Professional Documents

Culture Documents

Sandpiper S15 Bomba Neumatica

Uploaded by

Alejandro AdriasolaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sandpiper S15 Bomba Neumatica

Uploaded by

Alejandro AdriasolaCopyright:

Available Formats

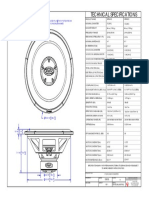

S15 METALLIC PUMP

TECHNICAL DATA SHEET

SERIES

STANDARD DUTY BALL VALVE PUMPS

Offering the widest range of performance and application capabilities

PERFORMANCE

SUCTION / DISCHARGE PORT SIZE HEADS UP TO

• 1½” NPT (internal) • 125 psi or 289 ft. of water

• 1½” BSP Tapered (internal) (8.6 Kg/cm2 or 86 meters))

• 1½” ANSI 150# Raised Face Flanges MAXIMUM OPERATING PRESSURE

CAPACITY • 125 psi (8.6 bar)

• 0 to 106 gallons per minute (0 to 401 LPM) DISPLACEMENT/STROKE

AIR DISTRIBUTION VALVE • .41 Gallon / 1.55 liter

• No-lube, no-stall design WEIGHTS

SOLIDS-HANDLING • Aluminum 53 lbs. (24kg)

• Up to .25 in. (6mm) • Cast Iron 93 lbs. (42kg)

• Stainless Steel 95 lbs. (43kg)

PSI

Perfomance based on water at ambient teme.pratu

BAR

10 (17) 20 (34)

7 100

100 P AIR CONSUMPTION IN SCFM

SI (6.8 Bar) 30 (51)

AIR PRESURE IN PSI

6

40 (68)

80

80 PSI (5

.4 Bar)

5

50 (85)

60

4 60 PSI (4.0

8 Bar)

3

40

40 PSI (2.72

Bar)

Fet

Metrs

2 30 9.1

25 7. 6

20 20 6

20 PSI (1.36 Bar)

1 Air Inlet Pesur 15 4. 5

10 3

5 1.5

0

0 10 20 30 40 50 60 70 80 90 100 110 GPM

0 50 100 150 200 250 300 350 400 LPM

5 YEAR LIMITED PRODUCT WARRANTY USE ONLY GENUINE SANDPIPER PARTS

EX

CLUSIVE

5 Year Guarantee for defects in material or workmanship. See All certification, standards, guarantees & warranties

FE

sandpiperpump.com/content/warranty-certifications originally supplied with this pump will be invalidated by the use of

AT U R E

for complete warranty, including terms and conditions, limitations service parts not identified as “Genuine

and exclusions. SANDPIPER Parts.”

Warren Rupp, Inc. • A Unit of IDEX Corporation

II 2G EEx m c T5

800 N. Main St., Mansfield, Ohio 44902 USA

II 2D c IP65 T100°C ISO 9001 Certified

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867 ISO 14001 Certified

DIMENSIONS

S15 Metallic - NPT

Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm)

The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed.

16.65

422.95 11.19

284.16

2 .25

57.15

1 1/2 NPT DISCHARGE PORT

9 .88

1" NPT EXHAUST PORT 250.83 R.25

6.35

1" NPT EXHAUST PORT

20.83 8 .00 7 .00

529.20 203.20 177.80

22.13

20.83 562.09

529.20

9 .53

11.71 242.16

1 1/2 NPT SUCTION PORT

297.55

4 .00

AIR INLET 101.60

3/4" NPT

4 .94

2 .18 2 .25

55.39 57.15 125.46

4 .00 12.06

101.60

. 63 306.44

2 .18

16.00 8.00

55.39 203.20

S15 Metallic - ANSI Flange

Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm)

The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed.

