flue gases

entire case studies. Steady state solutions are computed until within the duct. Pressure drop across the ESP inlet duct is

the residual values of computations converged. Reference 641.8 Pa (Fig 6). Pressure at inlet is high and then it reduces

pressure used for simulation is 101.325 Pa and hence the gradually and there is stagnation at the corners and then

static pressure at inlet is given as zero Pascal. drop in the pressure is very high. Therefore, the power

No. of No. of consumption will be high, so the pressure drop can be

Case Description

Elements Nodes reduced by placing guide vanes.

All rights reserved by www.ijsrd.com 1153

Modelling and Analysis of Flow through an Inlet Duct in an Electrostatic Precipitator

(IJSRD/Vol. 5/Issue 02/2017/315)

B. Case B- ESP Inlet Duct With six Guide Vanes

Fig 7 shows the location of ESP inlet duct with six guide

vanes. The guide vanes are placed at the six corner bends of

the inlet duct. By placing guide vanes in these cases, the

uniform flow of flue gas is achieved and pressure drop is

also decreased compared to all the earlier cases. The flow is

made more uniform by using six guide vanes.

Fig. 7: Computational model view of ESP inlet duct with six

guide vanes

Table 2 shows that using ANSYS 15.0 Software,

variation of pressure drop is within ±10%, which is under

acceptable range. Also the pressure drop is reduced from

641.8 Pa to 510.0 Pa. The presence of guide vanes reduces

the pressure drop around 20.53 %. This reduces the power

Fig. 5: Velocity contour of ESP inlet duct without guide consumption. Hence computational model for inlet duct of

vane ESP is validated and now the further optimum performance

The guide vanes are curved in shape and radius of is to be done for reducing the pressure drop and improving

curvature is 9mm. Flow variations in the outlet duct the efficiency of duct.

compared to previous cases are much reduced. This causes

the uniform flue gases distribution throughout the duct. The

velocity distribution is more uniform throughout the entire

region from inlet to outlet in this case. This makes the flue

gas distribution uniform. The velocity pattern at the outlet

portion is also uniform. This uniform distribution is due the

introduction of guide vanes at outlet region of the ESP inlet

duct. Fig 8 shows the velocity contour of ESP inlet duct

with six guide vanes.

Fig. 8: Velocity contour of ESP inlet duct with six guide

vane

Fig. 6: Pressure distribution in ESP inlet duct without guide

vane

The velocity distribution is more uniform Fig. 9. Pressure distribution in ESP inlet duct with six guide

throughout the entire region from inlet to outlet in this case. vane

The velocity at inlet increases and the velocity at the corners Table 2 shows that using ANSYS 15.0 Software,

decrease slightly because of the presence of guide vanes. variation of pressure drop is within ±10%, which is under

This makes the flue gas distribution uniform. The velocity acceptable range. Also the pressure drop is reduced from

pattern at the outlet portion is also uniform. This uniform 641.8 Pa to 510.0 Pa.

distribution is due to introduction of guide vanes at outlet Pressure Drop (Pa)

region of the ESP inlet duct. %age

Case Present Reference

Pressure drop at ESP inlet duct with six guide Variation

Result 1

vanes is 510 Pa as seen in Fig. 9. The pressure at the entry A (Without

of the duct is high and then it reduces at the first bend and it 641.8 692.8 + 7.36

Guide Vanes)

again reduces at the next bend and the pressure is uniform. B (With 6

Again, at the outlet region the pressure further decreases. 510.0 490.62 - 3.95

Guide Vanes)

Table 2 shows the comparison of pressure drop for Table 2: Validation of Present Results (For Pressure) With

present computational model using ANSYS 15.0 CFX and Previous Literature [1]

results obtained in base paper [1] using FLUENT 6.1.

