Professional Documents

Culture Documents

SCM Module 5 Notes

Uploaded by

Naik SamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCM Module 5 Notes

Uploaded by

Naik SamCopyright:

Available Formats

SCM Module 3 notes

SCM Module 5

Current Trends: Supply Chain Integration

Supply Chain Integration:

A typical firm is functionally organized, and material and information have to go through

multiple departments across the internal supply chain. As each function is myopic in nature

and is focusing on a narrowly defined local performance, there are many inefficiencies and

buffers at departmental boundaries. This is illustrated using two examples.

1. An electric machinery firm, which has a manufacturing plant in Mumbai, serves the

southern market through a stock point in Chennai. The Mumbai plant ships goods to

the Chennai stock point once a month because monthly demand amounts to

approximately a full truckload. Obviously by shipping goods using full truckloads, the

plant is able to minimize transportation costs. As it receives goods only once a month,

the Chennai stock point has to keep high safety stocks to ensure a reasonable level of

service to its customers. Thus, both the Mumbai plant and the Chennai regional stock

point have made so-called locally optimal decisions A detailed analysis shows that it

will be optimal (total transportation and inventory cost will be lowest) for the firm to

ship goods to Chennai from Mumbai once a week. There is a trade-off between

transportation and inventory costs, individual departments chose to ignore this trade-

off to make locally optimal decisions, resulting in a substantial increase in the overall

cost in the system.

2. A split pump manufacturer used to offer about 30-odd varieties of pumps in the

marketplace. As per the product design, the pump housing consisted of a top housing

and a bottom housing and the exact size of the pump housing varied with each model.

The machining of housings was one of the most critical tasks, involving expensive

equipment and a significant amount of time. One of the critical operations in the

machining of housing involved joint machining of both the housing castings (top and

bottom of same model) in one setup. However, the firm found that though it had a huge

inventory of housing castings, it rarely had matching pairs of top and bottom housing

castings, resulting in serious difficulties in scheduling machining operations, upsetting

promised customer delivery schedules. The purchase department had placed orders for

top housings with one vendor and bottom housings with another. Since one vendor had

quoted lowest for top housing castings and another had quoted lowest for bottom

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

housing castings, the purchase department had placed orders accordingly. While the

purchase department had substantially minimized the buying cost at the purchase stage,

this kind of ordering resulted in uncoordinated supply by each vendor leading to

constant problems for manufacturing. The manufacturing team faces serious problems

in scheduling its operations. Even with a huge inventory of individual top and bottom

housing castings, operations find it difficult to match pairs for manufacturing. Hence,

the company had a typical problem of high inventory and low customer service. A

simple solution therefore will be an order of top and bottom housing casting with the

same vendor with clear instructions to supply both castings of the same model in one

shipment. The purchase department had tried to similarly cut costs by splitting “C”

category hardware items’ orders to several suppliers and found eventually that many

times crucial shipments could not be made because of non-availability of some of these

items

Building partnership and trust in Supply chain Value of

Information:

Bullwhip Effect: Demand Volatility and Information Distortions

Across Supply Chains:

Supply chain coordination improves if all stages of the chain take actions that

together increase total supply chain profits. Supply chain coordination requires

each stage of the supply chain to take into account the impact its actions have

on other stages.

A lack of coordination occurs either because different stages of the supply chain

have objectives that conflict or because information moving between stages is

delayed and distorted. Different stages of a supply chain may have conflicting

objectives if each stage has a different owner. As a result, each stage tries to

maximize its own profits, resulting in actions that often diminish total supply

chain profits.

Today, supply chains consist of stages with many different owners. For

example, Ford Motor Company has thousands of suppliers from Goodyear to

Motorola, and each of these suppliers has many suppliers in turn.

Information is distorted as it moves across the supply chain because complete

information is not shared between stages.

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

This distortion is exaggerated by the fact that supply chains today produce a

large amount of product variety. For example, Ford produces many different

models with several options for each model. The increased variety makes it

difficult for Ford to coordinate information exchange with thousands of

suppliers and dealers.

The fundamental challenge today is for supply chains to achieve coordination

in spite of multiple ownership and increased product variety.

Many firms have observed the bullwhip effect, in which fluctuations in orders

increase as they move up the supply chain from retailers to wholesalers to

manufacturers to suppliers, as shown in Figure 1.

