Installation Manual

Uploaded by

josevalenciaTopics covered

- 组件连接,

- 机械载荷,

- 组件安装注意事项,

- 电气安装,

- 太阳能组件,

- 组件安装规范,

- 安装条件,

- 维护保养,

- 接线连接,

- 组件安装

Installation Manual

Uploaded by

josevalenciaTopics covered

- 组件连接,

- 机械载荷,

- 组件安装注意事项,

- 电气安装,

- 太阳能组件,

- 组件安装规范,

- 安装条件,

- 维护保养,

- 接线连接,

- 组件安装

Common questions

Powered by AICovering PV modules with opaque materials during installation is recommended to reduce the risk of electric shock or burns that can arise when the modules are exposed to sunlight and thus generating electricity . By blocking light exposure, the modules produce less current, reducing the risk of accidental shock or injury to the installation personnel. This practice is especially important when handling the PV module’s electrical connections, as it prevents potential harm during these tasks . Using opaque materials enhances safety by mitigating these risks effectively.

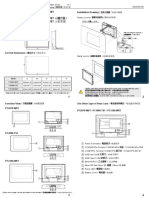

During the installation of solar modules, several safety precautions should be adhered to prevent accidents and ensure proper functionality of the PV system. Installers should wear protective headgear, insulated gloves, and rubber insulated shoes to prevent injuries from electrical shocks or equipment mishandling. It is critical not to install in adverse weather conditions like rain, snow, or strong winds as these conditions increase the risk of accidents such as tools slipping or modules being mishandled. Additionally, using dry insulated tools instead of wet ones can prevent electrical hazards. Finally, care should be taken to avoid placing excessive loads on the modules during installation to prevent damage to the cells or surface . These procedures are important to maintain the structural integrity of the modules and ensure the safety of those involved during installation.

Installers should calculate the maximum number of series-connected modules by considering the open circuit voltage (Voc) at the lowest expected local temperature, ensuring it does not exceed the maximum system voltage specification of DC1500V according to IEC61730 safety standards . In regions like Australia, additional compliance with AS/NZS 3000 and AS/NZS 5033 standards is required. The Voc correction factor, CVoc, is calculated using the formula CVoc=1- βVoc×(25-T), where T is the minimum ambient temperature expected, and β represents the module's temperature coefficient for Voc, as detailed in the module’s data sheet . This ensures compliance with safety standards and optimizes the PV system's capacity without overloading.

Shading significantly impacts the performance and efficiency of PV modules. While the document states that manufacturers may install bypass diodes to mitigate energy loss due to shading, any shadows cast on the PV modules can still lead to decreased power output . The text emphasizes avoiding shadows from trees, buildings, or other obstacles as shadows can result in a substantial loss of power output despite technological measures. Installers are encouraged to place panels in locations with maximum sunlight throughout the year to minimize shading effects and optimize energy production .

Not grounding the frames of PV modules poses risks of lightning and static-electricity damage to the modules, which can lead to electrical malfunctions and reduce the lifeline of the system. Grounding provides a path for electrical currents from lightning or static discharges, protecting both the modules and their users . Proper conduction of grounding involves ensuring full contact between the grounding device and the aluminum alloy frame, while penetrating the surface oxide film. Additionally, only the designated grounding marks on the frame should be used for this purpose, avoiding any drilling of additional grounding holes which could compromise the integrity of the panel's frame .

The document indicates that the power output of PV modules is affected by the installation angle relative to the true south in the Northern Hemisphere (or the true north in the Southern Hemisphere). Deviations of 30 degrees from the optimal south/north orientation can reduce power output by approximately 10% to 15%, while a 60-degree deviation can result in a 20% to 30% reduction in power output . To mitigate this, installers should carefully align PV modules to face directly south in the Northern Hemisphere or north in the Southern Hemisphere, taking into account local geographic and climatic conditions to maximize solar exposure throughout the year. Additionally, avoiding shading from obstacles like trees or buildings is critical as even with bypass diodes, shading can decrease output .

Regular maintenance is important for PV modules to ensure they perform efficiently and any potential defects are promptly addressed to prevent long-term damage. The document recommends specific maintenance actions such as visually inspecting the modules for appearance defects, checking for damage to the glass, ensuring there's no shading from objects, and verifying the condition of the connectors and cables to ensure no corrosion or rodent damage exists . Cleaning is also crucial to prevent dust or dirt accumulation, which could reduce output. Cleaning should ideally be done in the morning or evening when temperatures are lower to avoid thermal shock to the panels . Regular maintenance helps sustain the PV system’s efficiency and prolong its operational life.

Consulting local building departments before installing PV modules on rooftops is crucial because these entities provide guidance on suitable roofing materials that can safely support the modules without compromising fire safety. The document specifies that PV modules should be installed on fire-resistant materials, and determining the appropriate materials necessitates consultation with local authorities who understand regional building codes and safety standards . This consultation helps ensure compliance with local regulations, enhances the safety of the installation, and prevents potential legal and insurance issues related to fire hazards.

Using mirrors or lenses to focus sunlight on PV modules is prohibited because it can lead to operational hazards such as overheating, which may damage the module and decrease its efficiency. Enhanced focused sunlight increases the thermal load on the panels, potentially exceeding their capacity to dissipate heat, which can cause thermal stresses and lead to mechanical or electrical damage . This practice undermines the designed operating conditions of the modules and poses safety risks such as fire hazards, making its prohibition a necessary measure to preserve both module integrity and user safety .

In areas prone to heavy snow and wind, it is essential to adopt special protective measures during the installation of PV modules. The document specifies that standard design loads for snow and wind are 3600 Pa for the front and 1600 Pa for the back of the modules, with a safety factor of 1.5 times . If the installation site is characterized by extreme weather, additional reinforcements may be required to secure the modules adequately, ensuring they are not compromised by snow accumulation or high wind pressures. Adherence to these guidelines helps preserve the structural integrity and operational efficiency of the PV system under adverse weather conditions .