Professional Documents

Culture Documents

PWM Economaki Square

Uploaded by

Yamil PaladinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWM Economaki Square

Uploaded by

Yamil PaladinoCopyright:

Available Formats

Clever Folding Tables for Your Patio or Shop

OCTOBER 2011 ■ #192

Tantalizing

Try Square

Build the Tool that

Built Bridge City

Rocker Science:

Design Methods

For a Perfect Fit

Simple Hall Bench

Is a Snap to Build

Split Your Own:

The Best Oak

Money Can’t Buy

Federal Period

Diamond Banding

With Router & Jig

US $5.99

10

Free Video Visit with a Toolmaking Class: Visit popularwoodworking.com/oct11

cnVlZ2VyAE0RxSIEMTAuNAI4MAExBVVQ

JUYrVyBQdWJsaWNhdGlvbnMsIEluYyAo

SW9sYSBkaXZpc2lvbikPR3JlZ29yeSBL

Qy1BDDA3NDQ3MDAxMzU1NgA=

0 74470 01355 6

FnL1

01

02

03

04 04 0120

Display until October 17, 2011

popularwoodworking.com

~1110_PWM_c1_Cover_US.indd C1 7/13/11 10:35:03 AM

Try for Your Best Work

BY JOHN ECONOMAKI

Make the square that

launched Bridge City

with tools found

in most home shops.

F

rom 1977-1983 I made my living

as a studio furniture designer and

maker. In addition to making fur-

niture, I found most of the hand tools

available at the time so uninspiring and

inconsistent with the craftsmanship

values I was trying to impart in my fur-

niture, that I made my own.

The roots of my personal “home-

made” try square, however, go back to

the fall of 1973 and my fi rst days as a

rookie woodshop teacher. Amongst the

supplies ordered by my predecessor

were a dozen Stanley try squares. Sev-

eral of them were so visibly off I remem-

ber asking myself, “What do you call a

square that is not square?” The answer

I like best today: paint can opener.

Consequently, the first project for my

9th-grade students was pragmatic – they Student work. These beautiful try squares were made by John Economaki’s tool-making class at

were to make their own try squares. The the Marc Adams School of Woodworking.

design was centered on available materi-

als – a local veneer mill had donated all

its solid Brazilian rosewood shorts to Later in the fall, a vice principal asked Nobody could believe such quality and

the school, and the adjacent metal shop me if we had any projects to represent beauty could be accomplished in a “shop

had brass strips sitting around. So those the Industrial Arts program for Back- class.” It was an awesome experience

became the materials for the square. The to-School-Night. I asked for a student for the kids and enrollment in the pro-

design was quickly revealed as flawed; volunteer and about 20 students enthu- gram took off overnight. Quality work

too many students were splitting the siastically responded with polished try became the theme of all subsequent

handles while seating the rivets. My squares. We arranged them in an arc on projects.

original design was modified to add a a glass shelf in the display case in the

brass rivet seat, and that did the trick. main hall. Beside each square was the

Little did I know that 10 years later, in maker’s name.

1983, that exact square would launch a That little display completely “Everything’s a kit.”

new company named Bridge City Tool gobsmacked the parents, students, most — Michael Burns, instructor

Works. of the faculty and the administrators. College of the Redwoods

28 ■ POPULAR WOODWORKING MAGAZINE October 2011 LEAD PHOTO BY AL PARRISH (TOOLS MADE BY BOB KING, DANTE DIIANNI, MASOOD GARAHI,

BOB KINK & SAM PRATHER); STEP PHOTOS BY AJAX ALEXANDRE; ILLUSTRATION BY ROBERT W. LANG

1110_PWM_28-33_TrySquare.indd 28 7/21/11 3:44:54 PM

Teacher, Maker, Toolmaker of the major mail-order companies at able to share how to make it with you.

