Professional Documents

Culture Documents

HH09 - Provision Crane (CR172)

Uploaded by

Karikalan Jay0 ratings0% found this document useful (0 votes)

16 views30 pagesprovision crane

Original Title

HH09 - PROVISION CRANE (CR172)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentprovision crane

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views30 pagesHH09 - Provision Crane (CR172)

Uploaded by

Karikalan Jayprovision crane

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 30

fese, Tes CRAPR

10T X 18M (RK) PROVISIONS GRANE

INSTRUTITON BOOK

FINISHED PLAN

ORDER 1 TEM

WICC §-0651F

SECTION SHIP

i

MANABE ZOKL C

/LTD

<

337 8, TARABE , DHABAKT - SIL, BRUNE = REN, PRY

TL. (0895) 41 - $217 F 799-20 .

FAX (0888) 41 = 5568

1A = 179 DATE

‘CHECKED SUB

lant hit

CONTENTS

8 1. Specification

§ 2. Operation e+:

2-1 Prerparation semen

2-2 Operation

2—3 After operation

2-4 Safety device

2-5 Emergency operation

§ 3. Maintenance and ifspection

Mechanical parts

Procedure of replacing wire rope ~

3-3. Procedure of re-adjusting the limit valve ~

3-4 Wechanical of brake -e-e+sesesesee seen

3—5 Hydraulic oil

3—6 Lubricating points

3-7 Adjustment of hydraulic parts

84. Trouble and remedy

4-

Mechanical parts~--~

$5. Description of main parts ~~ s-~

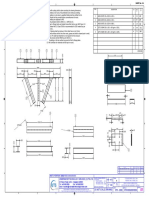

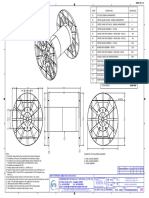

§6 Drawings .

87 Record of inspection ~~

§8 Spare part list & Tool list s+

PAGE

100

200

200

201

206

207

209

300

300

308

312

319

320

B21

322

400

400

500

600

700

800

$1

1)

2)

3)

4)

5)

b)

8)

9)

10)

200

Operation and caution on operation

Preparation

Prior to operation , the followings are io be checked .

Confirm thet all operation handles are in their neutral position

After confirming of pump unit on stern side. being crived , open valve at

21-8 , 22-2. ( Refer to valve drawing NO. DCB - 158-2 }

Tightness of fastening bolts on the turn table bearing is to be checked and

retightened if required .

Proper tightening torque 125 ket-n (M 27)

Tightness of fastening bolts on the middle of the jib and crane top are to be

checked and excharged if required .

Supply grease sufficiently to every lubricating points .

To be referred to” 2—6 Lubricating points ” .

Supply gear compound on the slewing gear . hoisting end luffing gear teath .

Confirm that ali the valves are set in open position .

serene OPEN

Stop valve for main line

( Emergency)

OPEN

Stop valve for brake cylinder

( Hoisting , Luffing and Slewing )

‘The oi] lever in the slewing device is to be checked .

If its level is low oil is to be supplied till the adequate of] level .

To be referred to” 2—5 llydraulic oil *

‘The air in the hydraulic cireuit is to be exhausted perfectly .

Confirm that the wire rope on the winch drum is winding orderly .

1-2 Operation

1) Operation

After the previous mentioned preparation, the crane is ta be operated by refering

to the ” ARRANGENENT OF CONTROL VALVE *

ARRANGEMENT OF CONTROL VALVE

LEVER BY-PASS VALVE

“on | Na NAHE

\ = SLEWING CONTROL VALVE _@

SLEW LEFT ot Rawat

LUFFING CONTROL VALVE

EEE

BL

va

HOISTING CONTROL VALVE _©

EWERGENCY STOP_VALVE

Saar

SERIA bh oy TNT

NORWALLY OPEN

ae Ow

202

LUFFING CONTROL VALVE ©

LUFF UP LUFF DOWN,

ce eee

SLEWING CONTROL VALVE ®.