All rights reserved by www.ijsrd.com 1154

Modelling and Analysis of Flow through an Inlet Duct in an Electrostatic Precipitator

(IJSRD/Vol. 5/Issue 02/2017/315)

The presence of guide vanes reduces the pressure 12 18

Without 6 guide

drop around 20.53 %. This reduces the power consumption. guide guide

guide van vanes

Hence computational model for inlet duct of ESP is vanes vanes

validated and now the further optimum performance is to be Maximum

done for reducing the pressure drop and improving the 641.8 510.0 402.1 479.2

Pressure (Pa)

efficiency of duct. % Reduction ---- 20.53 37.34 25.33

Table 3: Comparison of Reduction in Pressure Drop For All

IV. RESULTS AND DISCUSSIONS The Cases

The aim of this research is to further increase the duct

performance by improving the flow. It has been achieved by V. CONCLUSIONS

increasing the number of vanes at the bends and also by The numerical analyses of the flow through ESP inlet duct

giving fillet at the corners. The computational domain for are performed involving various cases – no guide vane, with

five case studies involving the simulation studies of flow six, twelve, eighteen as well as six, twelve and eighteen

through the inlet duct of ESP is performed by considering guide vanes with fillet. The flow distribution among the

inlet duct with 12 guide vanes, 18 guide vanes, The stream are studied both for existing and proposed layout.

boundary conditions for all the cases are similar and same as It has been concluded from this research that with

taken in the base paper [1]. six guide vanes the pressure drop reduced by around

A. ESP Inlet Duct with Twelve Guide Vanes 20.53%, with 12 guide vanes the pressure drop is reduced by

37.34%, with 18 guide vanes the pressure drop is reduced by

The maximum pressure value has been reduced from 641.8 25.33%, in the proposed model as compared to the existing

Pa for without guide vane to 402.1 Pa with 12 guide vanes layout of duct without guide vanes, which in turn results in

(Fig 10). The increase of guide vanes from 6 to 12 further saving of power consumption in inlet draught fan and

reduces the pressure drop around 37.34 %. This reduces the thereby improves the performance of ESP.

power consumption and increasing the duct efficiency.

B. ESP Inlet Duct with Eighteen Guide Vanes REFERENCES

Fig 11 shows the pressure distribution throughout the ESP [1] Seralathan S, Dinesh Kumar G, “Numerical Studies of

inlet duct with 18 guide vanes. The maximum pressure the Flow through the Inlet Duct of an ESP”,

value has been reduced from 641.8 Pa for without guide International Journal of Applied Engineering Research

vanes to 479.2 Pa with 18 guide vanes. The increase of ISSN 0973-4562 Volume 10, Number 13 (2015).

guide vanes to 18 further reduces the pressure drop around [2] Seralathan S, Baskar P, Karthik M, “Modelling

25.33 %. Simulation and Analysis of Flow through an Inlet Duct

in an Electrostatic Precipitator for Optimum

Performance”, International Conference on Mechanical

Engineering: Emerging Trends for Sustainability 29-31

Jan, 2014, MANIT Bhopal (M.P).

[3] C. Bhasker, “ Numerical Simulation of turbulent flow in

complex geometries used in power plants”, Advances in

engineering software, vol 33 (2002), pg 71-83.

[4] C. Bhasker, “Flow simulation in Electro-Static-

Precipitator (ESP) ducts with turning vanes”, Advances

in Engineering Software, vol 42 (2011), pg 501–512.

[5] Makhsuda Juraeva, Kyung Jin Ryu, Sang-Hyun Jeong

Fig. 10: Pressure distribution in ESP inlet duct with twelve and Dong Joo Song, “Effect of guide vanes on

guide vane recovering uniform flow in a ventilation duct in an

existing twin-track subway tunnel”, Journal of

Mechanical Science and Technology , Vol 29 (1)

(2015), pg 251-258.

[6] Kyung Hwan Kim, Jin GiPaeng and Young Hwan

Yoon, “Comparison between numerical computations

and measurements by LDV for fluid flow in rectangular

duct systems”, Journal of Mechanical Science and

Technology Vol 22 (2008), pg 1800-1807.

[7] J. Anagnostopoulos, G. Bergeles, “Corona discharge

simulation in wire-duct electrostatic precipitator”,

Journal of Electrostatics Vol 54 (2002), pg 129–147.

[8] A.S.M. Sayem, M.M.K. Khan, M.G. Rasul, M.T.O.

Fig. 11: Pressure distribution in ESP inlet duct with eighteen Amanullah, N.M.S. Hassan, “Effects of baffles on flow

guide vane distribution in an electrostatic precipitator (ESP) of a

Table 3 shows the comparison of reduction in coal based power plant”, 6th BSME International

pressure drop for all the cases mentioned above with the Conference on Thermal Engineering (ICTE 2014),

case of inlet duct without guide vanes. Procedia Engineering, vol 105 ( 2015 ), pg 529 – 536.