I quit my teaching job in 1978 and the time were adamant that Ameri- During the past four decades we have

became a full-time furniture designer cans would not pay for quality. Conse- produced tens of thousands of TS-2

and maker. In the late 1970s I had a quently, the TS-2 Master Try Square and try squares and it is my hope you can

“lunch hunch” that a couple of the tools the SA-2 Scratch Awl were introduced find the time and inspiration to cre-

I had designed and made would be of to the woodworking community in the ate a version for your shop. I believe it

interest to others – visitors to my shop November/December 1983 issue of Fine is one of the most rewarding weekend

almost always commented on them. So, Woodworking. I had spent every penny projects you will ever make and with a

in the summer months when my shop in the bank on that ad to find out that little care, will become an heirloom that

was unbearably hot, I would do small the mail-order companies were only will inspire future woodworkers in your

runs of my try square and a scratch awl, partly correct. family for multiple generations.

and place them on consignment at the There is an elegance and soul to the

Contemporary Crafts Gallery in Port- TS-2 try square, and I am thrilled to be Design Philosophy

land, Ore. It was nice to get a check in A try square is a simple tool that is can-

the mail every now and then. didly two “straight edges” affixed at 90°

Unfortunately, I took better care of to each other. And when both compo-

my tools than I did of my body. I rarely nents are parallel, both the inside sur-

wore a dust mask, and in early 1983 I faces of the square and the outside edges

woke up with double pneumonia and can be used as references. In addition,

was informed that it was caused by a the inside square and the outside square

hyper-allergic reaction to wood dust. are perfectly offset from each other,

My days as a furniture maker were over which means you can use the inside of

– as in overnight. the handle as a reference and scribe a

I thought high-quality tools might line using either the inside or outside

be of interest to woodworkers but all of the blade. Few woodworkers under-

stand that a traditional wooden-handled

try square (where just the inside face of

the handle is brass) is an inside square

only. You use the outside square at your

own risk.

EXPLODED VIEW

1 Rout the groove. After the handle stock

is prepped to 1.5" wide x .625" thick,

rout the .0625"-deep rivet seat grooves on the

router table using a 1⁄4" straight bit. (Toolmak-

ers always work in decimal inches.)

4 Two at a time. Note the orientation of

the brass wear face and the rivet seats in

this image. It is difficult to find 1⁄16" x 1⁄4" 360

brass, but 1⁄4" x 1⁄4" is readily available. This

can be beneficial when making more than one

handle at a time. Multiple handles can share a

length of 1⁄4" x 1⁄4" brass and be separated on

a band saw with a metal-cutting blade. After

3 Glue in the brass. Rosewoods need to

be wiped with acetone to remove the

surface oils. Contact cement is a good first-

sawing, both faces of the handle need to be

flush sanded on either a horizontal or vertical

belt sander – #120 grit is ideal. Never allow

2 Clean before glue. Using a maroon

Scotch-Brite pad, clean all brass surfaces

of tarnish – the material should be shiny prior

choice adhesive if the components need to be

separated. In addition to the rivet seat, adhere

one brass wear strip (.0625" x 1") to the face

the brass to get too hot to the touch. Handles

can also be flattened by drawfiling with a mill

file. The square’s second wear face will be

to applying adhesive. farthest from the rivet seat grooves. attached after the handle is slotted.

popularwoodworking.com ■ 29

1110_PWM_28-33_TrySquare.indd 29 7/13/11 2:02:46 PM

Over the years I have been involved Consider this: Most of the tools in Materials

in many discussions about what makes your workshop sit and do nothing most The TS-2 looks and works best when

a “great tool.” On one hand you have of the time. I believe there is another made with a dark, stable (dry) wood.

proponents who lament that any effort function for these “do nothing” tools Most of the dark rosewoods look great

(read cost) that does not contribute to (besides the obvious) that is equally with brass because the subtle reds in the

the obvious function is waste at best, important. That function is to inspire. wood and brass work together to create

and arrogance at worst. While they are sitting and doing noth- a rich, visual harmony. Whatever wood

ing, tools can inspire you to give your you select, imagine it photographed

best effort 100 percent of the time. in black and white alongside brass. If

This is accomplished by their beauty, the tonal ranges are close, the contrast

craftsmanship and soul – making it dif- will not be significant enough to create

ficult for you to justify quick or shabby visual interest.

work. The caveat to using exotics is that it

In short, quality is contagious. is rare to find them dried – the volume

6 Slot the handle.

Using a table

saw sled with a tenon

attachment, slot the

handle. The kerf of

the sawblade must

be thinner than your

square blade. Avoid

overcutting or under-

cutting the slot. If the

blade fits loose, your

square won’t last. If it’s

too tight, you won’t be

able to seat the blade.

