Professional Documents

Culture Documents

37 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

37 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

Uploaded by

tvwrightOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

37 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

37 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

Uploaded by

tvwrightCopyright:

Available Formats

Transmission Oil Heater

Caterpillar recommends installing a commercial

heating element when the transmission is started

and the ambient temperatures are −30 °C (−20 °F)

or less. Heaters facilitate starting the engine and

transmission in cold climates, and heaters reduce

the warm-up time required to get a power train

operational. The SAE “J1926 #40” (2 ½" STOR)

straight thread o-ring port in the converter housing is

the appropriate location to install a transmission oil

heater in the TH48-E70.

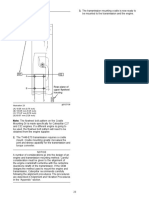

g03123719

Illustration 41

g03123686

Illustration 40 Left side view

(42) Cover (56) Appropriate location for the transmission oil heater (2 ½ inch

(103) Suction screen STOR plug) (No. 40 port)

(104) Magnetic tube assembly

(105) Wave washer

(106) Seal

As a rule, suppliers recommend 8 to 10 w per

(107) Nuts quart of sump oil. Commercial heaters with and

without thermostats are available in capacities

Suction screen (103) and magnetic tube assembly that are compatible with the TH48-E70 Petroleum

(104) are located on the end of the torque converter transmissions.

housing. A 330 mm (13 inch) extension from the

cover plate is required to remove the screen. Refer to “Transmission Oil Volumes” for more

information on TH48-E70 oil volume.

Exhaust Routing

Electronic Messenger

Engine emission controls increase exhaust

temperatures. Therefore, the cooling system and Electronic messenger is not available directly from the

the transmissions exterior, especially the oil sump factory with the TH48-E70 Petroleum Transmission,

and all electrical components, need adequate heat however the messenger may be ordered separately.

protection. If the engine exhaust is routed beside the

transmission, Caterpillar recommends routing the The Messenger monitoring system continuously

exhaust along the right side of the TH48-E70 power receives information from the following components

train. Heat shields with adequate air circulation are via the Cat Data Link and “J1939”: all sensors,

recommended when exhaust clearance is less than electronic control modules, and connected system

152 mm (6 inch). components. This information is received while

the keyswitch is on the ON position. The Cat Data

Link is a two wire system that allows two-way

communication between the Messenger and the

machine electronic control modules (ECMs). This

data link also supports communication between the

displays and the Cat Electronic Technician (ET)

service tool. The “J1939” data link is a two wire

system that allows bidirectional transfers of data at

high speed between the electronic control modules

(ECMs). The “J1939” is used on some applications to

send information to an instrument cluster.

37

You might also like

- TP31397-1 700 Ignition IncompleteDocument211 pagesTP31397-1 700 Ignition IncompleteAchim Maximilian Naumann d'Alnoncourt100% (1)

- DTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationDocument5 pagesDTC P1345 Crankshaft Position (CKP) - Camshaft Position (CMP) CorrelationChino PlagaNo ratings yet

- AHU InstructionDocument12 pagesAHU Instructionforevertay2000No ratings yet

- 320D-336D Excavator Elec. Control SysDocument38 pages320D-336D Excavator Elec. Control Sysjlrodriguezma91% (47)

- 3412 Generator Set Engines Electronically Contr-1 PDFDocument50 pages3412 Generator Set Engines Electronically Contr-1 PDFFrezgi Birhanu100% (1)

- DetroitDocument56 pagesDetroitAbabsa KomatsuNo ratings yet

- Engg. Manual TR-7570Document30 pagesEngg. Manual TR-7570Manish Gupta63% (8)

- PL1000E Install Guide REHS2362-00Document20 pagesPL1000E Install Guide REHS2362-00Teguhprabowo CenaNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument99 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya AnamNo ratings yet

