Professional Documents

Culture Documents

Welder Qualification Register

Uploaded by

Dedi Kartiwa0 ratings0% found this document useful (0 votes)

21 views11 pagesd

Original Title

Welder Qualification Register (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views11 pagesWelder Qualification Register

Uploaded by

Dedi Kartiwad

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

JACOBS WELDER QUALIFICATION REGISTER

[eon TR [CONTRACTNG. Ton aO- COS ensona = 60

Perit errs PROJECTNO, 3897 fnacna 2

wee wae ene nn one om 7

3]

co = ream a | Rs

os = Pre inon rr |

a = enon ET ES CE

ro = regen | 207A RT

as 2 rene aan — | sae war

cc aa —| si uF ws wa

a ne | sn Fw

ro} Preece | SH AF aE

s{sla|s/s|a/alala

[Document No = Fu-223

Revision 01

[Revised on: 26 Apr. 2008,

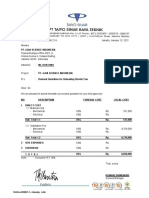

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

Manufacture's Name: PT. TAIYO SINAR RAYA TEKNIK KTP Ne. :3216075009850012

Welders Name Susitowat Record No. : Q5.4/\WPQT/ 001

Welder No weoi Dateof Test: 27 Januar 2020

PARNo. OF-ASME/ POR/ 08

Supporting WPS No. :O1/ ASME/ WPS/ 08, ee

‘Welding Process :GTAW FOR An vit |

Type MANUAL ArT AQVAL

|JOINTS ( aW-402) POSITION ( QW- 405 )

ae

Postion of Groove: PIPE 66

Position of Groove: PLATE -

|Weusing Progression = [ZJUp Hil [T]oown Hit

IBASE METAL ( QWw.403) PREHEAT ( QW-406)

IPN st toP No. 1 Preheat Temp. (Min) = None

[Thickness :3.1 mm Pipe Dia 1 inch Interpass Temp. (Max): 105°C

[FILLER METALS ( QW.404) lpwuT ( aw-407 )

lWeiaing Process: =GTAW HTemperature Gas (ES) > None

IF No. 18 [Time Range 2 None

JA. No. a

size of Electrode = JGAS (ai-40e)

[or Filer Metals 24mm shielaing ‘Argon 99.80%

IBacking s

Tayer('S) | Process | Se(mm) [OurentandPoianty | Ampere(A) | Votage(v) [Speed (mmimin| Other

Root__|_GTAW _|__24 mm. GEN. 30-90 70-20 2-60

Gapping | GTAW | 2-4 mm GEN 50-90) 10-20 720-60.

‘Visual Test Result ‘Accepted

Ponetrant Test Result ‘Accepted

Penetrant Test Ropert No. (a5.4/ PTT Oo%

Noto :

Test kupon disiapkan, dilas dan diuji sesuai

dengan persyaratan Standar ASME Section IX

pate I-02-20

[Bocument No FM223

[Revision = 01

[Revised on _: 26 Apr. 2008,

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

= PT. TAIVO SINAR RAYA TEKNIK KTP No, '3216075906860007

+ Sti Romi Record No. > Q5.4/ WPaT/ 002

‘Weider No wr.02 Date of Test: 27 Januari 2020

PQRNo. (O1-ASME/ PORI 08

‘Supporting WPS No, = O1/ ASME/ WPS/ 08

‘Welding Process :GTAW

Type MANUAL

lJoInTs ( aw-402)

POSITION ( QW- 405 )

Postion of Groove: PIPE 6G

Postion of cove: PLATE -

[Welding Progression = [Z]up Hat [CJoown Hi

IBASE METAL ( QW-403) PREHEAT ( QW-406 )

IPN. st toP No. 1 Preheat Temp. (Min): None

[Thickness 3.1 mm Pipe Dia 1 inch Interpess Temp. (Max): 105%

IFILLER METALS ( QW.404 ) PWHT ( QW-407 )

lWelsing Process craw [Temperature Gas (ES): None

IF. No. [Time Range None

JA. No.

size of Electrode |GAS (aw-408)

lor Filer Metals Shietcing ‘Argon 99,999

[Backing -

Layer(S) [Process | Size(mm) [Current and Polarty | Ampere(A) | Votage (V) [Speed mmimin) | _ Otper