The bullwhip effect distorts demand information within the supply chain, with

each stage having a different estimate of what demand looks like. The result in

a loss of supply chain coordination.

Proctor & Gamble (P&G) has observed the bullwhip effect in the supply chain

for Pampers diapers. The company found that raw material orders from P&G to

its suppliers fluctuated significantly over time. Farther down the chain, when

sales at retail stores were studied, it was found that the fluctuations, while

present, were small. It is reasonable to assume that the consumers of diapers

(babies) at the last stage of the supply chain used them at a steady rate. Although

consumption of the end product was stable, orders for raw material were highly

variable, increasing costs and making it difficult for supply to match demand.

Figure 1: Demand fluctuations at different stages of a supply chain

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

Effective Forecasting

The following basic, six-step approach helps an organization perform effective forecasting.

1. Understand the objective of forecasting.

2. Integrate demand planning and forecasting throughout the supply chain.

3. Understand and identify customer segments.

4. Identify the major factors that influence the demand forecast.

5. Determine the appropriate forecasting technique.

6. Establish performance and error measures for the forecast.

UNDERSTAND THE OBJECTIVE OF FORECASTING

Every forecast supports decisions that are based on the forecast, so an important first step is to

identify these decisions clearly. Examples of such decisions include how much of a particular

product to make, how much to inventory, and how much to order. All parties affected by a

supply chain decision should be aware of the link between the decision and the forecast. For

example, Wal-Mart's plans to discount detergent during the month of July must be shared with

the manufacturer, the transporter, and others involved in filling demand, as they all must make

decisions that are affected by the forecast of demand. All parties should come up with a

common forecast for the promotion and a shared plan of action based on the forecast. Failure

to make these decisions jointly may result in either too much or too little product in various

stages of the supply chain.

INTEGRATE DEMAND PLANNING AND FORECASTING THROUGHOUT THE

SUPPLY CHAIN

A company should link its forecast to all planning activities throughout the supply chain.

These include capacity planning, production planning, promotion planning, and purchasing,

among others. This link should exist at both the information system and the human resources

management level. As a variety of functions are affected by the outcomes of the planning

process, it is important that all of them are integrated into the forecasting process. In one

unfortunately common scenario, a retailer develops forecasts based on promotional activities,

whereas a manufacturer, unaware of these promotions, develops a different forecast for its

production planning based on historical orders. This leads to a mismatch between supply and

demand, resulting in poor customer service.

To accomplish this integration, it is a good idea for a firm to have a cross-functional team, with

members from each affected function responsible for forecasting demand and an even better

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

idea is to have members of different companies in the supply chain working together to create

a forecast.

Coordination in supply chain

Effectively managed supply chain relationships foster cooperation and trust, thus

increasing supply chain coordination. In contrast, poorly managed relationships lead to

each party being opportunistic, resulting in a loss of total supply chain profits. The

management of a relationship is often seen as a tedious and routine task. Top

management, in particular, is often very involved in the design of a new partnership but

rarely involved in its management. This has led to a mixed record in running successful

supply chain alliances and partnerships.

Figure 2 shows the basic process by which any supply chain partnership or alliance

evolves. Once the partnership has been designed and established, both partners learn

about the environment in which the partnership will operate, the tasks and processes to

be performed by each partner, the skills required and available on each side, and the

emerging goals of each side. The performance of each side is evaluated based on the

improvement in profitability and on equity or fairness. At this stage, a better evaluation

of the value of the partnership becomes available, which provides both parties in the

supply chain partnership an opportunity to revise the conditions of the partnership to

improve profitability and fairness. It is important that the initial contracts be designed

with sufficient flexibility to facilitate such alterations.

Formal contracts may be restructured to reflect the changes. As the business

environment and company goals change, the cycle repeats itself and the relationship

evolves. Any successful supply chain partnership will go through many such cycles. A

supply chain partnership falters if the perceived benefit from the relationship diminishes

or one party is seen as being opportunistic. Problems arise when communication

between the two parties is weak and the mutual benefit of the relationship is not

reiterated regularly. When managing a supply chain relationship, managers should

focus on the following factors to improve the chances of success of a supply chain

partnership:

1. The presence of flexibility, trust, and commitment in both parties helps a supply chain

relationship succeed. In particular, commitment of top management on both sides is

crucial for success.