SLEW RIGHT SLEW LEFT

eS eee

6

Lo:

SS

—

3

HOISTING CONTROL VALVE ©

___HOIsT UP

BY-PASS VALVE

limit cancel

HOIST DOWN

204

Control valve for luffing

It is used for up and down jib.

Control valve for slewing

It is used for slewing crane left and right.

Control valve for hoisting

Tt is used for up and down hook.

By-pass valve

ALL Limit can be released by pushing lever of by-pass valve before operator.

NOTE) Jib rest (lower limit cancel for luffing } should be surely done at no load.

Energency stop valve

Crane can be stopped by closing valve and cutting hyd.oil at emergency.

Pay enough attention to work of crane as shown next page at limit switch cancel,

© At upper limit cancel for hoisting

Pay attention to the interfere with the end cf jib or sheave and falling block.

Pay attention to work for striker of Limit switch box.

@ At lower limit cancel for hoisting

Pay attention to work for striker of Jinit switch box.

Pay-enough attention to rest winding roll of wire rope on drum.

When rope is paid out at max,confirm that more than three rol of vinding are

rest on drun.

205

@ Av upper iam cance: tor suring

Pay attention to work for striker of limit switch box.

Pay attention to jib not to touch stopper on crane body.

@ At lower limit cancel for luffing ( At jib rest )

Jib rest should be surely done at’ no load.

When jib is fallen dawn wore than 8° ,pay enough attention to rest wiring roll

of wire rope. ( more than 3 rolls }

Pay attention to vork for striker of limit switch box.

© At limit cancel for slewing left and right.

Pay attention to the interfere with around construction at slewing.

206

2) Remarks

a) Don't pull the Joad slantly.

b) Don't operate the-crane over the vated road.

c) Operate the crane seoothly.

The shock at starting and stopping shoud be avoided as

dar as possible and smooth operation shoud be kept.

AY

1

Sih

i

= pats

V. >: DDS

z5e

23 After operation

1) (Slew.the crane to the stowing position.

2)" In-cese.of. lowering the Jib, the by pass levey(@)is to be

ib isto be

operated 1b the position “BY-PASS” end the

vested.

3B)» Fasten’ the 3ib.

1) Confirm that J] operation handles are in theirs neutral position.

'3) Lock all of operating handles.

6) Return the valves of ship body to the former

Postion obsolutely. _

207

1-4 Safety device

1)

2)

3)

Limit valve ( To be referred to 2-3 adjusting the limit valve }

At upper Limit valve for luffing LVLH

@it lower Limit valve for luffing LVLL

@At upper Limit valve for hoisting LVHH

@At Jower Linit valve for hoisting LVHL

@At limit valve for slewing right LVSR

@At Limit valve for slewing left were LV SL

When any limit valves act under opretion the deck crane stops.

All Limit can be released by pushing lever of by-pass valve before operator.

Relief valve ( Set procedure to be referred to 2-7 )

a) On operation crane, the relif valve acts, in case of higher pressure than set

pressure.

‘b) When relief valve acts,reduce load or confirm of set pressure of relief

valve.

Limit valve for luffing ( To be referred to 2-3 adjusting the limit valve )

LVLH ( minimum radius )

Dat upper limit valve for luffing

Upper limit valve for luffing works at jib angle ab.79° and Jib stop.

( Post center form hook center at aM)

@s lower Limit valve for luffing LVLL ( meximum radius )

Lover Limit valve for luffing works at jib angle ab. 25° and jib stop.

( Post center form hook center at 18M )

1. When Limit valve (LVLH, LVLL) for luffing acts, luffing winch stops and

brake for winch, act automatinaiiy.

2. When Limit valve acts and crane stops,reture each operating handle to stop, and

turn over operating handle to rererse’ position

3. Jib can be lowered to the rest table by operating handle for luffing to lower

side with lever for by-pass valve of jib rest falling back ward.

208

4) Limit valve for hoisting ( To be referred to 2-3 adjusting the limit valve )

@sAt upper limit valve for hoisting ~ LVHH

At upper limit valve for hoisting works at hook stop. ( ab.tM1so from deck )

@it lower limit valve for hoisting ~~ LVHL

At lover Limit valve for hoisting works at hook stop.

