Professional Documents

Culture Documents

R-Cloud-2082016 LS+BR+S+PLEAT 0

R-Cloud-2082016 LS+BR+S+PLEAT 0

Uploaded by

yeuyeu555Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R-Cloud-2082016 LS+BR+S+PLEAT 0

R-Cloud-2082016 LS+BR+S+PLEAT 0

Uploaded by

yeuyeu555Copyright:

Available Formats

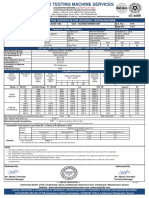

Inspection Report (PSI)

QIMA Service No. R-Cloud-2082016

INSPECTION DETAILS

Inspection Information

QAS Number: 2008180967-0 Audit Date 18-Aug-2020

Market Description US Product Team BRFS Womens Woven Tops

Brand BRFS Product Type Woven shirt

Style Regular Styles Audit Stage 1st Inspection

Sourcing Information

Vendor Name Gap South Vietnam - TEXMA VINA CO.,LTD

Factory Name TEXMA VINA CO.,LTD

Factory Location No.32, Road 2A, Bien Hoa IDNZ II

Booking Details

PO Number(s) YN93OTA Booking QTY 1000

Style Number 608991 Available Order QTY 1000 Pcs (100 % )

Test Reports (Pictures)

Report Type Availability Test Result Report(s) Number(s) and Comment(s)

Fabric/Yarn Test Yes Passed (6620)192-0004

Garment Test Yes Passed VNMT20032017

China special test report

(For China destination No N/A This is US shipment

only)

Snaps / Hook & Bar Pull

No N/A No Snaps / hook & bar on product

Test

OVERALL INSPECTION RESULT: Passed (Client has the final decision to Reject or Approve)

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 1 of 26

Inspection Report (PSI)

INSPECTION RESULTS

Sampling Plan I AQL 0.25

Defects Found 0

OCR AQL Within AQL

Max Accepted 0

Sample Size 32

Sampling Plan II AQL 0.65

Defects Found 0

Max Accepted 0

Packing AQL Within AQL Moisture Check

Passed

Result

Sample Size 3

Sampling Plan I

CRI / AQL (0) MAJ / AQL (2.5)

Defects Found

0 2

Max Accepted 0 2

Weight Check

N/A

Result

Workmanship and Inspected Inspected Quantity compared to

Within AQL Quantity Shipment Quantity

Measurements AQL

32 3.2%

Measured Measured Quantity compared to

Quantity Shipment Quantity

32 3.2%

Sampling Plan I

Special Summary of Sewing CRI / AQL (0) MAJ / AQL (1.0)

Within AQL Defects Found

Defects 0 0

Max Accepted 0 0

QAS Code Defect Description CRI MAJ

VS01 Loose or tight stitching 0 1

Puckers/twist/curling or roping hem, weaving

VS02 0 1

shirring defects by sewing

IMPORTANT REMARKS / GENERAL DEFECTS

1.Packing list, Po ship , Trim card, Approved sample provide by factory.

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 2 of 26

Inspection Report (PSI)

Number of Mandays spent for this QIMA reference: 1

Chief insp : Thi Hong_Cam Inspector 2 : Tran-Hong Quan

Report Reviewer : Michael Enecuela

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 3 of 26

Inspection Report (PSI)

Return to report summary

DEFECTS PICTURES(Workmanship, Packing/ OCR) (Draft Reports)

608991 - VS01-Apparel -01-Loose 608991 -VS02-Apparel-01-Puckering

Stitch at side seam_Major at Bottom hem _Major

Return to report summary

SPECIFICATIONS CHECK

A. Quantity

Description Result Comments

100% of the ship quantity of each PO in the

OK OK

booking must be finished and packed.

The shipment quantity should be within +/- 5% of

the PO quantity OK OK

(by color, by size, for each PO in the booking)

Quantity detail of the PO(s) inspected (Packed quantity: 100 %)

Available packed

PO Quantity Ship quantity Ship quantity

PO number Color quantity

(Pieces) (Pieces) (%)

(Pieces)

YN93OTA

'BR Black (01) 1000 1000 1000(100 %) 1000(100 %)

Total Quantity 1000 1000 1000 1000

B.ProductStyle (Pictures)

Conformity against Specifications (GSS /

OK No failure

BOM)

Conformity against Approved Sample

OK No failure

(GTS)

Fitting check OK No Failure

C. Product Colors

Color shading among all the pieces OK Check 7 pcs for color shading, no defect found

inspected

Light Box check OK U35

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 4 of 26

Inspection Report (PSI)

QC Room Light Check OK D65

D. Product Artworks/Labels (Pictures)

Logo / Artworks conformity N/A No Logo at product.