All rights reserved by www.ijsrd.com 1155

Modelling and Analysis of Flow through an Inlet Duct in an Electrostatic Precipitator

(IJSRD/Vol. 5/Issue 02/2017/315)

[9] M. E. Erdogan and C. E. Imrak, “Effects of the wall

curvature on the flow in a duct of uniform cross-

section”, ActaMechanica, Vol 167(2004), pg 123–130.

[10] Mi-Ae Moon, Kwang-Yong Kim, “Multi-objective

optimization of a guide vane in the turning region of a

rotating U-duct to enhance heat transfer performance”,

Journal of Heat mass transfer, online publication

(2012).

[11] BaoyuGuo, Aibing Yu, and Jun Guo, “Numerical

Modelling of ESP for Design Optimization” The 7th

World Congress on Particle Technology (WCPT7),

Procedia Engineering, Vol 102 ( 2015 ), pg 1366 –

1372.

[12] Tae-An Kim, D.-W. Kim, S.-K. Park, and Youn J. Kim

“Performance of a cross-flow fan with various shapes of

a rearguider and an exit duct”, Journal of Mechanical

Science and Technology, Vol 22 (2008), pg 1876-

1882.

[13] Tsrong-YiWen, IgorKrichtafovitch, AlexanderV.

Mamishev, “The key energy performance of novel

electrostatic precipitators”, Journal of Building

Engineering, Vol 2(2015), pg 77–84.

[14] Zakariya Al-Hamouz ,Amer El-Hamouz , Nabil

Abuzaid, “Simulation and experimental studies of

corona power loss in a dust loaded wire-duct

electrostatic precipitator”, Advanced Powder

Technology, Vol 22 (2011), pg 706–714.

[15] White, H. J., “Electrostatic precipitation of fly ash”,

APCA Reprint Series. Journal of Air Pollution Control

Association, 1977, Pittsburgh, PA.

[16] Katz, J., The Art of Electrostatic Precipitators. Munhall,

1979, PA: Precipitator Technology.

All rights reserved by www.ijsrd.com 1156

You might also like

- Engine Control (3Rz-Fe) : 2001 Toyota Tacoma (Ewd440U)Document8 pagesEngine Control (3Rz-Fe) : 2001 Toyota Tacoma (Ewd440U)Omar ZernaNo ratings yet

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Broadcrown CatalogueDocument28 pagesBroadcrown CatalogueSerimNo ratings yet

- CFD Analysis of Pelton TurbineDocument4 pagesCFD Analysis of Pelton TurbineSanam ManutdNo ratings yet

- Nesl Training ManualDocument91 pagesNesl Training ManualSOUMYA DEEP CHATTERJEENo ratings yet

- Transient Phenomena in Electrical Power Systems: Problems and IllustrationsFrom EverandTransient Phenomena in Electrical Power Systems: Problems and IllustrationsRating: 1.5 out of 5 stars1.5/5 (3)

- CFD Ball ValveDocument8 pagesCFD Ball ValveKelvin Octavianus DjohanNo ratings yet

- Air Compressor - Dq..Document13 pagesAir Compressor - Dq..rohan khariwale100% (2)

- Headbox Tappi2000cDocument11 pagesHeadbox Tappi2000cKrishnamoorthyRajanbabuNo ratings yet

- Butterfly Valve and FlowDocument5 pagesButterfly Valve and FlowMurugan RangarajanNo ratings yet

- Thermal Buckling Comparative Analysis Using Different FE Tools 01Document4 pagesThermal Buckling Comparative Analysis Using Different FE Tools 01Waldek BanasiakNo ratings yet

- Computational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992From EverandComputational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992S. MurakamiNo ratings yet

- Daftar Harga Eceran Disarankan Yamaha Genuine Parts Efektif 1 November 2022Document1,755 pagesDaftar Harga Eceran Disarankan Yamaha Genuine Parts Efektif 1 November 2022Ronnie LiemNo ratings yet

- Computational Fluid Dynamics Analysis of Electrostatic Precipitator OF 210Mw Thermal Power PlantDocument19 pagesComputational Fluid Dynamics Analysis of Electrostatic Precipitator OF 210Mw Thermal Power PlantSylvester marxNo ratings yet

- Comparative Study of Various Parameter of ESP by Using CFD: AbstractDocument9 pagesComparative Study of Various Parameter of ESP by Using CFD: AbstractAnonymous 9NqiyRj8ENo ratings yet