The head height is 3500 when wire rope .

1. When limit valve (LVHH, LVHL) for hoisting acts,hoisting winch stops

and brake for winch, act outomatinaiiy.

2. When limit valve acts and crane stops,reture each operating handle to stop, and

turn over operating handle to rererse position.

5) Limit valve for slewing acts ( LVSR ,LVSL )

Slewing right angle is 75° ,slewing left angle is 103° , limit valve for slewing

act and crane stops. ~

1. When limit valve (LVSR, LVS.) for slering acts, sleving winch stops and

brake for winch,act automatinaiiy.

2, When limit valve acts and crane stops,return each operating handle to neutral

position ,and turn over operating hanle to reverse position.

3. Push lever of by-pass valve before operator.

Fall operating handle for slewing to sleving direction,

Slewing for 360 * can be done.

209

2-5 Bmergency operation

In case the pipe should be damaged

hydraulic deck crane is so devised as to stop their function by

means of the hyd brake.

Manual procedure of releasing the hyd, brake is as follows,

1) Hoisting winch, Luffing winch,

2) Open two by-pass valves of counter-balance valve mounted

on hyd. motors. ‘

b) Release the turnbackle for the brake little by little.

(Record revolutions of the turnbackle.)

c) Return the turnbackle .to former position and close “two

by-pass valves mounted hyd. motor, after Jowering the

cargo,

re Rae

eons

s-oneH

Ee TET

SC oH OY TR

HONTM ONTAINT ¥ ONTISTON

ell

2) ‘Slewing devices

a) Open the by-pass valve of double counter-balance valve

mounted on slewing motor by closing the adjusting belt.

b) Release the turnbackle for the brake little by little.

(Record revolutions of the turnbackle.)

<) Return the turnbackle to former position and close the

by-pass valves mounted hyd. motor, after slewing the

crane,

EERE _

SLEWING DEVISE

“es fv pag y eo nayak

Seg W.COUNTER BALANCE VALYE

1

ESR secon

| | ADJUSTING SCREW FOR BY-PASS ¥. Ny

RE 9

\ HYD. MOTOR Le}

‘BY-PASS ¥.: CLOSED

~ i Key y ee

RL bose

% iid ‘BRAKE CYLINDER

¥

BEAS—y Noon

TURN BACKLE

Pay Ko PWOy PB Hh

LOCK BOLT FOR TURN BACKLE

300

. £3. HANTERANCE AND IRSPECTION

Bd Mechanical and hydraulic parts

D) Grane house and jib

+ every 3 months

2) Confirm no deformation and no crack

B) Inspect the eettings bolts. - + every 3 wonths

If Joosend, refesten thee securely.

. 2) Hire rope

2) Inspect the strands and

‘prior to operation

check the diaeeter. -

b) Inspect the fixed end of

srt prior to operation

the rope. ~

Prior 10 op

c) Supply the wire grease. s+peeeeeeresee

Replacing the wire rope with new one.

-1f the following condition is Sound, the wire rope is to be replaced

with new one immediately.

® The number of broken yarn ip over 1DE of yarn fer one ley.

© The rope diester is decreased over 7% of She 'vomina] size:

@ The rope is kinked.

© The rope is greatly deformed or corroded. .

3) Sheave

a) Inspect the wear at the groove

seretrssessssees prior to operation

of sheave, s-+++

When it is worn over 20% of rope dianeter, it is to be replaced,

b) ConSirm no defornation and

prior to operation

no crack. +

Af any deformation or crack is found, it is to be replaced.

4) Falling block

a) Inspect the wear at hook. stress prior to operation

b) Confire no deformation and

no crack, prior te operation .

5) Slewing reduction gear

a) Check the level of Jubrica-

Prior to operation

£ tion oil. +

Af its level is lok, oil is to be supplied 1i]] the adequate oi]

level.

In this case, supply the same oi.

b) Exchange the Jubrication oil.

+ every 6 months

Within the first year s++eeseessee

After the first year tevseeeeeeeeees every year

©), Confirm no abnormal noise or vibration. --- prior to operation

+ every 8 nonths

@ Inspect the setting bolts.