Labels Conformity

- Care Label

- Price Ticket OK Same as client s requirement

- Size Label

- Marketing and other Labels

CIT Tag Conformity

(Shipments to HK / China only) N/A No CIT Tag

Japan Packaging Recycling Mark Labeling

- Products that are packaged in paper

and/or plastic containers or wrapping

and are intended for sale in the Japan

N/A This order is shipped to US

market need to have recycling marks.

(applicable to all brands)

- Please refer to the relevance files to

the GI for more information

Return to report summary

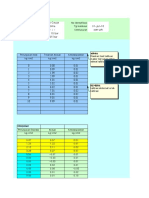

MEASUREMENTS AQL RESULTS

Description Result Comments

High elongation denim No N/A

“Final” Measurement Chart

Yes FINAL

Used

Measurements Defective List

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 5 of 26

Inspection Report (PSI)

Global Defects Overview

Critical Major + Major - Minor

0 0 0 0

Specific Defects Overview

Measurement point Critical Major + Major - Minor

1094-Minimum Neck Stretch 0 0 0 0

821964-Body Length from High Point of 0 0 0 0

Shoulder - Length from High Point of

821964-Body 0 0 0 0

Shoulder

1082-Neck- Width Edge to Edge 0 0 0 0

1097-Shoulder Width-Seam to Seam at Back 0 0 0 0

1120-Chest 1" Below Armhole 0 0 0 0

1258-Bottom Opening Straight 0 0 0 0

1290-Sleeve Length from Center Back 0 0 0 0

438830-Armhole Along Curve 0 0 0 0

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 6 of 26

Inspection Report (PSI)

Code Key critical POM's Tol. Tol. Tol. Tol. Size PXXS Size PXS Size PS

Maj. + Maj. - GSS + GSS - Spec Spec Spec

1094-Minimum Neck Stretch 0 0 0 0 23 0 0 23 0 0 0 0 0 0 0 0 23 0 0 0 0 0

821964-Body Length from High Point of Shoulder -

0 0 1/2 1/2 23 1/2 - 1/2 - 1/8 24 1/4 0 1/4 1/4 0 1/2 0 1/4 1/4 25 1/4 - 1/4 1/2 - 1/4 0

Curved Hem

821964-Body Length from High Point of Shoulder -

0 0 1/2 1/2 24 0 0 24 3/4 - 1/4 - 1/2 - 1/2 - 1/4 - 1/4 - 1/4 - 1/4 - 1/4 25 1/2 - 1/2 - 1/2 - 1/2 - 1/4 0

Curved Hem

1082-Neck Width Edge to Edge 0 0 1/8 1/8 8 1/2 1/8 1/8 8 1/2 - 1/8 0 1/8 1/8 0 - 1/8 0 - 1/8 8 1/2 0 1/8 - 1/8 1/8 - 1/8

1097-Shoulder Width-Seam to Seam at Back 0 0 1/4 1/4 14 - 1/4 0 14 1/2 0 0 - 1/4 - 1/4 0 - 1/4 0 - 1/4 15 1/8 - 1/4 0 - 1/4 - 1/4

1120-Chest 1" Below Armhole 0 0 1/4 1/4 17 3/4 0 - 1/4 18 3/4 1/4 0 0 1/4 1/4 - 1/4 - 1/4 0 19 3/4 0 0 1/8 - 1/4 1/4

1258-Bottom Opening Straight 0 0 1/4 1/4 19 1/8 1/8 20 - 1/4 0 0 0 1/4 0 0 - 1/4 21 1/4 0 1/4 0 0

1290-Sleeve Length from Center Back 0 0 1/2 1/2 28 1/4 0 1/8 29 - 1/8 0 0 0 0 1/4 0 1/4 29 3/4 1/4 1/4 - 1/4 1/8 1/4