16.63 11.19

422.28 284.16

4 .68

118.87 DISCHARGE PORT

1 1/2" RF 150# ANSI

5/8" DIA,(4) HOLES EQ. SPC'D

ON 3.88" DIA. BOLT CIRCLE

12.88

327.03

1" NPT EXHAUST PORT 4 .94 .50 MOUNTING HOLES

125.41 12.70

24.85

631.19 R.25

6.35

22.91

20.41 22.41

581.91

20.41 518.41 569.21

12.87

518.41 10.61 7 .00 326.90

SUCTION PORT

1 1/2" RF 150# ANSI 269.49 177.80

5/8" DIA.,(4) HOLES EW. SPC'D. ON 4 .00 6 .44

9 .41 3.88" DIA. BOLT CIRCLE

13.41 101.60 163.45

238.95

340.55

2 .00

50.80 3 .00 AIR INLET

76.20 3/4" NPT

6 .44

163.51

2 .00 9 .88

. 38 50.80 250.83

9.53 4 .68

BOTTOM VIEW

3 .00 118.87

2 .00

76.20

50.80

12.87

326.90

Warren Rupp, Inc. • A Unit of IDEX Corporation

800 N. Main St., Mansfield, Ohio 44902 USA

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867

EXPLANATION OF PUMP NOMENCLATURE

Your Model

#: __

S ____ __ __ __ __ __ __ __ __ __ ____

(fill in from pump

nameplate)

Pump Pump Check Design Wetted Diaphragm/ Check Valve Non-Wetted Porting Pump Pump Kit

Brand Size Valve Level Material Check Valve Seat Material Options Style Options Options

Model #: S XX X X X X X X X X X XX

PUMP BRAND I EPDM/Santoprene PORTING OPTIONS E2. Solenoid Kit with 24VAC/12VDC

S SANDPIPER® G PTFE-Neoprene/PTFE N NPT Threads Coil

M Santoprene/PTFE B BSP (Tapered) Threads E3. Solenoid Kit with 12VDC

PUMP SIZE N Neoprene/Neoprene Explosion-Proof Coil

R Raised Face 150#

15 1 1/2”

V FKM/FKM Threaded ANSI Flange E4. Solenoid Kit with 110VAC Coil

CHECK VALVE TYPE Z One-Piece Bonded/PTFE W Welded Raised Face 150# ANSI E5. Solenoid Kit with 110VAC

B Ball Flange Manifolds Explosion-Proof Coil

CHECK VALVE SEAT

W Weighted Ball E6. Solenoid Kit with 220VAC Coil

A Aluminum PUMP STYLE E7. Solenoid Kit with 220VAC

DESIGN LEVEL C Carbon Steel S Standard

Explosion-Proof Coil

1 Design Level S Stainless Steel

T PTFE

PUMP OPTIONS E8. Solenoid Kit with 110VAC, 50 Hz

WETTED MATERIAL W UHMW

0 None Explosion-Proof Coil

A Aluminum 6 Metal Muffler E9. Solenoid Kit with 230VAC, 50 Hz

I Cast Iron NON-WETTED MATERIAL OP- Explosion-Proof Coil

TIONS KIT OPTIONS SP. Stroke Indicator Pins

S Stainless Steel

00. None

H Alloy C A Painted Aluminum A1. Solenoid Kit with 12 VDC

P0. 10.30VDC Pulse Output Kit

X Unpainted Aluminum I Cast Iron ATEX Compliant Coil

P1. Intrinsically-Safe 5.30VDC,

J Painted Aluminum w/PTFE A2. Solenoid Kit with 24 VDC

DIAPHRAGM/CHECK VALVE MA- Coated Hardware

110/120VAC 220/240 VAC

ATEX Compliant Coil

TERIALS S Stainless Steel with

Pulse Output Kit

A3. Solenoid Kit with 110/120 VAC

1 Santoprene/Santoprene P2. 110/120 or 220/240VAC

Stainless Steel Hardware 50/60 Hz ATEX Compliant Coil

2 PTFE-Santoprene/PTFE Pulse Output Kit

Y Painted Aluminum with A4. Solenoid Kit with 220/240 VAC

B Nitrile/Nitrile E0. Solenoid Kit with 24VDC Coil

Stainless Steel Hardware 50/60 Hz ATEX Compliant Coil

C FKM/PTFE E1. Solenoid Kit with 24VDC

Z Cast Iron with

E EPDM/EPDM Explosion-Proof Coil

Stainless Steel Hardware

MATERIALS

Material Profile: Operating

Temperatures:

POLYPROPYLENE: A thermoplastic polymer. Moderate tensile

and flex strength. Resists stong acids and alkali. Attacked by

180°F

82°C

32°F

0°C

CAUTION! Operating temperature limitations are as follows: chlorine, fuming nitric acid and other strong oxidizing agents.