5 Trim the handle. Use a non-ferrous

blade to trim the ends square to a final

length of 4.75."

8 Drill. Screw. Sand. Lay out the screw

holes using the exploded image on page

29 as your pattern. Carefully drill the shank

holes to the proper depth (not too deep!),

drill the pilot holes, and carefully countersink

7 The other wear face. After slotting,

attach the other .0625" brass wear plate.

Remove the overhanging brass with the band

(single-flute countersinks do not chatter) each

hole so the screw heads seat proud; they will

be dressed flush on a stationary belt sander. 9 Parallel & identical. After flush sanding,

both faces should look like this. Now,

saw and flush sand both faces. When the Use the bottom of an aerosol can to lay out a the square edges need to be paralleled by

glue is dry, the large faces of the brass blade crown on both ends. Sand to the crown line hand on a flat surface. Using a caliper, mea-

are grained by “going through the grits” (#80 using a belt sander, or by hand with a file. sure across the brass wear plates and both

through #400 followed by a maroon Scotch- Once it’s shaped, go through the grits and pol- ends should have identical measurements.

Brite pad), using a wooden sanding block – ish the ends but make sure to keep the hard Once the edges are parallel, ensure the faces

graining is along the length. line between the faces and ends crisp. are flat.

30 ■ POPULAR WOODWORKING MAGAZINE October 2011

1110_PWM_28-33_TrySquare.indd 30 7/13/11 2:03:02 PM

produced is so low that nobody has a rod and the brass rivets are cut from to be wide enough to avoid a top-heavy

reliable kiln schedule. Over the years 3 ⁄16" brass round stock. and unstable square.

we had all of our rosewoods dried in The width of the handle deter-

vacuum kilns to a moisture content of Proportions mines the amount of surface area that

less than 8 percent. Ebonized woods Try square proportions are a big deal to is exposed to the blade for joinery pur-

would be a great alternative to exotics. avoid looking awkward or “gangly.” All poses as well as the gripping surfaces.

If you are going to make this tool, the of the major dimensions of Bridge City Too narrow and the joint integrity is at

most important step you can take is to squares have conformed to the Golden risk; too large and the square looks awk-

make sure your material is in the range Mean, or a 1:1.618 ratio. The TS-2, when ward. We recommend that the handle

of 6- to 8-percent moisture content. made correctly, should fit precisely in a width be equal to the blade width plus

There are generally two types of box with inside dimensions of 8" x 5". or minus 10 percent.

brass alloy readily available that are The other proportional dimensions Lastly, you will want the blade to

commonly referred to as 260 and 360 that are important include the width protrude about .250" from the top of

brass. In its half-hard condition, 260 and thickness of the handle in relation the handle. (FYI: Toolmakers always

brass has a machinability rating of 30 to the blade. Because the TS-2 can be work in decimal inches – good calipers

compared to 360 brass, which is rated used as either an inside or outside ref- are a must.)

at 100. Consequently, when you pur- erence, it must be able to sit on a flat

chase brass for the TS-2 Try Square, surface with the blade vertical. When Construction Considerations

specify 360 half-hard, or “free machin- used this way, the handle becomes a Working with brass is not difficult – it

ing” brass stock. base for the blade and therefore needs can be thought of as a really hard, grain-

There are two brass rivets and four less wood. It can be sawn on a table saw,

steel rivets used in making the TS-2. miter saw or radial-arm saw equipped

The steel rivets are cut from 1 ⁄ 8" drill

10 Dress the blade. Remove the factory

tarnish and scale by sanding through

all grits (from #80 to #400 – don’t skip any –

then a maroon Scotch-Brite pad). Beginning

.375" from the blade’s top edge, file a bevel to

the opposite edge ultimately removing .0625"

11 Just a dab. All it takes is two small

drops of slow-setting (30 seconds)

cyanoacrylate per slot face. Wipe off excess

from the blade’s bottom. This taper is a glue

pocket that prevents adhesive from squirting

out of the square slot during assembly.

with a rag. Rubber gloves are a must, unless

you enjoy having a partially assembled try

square stuck to your hand.

12 And slide them together. Carefully

insert the blade working the adhesive

down and back.

13 Out of whack. Here you can clearly see the square is obtuse

– there are about 15 seconds left to adjust.