438830-Armhole Along Curve 0 0 1/4 1/4 8 1/4 0 1/8 8 3/4 1/4 1/8 - 1/4 - 1/4 0 1/4 0 0 9 1/4 1/4 0 - 1/4 - 1/4 0

Total

CRITICAL (CPSC POM only) 0

Maj + Defect 0

Maj - Defect 0

Min Defect 0

Code Key critical POM's Tol. Tol. Tol. Tol. Size PS Size PM Size PL

Maj. + Maj. - GSS + GSS - Spec Spec Spec

1094-Minimum Neck Stretch 0 0 0 0 23 0 0 0 0 23 0 0 0 0 0 0 0 0 0 23 0

821964-Body Length from High Point of Shoulder - 0 0 1/2 1/2 25 1/4 0 0 - 1/4 25 3/4 - 1/4 - 1/2 - 1/4 - 1/4 1/4 0 - 1/4 - 1/4 - 1/2 26 1/2 0

Curved Hem

821964-Body Length from High Point of Shoulder -

0 0 1/2 1/2 25 1/2 - 1/4 0 - 1/4 - 1/2 26 1/4 - 1/2 - 1/4 - 1/4 - 1/4 - 1/4 - 1/4 - 1/4 - 1/4 - 1/4 27 - 1/4

Curved Hem

1082-Neck Width Edge to Edge 0 0 1/8 1/8 8 1/2 - 1/8 - 1/8 1/8 - 1/8 8 3/4 1/8 1/8 0 1/8 - 1/8 - 1/8 1/8 0 1/8 9 - 1/8

1097-Shoulder Width-Seam to Seam at Back 0 0 1/4 1/4 15 - 1/4 - 1/4 - 1/4 - 1/4 15 1/2 - 1/4 - 1/4 0 0 0 - 1/4 - 1/4 - 1/4 - 1/4 16 1/4 0

1120-Chest 1" Below Armhole 0 0 1/4 1/4 19 3/4 - 1/4 - 1/4 - 1/4 1/4 20 3/4 - 1/4 - 1/4 1/4 - 1/4 0 0 - 1/8 0 - 1/4 22 1/4 1/4

1258-Bottom Opening Straight 0 0 1/4 1/4 21 - 1/4 0 0 0 22 0 0 0 0 0 - 1/4 - 1/4 - 1/4 0 23 1/2 0

1290-Sleeve Length from Center Back 0 0 1/2 1/2 29 3/4 1/8 - 1/4 - 1/4 - 1/4 30 1/4 1/4 - 1/4 - 1/4 0 - 1/8 0 - 1/4 1/4 - 1/8 31 - 1/4

438830-Armhole Along Curve 0 0 1/4 1/4 9 1/4 0 0 - 1/4 - 1/4 9 3/4 - 1/4 0 0 - 1/4 1/4 - 1/4 1/4 0 - 1/8 10 1/2 0

Total

CRITICAL (CPSC POM only) 0

Maj + Defect 0

Maj - Defect 0

Min Defect 0

Fitting PETITE Signed by :

Factory representative

Code Key critical POM's Tol. Tol. Tol. Tol. Size PL

Maj. + Maj. - GSS + GSS - Spec

1094-Minimum Neck Stretch 0 0 0 0 23 0 0 0

821964-Body Length from High Point of Shoulder -

0 0 1/2 1/2 26 1/2 - 1/2 1/4 1/2

Curved Hem

821964-Body Length from High Point of Shoulder - 0 0 1/2 1/2 27 - 1/2 0 - 1/4

Curved Hem

1082-Neck Width Edge to Edge 0 0 1/8 1/8 9 1/8 1/8 1/8

1097-Shoulder Width-Seam to Seam at Back 0 0 1/4 1/4 16 1/4 1/4 0 1/4

1120-Chest 1" Below Armhole 0 0 1/4 1/4 22 1/4 1/4 0 0

1258-Bottom Opening Straight 0 0 1/4 1/4 23 1/2 - 1/4 - 1/4 0

1290-Sleeve Length from Center Back 0 0 1/2 1/2 31 0 - 1/4 0

438830-Armhole Along Curve 0 0 1/4 1/4 10 1/2 - 1/4 - 1/4 - 1/4

Total

CRITICAL (CPSC POM only) 0

Maj + Defect 0

Maj - Defect 0

Min Defect 0

Return to report summary

BARCODE / OCR AQL RESULTS

Defect Description Qty

Damaged price ticket 0

Wrong barcode/size on price ticket 0

Barcode on hang tag cannot be scanned 0

Missing hang tags (with bar-codes) 0

Return to report summary

PACKING AQL RESULTS

Total ship

Auditor Total inspected cartons Number of defective cartons

cartons

Factory audit (F.A) 3 0

14

Inspector audit (A.A) 3 0

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 7 of 26

Inspection Report (PSI)