Max. Min.

PVDF: (Polyvinylidene Fluoride) A durable fluoroplastic with 250°F 0°F

CONDUCTIVE ACETAL: Tough, impact resistant, ductile. Good 190°F -20°F

excellent chemical resistance. Excellent for UV applications. 121°C -18°C

abrasion resistance and low friction surface. Generally inert, 88°C -29°C

High tensile strength and impact resistance.

with good chemical resistance except for strong acids and

oxidizing agents. SANTOPRENE®: Injection molded thermoplastic elastomer with 275°F -40°F

no fabric layer. Long mechanical flex life. Excellent abrasion 135°C -40°C

EPDM: Shows very good water and chemical resistance. Has 280°F -40°F

resistance.

poor resistance to oils and solvents, but is fair in ketones and 138°C -40°C

alcohols. UHMW PE: A thermoplastic that is highly resistant to a broad 180°F -35°F

range of chemicals. Exhibits outstanding abrasion and impact 82°C -37°C

FKM (FLUOROCARBON): Shows good resistance to a wide 350°F -40°F

resistance, along with environmental stress-cracking resistance.

range of oils and solvents; especially all aliphatic, aromatic and 177°C -40°C

halogenated hydrocarbons, acids, animal and vegetable oils. URETHANE: Shows good resistance to abrasives. Has poor 150°F 32°F

Hot water or hot aqueous solutions (over 70°F(21°C)) will attack resistance to most solvents and oils. 66°C 0°C

FKM.

VIRGIN PTFE: (PFA/TFE) Chemically inert, virtually impervious. 220°F -35°F

HYTREL®: Good on acids, bases, amines and glycols at room 220°F -20°F Very few chemicals are known to chemically react with PTFE; 104°C -37°C

temperatures only. 104°C -29°C molten alkali metals, turbulent liquid or gaseous fluorine and a few

fluoro-chemicals such as chlorine trifluoride or oxygen difluoride

NEOPRENE: All purpose. Resistance to vegetable oils. Gener- 200°F -10°F

which readily liberate free fluorine at elevated temperatures.

ally not affected by moderate chemicals, fats, greases and 93°C -23°C

many oils and solvents. Generally attacked by strong oxidizing Maximum and Minimum Temperatures are the limits for which these materials can be

acids, ketones, esters and nitro hydrocarbons and chlorinated operated. Temperatures coupled with pressure affect the longevity of diaphragm pump

aromatic hydrocarbons. components. Maximum life should not be expected at the extreme limits of the

temperature ranges.

NITRILE: General purpose, oil-resistant. Shows good solvent, 190°F -10°F

oil, water and hydraulic fluid resistance. Should not be used with

highly polar solvents like acetone and MEK, ozone, chlorinated

88°C -23°C

Metals:

hydrocarbons and nitro hydrocarbons. ALLOY C: Equal to ASTM494 CW-12M-1 specification for nickel and nickel alloy.

NYLON: 6/6 High strength and toughness over a wide tem- 180°F 32°F STAINLESS STEEL: Equal to or exceeding ASTM specification A743 CF-8M for corro-

perature range. Moderate to good resistance to fuels, oils and 82°C 0°C sion resistant iron chromium, iron chromium nickel and nickel based alloy castings for

chemicals. general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

For specific applications, always consult the Chemical Resistance Chart.

II 2G EEx m c T5

II 2D c IP65 T100°C

Warren Rupp, Inc. • A Unit of IDEX Corporation

NOTE: See service manual for ATEX details.