‘Fetightening at loosening

every yeer

€) Inspect the brake. s++++esreeee

Refer 10 3.5 “Maintenance of brake” .

prior te operation

8) Grease Jubrication -

Refer to 3.6 “Lubricating points”.

T) Slowing bearing and Hoisting winch.

Supply open gear oi], + prior to operation

302

9) Hydraulic of]

a) Check the colour and transparency. ~~ every 3 months

Pick up the samples at main circuit and head tank,

and compare them with new oi] which is sampled

previously.

+ In case that its colour is milk white

and transparency is bad. oil mixed with water

«In case that its colour is brown

and ii has a stimulant smell. ——— deteriorated oj]

To use oi} mixed with water or deteriorated of is bad

jor the byéravlic devices. Please exchange hydraulic

oil. After exchanging oi] it is necessary to exhaust”

the air conpletely.

every year

b) Check a quality of oil by of] maker.

10) Oj] leakage

0i] leaks are to be mended zs soon zs they are found,

because such Jezkage often Jeads to serious consequences.

1)) Linit valve

Check the lini valve “= prior to operation

at no Jozd operation

1

PE) WeETERANCE cuECE an an cTMEKT

WORKING OIL AND LUBRICATING OIL

303

USE KIND

MAINTENANCE = CHECK,

‘WORKING OTL

Wear resistance hyd.

working oil

ISO VG 46

equivalent

WORKING OIL. FOR

HYD. REMOTE CONTR

OL DEVICE control device

Ref. to iten ~ Recommended

working oil ~ for hyd.renote

LUBRICATING OIL

FOR CLOSED GEAR | ed gear grade 2

or 320 equivalent

JIS K 2218 gear oil for clos

180 V6 150

1) Check color and transparency

at every voyage or every thr

ee months.

To send the sample of workin

§ oil to ojlmaker to ask the |

inspection

3) To accept the advice of oi]

maker whether it could be

used continuously or not.

LUBRICANT FOR

JIS K 2220 equivalent of gea

Lubricate every month and

OPEN GEAR | r compound grade 1, n0.2 before or after use.

GREASE FOR JIS K 2220 equivalent of gre Lubricate every week and

BEARING | ase for rolling bearing before or after use.

grade 1,n0.2

Discuss about decision of brand for above working and luricating oi] with oil maker

and our company.

A. Check of orking oil (Inspection procedure on site)

Extract oil from main circuit and drain of oil tank.and compare it with new oi)

which has been ex

When color shows

When color shows

Using water mixed

Exchange to nex oil.

‘acted and kept beforehand.

Light white and milk white, and transparency is not good,

brown or sell is stimulus,

and declined oil occur bad influence to hyd. device.

mix water.

declination of oi}

6

B. About exchange of working oil and lubricating oi.

&) Use fixed same brand vorking oi] and lubricating oil.

b) Clean inside the tank et exchanging.

c) Teke care so as not to involve dust or foreign matters, and supply working

oi] through filter of more than 200 mesh.

. Others

Vorking oi] will decline sooner with high tenperature, take care thet oil tempera

‘ture sould not be more than

6st.

RECOMMENDED OJLS FOR HYDRAULIC SYSTEM

CANTIKEAR TYPE PETROLEUK FLUID) 10 V6 46

No} MAKER GOODS MAKE

1] syoseK) suet | Tellus oi} 48

|

\

2| wexitsy Daphne super liydro 46

Neo fluid 405

3] NIPPON OL Super hiyrend — 46

4} COSKO Cosmo hydro AR 46

8 | KYOSEKI Kyoseki hydiux 46

8 | kyanus Unit of] HR — 46

7| mitsupisHi Diasond hydro fluid EP 46

8| Esso Nuto HP = 46

Uni power SQ 46

9 | MOBIL [obit OTe 25

|

10 | GENERAL | General panol 46

304

RECOMMEND OTLS FOR HYDRAULIC SYS

( ANTIVEAR TYPE PETROLEUM FLUID) ISO VG 46

305

No. MAKER GOODS NAME

11] BP Energol HLP 45

’