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

2. Good organizational arrangements, especially for information sharing and conflict

resolution, improve chances of success. Lack of information sharing and the inability

to resolve conflicts are the two major factors that lead to the breakdown of supply chain

partnerships.

3. Mechanisms that make the actions of each party and resulting outcomes visible help

avoid conflicts and resolve disputes. Such mechanisms make it harder for either party to be

opportunistic and help identify defective processes, increasing the value of the relationship

for both parties.

4. The more fairly the stronger partner treats the weaker, vulnerable partner, the stronger

the supply chain relationship tends to be.

Figure 2: Process of alliance and partnership Evolution

The issue of fairness is extremely important in the supply chain context because

most relationships involve parties with unequal power. Unanticipated situations that

hurt one party more than the other often arise.

The more powerful party often has greater control over how the resolution occurs.

The fairness of the resolution influences the strength of the relationship in the

future.

The relationship between Marks & Spencer and a manufacturer of a kitchen product

provides an excellent example of a fair sharing of benefits. A few months after the

product's introduction, the manufacturer realized that costs had been miscalculated

and exceeded the price at which the product was being sold to Marks & Spencer.

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

Meanwhile, given its low retail price, customers found the product an outstanding

value and made it a big hit.

When the manufacturer brought the problem to the attention of Marks & Spencer,

its managers helped the manufacturer reengineer both the product and the process

to lower cost. Marks & Spencer also lowered its margin to provide a sufficient profit

for the manufacturer. The outcome was one in which the relationship was

strengthened between the two partners because Marks & Spencer's fairness allowed

a resolution that recognized the manufacturer's needs. In the long run, both partners

benefited and a higher level of trust developed.

Supply chain Restructuring:

Introduction:

In the era of globalization, firms are under relentless pressure to continuously

improve their supply chain performance so as to minimize cost and maintain high

levels of customer service.

In the last decade, several leading firms have reaped substantial benefits by working

on initiatives involving supply chain integration and supply chain optimization.

These initiatives have helped these firms in ensuring above-average business

performance in their respective industry sectors.

But in the last few years, leading firms have realized that initiatives involving

supply chain integration and supply chain optimization are not enough for ensuring

above-average business performance. These initiatives are necessary for the very

survival of a firm. These do not ensure an above-average performance.

Supply chain integration and related best practices have received adequate attention

in the industry. These practices have percolated down from the best firms to emerge

as necessary but insufficient conditions for firms to establish themselves as market

leaders.

Industries have realized that if they want to retain their leadership, they will have to

go beyond these initiatives and look at ways in which they can restructure supply

chain architecture and processes. Supply chain restructuring focuses on these

innovative practices that separate leaders from the “also-ran” companies.

Unlike supply chain integration and supply chain optimization, supply chain

restructuring goes beyond supply chain function and requires integrating product

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

and process engineering with supply chain function. Similarly, it may also involve

closer integration between marketing and supply chain function.

Supply Chain Mapping:

Before a firm sets out to restructure its supply chain, it has to find a method to

successfully capture and evaluate the existing supply chain processes. The method

used to capture current supply chain processes is termed supply chain mapping.

As can be seen in Figure 3, existing supply chain processes can be characterized on

the basis of the following dimensions:

• Shape of the value-addition curve

• Point of differentiation

• Customer entry point in the supply chain

Figure 3: Supply chain mapping:

existing position.

Restructuring of the supply chain process involves altering the supply chain on at least one the

three dimensions. It may also involve altering more than one dimension of the supply chain

process. We initially take one dimension at a time and later on discuss a specific innovation,

which involves altering two dimensions in the process.

Value-addition Curve:

The supply chain encompasses all the activities/processes associated with the

transformation of goods from the raw material stage to the final stage when the goods

and services reach the end customer.

A typical supply chain starts with some input material and information, which are

transformed into the end product and delivered to the customer. This transformation

involves a number of activities, with each activity taking time, incurring cost and adding

value.

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

One can debate on whether all activities add value or if there some activities that are

non-value-added activities. At this stage, we assume that the firm has removed all non-

value added activities from the supply chain processes.

On the x-axis we have the total time in a chain or the average flow time in the chain

and on the y-axis we have the total cost (cumulative) in the chain.

Customer Entry Point in the Supply Chain:

The point at which a customer places an order is shown as a dotted line in Figure 3. In

several industries customers expect material off the shelf in the neighbourhood retail

store.