14

the trick.

Taps fix it. This block of wood in a vise is great way to persuade

the blade to where it belongs. A couple light taps usually does

popularwoodworking.com ■ 31

1110_PWM_28-33_TrySquare.indd 31 7/13/11 2:03:16 PM

with a triple-chip blade or any blade be coated – and when they are no lon- steel and brass in this case, simultane-

that is designed for non-ferrous metals. ger tacky, pressed together. The main ously generates substantial heat. Both

Safety glasses are a must, and I highly advantage of contact cement is that if the rivet seats and the wear plates are

recommend a face shield. Other ways the project takes an unexpected turn mechanically bonded to the wooden

of cutting brass include metal-cutting south, the material can be removed and handle. As these metal surfaces get hot

band saws, reciprocating saws and, of replaced without damaging the wood they expand between the anchor points

course, a hacksaw. I also strongly rec- substrate. and away from the wooden handle. If

ommend a zero-clearance throat plate Mechanical bonds are not limited to you are not extremely careful, you will

for the table saw or the less expensive fasteners. If you have access to a mill- ruin the handle blank.

alternative, a false table slotted in 1 ⁄8"- ing machine, the brass and wood can

thick hardboard, such as Masonite. be dovetailed together – it is not an easy Squaring the Blade to the Handle

It is always best to attach brass to joint but it looks great. The blade is affixed to the handle with

wood with both a chemical (adhesive) The beauty of the TS-2 is in the per- a slow-setting cyanoacrylate adhesive

and a mechanical bond. In making the fect flush surfaces of the steel, brass and when dry, four rivets are inserted

TS-2 we will use both adhesives and and wood. Whenever you have mul- for shock protection.

brass wood screws. Exotic woods tend tiple materials with disparate hardness, But first you need a reference for 90°,

to be oily so you will want to wipe the the only way to flush them is with abra- and this is easier than you might imag-

surfaces to be glued with acetone prior sives. This can be done by draw filing ine. In the home shop, you can create

to applying an adhesive. Any quality with a mill fi le, or using a stationary a 90° reference by using the “flip-flop

contact cement will work great – both belt sander – the latter is not without method” of crosscutting stock with par-

the wood and brass surfaces need to considerable risk. allel edges. Take your stock and crosscut

Power-sanding metal, such as the it in half. Flip one half, and with both

Supplies

1 u handle blank, wood of your choice,

L = 6", W = 1.5", T = .75"; edges and

faces parallel to each other, all

corners and ends square

1 u blade, 360 brass bar, 1⁄8" x 11⁄2",

L = 7.9385" (715⁄16")

2 u wear faces, 360 brass bar,

1⁄16" x 1", L = 6"

2 u rivet seats: 360 brass bar, 1⁄16" x

1⁄4", L = 6"

2 u brass rivets: 360 brass round, 3⁄16"

diameter x 1"

4 u steel rivets: drill rod, 1⁄8" diameter

12 u brass wood screws, #4 x 3⁄8"

Phillips (McMaster-Carr

#92114A108) 15

mallet.

Another adjustment. Oops! Went

too far … a couple taps with a rubber 16 Victory. The square is now light-tight

to the reference.

u non-ferrous table saw blade, or chop

saw blade with a kerf less than 0.120"

u ball-peen hammer

u center punch

u scratch awl/marking knife

u drill press or drilling jig

u mill file

u cyanoacrylate adhesive (slow set)

u contact cement

u #120-, #180-, #220-,#320- and #400-

grit abrasive paper

u Scotch-Brite pad (maroon)

u

u

paste wax

82° countersink (chatter free)

17 Ready to rivet. Once the blade is

seated lay out the five rivet holes: four

1 ⁄ 8" holes in the rivet seat and one 3 ⁄ 16" rivet. 18 Only slightly proud. The rivets

should be only .0625" longer than

u safety glasses and face shield Mark with a center punch (don’t punch too the handle thickness. Insert rivets into the

hard) and drill on a drill press. holes as shown.