12| CALTEX Rando Oi1 BD 46

TEXACO

13] CASTROL Tyspin AWE 46

14| CHEVRON Hydraulic Oil 46

15/GULF Wechanisa LP 46

16/ELF Visga 46

306

RECOMMENDABLE OILS FOR LUBRICANT

CLOSED GEAR OPEN GEAR| RUBBING POSITION

SPUR GEAR HORH GEAR BEARING CLUTCH

180 VG1i50 VG320

1| suKixou _ Hori 6G | _

2] SHOSEK] | Omelu oi! 150 Duel of) 320

SUELL | G-€ of) 150 SE G-C oi! 820 SE Cargiaw coupound D| Sunlight grease 2

| Albanie greese 2

. |

w| IDEMITSU | Daphne super Daphne super

gear oi} 150 gear oi] 320

Dephne CE "| Dapline CE Daphne Oren Daphne Coronecks

Compound ~ 150S Compound 3208 weer off No2 grease ~ 2

4 WWIPPOW O11] Bonnoek SP150 | Bonnosk SP320 Crenock He | Linockes

#150 320” Coupound = 1)» erease ~ 2

5 | cosKo | Cosuo gear $E150 | Cosmo gear SE320 | Cosmo gear compound Cosmo grease dynsinas

#0150 #0320 | toe No2

6 | KYOSEK] | Kyoseki ES geer G150| Kyoseki ES gear 6320

i Kyoseki Reduclus | Hyoseki Reductus —_| Kyoseki gear Kyoseki Rizonicks

150 | 820 Compound No2 grease Not

7 xyowus | Snep of) 1080 {Snev oi} 2080 | sear Coupound 2 | Kygnus HP erease 2

8 WITSUBISH] Diazond sear | Dienond sear

Juob SP150 Job $820

Diasond super Diawond super Nilschishi seer | Disnond Kel Linarnath

gear luob SP150 gear Juob SP820 Coupound = 2 presse - 2

9] ESs0 | Spaltan EPI50 Spalten EPS20 | Jus 2563 Ristun 2

Selet fluid 4k | Bescon 2

10[ MOBIL | Kobi] wear 629 Kobil pear 682 Nobil Tack 00 Mobilbx 2

13 | GENERAL | Genera! gear roli | General geer roll | Geners! gear Genera! greese

150 320 Counound Ho) NP 2

RECOMMENDABLE OILS FOR

wee

LUBRICANT

CLOSED GEAR

OPEN GEAR

RUBBING POSITION

BEARING CLUTCH

SPUR GEAR|WORM GEAR

ve] VG 150 vG 320

312 | BP Energol GR-XP 150 | Energol GR-XP 320 | Energrease 0G Energrease LS 2

Energol SG 150

13 | CALTEX | Meropa Lubricant | Meropa Lubricant | Crater 2 Waltifak EP 2

TEXACO 150 320 Waltifak 2

14 | CASTROL | Castrol Alpha SP | Castrol Alpha SP | Rustilo $53 Soheerol AP 2

150 320

15 | CHEVRON | NL Gear Compound | NL Gear Compound | Pinion Grease 100 | Dura-Lith Grease

150 320 EP?

15 [GULF | EP Lubricant HD | EP Lubricant ED | Lubeote No.1 Crown Grease No.2

150 320

17 |ELF | Epona Z 150 Cardrexa DC 1 Wultiservice

Epexa 2

BL

Wise rope is replaced in the following procedure,

®

@

@

Procedure of replacing wire rope

Put the Jib on the jib rest.

Remove the set bolt or chain of sprocket on the end of shaft and

re-adjust the limit switches .

Renove ihe end set pin of wire rope (at the, DEADEYE side).

Cut the wire rope at near the DEAD EYE and connect the new wire

rope with the old one.

Loose the'set bolts on drum flange and remove the end of rope.

Hhile jinding the old wire rope at lon speed of winch, pay out

it fron the rachine room. .

When the end of new wire rope cones to the point near drum

flange, stop the winch. -

In case of winding the wire rope, pay attention to the connected

part when i passes wire guard, falling blook and sheave.