Root_—|_ GTAW_| 24 mm ‘BGEN. 20-0, 70-20 2-60

Gapping | craw | —2.4 mm: ‘DCEN- 30-90 “10-20 20-60

Visual Test Resut ‘Accopied

Peneirant Test Resut ‘Accepted

Penetrant Test Repor No. (05.41 P17 001

Note :

‘Test kupon disiapkan, dilas dan diuj! sesual

dengan persyaratan Standar ASME Section IX

Date

Docu No FBS

Revson 01

Revised on _: 26 Apr. 2008

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

Manufocur’s Name: PT. TAIYO SINAR RAYA TEXNIK KTP ho. eavoraao1760002

Welders Name ko Basu RecoriNo, = 54/\WParT 008

Welder No wos Date of Test: 27 tra 2020

PaRNo OF-ASME! POR/ 08

Supporing WPS No, :01/ ASME/ WPS/08 VAI

AL

nmap cena FOR APPROVAL

Tye MANUAL.

JOINTS ( QW-402 ) |POSITION ( QW- 405 )

16

aaa nnpeageiaes

Ws Posten ot Groove: PLATE -

ah t Hit [oown Hit

Welding Progression at Jou

|BASE METAL ( QW-403 ) |PREHEAT ( QW-406 )

Put woP No. 1 Prehest Temp. (Min) = None

Liciness :3,1 mm Pipe Dia 1 inch nterpass Temp. (Max): 105

FILLER METALS ( Qw.404) pwer (aw-407 )

lWeicing Proooes craw [Temperature Gas (ES) = None

Fn. 8 Irene Range = Nene

Ian. ‘

Size of Electrode al |GAS (QW-408)

or Fier Mets 24mm sheuing ‘Argon 99.90%

Backing i.

Layer(S) | Process | Size(mm) |Current and Polarity Ampere (A) Nolage (V)_|Speed (mm/min) Other

Root | GTAW | 24mm GEN 30-90 10-20 | 20-60

caspng_| craw | 2.4mm CEN 50.90 0-20 | 20-60

Visual Test Rest ‘ecapied

Panetant Test Rest ‘Accepted

Penetrant Test Report No. Gear Pr 004

Note:

Test kupon disiapkan, ilas dan dij sesual

ddongan persyaratan Standar ASME Section IK 5

Date: [Horr pe

[Document No F225

lRevision —:01

[Revised on _: 2 Apr. 2008

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

Manufacture's Name = PT. TAIYO SINAR RAYA TEKNIK.

Welders Name Sutkno KTP No, 3520051811820001,

Weider No WF-04 Recor No. Q5.4/ WPQT/ 004

PQRNo, (O1-ASME! POR! 08 Date of Test_: 27 Januari 2020

‘Supporting WPS No, :01/ ASME/ WPS! 08

oo FOR APPP” AL

|JOINTS ( Qw-402) POSITION ( QW- 405 )

7

Postion of Groove: PIPE 6G

WEE Tr poston of Groove: PLATE -

at f Welding Progrossion : [Z]Up Hit [—]Down Hil

[BASE METAL ( QW-403) PREHEAT ( QW-406 )

PN: toP No, 1 JPreneat Temp. (Min): None

[Thickness =3.1 mm Pipe Dia 1 inch linterpass Temp. (Max): 105°C

|FILLER METALS ( QW-404 ) PWHT ( QW-407 )

lWelcing Process GTAW [Temperature Gas (ES) : None

IF. No. 6 [Time Range = None

JA. No. I

eee : |GAs (aw-408)

[Or Filer Metals. 24mm |shieaing ‘Aigon 98,99%

leacking .

Layer(S) | Process | Size(mm) [Curent and Polarity | Ampee(A) | Voltage (V) [Speed (mmimin)| Other