In such a case, the customer entry point is at the end of chain and is the same as the

delivery time. But in several industries it is not uncommon for customers to give some

amount of delivery lead time and in such a case obviously the customer entry point will

be ahead of the delivery time. This is similar to build-to-order or configure-to-order

supply chain situations.

Essentially, the customer entry point captures the order to delivery lead time. This

dimension is important because all the operations before the customer order has to be

done based on forecast, whereas after the customer order one will be working with

actual orders.

In other words, before the customer entry point all the activities are carried out based

on forecast while subsequent activities are done based on order. As discussed in the

chapter on demand forecasting, however good the forecasting process, as per the first

law of forecasting, a forecast is always wrong.

So if bulk of the activities can be carried out based on order rather than forecast one

does not have to worry about the likely forecast error that is inherent in any forecasting

exercise.

Point of Differentiation:

The concept of the point of differentiation is valid for any organization that is offering

a variety of end products to customers. Products are made in a supply chain consisting

of multiple stages. As the product moves in the chain, progressively, the product

assumes an identity that is closer to the end product.

The point of differentiation is a stage where the product gets identified as a specific

variant of the end product. We will illustrate the concept using a toothpaste

manufacturing firm. Let us assume that the firm offers variety only in pack sizes.

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

In such a firm, the packing stage is a point of differentiation. At a packing station the

same basic material, that is, toothpaste, is packed in sizes of varying dimensions. So till

the packing station one has been working with the generic material, but at the packing

station the firm has to make an irreversible decision in terms of committing the generic

material to a specific product variant. Similarly, at a garment manufacturing firm, at the

stitching stage the firm is committing the fabric to different sizes and styles of garment.

In automobile manufacturing firms like Tata, where usually large variety is offered in

terms of colours, the painting stage becomes the point of differentiation because at that

stage the firm makes an irreversible decision about the colour of the car.

Supply Chain Process Restructuring:

Supply chain process restructuring involves playing around with at least one of the three

dimensions of the supply chain in the direction as shown below:

• Postpone the point of differentiation. By moving the point of differentiation as much

as possible, a bulk of the activities can be carried out using the aggregate-level forecast

rather than the variant-level forecast.

• Alter the shape of the value-addition curve. Shift the bulk of the cost addition as

late as possible. This will reduce the inventory in the chain and also help the firm in

having some flexibility. If the bulk of the cost addition takes place at a later point in

time in the chain, one will be in a position to respond to unforeseen changes with the

least cost.

• Advance the customer ordering point. Move from an MTS to a CTO supply chain.

By moving the customer ordering point as early as possible, one can carry out the bulk

of the activities against an order, which reduces the importance of forecasting. If one

were also able to postpone the point of differentiation, one will be able to move from

an MTS to a CTO supply chain.

In a CTO supply chain, since the point of differentiation takes place after customer

order, one does not have to prepare a variant-level forecast.

Before we get into a detailed discussion about supply chain restructuring, it will be

important to compare it against supply chain integration and supply chain optimization.

As can be seen in Figure 4, supply chain integration and supply chain optimization

focus on lowering the value-addition curve. This results in overall reduction in cost and

time and will result in an absolute shift in the point of differentiation but the relative

position of the point of differentiation does not change. Unlike these two approaches,

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

supply chain restructuring affects the shape of the value-addition curve, shifts customer

ordering, or shifts the point of differentiation.

This will essentially require supply chain process restructuring and may also involve a

change in product design or a change in the product service bundle offered to customers.

Supply chain restructuring is likely to bring in substantial business benefits in general

and in special cases it fundamentally changes the way in which the supply chain is

managed by moving from the MTS to the CTO business model.

Figure 4: Impact of supply chain

Integration /optimization.

Postpone the Point of Differentiation:

Delaying an operational process that results in variety explosion or customization to a

later point in the supply chain postpones the point of product differentiation. Delaying

the differentiating operations, apart from reducing inventories, also reduces the time

period for which one has to carry out forecasting at the variant level and thereby reduces

inventory and improves customer service and reduces product obsolescence.

Postponement for Reducing Transportation Cost

Usually, postponing of the assembly process is carried out for shifting the point of

differentiation to a later stage. But there have also been cases where firms have used

the postponement strategy for delaying an operational process to a later point in the

supply chain in order to reduce transportation costs. Transportation cost is reduced in

the case of bulky finished products by shifting the assembly operations to the customer

end as transporting parts as kits is cheaper than transporting a finished product.