32 ■ POPULAR WOODWORKING MAGAZINE October 2011

1110_PWM_28-33_TrySquare.indd 32 7/13/11 2:03:29 PM

pieces resting against a known straight all are different thicknesses. We used Last, both the blade and the handle

edge, the “gap” between the ends is twice the KM-1 Kerfmaker on a sliding table need to have dead-parallel edges. This

the error of your cut. Adjust until the with a tenon jig to cut the slots. They can be done by hand by carefully sand-

cuts “click” together and you will have all came out spot on. The alternative is ing on a flat surface (glass or machine

a reference that is plenty accurate for an to creep up on the final dimension with top). It is possible to get them within

8" try square. In my toolmaking classes multiple cuts. All it takes is a little slip .001" or better with this method. A good

we set the blades against a machinist and the square’s blade will be too loose pair of calipers is needed for this step.

90° angle plate to save time. to remain attached to the handle over

time. Too tight and you will never be Summary

Caveats able to adjust the blade to 90° before For almost 40 years this try square has

There are a couple caveats in making the adhesive sets. (If this happens, use been a pure joy in my life. It is one of the

this square that, if ignored, will ruin a rubber mallet to break the blade free most popular tools we have ever made

the project. First is the slotting of the and start again.) and it will be a trusty and faithful addi-

blade. In my toolmaking classes each The 82° countersinks need to be tion to your shop. When not in use, put it

blade is hand-dressed. Consequently, dead on. Too deep and there will be a in a place where you can see it – or more

ring around each screw head. Too shal- accurately, where it can see you. I assure

low and you will sand away the Phillips you, repeating 9th grade will never be

recess. Here is where a little practice more fun nor more rewarding. PWM

pays big visual dividends.

John is the founder of Bridge City Tool Works and

teaches classes in toolmaking, design and creativity.

19 Tap the rivets. Use a ball-peen ham-

mer and seven to 10 taps (the weight 20 Tap the other side. Flip the handle

and repeat the previous step. You

of the hammer is sufficient – save your effort

for the gym). All you are trying to do here is

slightly flare the top of the rivet.

should see no gaps between the rivet and the

hole, nor should the rivets move. Do not use

too much force – you can split the handle.

21 Brass rivet. Use the same steps for

the 3 ⁄16" rivet. These rivets provide

shock protection if the square is dropped.

u Go Online FOR MORE …

For links to all these online extras, go to:

u popularwoodworking.com/oct11

VIDEO: Watch a short clip of John teach-

ing a toolmaking class.

BLOG: Read John’s funny blog about

furniture design and making tools.

WEB SITE: Bridge City Tool Works, John’s

day job.

TO BUY: “Tool Making for Woodwork-

ers” by Ray Larsen.

22 Flushed. Carefully flush sand the

rivets on a stationary sander. (I

23 Final sanding. Once the rivets are

flush, hand sand through the grits

all the way up to #400. Take a couple strokes

IN OUR STORE: “Metalwork for Crafts-

men” by Emil F. Kronquist.

prefer a horizontal sander for this step but an on the corners to remove burrs. The handle Our products are available online at:

edge sander was all I had available for this should not feel sharp on the corners. Use a uShopWoodworking.com

build.) Do not let the brass get too hot – it has maroon Scotch-Brite pad on all surfaces and

nowhere to go but into the sanding belt. finish with a high-quality paste wax.

popularwoodworking.com ■ 33

1110_PWM_28-33_TrySquare.indd 33 7/13/11 2:03:41 PM

You might also like

- Splay-Legged Table: A Project Plan For Building A Simple Splay-Legged Table With Refined FlairDocument7 pagesSplay-Legged Table: A Project Plan For Building A Simple Splay-Legged Table With Refined FlairGustavo ApellidoNo ratings yet

- English Layout SquareDocument2 pagesEnglish Layout Squarev00d00bluesNo ratings yet

- Woodcademy Folding Router Table Plans R2Document45 pagesWoodcademy Folding Router Table Plans R2Yamil PaladinoNo ratings yet

- Moreww 2007 03-04 PDFDocument32 pagesMoreww 2007 03-04 PDFlhernandezmNo ratings yet

- Portable Miter Saw StationDocument17 pagesPortable Miter Saw StationCarlos CostaNo ratings yet

- FW1124 SideTable PDFDocument7 pagesFW1124 SideTable PDFMitch Arch100% (1)

- WOODWORKING GUIDE - Sharpening ToolsDocument4 pagesWOODWORKING GUIDE - Sharpening ToolsJd DiazNo ratings yet