- Simulation and Experimental Investigation On A Dynamic Lateral Flow Mode in Trepanning Electrochemical MachiningDocument7 pagesSimulation and Experimental Investigation On A Dynamic Lateral Flow Mode in Trepanning Electrochemical Machiningkaushalshah28598No ratings yet

- A CFD Study of Diffuser Performance of Gas Dynamic Laser SystemDocument7 pagesA CFD Study of Diffuser Performance of Gas Dynamic Laser SystemAngel BriceñoNo ratings yet

- Simulation and Analysis of Fluid Flow in A Pipe With LeakDocument16 pagesSimulation and Analysis of Fluid Flow in A Pipe With LeakKrisNo ratings yet

- Grapsas V Etal - 2006 - Experimental and Computational Study of A Radial Flow Pump ImpellerDocument9 pagesGrapsas V Etal - 2006 - Experimental and Computational Study of A Radial Flow Pump ImpellerAndronikos Filios100% (1)

- Flow Simulation in An Electrostatic Precipitator of A Thermal Power Plant - Shah Et Al - 2009Document7 pagesFlow Simulation in An Electrostatic Precipitator of A Thermal Power Plant - Shah Et Al - 2009SylvesterNo ratings yet

- Design, Construction and Simulation of Tesla Turbine: Keywords - Physical Model, CFD Simulation, RadialDocument9 pagesDesign, Construction and Simulation of Tesla Turbine: Keywords - Physical Model, CFD Simulation, RadialhatemNo ratings yet

- Comparative Study of Various Parameter of ESP by Using CFD: AbstractDocument9 pagesComparative Study of Various Parameter of ESP by Using CFD: AbstractSylvesterNo ratings yet

- ETMM11 KhatirEtAl Accepted PDFDocument9 pagesETMM11 KhatirEtAl Accepted PDFUbuntu PremNo ratings yet

- CFD Simulation of Compressible Flow Inside A Gas Centrifuge Using OpenFOAMDocument8 pagesCFD Simulation of Compressible Flow Inside A Gas Centrifuge Using OpenFOAMIJRASETPublicationsNo ratings yet

- CFD Numerical Simulation of Archimedes Screw Turbine With Power Output AnalysisDocument8 pagesCFD Numerical Simulation of Archimedes Screw Turbine With Power Output AnalysisShahzaib KhanNo ratings yet

- A Comparative Study and Flow Analysis of Multiple Branch Pipe Flow Header Used in Tube Heat ExchangersDocument5 pagesA Comparative Study and Flow Analysis of Multiple Branch Pipe Flow Header Used in Tube Heat ExchangersSaad Bin ZiaNo ratings yet

- Publisher PDF Fulltext Simulation of Mass Flow Rate of Air ThroughDocument7 pagesPublisher PDF Fulltext Simulation of Mass Flow Rate of Air Throughranaware ajinkyaNo ratings yet

- Extraction Columns.: Proceedings PaperDocument10 pagesExtraction Columns.: Proceedings PaperAnonymous q1gGEpNo ratings yet

- Hydraulic Design of Headrace and Tailrace Channel For ADocument10 pagesHydraulic Design of Headrace and Tailrace Channel For AVineet Chaudhary0% (1)

- Numerical Investigation of Parameters Affecting Discharge Line Pressure Pulsations in Hermetic Reciprocating CompressorsDocument9 pagesNumerical Investigation of Parameters Affecting Discharge Line Pressure Pulsations in Hermetic Reciprocating CompressorsGokuNo ratings yet

- Pipe Attached With NozzleDocument4 pagesPipe Attached With NozzleAny BodyNo ratings yet

- Modelling Pressure Deficient Water Distribution Networks in EpanetDocument6 pagesModelling Pressure Deficient Water Distribution Networks in EpanetRahul KumarNo ratings yet

- Computational Analysis of Naca 23012 Airfoil With Plasma ActuatorDocument12 pagesComputational Analysis of Naca 23012 Airfoil With Plasma Actuatorvarun karthikeyanNo ratings yet

- Zahariea 2016 IOP Conf. Ser. Mater. Sci. Eng. 161 012041Document7 pagesZahariea 2016 IOP Conf. Ser. Mater. Sci. Eng. 161 012041sompornNo ratings yet