Postponement in Bicycle Industry

The bicycle industry in India belongs to a category of industries that traditionally

practices the postponement strategy. The reasons for this practice are as follows:

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

• To reduce transport complexities and costs. The bicycle manufacturers limit their

activities to production of frames, handle bars and transmission parts. Other suppliers

produce the tyres, tubes, seats and many extra fittings. A large number of bicycle

dealer’s stock products of all bicycle manufacturers. The bicycle purchasing process is

as follows: when the customer arrives at the bicycle shop, she/he opts for a particular

frame size offered by a particular bicycle manufacturer. Similarly, she/he will opt for a

particular tyre size, offered by a particular tyre manufacturer and so on. Given this

situation, it is imperative that the assembly of the final product is carried out at the

dealer point. Additionally, the entire assembly takes just 15–30 minutes.

• Less exposure to damage than when transported as fully assembled bicycles.

• Less need for shop space when material is stocked as components instead of as fully

assembled bicycles.

• Low-technology nature of the assembly operation, which ensures there are no

inconsistencies in product quality.

Though the bicycle industry has worked on the idea of postponement of assembly so as

to primarily reduce transportation cost, they can also take advantage of this strategy and

offer higher variety. The bicycle industry can design a modular-level variety and allow

customers to choose a combination of modules and the retailer can assemble the

bicycle, which is essentially configured to customer requirements. This facilitates the

bicycle industry’s transition to a mass-customization environment.

Problems with Implementing the Postponement Strategy

The examples cited above help in understanding the industrial and technological

characteristics that make the postponement strategy viable. In general, postponement

strategy is likely to be advantageous in the following situations:

• High level of product customization

• Existence of modularity in product design

• High uncertainty in demand

• Long transport lead time

• Short lead time of postponed operation

• Low value addition in transportation

• High value addition in postponed operation

• Difference in tariff rates for components and finished goods in different markets.

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

THE ROLE OF IT IN NETWORK DESIGN:

Even though it may seem at first glance that the strategic nature of the network design

problem makes information technology systems less valuable, good IT systems can

significantly improve the capability of a network designer. In this chapter, we discuss

a variety of methodologies in Excel that can be used to solve network design problems.

Even though the core models are the same, problems in practice tend to be much larger

than the problems considered in the chapter. For much larger problems, there are four

ways that an IT system can help with network design relative to the use of a general-

purpose tool such as Excel.

1. A good network design IT system makes the modeling of the network design

problems much easier than in a general-purpose tool such as Excel. These applications

have many built-in tools that facilitate an accurate description of a large supply chain

network and incorporate realistic features that would be time consuming and difficult

to build in Excel.

2. An IT system contains high-performance optimization technologies, which deliver a

high-quality solution for large problems in a reasonable amount of time. Although

Excel's solver can be upgraded, there are many cases in which the size and complexity

of the optimization require a more sophisticated system that a network design

application can provide.

3. A good network design application also allows for an analysis of various "what if"

scenarios. Given the uncertainty associated with forecasts, the ability to evaluate

network designs in a variety of scenarios is a very powerful tool for a designer. A

network designer may find it much more appropriate to select a design that gives very

good costs in many likely scenarios rather than a design that is optimal in one scenario

but very poor in another. The ease of modeling and speed of solution allows a good

network design application to facilitate what-if analysis to a far greater extent than a

general-purpose tool such as Excel.

4. Finally, network design applications are structured to interface easily with the

planning and operational software used by firms, which contain much of the actual data

required for network design. The ease of interfacing with the data source speeds up the

creation and solution of a network design model.

Network design applications are often quite inexpensive relative to the other uses of IT

we discuss. Network design applications, sometimes called supply chain strategy

modules, are often thrown in for free on top of the much more expensive planning and

Dept. of Mechanical Engineering, MITE

SCM Module 3 notes

execution modules. In fact, many companies have rights to these products without even

realizing it, as a result of past software purchases.

There are some caveats, however, to the use of IT systems in network design.

Network design decisions are strategic and involve many factors that are hard to

quantify.

When using a network design tool, it is easy to fall into the trap of allowing the

application to make the decision based only on aspects that are quantifiable. Important

factors such as culture, quality-of-life issues, and cost of coordination that are hard for

IT to handle can be significant in making a network design decision. Thus, relevant non

quantifiable factors should be included with the output of IT systems when making

network design decisions.