Defect Description Qty

Wrong Ratio 0

Missing Quantity 0

Wrong Shipping Marks 0

Damaged cartons / EDI stickers / EDI barcode cannot be scanned 0

Carton not as specified (size and construction ) 0

Metallic component found 0

Over Packed carton 0

Wrong Labelling on cartons 0

Shipping Marks ( Pictures )

Description Result Comments

Carton short side (EDI Sticker) OK REF PHOTO BELOW

Carton long side OK REF PHOTO BELOW

Return to report summary

TESTS AND SPECIAL REQUIREMENTS

Test Description Result

Needle detection test (Full sample size) Passed

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 8 of 26

Inspection Report (PSI)

Moisture content check (for Indonesia, Vietnam, Passed

Cambodia, Bangladesh, Myanmar) Maximum acceptable

Highest moisture finding (%)

moisture content (%)

Upper Value : 13 Lower Upper Value :38 Lower Value

Using Aqua Boy meter (provided by the factory) Value< 0.4 % :0.4%

Perform a moisture check (each compositions) on 1 Fabric composition:

100 % Polyester

garment per carton selected.

AquaBoy scale used:

Any finding above GAP maximum acceptable moisture 100 % Polyester

content will fail the result.

If the Aqua Boy cannot be provided by the factory, please

remark the reason in your report.

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 9 of 26

Inspection Report (PSI)

ADDITIONAL TESTS

Description Result

Button check (Full sample size)

1/Check the quality of the button and button holes

2/Check the stitches on button to make sure it is fixed securely and pull by hand on the buttons

3/Button should fit exactly the button hole

4/Buttons/Button holes should be well balanced

5/Check if any spare button is required

For Baby and Children garments, please perform additional pull test (following Hook & Bar / Snaps

Passed

requirements – 20 pieces).

Check if the buttons are cross stitched (no parallel stitching allowed).

Check if the “rabbit ears” are available on the lockstitch.

Acceptable maximum length of thread (rabbit ears) is 1/4”.

Missing rabbit ears is considered as critical for Baby & Children garments.

If any defect found, focus on these defects during the visual inspection and record all defectives (as

critical) in the Workmanship AQL section

Mold prevention check

1/ Products should have no moisture visual defect, no moisture odor, no humidity hand feeling.

2/ Cartons should be inside of the warehouse/factory on pallets (no contact with walls/floor, at least

0.5m away from window), dry (check the bottom of cartons) and without moisture or mold. Passed

3/ Storing areas of cartons, products, fabric, material should be clean, dry, with ventilation and

without mold/water on walls.

4/ Relative humidity in storing area should be < 65%.

(Check factory’s hygrometer)

Symmetry and shape check (Full sample size)

1/ Check if the design is symmetric for the sleeves, collar, shoulders, placket at the bottom, side seams

etc.

2/ Check if the garment twists and measure the difference if any

3/ Check if there is no shape problem on the product. Shape should be exactly same as approved

sample, well balanced, not wavy and perfectly symmetrical.

Poor neck shape, curvy side-seam, uneven and poor bottom shape are not acceptable

Passed

Symmetry and shape check (Full sample size)

1/ Check if the design is symmetric for the sleeves, collar, shoulders, placket at the bottom, side seams

etc.

2/ Check if the garment twists and measure the difference if any

3/ Check if there is no shape problem on the product. Shape should be exactly same as approved

sample, well balanced, not wavy and perfectly symmetrical.

Poor neck shape, curvy side-seam, uneven and poor bottom shape are not acceptable

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 10 of 26

Inspection Report (PSI)

Pressing check (Full sample size)

1/ Check if the garment is well ironed.

2/ Garments must be ironed and folded within the appropriate style Passed

If any defect found, focus on these defects during the visual inspection and record all defectives in the

Workmanship AQL section

Color shading check within the same carton

-Within the same carton: Check the color shading between the pieces selected for the workmanship.