- Popular Woodworking 2009-12 No. 180Document59 pagesPopular Woodworking 2009-12 No. 180Miguel A. Ramirez100% (1)

- 2022 Eagle Claw Catalog 2022-WebDocument107 pages2022 Eagle Claw Catalog 2022-WebJorge Alberto Perez LopezNo ratings yet

- Chip Carving: The Top Online Handbook: Find The Best Wood Carving Tools, Guides, Tutorials, and More!Document10 pagesChip Carving: The Top Online Handbook: Find The Best Wood Carving Tools, Guides, Tutorials, and More!pitbullNo ratings yet

- GRABBE, Lester L. & BELLIS, Alice O., Eds. (2004), The Priests in The Prophets... JSOTSS 408, London-NY, T&T ClarkDocument243 pagesGRABBE, Lester L. & BELLIS, Alice O., Eds. (2004), The Priests in The Prophets... JSOTSS 408, London-NY, T&T ClarkYamil Paladino100% (1)

- Basic Scribing TechniquesDocument6 pagesBasic Scribing TechniquesLen S100% (1)

- Stone Fox BookletDocument19 pagesStone Fox Bookletapi-220567377100% (3)

- Spoon Carving - by Peter FollansbeeDocument4 pagesSpoon Carving - by Peter FollansbeeAlan SouzaNo ratings yet

- 1990 1 JanFebDocument25 pages1990 1 JanFebRocio Mtz100% (1)

- Golden Ratio CalipersDocument4 pagesGolden Ratio CalipersFrancois VaaltynNo ratings yet

- Hide Glue: A Closer LookDocument5 pagesHide Glue: A Closer Lookfernangd100% (1)

- Sash PlanesDocument5 pagesSash PlanesBlakdawg15100% (1)

- Popular Woodworking - 017 - 1984 PDFDocument52 pagesPopular Woodworking - 017 - 1984 PDFKawchhar Ahammed100% (1)

- Free Plan Small CabinetDocument9 pagesFree Plan Small CabinetAlexandre R. PeixotoNo ratings yet

- Router BitDocument44 pagesRouter Bitsunrise designNo ratings yet

- Popular Woodworking No 103 July 1998Document84 pagesPopular Woodworking No 103 July 1998EliseuJoséDosSantosNo ratings yet

- The Art of Woodworking-Wood FinishingDocument148 pagesThe Art of Woodworking-Wood FinishingMirko AleksicNo ratings yet

- Tabletop ArtistryDocument5 pagesTabletop ArtistrysossieNo ratings yet

- Woodcraft Magazine - Issue 112Document68 pagesWoodcraft Magazine - Issue 112Gary TanNo ratings yet

- Comfort in A Morris Chair: Craftsman-StyleDocument5 pagesComfort in A Morris Chair: Craftsman-Stylegromov.kirill1No ratings yet

- The Shel L Game: Ti Ps For Ca Rvi NG A Classic Newpo RT Shel LDocument4 pagesThe Shel L Game: Ti Ps For Ca Rvi NG A Classic Newpo RT Shel LTAANGTAWAN007No ratings yet

- Shut The Box Diy PlanDocument4 pagesShut The Box Diy Planjofoeus100% (1)

- Gilbert Erector Set GuidebookDocument72 pagesGilbert Erector Set Guidebookdomingojs233710No ratings yet

- German Ring TurningDocument7 pagesGerman Ring TurningInform7105No ratings yet

- Late Summer 2014Document24 pagesLate Summer 2014flanker_13No ratings yet

- Basics of Softwood SawmillingDocument4 pagesBasics of Softwood SawmillingChuck Achberger100% (1)

- 94 Shooting-BoardDocument6 pages94 Shooting-Boardbjørn vidar andersenNo ratings yet

- Computer Desk - 002pdfDocument12 pagesComputer Desk - 002pdfShahin R KrishnaNo ratings yet

- FW1124 - Rodriguez Tilt Top Table PDFDocument9 pagesFW1124 - Rodriguez Tilt Top Table PDFbarbara100% (1)

- Popular Woodworking - 014 - 1983 PDFDocument44 pagesPopular Woodworking - 014 - 1983 PDFKawchhar AhammedNo ratings yet

- Benchcrafted Moxon ViseDocument12 pagesBenchcrafted Moxon VisexlotoxNo ratings yet