- European Journal of Mechanics B/Fluids: Sylvain Tridon, Stéphane Barre, Gabriel Dan Ciocan, Laurent TomasDocument15 pagesEuropean Journal of Mechanics B/Fluids: Sylvain Tridon, Stéphane Barre, Gabriel Dan Ciocan, Laurent TomasIván David Flores ArteagaNo ratings yet

- Bischoff 2012Document6 pagesBischoff 2012nkiran022No ratings yet

- IJET Ambareen Khan 18802Document5 pagesIJET Ambareen Khan 18802Animesh KumarNo ratings yet

- Ijeir 905 FinalDocument5 pagesIjeir 905 Finalvarun karthikeyanNo ratings yet

- Numerical Analysis of Axial-Flow Pump With DiffereDocument7 pagesNumerical Analysis of Axial-Flow Pump With Differe고현No ratings yet

- SPE-185861-MS Pressure Transient Analysis in Advanced Wells Completed With Flow Control DevicesDocument20 pagesSPE-185861-MS Pressure Transient Analysis in Advanced Wells Completed With Flow Control DevicesM.No ratings yet

- Electrostatic Precipitators: Presented byDocument48 pagesElectrostatic Precipitators: Presented byDevesh Pratap SinghNo ratings yet

- Anti-Clogging Drip Irrigation Emitter Design Innovation: Ali Abdulqader Mohammed AliDocument11 pagesAnti-Clogging Drip Irrigation Emitter Design Innovation: Ali Abdulqader Mohammed AliVijay ChavanNo ratings yet

- CE362 Lab ManualDocument12 pagesCE362 Lab ManualDEEPAK KUMAR MALLICKNo ratings yet

- Numerical Prediction of A Bulb Turbine Performance Hill Chart Through RANS SimulationsDocument9 pagesNumerical Prediction of A Bulb Turbine Performance Hill Chart Through RANS SimulationsIvan Batistic BeloNo ratings yet

- The National Institute of Engineering: Comparative CFD Analysis On Laminar Flow Through Nozzle Attached To PipeDocument6 pagesThe National Institute of Engineering: Comparative CFD Analysis On Laminar Flow Through Nozzle Attached To PipeAny BodyNo ratings yet

- Tip Leakage FlowDocument15 pagesTip Leakage FlowMuhammad Zubair SheikhNo ratings yet

- CFD FinalDocument17 pagesCFD FinalSameer NasirNo ratings yet

- Modeling of Annular Prediffuser For Marine Gas Turbine Combustor Using CFD - A Study On The Effect of Strut ConfigurationDocument12 pagesModeling of Annular Prediffuser For Marine Gas Turbine Combustor Using CFD - A Study On The Effect of Strut Configurationrajarathnam.kNo ratings yet

- Effect of Chevron On The Decay Characteristics of Compressible Round JetDocument8 pagesEffect of Chevron On The Decay Characteristics of Compressible Round JetTJPRC PublicationsNo ratings yet

- Cowl DeflectionDocument7 pagesCowl DeflectionSrinivasan GunasekaranNo ratings yet

- Numerical Simulation of Turbulent Flow Through A Francis Turbine RunnerDocument6 pagesNumerical Simulation of Turbulent Flow Through A Francis Turbine RunnerAngel CerriteñoNo ratings yet

- Optimization of Vane Diffuser in A Mixed-Flow Pump For High Efficiency DesignDocument7 pagesOptimization of Vane Diffuser in A Mixed-Flow Pump For High Efficiency DesignMohamed Amine AchouriNo ratings yet

- Sprinkle and Trickle Irrigation System Design Using Tapered Pipes For Pressure Loss AdjustingDocument9 pagesSprinkle and Trickle Irrigation System Design Using Tapered Pipes For Pressure Loss AdjustingAshoq HussainNo ratings yet

- 2000 2 PDFDocument56 pages2000 2 PDFarisandiyusufNo ratings yet

- Study On The Leakage Flow Through A Clearance GapDocument10 pagesStudy On The Leakage Flow Through A Clearance GapShannon HutchinsonNo ratings yet

- A Key Geometric Parameter For The Flow Uniformity in Planar SOFC StacksDocument12 pagesA Key Geometric Parameter For The Flow Uniformity in Planar SOFC StacksDiego PuertoNo ratings yet