- Power System Design For Electric Car PDFDocument8 pagesPower System Design For Electric Car PDFSandeep Kumar0% (1)

- Vernier Throttle For CATDocument12 pagesVernier Throttle For CATJose RojasNo ratings yet

- 4JB1 Isuzu EnginesDocument148 pages4JB1 Isuzu EnginesMiguelNo ratings yet

- TFE 731 Chap 76Document42 pagesTFE 731 Chap 76Egor85100% (4)

- Rdce 08M040 05 PDFDocument64 pagesRdce 08M040 05 PDFJabbar RahmyNo ratings yet

- P425 HP375WCU T4i Service Manual (E85) 8-6-2012Document159 pagesP425 HP375WCU T4i Service Manual (E85) 8-6-2012General RiuSA100% (1)

- Kenr9570kenr9570-01 SisDocument17 pagesKenr9570kenr9570-01 SisPablo Gaspar D'Agostini Amengual100% (1)

- Evolve Mock Computer Test With AnswersDocument36 pagesEvolve Mock Computer Test With Answerslindelwa18100% (2)

- DEED OF ABSOLUTE SALE-motor Vehicle SCDIDocument2 pagesDEED OF ABSOLUTE SALE-motor Vehicle SCDIJosEs-Men100% (1)

- Ti108rae RTD TH 11 TH 12 TiDocument14 pagesTi108rae RTD TH 11 TH 12 TiNestor Ferrel FloresNo ratings yet

- 03-01-03 - TEM Evo System Manual Serial CommunicationDocument27 pages03-01-03 - TEM Evo System Manual Serial CommunicationFio LoNo ratings yet

- Data Bulletin SEPAM™ 49RMS Application Note: Protection For Motor Applications Class Number 3000Document10 pagesData Bulletin SEPAM™ 49RMS Application Note: Protection For Motor Applications Class Number 3000Ryan Anthony UmaliNo ratings yet

- Critical Software Follow-Up Fabrice BedouchaDocument150 pagesCritical Software Follow-Up Fabrice BedouchaHamid MarjiNo ratings yet

- Manual Taller Despiece GuzziDocument3 pagesManual Taller Despiece GuzziFabi ChipoNo ratings yet

- Tarea1 Ingles Tecnico - Diego Choque CentonDocument8 pagesTarea1 Ingles Tecnico - Diego Choque Centondiego choqueNo ratings yet

- Guia Comunicacion j1939 y Rs 485Document14 pagesGuia Comunicacion j1939 y Rs 485Miguel 1856No ratings yet

- Siemens PTC RTD Thermocouples Section7 Rev1Document16 pagesSiemens PTC RTD Thermocouples Section7 Rev1DelfinshNo ratings yet

- Trafo Temp ControllerDocument8 pagesTrafo Temp ControllerNey VelNo ratings yet

- Pc-A Imm7000 - A809bDocument8 pagesPc-A Imm7000 - A809bJuan GarcíaNo ratings yet

- 131 CAT ESCM ReplacementDocument2 pages131 CAT ESCM ReplacementIlluminati Sky EulerNo ratings yet

- Powercore Tec-10: Turnkey Electronic ControllerDocument2 pagesPowercore Tec-10: Turnkey Electronic ControllerMatias Alfredo Contreras KöbrichNo ratings yet

- Term 3042 - ISX CM570 IntroductionDocument4 pagesTerm 3042 - ISX CM570 Introductionralph arisNo ratings yet

- Mdu - Bue 2Document16 pagesMdu - Bue 2Pritam JadhavNo ratings yet

- PWR-EFI-1 Conversion Overview For 911/930 TurbosDocument6 pagesPWR-EFI-1 Conversion Overview For 911/930 Turbosdenidarmawan136No ratings yet

- Term 3039 - ISM CM570 IntroductionDocument4 pagesTerm 3039 - ISM CM570 Introductionralph arisNo ratings yet