- For Woodworking Lovers Issue 2Document24 pagesFor Woodworking Lovers Issue 2For Woodworking LoversNo ratings yet

- Katherine Keesling - The Votive Statues of The Athenian Acropolis - (2003, Camb)Document302 pagesKatherine Keesling - The Votive Statues of The Athenian Acropolis - (2003, Camb)vadimkoponevmail.ru100% (2)

- An Introduction To Insurance AccountingDocument86 pagesAn Introduction To Insurance AccountingTricia PrincipeNo ratings yet

- ArtofWoodworking WorkbenchDocument4 pagesArtofWoodworking Workbenchsalulai100% (1)

- Threading OptionsDocument3 pagesThreading Optionsapi-522254901No ratings yet

- Arts & CraftsDocument29 pagesArts & CraftsMary Charisse SandroNo ratings yet

- American Woodworker 143Document58 pagesAmerican Woodworker 143nocturnusNo ratings yet

- In The Lap of Luxury: WoodshopDocument60 pagesIn The Lap of Luxury: WoodshopGeorge Vlad AndronicNo ratings yet

- Wall Chart - Drying - How Wood Loses MoistureDocument1 pageWall Chart - Drying - How Wood Loses MoistureXihuitl61100% (1)

- Collection: Dining & Bedroom FurnitureDocument28 pagesCollection: Dining & Bedroom FurniturenmclaughNo ratings yet

- Popular Woodworking - 012 - 1983 PDFDocument44 pagesPopular Woodworking - 012 - 1983 PDFKawchhar Ahammed100% (1)

- Analyzing Potential Audit Client LakesideDocument22 pagesAnalyzing Potential Audit Client LakesideLet it be100% (1)

- Honing GuidesDocument6 pagesHoning Guidesimoon63No ratings yet

- Woodcarving Illustrated Issue 98 Spring 2022From EverandWoodcarving Illustrated Issue 98 Spring 2022No ratings yet

- Veritas Low-Angle Jack Plane 62Document7 pagesVeritas Low-Angle Jack Plane 62opilio100% (1)

- A Hancock Shaker Clock: Project Reference GuideDocument9 pagesA Hancock Shaker Clock: Project Reference GuidePakito XtradaNo ratings yet

- French Polishing and EnamellingA Practical Work of Instruction by Bitmead, RichardDocument73 pagesFrench Polishing and EnamellingA Practical Work of Instruction by Bitmead, RichardGutenberg.org0% (1)

- Champion The Lumber HorseDocument3 pagesChampion The Lumber HorseRowina Wamani67% (3)

- Building The Wee Lassie Canoe v3Document115 pagesBuilding The Wee Lassie Canoe v3livebyfireNo ratings yet

- Many Forms of - KANNA - Japan Woodworking and Blade Tools DescriptionDocument23 pagesMany Forms of - KANNA - Japan Woodworking and Blade Tools DescriptionMiralia BenciuNo ratings yet

- Lie Nielsen Catalog 2013Document72 pagesLie Nielsen Catalog 2013Jose Luis GregorioNo ratings yet

- Resources For Making Bandsawn BoxesDocument4 pagesResources For Making Bandsawn BoxesFelixPNo ratings yet

- Make A Pocket Hole JigDocument7 pagesMake A Pocket Hole JigJose AmentaNo ratings yet

- Raspberry Pi GPIO PracticeDocument68 pagesRaspberry Pi GPIO Practicedjrao81No ratings yet

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderFrom EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderNo ratings yet

- 3d Pic 02 Jesus and ZacchaeusDocument8 pages3d Pic 02 Jesus and ZacchaeusYamil PaladinoNo ratings yet

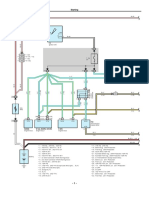

- Diagrama Hilux 2012 ENGINE StartingDocument5 pagesDiagrama Hilux 2012 ENGINE StartingYamil Paladino0% (1)

- Tocador de Baño RústicoDocument18 pagesTocador de Baño RústicoYamil PaladinoNo ratings yet

- Andrew Harris Woodwork Patio TableDocument16 pagesAndrew Harris Woodwork Patio TableYamil PaladinoNo ratings yet