Fix the end of now wire rope with the set blots on drum flange.

nd {ix the other end with the end set pin of wire rope.

Hake sure thet 8 or more renaining coils of wire rope (the

rest coil) is left on the hoisting drun.

Fix the spying pin or chain of sprocket on the end of shaft and

“ re-adjust the limit switches .

( Refor to ” adjustment of Limit valve ~ }

WIRE ROPE

for hoisting : P20 x 1854

for luffing $18 x 115

31

WIRE ROI

RIGGING

24%-0-FRD

J1B TOP SHEAVE

VI bo FUT

HOUSING TOP_SHEAVE

DEAD EYE

FoRTt

LUFFING DRUN

DED Ss

+ FALLING BLOCK

HOISTING pRUW Leas. BE

pa-vvy7ao?

BEoA .

312

2~—3 Procedure of re-adjjusting the limit valve

After replacing the wire rope, the limit valve needs its re-adjustment for the

sake of keeping the safety of wire and each machinery .

+ Limit svitches are as follows .

Ost upper limit valve for luffing sree LVL

@bht lower limit valve for luffing LVLL

ht upper limit valve for hoisting LVHH

@st lower linit valve for hoisting ~ LVBL

@At Limit valve for slewing right LVSR

@iAt limit valve for slewing left ~ LVSL

NOTE

‘Adust this at no load , and confirm that ship body is level state .

Qst vpper limit valve for luffing { mininun radius) - LVL H

@) Hoist the jib at Jow speed and stop it at minimus working radius. and stop

‘the crane .(AB791 (44 FROM CRANE POST CENTER)

b) Turn the screw rod@ with hand until the striker® cone into contact with

‘the limit valve ( LVLH) .

( Linit velve should be in the state of being push for 2 mm~ 5 mm )

c) Set the chain or pin on the sprocket .

G) Confirm that winch will stop and limit valve works at fixed position after

setting limit valve { LVLH) -

@) If it is not stopped at Fixed position, to loosen set bolt (NB), and to adjust

wlever (L. H) . to move left and right .

crc unaie bar

A

| AFT FORE

318

{ Bn

| came mer

7 ~ g a | :

319

3-4.Maintenance of Brake

The hoisting winch and latfing winch and. slewing device are

fitted each with a set of brake device,

lt is released by hyd. pressure and fastened by spring force. ”

Check the brake device as follow ~ every 6 months

1) Confirm that the stroke gauge indicates between -H and L,

2), Adjust the stroke gauge “H” by fastening the turnbuckle if

the stroke gauge is below “L".

3) In case that the stroke gauge cannot readjust,renew the

brake lining.

BRAKE CYLINDER

ADJUSTING BOLT

a.

J

Bu Gaaiabo

A A B F 4 ;

|

1

al

7

4)°@ SANDWICH PLATE.

7 st

Le @ BASE FOR FLOW

: CONTROL. VALVE

OF HOISTING

2 LI

THE CENTER LINE

OF SLEWING

4 | see |

CR PAY OUT L

- i

NILA eas SECTIONAL VIEW.

5:

|

| ,

yore

ios

§ ) 0 PS (

| * v

8 | ee

7

xl Re

tal laps says

Ke

wake SERRE

EPS

7

L J

[arse]

I

\

J : [

q

2 Qarseeate pee .

£2 THE CENTER LiNE

2 7 OF HOUSE BASE

'

3 3

| Ria r

ete

ns. te

4 ‘ 2

< eo

f

{

| ch Hl

| il 1D, MoT?

m SLEWNG

5 5

| ‘

L

6 |

a | (ee = 8 2 hadn a[a a] we fa

“| #e Se S T Ce ew 20s

3 AA PIPING OF DRAIAT

J Le reoT Le

| :

|

J sste-teet r 4 | 380 | at ee

i

a | Le | Et

JOINT | 3 ne fo fea

L | jens peu 22 S07 8 fe

cow Repematett REE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Buk Crane-Lattice Boom Corrosion Verification by Calculation-13-4-2023Document2 pagesBuk Crane-Lattice Boom Corrosion Verification by Calculation-13-4-2023Karikalan JayNo ratings yet