800 N. Main St., Mansfield, Ohio 44902 USA

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867 SP_DS_TemplateDataSheet_0817

You might also like

- Handbook of Structural EngineeringDocument76 pagesHandbook of Structural EngineeringRajeev Ranjan100% (8)

- Dyneema Vs SteelDocument5 pagesDyneema Vs SteelSaurabh KumarNo ratings yet

- Size ReductionDocument28 pagesSize Reductionchurvalooo100% (1)

- Load Combination To Euro CodeDocument5 pagesLoad Combination To Euro CodeAbdul Hameed HatemNo ratings yet

- Sigma Buffer ChartDocument2 pagesSigma Buffer CharttianajokicNo ratings yet

- Axial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsDocument4 pagesAxial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsMainuddin AliNo ratings yet

- Sandpiper s1f PumpDocument3 pagesSandpiper s1f PumpAdi PurnomoNo ratings yet

- s05 M StandardDocument3 pagess05 M Standardlaura.diazNo ratings yet

- S1F Non-Metallic Pump: Technical Data SheetDocument3 pagesS1F Non-Metallic Pump: Technical Data SheetspattacutNo ratings yet

- S30 Non-Metallic Containment Duty Pump: Technical Data SheetDocument2 pagesS30 Non-Metallic Containment Duty Pump: Technical Data SheetMuhamad nurul aminNo ratings yet

- Metallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpDocument6 pagesMetallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpCarlos Alberto OspinaNo ratings yet

- HDF1 M HdflapDocument2 pagesHDF1 M HdflapAlvaro Iparraguirre NavarroNo ratings yet

- Sump PumpDocument2 pagesSump PumpRAM SANNo ratings yet

- S20 Metallic Pump: Technical Data SheetDocument3 pagesS20 Metallic Pump: Technical Data SheetDang LucNo ratings yet

- s30 SMetallic Data SheetDocument5 pagess30 SMetallic Data Sheetluis miguel velarde manriqueNo ratings yet

- s20 Metalik Data Sheet Rev0817Document2 pagess20 Metalik Data Sheet Rev0817STEPF cryptoNo ratings yet

- pb025 NM STANDARDDocument3 pagespb025 NM STANDARDAlvaro Iparraguirre NavarroNo ratings yet

- Sandpiper Standard Duty Metallic Pumps s30 Data SheetDocument3 pagesSandpiper Standard Duty Metallic Pumps s30 Data Sheetjose manuel alvarez rodriguezNo ratings yet

- Operating Instructions: 1" Elima-Matic Bolted PumpDocument13 pagesOperating Instructions: 1" Elima-Matic Bolted PumpJOSE INESNo ratings yet

- Sandpiper s30nmdl2dsDocument4 pagesSandpiper s30nmdl2dsYongfeng QianNo ratings yet

- Bomba Neumatica Sandpiper Metalica Modelo S20Document8 pagesBomba Neumatica Sandpiper Metalica Modelo S20Edgar EncinaNo ratings yet

- Bulldog 43:1 Air-Powered Pump: Ideal For Blowout Preventor SystemsDocument2 pagesBulldog 43:1 Air-Powered Pump: Ideal For Blowout Preventor Systemsangel benito PortilloNo ratings yet

- VM Sludgemaster Rev1222Document15 pagesVM Sludgemaster Rev1222Pkk Siam Rayong co-saleNo ratings yet

- Belgas p39Document4 pagesBelgas p39Syach FirmNo ratings yet

- Catalogue - Husky Pump 1050 Stainless SteelDocument1 pageCatalogue - Husky Pump 1050 Stainless Steelahmadhafiz.engNo ratings yet

- 3" and 4.25" Grease Pumps - SpecificationsDocument7 pages3" and 4.25" Grease Pumps - SpecificationsZaidi OktariNo ratings yet

- Eaton 421 Pump Sheet Vers-BDocument2 pagesEaton 421 Pump Sheet Vers-Bdzakky syahputraNo ratings yet

- FireBall Grease Pump SpecificationsDocument1 pageFireBall Grease Pump SpecificationsInstruktur MesinNo ratings yet

- WildenDocument1 pageWildenjose coelhoNo ratings yet

- DBB8666 Fuel Filter Data SheetDocument2 pagesDBB8666 Fuel Filter Data SheetJamyansuren TseveendorjNo ratings yet

- PCT 267510 PDFDocument2 pagesPCT 267510 PDFMiguel VlntìnNo ratings yet

- Typical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealDocument6 pagesTypical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealSonia Marcela AriasNo ratings yet