- The Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkDocument6 pagesThe Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkPrashant Sangulagi100% (1)

- TT418A DTCs P2135 & P2101 Theory & Diagnostics 1 11 2011Document3 pagesTT418A DTCs P2135 & P2101 Theory & Diagnostics 1 11 2011Investor Protection100% (2)

- 3516B Generator Set ZAR00001-UP (SEBP4058 - 27) - DocumentationDocument21 pages3516B Generator Set ZAR00001-UP (SEBP4058 - 27) - DocumentationMaik AmayaNo ratings yet

- OlkDocument16 pagesOlkcristianNo ratings yet

- 852 318 Datasheet Usb OptionDocument4 pages852 318 Datasheet Usb OptionDaniel SubelzaNo ratings yet

- Thermon HPTDocument2 pagesThermon HPTParag B HatwarNo ratings yet

- Technical Info Temperature Sensor 22 (FAE 33160)Document2 pagesTechnical Info Temperature Sensor 22 (FAE 33160)GIUSEPPENo ratings yet

- Technical Information: ConnectorDocument2 pagesTechnical Information: Connectorsarel CoetzerNo ratings yet

- Electrical Systems & Traction Alternator Design & Aux. System DesignDocument11 pagesElectrical Systems & Traction Alternator Design & Aux. System DesignVangara HarshuNo ratings yet

- TAC Xenta 300: Programmable Controller 11 Aug 2003Document4 pagesTAC Xenta 300: Programmable Controller 11 Aug 2003NATHANNo ratings yet

- 1ZSE 5483-104 en Rev 6 - Low ResDocument20 pages1ZSE 5483-104 en Rev 6 - Low Rescrcruzp100% (1)

- 1ZSE 5483-104 en Rev 5 - Low ResDocument20 pages1ZSE 5483-104 en Rev 5 - Low ResadbNo ratings yet

- SalesDocument66 pagesSalesDaniel MilosevskiNo ratings yet

- BoilerDocument2 pagesBoilerxxxtigerNo ratings yet

- Rehs2362 02Document24 pagesRehs2362 02zekaNo ratings yet

- TAC Xenta® 491/492Document2 pagesTAC Xenta® 491/492SswahyudiNo ratings yet

- TAC Xenta 411/412: Digital Input Module 29 Aug 2002Document2 pagesTAC Xenta 411/412: Digital Input Module 29 Aug 2002NATHANNo ratings yet

- 1e 3PP Musg 01015Document5 pages1e 3PP Musg 01015Mohamed HassanNo ratings yet

- WWW - Johnsoncontrols.in Content Dam WWW Jci Be Eu Library Product Information Bms Products Electronic Control Tech Info Facility Explorer Product Bulletin TUC0311 Europe 12 2011Document11 pagesWWW - Johnsoncontrols.in Content Dam WWW Jci Be Eu Library Product Information Bms Products Electronic Control Tech Info Facility Explorer Product Bulletin TUC0311 Europe 12 2011Leo Prasanth Xavier MartinNo ratings yet

- Technical Information: NC Software 286 02x XXDocument92 pagesTechnical Information: NC Software 286 02x XXterryNo ratings yet

- LT6 CatalogueDocument24 pagesLT6 CatalogueMohamed Elsayed HasanNo ratings yet

- TAC Xenta 280: Programmable Controller 2 Mar 2005Document4 pagesTAC Xenta 280: Programmable Controller 2 Mar 2005Mario PuceljNo ratings yet

- Inside This Issue: ? ?techtipsDocument4 pagesInside This Issue: ? ?techtipscarmaNo ratings yet

- TurboTronikNT340 341TurboControllerDocument22 pagesTurboTronikNT340 341TurboControllerJanet RiveroNo ratings yet

- Generator SpecsDocument33 pagesGenerator SpecsVivekKajlaNo ratings yet

- Operating Manual: WarningDocument36 pagesOperating Manual: WarningRabeh BougouffaNo ratings yet