- Ex4 deDocument9 pagesEx4 deKarikalan JayNo ratings yet

- FA2B Winch SpecificationsDocument3 pagesFA2B Winch SpecificationsKarikalan JayNo ratings yet

- Sea Fastening Beams For HLS-25-4-23 (5 45)Document11 pagesSea Fastening Beams For HLS-25-4-23 (5 45)Karikalan JayNo ratings yet

- Offshore Personnel Transfer by Crane Guidelines - Rev 0Document32 pagesOffshore Personnel Transfer by Crane Guidelines - Rev 0wahyu nugrohoNo ratings yet

- Illage - Full Skid Assembly For Mfg-Rev A2Document1 pageIllage - Full Skid Assembly For Mfg-Rev A2Karikalan JayNo ratings yet

- Ucf 210 - 20230120Document6 pagesUcf 210 - 20230120ilfakeNo ratings yet

- HH06 - (CR171) 13Tx18M (R) HOSE HANDLING CRANEDocument158 pagesHH06 - (CR171) 13Tx18M (R) HOSE HANDLING CRANEKarikalan JayNo ratings yet

- Illage - Smaller Skid Assembly For MFGDocument1 pageIllage - Smaller Skid Assembly For MFGKarikalan JayNo ratings yet

- PNL Jib Crane GA & PicturesDocument5 pagesPNL Jib Crane GA & PicturesKarikalan JayNo ratings yet

- Illage - Full Skid Assembly For Mfg-Rev A2Document1 pageIllage - Full Skid Assembly For Mfg-Rev A2Karikalan JayNo ratings yet

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDocument1 pageSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayNo ratings yet

- Illage & Gantry With Spooler - Ga For Manufacturing-Rev A2-.Document1 pageIllage & Gantry With Spooler - Ga For Manufacturing-Rev A2-.Karikalan JayNo ratings yet

- Tuition Grant Option Form PDFDocument1 pageTuition Grant Option Form PDFKarikalan JayNo ratings yet

- 5.detail A, B, C & H, Mounting Plates 15 & 17-Rev A2Document1 page5.detail A, B, C & H, Mounting Plates 15 & 17-Rev A2Karikalan JayNo ratings yet

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDocument1 pageSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayNo ratings yet

- SHEET No 15 REINFORCEMENTS RINGS WELD TO SHELLDocument1 pageSHEET No 15 REINFORCEMENTS RINGS WELD TO SHELLKarikalan JayNo ratings yet

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDocument1 pageSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayNo ratings yet

- Sheet No 10 - Concise title for structural steel sheet drawingDocument1 pageSheet No 10 - Concise title for structural steel sheet drawingKarikalan JayNo ratings yet

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDocument1 pageSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayNo ratings yet

- 00031361-A WCU T1 Wiring DiagramDocument8 pages00031361-A WCU T1 Wiring DiagramKarikalan JayNo ratings yet

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDocument1 pageSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayNo ratings yet

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDocument1 pageSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayNo ratings yet

- SHEET No 04 CENTER SQUARE ASSY 2 DETAILDocument1 pageSHEET No 04 CENTER SQUARE ASSY 2 DETAILKarikalan JayNo ratings yet

- SHEET No 01 REEL FULL ASSLY GA DWGDocument1 pageSHEET No 01 REEL FULL ASSLY GA DWGKarikalan JayNo ratings yet

- 00027646-C JB Wiring DiagramDocument37 pages00027646-C JB Wiring DiagramKarikalan JayNo ratings yet

- Distribution Cabinet Tensioner 1 Technical DocumentationDocument77 pagesDistribution Cabinet Tensioner 1 Technical DocumentationKarikalan JayNo ratings yet

- 00027639-B DCPR1 Wiring DiagramDocument67 pages00027639-B DCPR1 Wiring DiagramKarikalan JayNo ratings yet

- 00027634-B RCC Wiring DiagramDocument50 pages00027634-B RCC Wiring DiagramKarikalan JayNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)