- All-Flo 1.5 Inch Bolted AOD Pump Data SheetDocument4 pagesAll-Flo 1.5 Inch Bolted AOD Pump Data SheetfvcasadosNo ratings yet

- Fixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsDocument4 pagesFixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsДаниил СторчеусNo ratings yet

- Fixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsDocument4 pagesFixed Displacement Bent Axis Piston Pumps: For Truck ApplicationsДаниил СторчеусNo ratings yet

- Bap 01 T B PDFDocument4 pagesBap 01 T B PDFyoberNo ratings yet

- Bap 01 T A PDFDocument4 pagesBap 01 T A PDFyoberNo ratings yet

- rfp4415 4815Document1 pagerfp4415 4815Anthony Shawn BateNo ratings yet

- Simrad - Axis VHF-TECH SPECDocument1 pageSimrad - Axis VHF-TECH SPECEvgeniiNo ratings yet

- Relays & Volume Boosters: Type 20Document8 pagesRelays & Volume Boosters: Type 20Jholman SanchezNo ratings yet

- Catalog 3900 - Flow Control Valves: F SeriesDocument3 pagesCatalog 3900 - Flow Control Valves: F SeriesRaul CalizayaNo ratings yet

- Relief Valves RH4 SeriesDocument6 pagesRelief Valves RH4 SerieslorenzoNo ratings yet

- S07nmdl1ds ENDocument5 pagesS07nmdl1ds ENYongfeng QianNo ratings yet

- FireBall Oil Pump SpecificationsDocument1 pageFireBall Oil Pump SpecificationsInstruktur MesinNo ratings yet

- Aspro CNG Data 20190225Document1 pageAspro CNG Data 20190225KASIMNo ratings yet

- Flojet Industrial Pump N5100-020Document4 pagesFlojet Industrial Pump N5100-020Felipe Frutuoso0% (1)

- Drum PumpDocument1 pageDrum PumpArelysSotilloNo ratings yet

- Scanjet Datasheet Bio7SBDocument2 pagesScanjet Datasheet Bio7SBGabriel TravassosNo ratings yet

- ADC 3010 AC 212 Series RegulatorDocument2 pagesADC 3010 AC 212 Series RegulatorkicsnerNo ratings yet

- Barometric, Gage or Absolute Pressure Ranges: PX2700 SeriesDocument2 pagesBarometric, Gage or Absolute Pressure Ranges: PX2700 SeriesicsNo ratings yet

- WD Bredel 25 32 enDocument2 pagesWD Bredel 25 32 enMario CalvisiNo ratings yet

- Water Pumps For Desalination: Data SheetDocument12 pagesWater Pumps For Desalination: Data SheetMarco Antonio GodoyNo ratings yet

- Husky 1050 Plastic Pumps: Technical SpecificationsDocument2 pagesHusky 1050 Plastic Pumps: Technical SpecificationsRene Gabriel CatorcenoNo ratings yet

- 152 Series RegulatorsDocument1 page152 Series RegulatorsScientific EquipmentNo ratings yet

- Mark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)Document4 pagesMark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)prihartono_diasNo ratings yet

- 6 X 28 Extra-Flow Product Data Sheet: Membrane CharacteristicsDocument2 pages6 X 28 Extra-Flow Product Data Sheet: Membrane CharacteristicsDonatas BertasiusNo ratings yet

- 6000 - Spec BooterDocument2 pages6000 - Spec BooterCasanova FernandoNo ratings yet

- Liqui-Cel EXF-10x28 Data Sheet LC-1031Document2 pagesLiqui-Cel EXF-10x28 Data Sheet LC-1031LuisAngelCordovadeSanchezNo ratings yet

- Husky3300 TechspecsEN ADocument3 pagesHusky3300 TechspecsEN AAlvialvarezNo ratings yet

- Binks AX260L Air Motor BreakdownDocument11 pagesBinks AX260L Air Motor BreakdownAryo KamandanuNo ratings yet

- P39 Standard Gas Regulators: Applications SpecificationsDocument4 pagesP39 Standard Gas Regulators: Applications SpecificationsAlexander Charry GiraldoNo ratings yet