- Reducing Channel Flow Energy Losses Using Deflectors: Sanjin FUĆAK, Zoran ČARIJA, Zoran MRŠADocument9 pagesReducing Channel Flow Energy Losses Using Deflectors: Sanjin FUĆAK, Zoran ČARIJA, Zoran MRŠAZoric BobbyNo ratings yet

- Zakharov 2006Document13 pagesZakharov 2006Badri VrsnprasadNo ratings yet

- Wang2019 PDFDocument17 pagesWang2019 PDFGabriel Lopez BarajasNo ratings yet

- Study of Numerical Simulation Applying To The Design of An Orifice With High-Velocity WaterjetDocument10 pagesStudy of Numerical Simulation Applying To The Design of An Orifice With High-Velocity WaterjetYu HuiNo ratings yet

- Volume (10) Issue (2) 160-173Document14 pagesVolume (10) Issue (2) 160-173abhisek haldarNo ratings yet

- Design of The HVA Water TunnelDocument10 pagesDesign of The HVA Water TunnelSjoerd_BNo ratings yet

- Numerical Study of Pressure Fluctuations Caused by Impeller-Diffuser Interaction in A Diffuser Pump StageDocument9 pagesNumerical Study of Pressure Fluctuations Caused by Impeller-Diffuser Interaction in A Diffuser Pump Stageluma fadhilNo ratings yet

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- 1448 - P 31 - Smoke Point PDFDocument9 pages1448 - P 31 - Smoke Point PDFSameer MandalNo ratings yet

- 6 Etching - IiDocument24 pages6 Etching - IiPRAVEEN MNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.CjananiNo ratings yet

- Solved Examples and ExcerciseDocument8 pagesSolved Examples and Excercisevedang agarwalNo ratings yet

- assetsdocumentsNorth20America20DocumentsInformation CenterCatalogs01!$CCW Catalog PDFDocument132 pagesassetsdocumentsNorth20America20DocumentsInformation CenterCatalogs01!$CCW Catalog PDFMiguel ContrerasNo ratings yet

- Various Types of Arc WeldingDocument16 pagesVarious Types of Arc Welding2031 Ayush KshirsagarNo ratings yet

- Chem AlokDocument19 pagesChem AlokRiya TiwariNo ratings yet

- KDN-U203-D V2.2 DatasheetDocument12 pagesKDN-U203-D V2.2 DatasheetRiad LARBINo ratings yet

- Vitomax HS Technical DataDocument26 pagesVitomax HS Technical DataamirokhovatNo ratings yet

- WD 1409 RDDocument51 pagesWD 1409 RDJhonatan K LieblNo ratings yet

- G 2-7 FF 265L DimensionalDocument1 pageG 2-7 FF 265L DimensionalHugo José Abreu de SouzaNo ratings yet

- Operation Manual: Daikin Altherma Indoor UnitDocument24 pagesOperation Manual: Daikin Altherma Indoor Unitikac3No ratings yet

- Taser Final Document Print 6-29Document24 pagesTaser Final Document Print 6-29GiyoNo ratings yet

- CH 14Document6 pagesCH 14Boss S.JNo ratings yet

- Battery Balancer ENDocument2 pagesBattery Balancer ENtrnNo ratings yet

- 2007 Injectors CumminsDocument2 pages2007 Injectors CumminsAung Wai YanNo ratings yet

- SERVO Motor Sizing CalculationsDocument9 pagesSERVO Motor Sizing CalculationsMahesh PatilNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument23 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAKHAND PRATAP SINGH IET LucknowNo ratings yet

- SBA (S) 2512 Rev 4Document4 pagesSBA (S) 2512 Rev 4jvnraoNo ratings yet

- Acti9 SPD Catalog v1 enDocument76 pagesActi9 SPD Catalog v1 enYazhisai SelviNo ratings yet

- Comparative Analysis of MPPT Based Solar Charge ControllerDocument7 pagesComparative Analysis of MPPT Based Solar Charge ControllerMechanical Robot Designers V CreationsNo ratings yet

- B5.9C Manual Summary (T.T.H)Document25 pagesB5.9C Manual Summary (T.T.H)SS YSNo ratings yet

- Tabela C ClientesDocument12 pagesTabela C Clientesmarcos viniciusNo ratings yet

- Thermal Expansion - PDF - 90586Document41 pagesThermal Expansion - PDF - 90586M. N100% (1)

- Electrochemical DesalinationDocument7 pagesElectrochemical Desalinationbaruc lealNo ratings yet