Passed

If any discrepancy found within the same carton, record the carton number and count it as one major

defect

Sample size selection

Passed

Was the inspector allowed to perform the sampling size expected by client fully randomly? If yes, the

result is Passed, If not, the result is Failed

Return to report summary

FACTORY GENERAL INFORMATION

Is the factory/workshop location same as booked by the

Yes

client?

Are the goods in the same location or in 2 different

1 Factory

factories?

If 2 factories, what is the travel time? NO

Factory/workshop cooperation Average

Factory/workshop organization Average

Factory/Workshop cleanliness Rather Clean

Inspection Room Lighting Conditions Rather Bright

Inspection Room Cleanliness Rather Clean

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 11 of 26

Inspection Report (PSI)

Return to report summary

ADDITIONAL PICTURES

Your Product

Bulk picture Front View Bulk picture Back View

Fitting Check Fitting Check

Fitting Check Fitting Check

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 12 of 26

Inspection Report (PSI)

Color shading check Color shading check

Approved sample pictures

Approved sample Front View Approved sample Back View

Approved sample Seal Lock or Stamp

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 13 of 26

Inspection Report (PSI)

Packing/Packaging Pictures

Shipping mark long side Shipping marks short side (EDI sticker)

Carton stack or pile A.A chop on selected cartons

Opened carton – Pack Type 1 Unit packing

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 14 of 26

Inspection Report (PSI)

Labeling Pictures

Price Ticket (Front) Price Ticket (Back)

Care label (Front)

Care label (Back) Care label (Back)

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 15 of 26

Inspection Report (PSI)

Main Label

Hangtag Hangtag

Hangtag Hangtag

Test report pictures

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 16 of 26

Inspection Report (PSI)

Test Reports Test Reports

Test Reports Test Reports

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 17 of 26

Inspection Report (PSI)

Test Reports Test Reports

Test Reports

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 18 of 26

Inspection Report (PSI)

Return to report summary

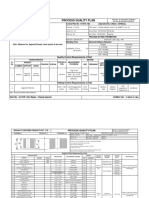

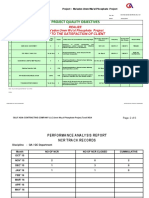

DRAFT REPORTS

GAP Draft report signed by factory (Form 8)

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 19 of 26

Inspection Report (PSI)

Measurement sheets signed by factory (Form 9)

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 20 of 26

Inspection Report (PSI)

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 21 of 26

Inspection Report (PSI)

Inspector Packing Audit Sheet signed by factory (Form 10)

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 22 of 26

Inspection Report (PSI)

Factory Packing Audit Sheet

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 23 of 26

Inspection Report (PSI)

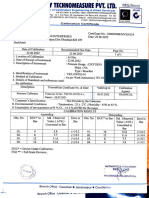

Factory Disclaimer

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 24 of 26

Inspection Report (PSI)

QIMA Code of Conduct

Original signature from Factory Manager accepting QIMA conditions on Shipment authorization and bribery issues

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 25 of 26

Inspection Report (PSI)

TOOLS USED FOR THIS INSPECTION

MOISTURE TESTER

Record your decision about this production lot and generate statistics on your Dashboard :

Approve Reject

(You can opt to inform your Supplier of your decision)

Return to report summary

IMPORTANT NOTES

THE ABOVE RESULT(S) REFLECT(S) QIMA LIMITED’S FINDINGS AT THE TIME AND PLACE OF INSPECTION.

THIS REPORT DOES NOT RELEASE THE BUYER OR SELLER FROM CONTRACTUAL RESPONSIBILITIES, NOR

DOES IT PREJUDICE THE BUYER’S RIGHT OF CLAIM TOWARD THE SELLER/SUPPLIER FOR COMPENSATION

FOR ANY APPARENT AND/OR HIDDEN DEFECTS NOT DETECTED DURING INSPECTION OR OCCURRING

ANYTIME THEREAFTER.