- Ask Experts: Winding Thermal ProtectionDocument2 pagesAsk Experts: Winding Thermal ProtectionRonald LlerenaNo ratings yet

- EctDocument6 pagesEctLina M. Abd ElSalamNo ratings yet

- 1 ImDocument130 pages1 ImbrendaalanisgueraNo ratings yet

- Technical Support FerretechDocument7 pagesTechnical Support FerretechpraveenNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- 45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuideDocument1 page45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuidetvwrightNo ratings yet

- 24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 11 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page11 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 9 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page9 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 3 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page3 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 5 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page5 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 8 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page8 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 6 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page6 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 98 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page98 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 4 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page4 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Special Instruction: Mechanical Application and Installation Guide For TH48-E70 Petroleum TransmissionsDocument1 pageSpecial Instruction: Mechanical Application and Installation Guide For TH48-E70 Petroleum TransmissionstvwrightNo ratings yet

- 97 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page97 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 96 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page96 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 95 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page95 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 93 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page93 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- ArranqueDocument1 pageArranqueJorge LecchiNo ratings yet

- Decopling PointDocument27 pagesDecopling Pointhimanshu singhNo ratings yet

- Mikuni Part 2 1Document5 pagesMikuni Part 2 1diegoNo ratings yet

- Valve StandardsDocument20 pagesValve StandardsCosimoNo ratings yet

- This Study Resource Was: Assignment: Changing TiresDocument1 pageThis Study Resource Was: Assignment: Changing TiresCourse heroNo ratings yet

- CharacteristicsDocument82 pagesCharacteristicsTrafiku RrugorNo ratings yet

- 840 E Series Brochure-2Document36 pages840 E Series Brochure-2pham huyNo ratings yet

- Parking and Accident Studies ReportDocument12 pagesParking and Accident Studies ReportJames Kyle Apa-apNo ratings yet

- R&I Timing Case Cover 156 Eng. #2Document3 pagesR&I Timing Case Cover 156 Eng. #2Art ArevshatianNo ratings yet

- PR RaiseDocument12 pagesPR RaiseRey MbayangNo ratings yet

- KASI - A4 - Catalog Produse Recomandate - 2022Document28 pagesKASI - A4 - Catalog Produse Recomandate - 2022Nicolae Mircea Pacurar-SimutNo ratings yet

- Volkswagen New Beetle, Marketing Case StudyDocument50 pagesVolkswagen New Beetle, Marketing Case StudyNishanth C Mohan0% (1)

- Chelsea HY25-2859-Part List PTODocument20 pagesChelsea HY25-2859-Part List PTOPrajna SatyaNo ratings yet

- Instructions (00885) : Three Year WarrantyDocument5 pagesInstructions (00885) : Three Year WarrantyprogramaincNo ratings yet

- Danfoss: New Light Commercial Scroll CompressorsDocument1 pageDanfoss: New Light Commercial Scroll Compressors12345laurNo ratings yet

- Automotive Sensor System: Interaction With ABS Anti-Lock Braking SystemDocument21 pagesAutomotive Sensor System: Interaction With ABS Anti-Lock Braking Systemmehtanandini2004No ratings yet

- Specification Sheet: Standby Generator SetDocument2 pagesSpecification Sheet: Standby Generator SetAdrian MoratayaNo ratings yet

- SyllabusDocument228 pagesSyllabusGOKUL SNo ratings yet

- Owner'S, Installation & Parts Manual: V-Box Spreader Poly Dual Electric Model Pde800 - 2 Cubic YardDocument44 pagesOwner'S, Installation & Parts Manual: V-Box Spreader Poly Dual Electric Model Pde800 - 2 Cubic Yard曲小No ratings yet

- Beard Harvey Helen 1980 PhilippinesDocument18 pagesBeard Harvey Helen 1980 Philippinesthe missions networkNo ratings yet