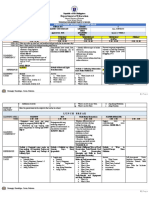

- Grade 6 Quarter 3 WHLP WEEK 4Document3 pagesGrade 6 Quarter 3 WHLP WEEK 4JaneDandanNo ratings yet

- Advanced Accounting PDFDocument14 pagesAdvanced Accounting PDFYvette Pauline JovenNo ratings yet

- IMU 25,26 Oct 2014 (Other) ResultDocument2,582 pagesIMU 25,26 Oct 2014 (Other) ResultMuhammadFarhanShakee100% (1)

- Partnership Dissolution QuizDocument8 pagesPartnership Dissolution QuizLee SuarezNo ratings yet

- 3 Materi 5 TOEFLDocument14 pages3 Materi 5 TOEFL0029 Lona Anggina NstNo ratings yet

- Clarifying Oracle EPM Versioning - PatchesDocument3 pagesClarifying Oracle EPM Versioning - PatchesSathish BalaNo ratings yet

- English Club ConstitutionDocument27 pagesEnglish Club ConstitutionJude Martin AlvarezNo ratings yet

- Digital Mining Technology CAS-GPS Light Vehicle System Technical SpecificationDocument5 pagesDigital Mining Technology CAS-GPS Light Vehicle System Technical SpecificationAbhinandan PadhaNo ratings yet

- Route StructureDocument3 pagesRoute StructureAndrei Gideon ReyesNo ratings yet

- PNB's Financial Inclusion Initiatives and TechnologiesDocument18 pagesPNB's Financial Inclusion Initiatives and TechnologiesShreya DubeyNo ratings yet

- Kyle Capodice Ecet Candidate ResumeDocument1 pageKyle Capodice Ecet Candidate Resumeapi-394690479No ratings yet

- Trauma-Informed CounselingDocument1 pageTrauma-Informed Counselingapi-492010604No ratings yet

- B IngDocument2 pagesB IngsyfnanyNo ratings yet

- 12th English Elec Lyp 2013 DelhiDocument10 pages12th English Elec Lyp 2013 DelhiKanishkha SivasankarNo ratings yet

- The Routledge Handbook of Translation and Culture by Sue-Ann Harding (Editor), Ovidi Carbonell Cortés (Editor)Document656 pagesThe Routledge Handbook of Translation and Culture by Sue-Ann Harding (Editor), Ovidi Carbonell Cortés (Editor)Rita PereiraNo ratings yet

- Call For Applications To JASTIP-Net 2021 Guidelines For ApplicantsDocument6 pagesCall For Applications To JASTIP-Net 2021 Guidelines For ApplicantsNadya IrsalinaNo ratings yet

- Edexcel iGCSE ICT Software MindmapDocument1 pageEdexcel iGCSE ICT Software MindmapPaul ZambonNo ratings yet

- Lion King RPHDocument4 pagesLion King RPHFauzan AzizNo ratings yet

- FVNL"'" - TT - ..: MycotaDocument8 pagesFVNL"'" - TT - ..: MycotaAmbesh JhaNo ratings yet

- Module 6 Questions and AnswersDocument10 pagesModule 6 Questions and AnswersProject InfoNo ratings yet

- Child Rights and Juvenile Justice in India MedhaDocument23 pagesChild Rights and Juvenile Justice in India MedhaLaw ColloquyNo ratings yet

- Art of Public Speaking 11th Edition Lucas Test BankDocument25 pagesArt of Public Speaking 11th Edition Lucas Test BankBryanMillernicy100% (49)

- Tools for Theft InvestigationDocument15 pagesTools for Theft InvestigationMalagant EscuderoNo ratings yet

- Marine Environmental ResearchDocument11 pagesMarine Environmental ResearchPierre Otoniel Carmen MunaycoNo ratings yet

- Tourist Spot in Ilocos Norte PhilippinesDocument1 pageTourist Spot in Ilocos Norte Philippinescharlie besabellaNo ratings yet

- Paths To Mastery Lesson 17 Speaking Tips From Dale Carnegie The Quick and Easy Way To Effective SpeakingDocument10 pagesPaths To Mastery Lesson 17 Speaking Tips From Dale Carnegie The Quick and Easy Way To Effective SpeakingZelic NguyenNo ratings yet