End of the Report

QIMA-QR-16-01A(GAP) www.qima.com - ©1997-2020 QIMA Limited Page 26 of 26

You might also like

- Ethnobotany of Medicinal Plants Used in Xalpatlahuac, Guerrero, MéxicoDocument7 pagesEthnobotany of Medicinal Plants Used in Xalpatlahuac, Guerrero, MéxicoEmmanuel Torre ArenasNo ratings yet

- BROUWER: Guitar Music, Vol. 2 - Decameron Negro (El) : Preludios EpigramaticosDocument2 pagesBROUWER: Guitar Music, Vol. 2 - Decameron Negro (El) : Preludios EpigramaticosSteven ThachukNo ratings yet

- Echocardiography ExaminationDocument73 pagesEchocardiography ExaminationNovita100% (2)

- Hazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesFrom EverandHazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesNo ratings yet

- Cortec Brochure PDFDocument24 pagesCortec Brochure PDFninzauNo ratings yet

- Examen Extraordinario de Ingles IiDocument7 pagesExamen Extraordinario de Ingles Iimorto009No ratings yet

- 3PH Electric Chain Hoist ManualDocument48 pages3PH Electric Chain Hoist ManualOliver HermosaNo ratings yet

- Answers & Solutions: NEET (UG) - 2019Document37 pagesAnswers & Solutions: NEET (UG) - 2019Thirupathi ReddyNo ratings yet

- 1944 - Goland and Reissner - The Stresses in Cemented JointsDocument11 pages1944 - Goland and Reissner - The Stresses in Cemented JointsAbril Yu-ShanNo ratings yet

- U 897 DWM 600Document1 pageU 897 DWM 600Amit KumarNo ratings yet

- SM 11Document245 pagesSM 11Paulo Gomes de Souza50% (2)

- Certificado TermohigrometroDocument1 pageCertificado Termohigrometroconsuelo alarcon ramosNo ratings yet

- 2305-0-15702-Po 14459702Document3 pages2305-0-15702-Po 14459702Alfonso LopezNo ratings yet

- IOMQC Familiy TentsDocument18 pagesIOMQC Familiy TentsNibasB.ApuNo ratings yet

- 2305-0-17142-Po 14520706Document4 pages2305-0-17142-Po 14520706Alfonso LopezNo ratings yet

- Testi: OrationDocument1 pageTesti: OrationSusil Kumar SahooNo ratings yet

- IOMQC Collapsible Jerry CansDocument13 pagesIOMQC Collapsible Jerry CansNibasB.ApuNo ratings yet

- Crs 000007Document2 pagesCrs 000007ahetesham marufNo ratings yet

- 2305-0-17130-Po 14523749Document3 pages2305-0-17130-Po 14523749Alfonso LopezNo ratings yet

- Interim Report Fats & Oil R-II 2022 PDFDocument17 pagesInterim Report Fats & Oil R-II 2022 PDFMunazza SohailNo ratings yet

- TN142Document2 pagesTN142Francisco CarvalhoNo ratings yet

- DF 22obhb 19 08 22-1Document1 pageDF 22obhb 19 08 22-1QCLAB SURABRAJANo ratings yet

- QC Bag ClearDocument17 pagesQC Bag ClearJesús Vega SabásNo ratings yet

- CPK Report FormatDocument2 pagesCPK Report FormatDeepak BhartiNo ratings yet

- Iga 7180Document2 pagesIga 7180nake s (风流少年)No ratings yet

- Crs 000008Document2 pagesCrs 000008ahetesham marufNo ratings yet

- Hcy 7180Document2 pagesHcy 7180nake s (风流少年)No ratings yet

- 2629 01Document4 pages2629 01Global QualityNo ratings yet

- HDL 7180Document2 pagesHDL 7180nake s (风流少年)No ratings yet

- 1788.01 Expires 7.31.2024 (Issued 7.22.2022)Document4 pages1788.01 Expires 7.31.2024 (Issued 7.22.2022)Nook SudkhetNo ratings yet

- Cotex PharamaDocument50 pagesCotex Pharamatahir royalNo ratings yet

- Mega Check Developer 8003 230404Document1 pageMega Check Developer 8003 230404Nguyễn ChiếnNo ratings yet

- Test Report: Exhaust Emissions at Room Temperature After A Cold StartDocument9 pagesTest Report: Exhaust Emissions at Room Temperature After A Cold StartDiego LincangoNo ratings yet

- 2305-0-18456-Po 14523644Document2 pages2305-0-18456-Po 14523644Alfonso LopezNo ratings yet