Dept. of Mechanical Engineering, MITE

You might also like

- SIXSupply Chain CoordinationNOTES Synthese 1Document59 pagesSIXSupply Chain CoordinationNOTES Synthese 1Arnaud LiegeoisNo ratings yet

- FinalAssignmentDocument5 pagesFinalAssignmentAB BANo ratings yet

- Simchi Levi3E SMDocument56 pagesSimchi Levi3E SMKhang HuynhNo ratings yet

- Indroduction To Supply Chain 1Document38 pagesIndroduction To Supply Chain 1Tansen John100% (2)

- Supply Management NewDocument4 pagesSupply Management NewMurugan SaravananNo ratings yet

- Samples Solution Manual Designing and Managing The Supply Chain 3rd Edition by David Simchi Levi SLM1060Document11 pagesSamples Solution Manual Designing and Managing The Supply Chain 3rd Edition by David Simchi Levi SLM1060mathimurugan n0% (1)

- ManualDocument41 pagesManualTuan Bình0% (2)

- Oscm Module - IvDocument10 pagesOscm Module - IvRadha Krishna - with youNo ratings yet

- Forecasting Midterm Lectures 2019Document60 pagesForecasting Midterm Lectures 2019Rommel JunioNo ratings yet

- Bull-Whip Effect: A Critical Analysis ofDocument15 pagesBull-Whip Effect: A Critical Analysis ofHarsh ShahNo ratings yet

- Evolution of Supply ChainDocument34 pagesEvolution of Supply ChainpavonineNo ratings yet

- Solution Manual For Designing and Managing The Supply Chain 3rd Edition by David Simchi LeviDocument56 pagesSolution Manual For Designing and Managing The Supply Chain 3rd Edition by David Simchi LeviOmnia MustafaNo ratings yet

- Research Paper On Supply Chain ManagementDocument6 pagesResearch Paper On Supply Chain Managementp0zikiwyfyb2100% (1)

- Origin of Supply Chain ManagementDocument4 pagesOrigin of Supply Chain ManagementMurugan SaravananNo ratings yet

- Lecture NotesDocument37 pagesLecture NotesGangadhar MamadapurNo ratings yet

- Lecture Notes For Supply Chain Management MGT 561-Must Be Read in Collaboration With Text BookDocument36 pagesLecture Notes For Supply Chain Management MGT 561-Must Be Read in Collaboration With Text BookGurunathan MariayyahNo ratings yet

- Supply Chain MnagementDocument5 pagesSupply Chain MnagementDanish AhsanNo ratings yet

- Bull Whip EffectDocument5 pagesBull Whip EffectNandhini RamanathanNo ratings yet

- 1.1 What Is A Supply Chain?Document5 pages1.1 What Is A Supply Chain?chitraNo ratings yet

- SCM With ExamplesDocument23 pagesSCM With ExamplesPRADIP BANERJEENo ratings yet

- Student Name: Eyasu Araya ID Number: MBA/4515/19 Section A Year 1, Semester 2Document7 pagesStudent Name: Eyasu Araya ID Number: MBA/4515/19 Section A Year 1, Semester 2Kalayou TekleNo ratings yet

- Supply Hub ResearchDocument30 pagesSupply Hub Researchharsh gNo ratings yet

- PostponementDocument21 pagesPostponementashu_scribd007No ratings yet

- Supply Chain MGTDocument16 pagesSupply Chain MGTzakuan79No ratings yet

- Midterm NotesDocument5 pagesMidterm NotesGupta KiraNo ratings yet

- The Executive's Guide Supply Chain ManagementDocument13 pagesThe Executive's Guide Supply Chain ManagementBidyut Bhusan PandaNo ratings yet

- UNIT 2 - What Is The Right Supply Chain For Your ProductDocument5 pagesUNIT 2 - What Is The Right Supply Chain For Your Producthalam29051997No ratings yet

- Supply Chain Executive SummaryDocument6 pagesSupply Chain Executive Summarya3san100% (6)

- Supply Chain Management Homework 1 ToDocument51 pagesSupply Chain Management Homework 1 ToTan NguyenNo ratings yet

- Supply Chain ManagementDocument9 pagesSupply Chain ManagementRupesh SinghNo ratings yet