- Compressor/Vacuum Pumps For Liquid Waste Tankers: Truck SeriesDocument4 pagesCompressor/Vacuum Pumps For Liquid Waste Tankers: Truck Seriessourov mutsuddyNo ratings yet

- PH 1600 Series Data Sheet en 126926Document4 pagesPH 1600 Series Data Sheet en 126926detroja tusharNo ratings yet

- Aro Flow Super-Duty Series Regulators PDFDocument2 pagesAro Flow Super-Duty Series Regulators PDFAntonio SerranoNo ratings yet

- Method Statement Log-CivilDocument1 pageMethod Statement Log-CivilDia AjjouriNo ratings yet

- Catalogue Centrifugal Pumps 2Document54 pagesCatalogue Centrifugal Pumps 2Velez SantanderNo ratings yet

- 2nd YearDocument24 pages2nd YearAlxalx Alex50% (2)

- BTU &BTA Reference LayoutDocument8 pagesBTU &BTA Reference LayoutMilbert CandelarioNo ratings yet

- Link Buku Teknik MesinDocument5 pagesLink Buku Teknik MesinMuhammad Fikri100% (1)

- Sensors Pt100 TF Datasheet e ZIEHL-1Document4 pagesSensors Pt100 TF Datasheet e ZIEHL-1Anom HarimurtiNo ratings yet

- Is-10810 - 5 Methods of Test For Cables ResistanceDocument3 pagesIs-10810 - 5 Methods of Test For Cables ResistancepankajnbiNo ratings yet

- ONGAKU Manual SmallerDocument15 pagesONGAKU Manual SmallerEsteban BikicNo ratings yet

- Grain Size Effects in Aluminum Processed by Severe Plastic DeformationDocument6 pagesGrain Size Effects in Aluminum Processed by Severe Plastic DeformationuuseppNo ratings yet

- Cat ArielDocument107 pagesCat Arieljorge velasquezNo ratings yet

- Trade: Fitter: Syllabus For The SubjectDocument29 pagesTrade: Fitter: Syllabus For The SubjectPrabhuNo ratings yet

- Manual: Type: HSR1010, HSR2010, HSR3010, HSR4010, HSR5010, HSR6010, HSR8010, HSR10010, HSR12010, HSR16010Document21 pagesManual: Type: HSR1010, HSR2010, HSR3010, HSR4010, HSR5010, HSR6010, HSR8010, HSR10010, HSR12010, HSR16010CleiberNo ratings yet

- Reactive Dye PrintingDocument15 pagesReactive Dye Printingsandipsoni221811No ratings yet

- Precase Concrete Pipes (Mac, 16)Document4 pagesPrecase Concrete Pipes (Mac, 16)KpChuaNo ratings yet

- Chapter 2 Advances in Concrete Properties and Concrete Making MaterialsDocument77 pagesChapter 2 Advances in Concrete Properties and Concrete Making MaterialsMosisa ShelemaNo ratings yet

- PFI HFB High Flow Pleated Bag Filter CartridgeDocument2 pagesPFI HFB High Flow Pleated Bag Filter Cartridgebennypartono407No ratings yet

- 03-Senr3130!08!01-All Torque SpecificationsDocument16 pages03-Senr3130!08!01-All Torque Specificationsgustavoespinosam100% (1)

- Listino Sea RecoveryDocument117 pagesListino Sea RecoveryEduardo Harold ChapuzNo ratings yet

- PPPDocument5 pagesPPPscbd83No ratings yet

- Muzaffarpur Thermal Power Project (2 X 195 MW) : Sr. Description by by No Vendor BHEL A MechanicalDocument3 pagesMuzaffarpur Thermal Power Project (2 X 195 MW) : Sr. Description by by No Vendor BHEL A MechanicalHimadri SNo ratings yet

- Certificado Brida 3Document1 pageCertificado Brida 3juan aguilarNo ratings yet

- ALLSTYLE CatalogwebDocument48 pagesALLSTYLE CatalogwebjorgegalezoNo ratings yet

- Your Total Utility Solution: CatalogDocument40 pagesYour Total Utility Solution: CatalogMichael Parohinog GregasNo ratings yet