- 2066 01Document4 pages2066 01Global QualityNo ratings yet

- HBDH 7180Document2 pagesHBDH 7180nake s (风流少年)No ratings yet

- Contractor Approved Typical Inspection Plan: Classification - INTERNALDocument10 pagesContractor Approved Typical Inspection Plan: Classification - INTERNALMohamed Reda Hussein SengarNo ratings yet

- Calibration ServiceDocument1 pageCalibration ServiceTinotenda MazhoweNo ratings yet

- C1B Outlet CO AnalyzerDocument1 pageC1B Outlet CO Analyzershahil.ali1985No ratings yet

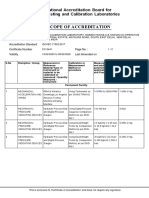

- (A Division of Testing & Calibration India (Opc) Pvt. LTD)Document1 page(A Division of Testing & Calibration India (Opc) Pvt. LTD)santanushee8No ratings yet

- Kalibrasi PressureDocument11 pagesKalibrasi PressureageihwanNo ratings yet

- Way To Zero Defect: Prepared by VishnuDocument9 pagesWay To Zero Defect: Prepared by VishnudpnairNo ratings yet

- Qa & QC UusdaDocument40 pagesQa & QC UusdaAmir SohailNo ratings yet

- Qa & QC UusdaDocument40 pagesQa & QC UusdaAmir SohailNo ratings yet

- Method Formate-ISODocument4 pagesMethod Formate-ISOswapon kumar shillNo ratings yet

- Sample Inspection Report For Garment Softshell CoatDocument38 pagesSample Inspection Report For Garment Softshell CoatPrashant A UNo ratings yet

- IOMQC BlanketsDocument14 pagesIOMQC BlanketsNibasB.ApuNo ratings yet

- Report of Calibration: 03-03-2022 02-09-2022 05-03-2022 MQS/229001/12 & 02-03-2022 MQS/229001/12/01Document2 pagesReport of Calibration: 03-03-2022 02-09-2022 05-03-2022 MQS/229001/12 & 02-03-2022 MQS/229001/12/01Yasir Yasir KovanNo ratings yet

- Adobe Scan 19-Apr-2024Document1 pageAdobe Scan 19-Apr-2024manish yadavNo ratings yet

- TWist CounterDocument1 pageTWist Countermanish yadavNo ratings yet

- C1B Outlet O2 AnalyzerDocument1 pageC1B Outlet O2 Analyzershahil.ali1985No ratings yet

- DF 22okgb 29 07 22Document1 pageDF 22okgb 29 07 22QCLAB SURABRAJANo ratings yet

- Diasys: Immunoglobulin EDocument2 pagesDiasys: Immunoglobulin Enake s (风流少年)No ratings yet

- Anton Paar USA ISO 17025 Updated May 2020Document3 pagesAnton Paar USA ISO 17025 Updated May 2020nabilaNo ratings yet

- Copie de Weekly Fabric Meeting W18Document17 pagesCopie de Weekly Fabric Meeting W18Tantely RAKOTOARISOANo ratings yet

- Production Control Plan 4111078Document10 pagesProduction Control Plan 4111078Yogesh PatilNo ratings yet

- Adobe Scan 02-Jul-2022Document5 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- 1114-1182 Vij Engineers & Consultants PVT LTD UTE - 40-1156Document1 page1114-1182 Vij Engineers & Consultants PVT LTD UTE - 40-1156VikasNo ratings yet

- Certificats BackupDocument17 pagesCertificats BackupS. KaciouiNo ratings yet

- Request For Ready Mix ConcreteDocument6 pagesRequest For Ready Mix Concretesarsan nedumkuzhiNo ratings yet

- Thind Rice MillsDocument1 pageThind Rice MillsGyaan Disha To choose right pathNo ratings yet

- GraphIsotherm Linear STTN - A - 20150226 - 1 30C - 0,5MM - 3 JamDocument1 pageGraphIsotherm Linear STTN - A - 20150226 - 1 30C - 0,5MM - 3 JamYunus HidayatNo ratings yet

- Test ReportDocument8 pagesTest ReportNishantNo ratings yet

- Ficha Técnica - Cloruro de PotasioDocument1 pageFicha Técnica - Cloruro de PotasioJOHANA DIAZ PARDONo ratings yet