- Postponement Teaching NoteDocument20 pagesPostponement Teaching NoteZakiah Abu KasimNo ratings yet

- Chopra and Meindl-Chapter 10Document4 pagesChopra and Meindl-Chapter 10Abc AnalysisNo ratings yet

- SCM - Subhradeep HazraDocument22 pagesSCM - Subhradeep HazraSubhradeep HazraNo ratings yet

- Lecture Notes: Long Lead Times Customer ExpectationsDocument19 pagesLecture Notes: Long Lead Times Customer ExpectationsEmad RashidNo ratings yet

- Supply Chain ManagementDocument20 pagesSupply Chain ManagementŞermin ŞahinNo ratings yet

- SCM - Question and AnswersDocument7 pagesSCM - Question and Answersdr jaimanNo ratings yet

- Barriers To Implementing Flow ManagementDocument12 pagesBarriers To Implementing Flow ManagementRahul YadavNo ratings yet

- Important Question and AnswersDocument7 pagesImportant Question and Answersshamal0392% (25)

- CPFR Value by YossiDocument15 pagesCPFR Value by YossiSaurabh JainNo ratings yet

- Article 1 - What Is The Right Supply Chain For Your ProductDocument15 pagesArticle 1 - What Is The Right Supply Chain For Your ProductEmile JanssensNo ratings yet

- Inventory Management ProjectDocument89 pagesInventory Management ProjectVinay Singh100% (1)

- What Is Bullwhip Effect EditedddDocument11 pagesWhat Is Bullwhip Effect EditedddEdlawit AwegchewNo ratings yet

- HW - Chapter 4Document7 pagesHW - Chapter 4Yến NhưNo ratings yet

- Discussion QA 9to17Document56 pagesDiscussion QA 9to17April Reynolds100% (16)

- Supply Chain ManagementDocument29 pagesSupply Chain ManagementShamNo ratings yet

- Project Report On Inventory ManagementDocument58 pagesProject Report On Inventory ManagementMujif Rahuman80% (5)

- Bullwhip EffectDocument35 pagesBullwhip EffectKrishnaditya Singh Rathore100% (1)

- Discussion ch09Document3 pagesDiscussion ch09Umar HarizNo ratings yet

- UNIT 2 - What Is The Right Supply Chain For Your ProductDocument9 pagesUNIT 2 - What Is The Right Supply Chain For Your ProductHuỳnh Thanh TuyềnNo ratings yet

- SCM Test 3 Q&ADocument9 pagesSCM Test 3 Q&AnarinebalasubramaniNo ratings yet

- Jacobs2ce ISM Ch13Document11 pagesJacobs2ce ISM Ch13Fernando D'OriaNo ratings yet

- How to Optimise Your Supply Chain to Make Your Firm Competitive!From EverandHow to Optimise Your Supply Chain to Make Your Firm Competitive!Rating: 1 out of 5 stars1/5 (1)

- The Strategy Machine (Review and Analysis of Downes' Book)From EverandThe Strategy Machine (Review and Analysis of Downes' Book)No ratings yet

- An Introduction to Global Supply Chain Management: What Every Manager Needs to UnderstandFrom EverandAn Introduction to Global Supply Chain Management: What Every Manager Needs to UnderstandNo ratings yet

- Operations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationFrom EverandOperations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationNo ratings yet

- Kanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryFrom EverandKanban the Toyota Way: An Inventory Buffering System to Eliminate InventoryRating: 5 out of 5 stars5/5 (1)

- Lean-based Production Management: Practical Lean ManufacturingFrom EverandLean-based Production Management: Practical Lean ManufacturingNo ratings yet

- Value Nets (Review and Analysis of Bovet and Martha's Book)From EverandValue Nets (Review and Analysis of Bovet and Martha's Book)No ratings yet

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesFrom EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesRating: 4.5 out of 5 stars4.5/5 (3)

- Robbery and Hold-Up CountermeasuresDocument10 pagesRobbery and Hold-Up CountermeasuresMildred B. Austria100% (2)

- Tugas DMD GROUP 01Document8 pagesTugas DMD GROUP 01ulviqhj354No ratings yet

- Cot 2Document9 pagesCot 2Wowie J CruzatNo ratings yet

- KIFHP - CARE - First Interim Narrative ReportDocument39 pagesKIFHP - CARE - First Interim Narrative ReportEliNo ratings yet