- Breath Alcohol Tester WGSensorDocument40 pagesBreath Alcohol Tester WGSensorbrunowangNo ratings yet

- OVP - OQ Test Protocol: Overall Test Result PASSEDDocument8 pagesOVP - OQ Test Protocol: Overall Test Result PASSEDAli RizviNo ratings yet

- Scope of Accreditation: PCSIR Labs Complex, Peshawar (PLC)Document51 pagesScope of Accreditation: PCSIR Labs Complex, Peshawar (PLC)shoaib naqviNo ratings yet

- Scope Location 1 CC-2441Document2 pagesScope Location 1 CC-2441Ravi Dilawari [Aspire]No ratings yet

- Types of Nouns: Albert Einstein The President My Mother A GirlDocument5 pagesTypes of Nouns: Albert Einstein The President My Mother A GirlaudyNo ratings yet

- Chapter 5 Genetic Resources in AgricultureDocument59 pagesChapter 5 Genetic Resources in AgricultureMuhammad HaiqalNo ratings yet

- 2nd Quarter TLE ICT 7 - Chapter 7Document11 pages2nd Quarter TLE ICT 7 - Chapter 7Raymond PunoNo ratings yet

- Episodes of Mania/Depression: Psychopathophysiology (Bipolar 1 Disorder, Mre Manic With Psychotic Features)Document1 pageEpisodes of Mania/Depression: Psychopathophysiology (Bipolar 1 Disorder, Mre Manic With Psychotic Features)KathHinlogNo ratings yet

- Tutorial 1. Deflection of Beam (Part-A)Document2 pagesTutorial 1. Deflection of Beam (Part-A)akash_solanki_7100% (1)

- Acids and BasesDocument11 pagesAcids and BasesTanya NdlovuNo ratings yet

- WHO 9789241565639-EngDocument476 pagesWHO 9789241565639-Engsofiabloem100% (1)

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- 4 Huckel PDFDocument24 pages4 Huckel PDFFarman UllahNo ratings yet

- Disassembly/Assembly: Primus® Family Breathing SystemDocument2 pagesDisassembly/Assembly: Primus® Family Breathing Systemheru pratiknoNo ratings yet

- Three-Dimensional Assessment of Transverse Skeletal Changes After Surgically Assisted Rapid Maxillary Expansion and Orthodontic Treatment - A Prospective Computerized Tomography StudyDocument9 pagesThree-Dimensional Assessment of Transverse Skeletal Changes After Surgically Assisted Rapid Maxillary Expansion and Orthodontic Treatment - A Prospective Computerized Tomography StudySoe San KyawNo ratings yet

- Cloud Computing Dissertation PDFDocument7 pagesCloud Computing Dissertation PDFCollegePapersHelpManchester100% (1)

- LT E Mscb-Bill Augest PDFDocument2 pagesLT E Mscb-Bill Augest PDFRohidas TodkarNo ratings yet

- Introduction To Geo-InformaticsDocument54 pagesIntroduction To Geo-Informaticsmuhammad ahmedNo ratings yet

- Sem I Novdec 2011Document0 pagesSem I Novdec 2011vvn003No ratings yet

- Climate Change Impacts Throughout The Water CycleDocument8 pagesClimate Change Impacts Throughout The Water CycleZuriNo ratings yet

- A Note On The Guru CultDocument4 pagesA Note On The Guru CultEstudante da VedantaNo ratings yet

- CAC Quiz No. 3 PDFDocument14 pagesCAC Quiz No. 3 PDFEdi wow WowNo ratings yet

- GH 1832 Auto GH 1835 Manual: Key Features Key SpecificationsDocument4 pagesGH 1832 Auto GH 1835 Manual: Key Features Key Specificationsalejandro calixtoNo ratings yet

- Bevel Helical Geared Motor KAD68Document1 pageBevel Helical Geared Motor KAD68Parmasamy SubramaniNo ratings yet

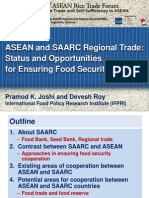

- PPT: ASEAN & SAARC Regional Rice Trade: Status & Opportunities For Ensuring Food SecurityDocument36 pagesPPT: ASEAN & SAARC Regional Rice Trade: Status & Opportunities For Ensuring Food SecurityASEAN Rice Trade ForumNo ratings yet