- Chapter 1 - Business Driven TechnologyDocument3 pagesChapter 1 - Business Driven TechnologyMary LisaNo ratings yet

- 2023 WARN Notice ListingsDocument15 pages2023 WARN Notice ListingsMasonNo ratings yet

- The Apotheosis of Ownership' - Why NFTs Will Drive The Digital EconomyDocument8 pagesThe Apotheosis of Ownership' - Why NFTs Will Drive The Digital EconomyBaggyNo ratings yet

- BMI FormulasDocument2 pagesBMI Formulasbarb201No ratings yet

- Vanicek Et Al CGG 42 1 Geoid&QuasiGeoidDocument17 pagesVanicek Et Al CGG 42 1 Geoid&QuasiGeoidLeni HelianiNo ratings yet

- Companion Study Guide: 15 LessonsDocument124 pagesCompanion Study Guide: 15 LessonsLuisk MaldonadoNo ratings yet

- Las - 9-12Document11 pagesLas - 9-12maria teresa aparreNo ratings yet

- SIEPAN 8PU Low Voltage Switchboards Technology by SiemensDocument4 pagesSIEPAN 8PU Low Voltage Switchboards Technology by SiemensaayushNo ratings yet

- In The Garden of Beasts by Erik Larson - Reading Group GuideDocument9 pagesIn The Garden of Beasts by Erik Larson - Reading Group GuideCrown Publishing Group100% (1)

- L-B-R-P For Psychic Self DefenceDocument2 pagesL-B-R-P For Psychic Self DefenceTemple of the starsNo ratings yet

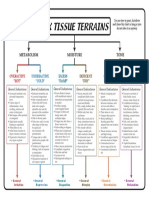

- 6 Tissue Terrains ColorDocument1 page6 Tissue Terrains Colorஆ.க.கோ. இராஜேஷ்வரக் கோன்No ratings yet

- Chowdhury Fatima Rokon Tuli Former Manager Training & Development. Mobile:880-01615769895 Website: Address:483/1, Shewrapara, Mirpur, Dhaka-1216Document4 pagesChowdhury Fatima Rokon Tuli Former Manager Training & Development. Mobile:880-01615769895 Website: Address:483/1, Shewrapara, Mirpur, Dhaka-1216Rabiul AwalNo ratings yet

- ACSFCover Letter ExampleDocument2 pagesACSFCover Letter ExampleDarkwinger 1430No ratings yet

- Casals Song of The BirdsDocument4 pagesCasals Song of The BirdsHiroka MatsumotoNo ratings yet

- Sas Open Source Integration 112134Document21 pagesSas Open Source Integration 112134PapasimaNo ratings yet

- Anatomy Final All Questions (New)Document175 pagesAnatomy Final All Questions (New)Sevval OzcelikNo ratings yet

- Creative Safety Supply: 2011 CATALOGDocument36 pagesCreative Safety Supply: 2011 CATALOGwajibhai99No ratings yet

- PEOPLE Vs Rodolfo DiazDocument9 pagesPEOPLE Vs Rodolfo DiazRaymondNo ratings yet

- Zenith Aircraft Stol CH 701: Wing Spar Wing Spar Main Gear StiffenerDocument16 pagesZenith Aircraft Stol CH 701: Wing Spar Wing Spar Main Gear StiffenerSteven100% (1)

- Finance Notes at Mba FinanceDocument40 pagesFinance Notes at Mba FinanceBabasab Patil (Karrisatte)No ratings yet

- Kaitlyn Duron ResumeDocument2 pagesKaitlyn Duron Resumeapi-453866596No ratings yet

- Jimmy Lim 2Document33 pagesJimmy Lim 2Ramsraj100% (1)

- STT Tecnica QuirúrgicaDocument5 pagesSTT Tecnica QuirúrgicaNathaly GuevaraNo ratings yet

- The Invention of The Internet Connecting The WorldDocument14 pagesThe Invention of The Internet Connecting The WorldSolomia Sushko100% (1)

- Practice Session Vol 1 - Legato Timing Amp Amp TiDocument12 pagesPractice Session Vol 1 - Legato Timing Amp Amp TiHarsh ShandilyaNo ratings yet

- IELTS Writing Task 2 Essay SamplesDocument20 pagesIELTS Writing Task 2 Essay Samples27. Minh PhươngNo ratings yet