Root | GtaW [24mm CEN 50-90 10-20 20-60

Capping | craw | 24mm. CEN 50-90 10-20 20-60,

Visual Test Result ‘Accepted

Penetrant Test Result ‘Accepted

Penetrant Test Report No. (5.41 PT/ 007

Pr

4

Note : ‘oproved by Jacobs inspected by PT Taiyo Sar

‘Test kupon distapkan,dilas dan diuji sesual <3 ees

‘dengan persyaratan Standar ASME Section IX

Po

Date: li-0t-lo Date : 27 JANUAR: Jogo

aaa TS

bandon 30 A. 200

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

Tangacizes ave FT TAVO SHAR RAYA TERM wien aeeremoetora

Msersnone Suto Reowe io. Os4/ what cs

wet wear Otto 27 Jan

norne OtaSMes Po

Sinporing WPS No, 1 ASME! WPS/ 08 FOR APPROVAL |

‘Welding Process GTAW + SMAW z

we MANUAL

[JOINTS ( QW-402 ) |POSITION ( QW- 405 )

ero Posten terooe - PRE 66

Penton tGroe : PLATE -

W =

sae Pe

IWelding Progression

Jue ran Joon Hi

BASE METAL ( QW-403 ) PREHEAT ( QW.406 )

IPN. 4 to Po. 1 Preheat Temp. (Min): None

Thickness :4,9 mm Pipe Dia 6 inch lInterpass Temp. (Max): 116°

FILLER METALS ( QW-404 ) PWHT ( QW-407 )

Welding Process GTAW sMAW Temperature Gas (ES) = None

IF No. 6 4 {Time Range None

|A.No. 1 1

eerie 7 samm {SAS (QW-408), ELECTRICAL (aW-408)

|Or Filer Metals 24mm - Shielding ‘Argon £9,99%

|SFA Speccation SFAS18 sFA51 [Backing -

[AWS Clasification ER 70S 7016 _|CurentType Polanty ___DCEN (GTAW), DCEP (SMAW)

Layer(S) | Process | Size(mm) [Curentand Polenty | Ampere(A) | Vottage(V) [Speed (mm/min | Other

Root__| GTAW | 2.4mm ‘DOEN 75-100 10-20 60-100

File [tan | 2.4mm GEN 75-100 10-20 60-100

‘Gepping | SMAW | 3.2mm DOEP. 75-110 10-20 0-100

Visual Test Result ‘Accepted

Penetrant Test Result ‘Accoptod

Penetrant Test Report No (05. PTI 004

Note: ‘Approved by Jacobs Inspected by PT Taio Sinar_

‘Test kupon disiapkan, dias dan di sosua See

dengan persyaratan Standar ASME Section IK .

Date: ji-0220 Date : 27 JANUAR 2020

[Document No : F223

Pvsor

oat n 38 A 208

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

Taniaareshane PT TAYOSNAR AYATERN Wine sara

Wiewers nae St Romin Recs: 054/ Pa o8

vase woe Daw otto 2 snn 220

Porn Oras Paco

supprcg WPS o_O AME WPS/08 We

Wkng Poses OTAW+ SMA FOR APPROV.

Te maNuAL

JOINTS ( QW-402 ) |POSITION ( QW- 405 )

Pomnatcone - PRE 66

ey = hi [Position of Groove: PLATE -

*

a5 fe ji [Welding Progression Jp Hil []Down Hilt

BASE METAL ( QW-403 ) | PREHEAT ( QW-406 )

et Pretest Ton. (Min) = Were

Theiss 49 mm Pees 8 hen ase Tene (Mos) 18

FILLER METALS ( QW-404 ) |PWHT ( QW-407 )

betes Pen cram surw framerate at (ES) = Now

ne ° finotare oo

reece : adm JOAS (W400, ELECTRICAL (W400)

fs Casen cers __e7oie_[euew'ypeoery __oceN tw, oer (swam

Layer(S) | Process | Size(mm) |Currentand Polarty | Ampere(A) | Voltage (V) [Speed (mm/min )| Other

Fos —[ oraW [Zane [oo remo —| 0-60-10

Fir —[ erat | zane | Doe 75-100 | Wear | —e0=9

Capping | SMAW_ 32mm, DCEP 75-110 10-20 60-100

aa Tear Tea

Pere Tests Aesmid

Perea Test Repe sara

Note :

‘Test kupon disiapkan, dilas dan diuji sesual

dengan persyaratan Standar ASME Section IX

“Approved by

Date:

“Jacobs

Date: 27 JANUAR 2020

[Document No = F223

Revision: 01

[Revised on _: 26 Apr. 2008

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

‘Manufacture's Name PT. TAIYO SINAR RAYA TEKNIK, KTP No, '3827072401760002

Welders Name Eko Basuki Record No. Q6.4/ WPQT/ 007

Welder No Wr-03 Date of Test :27 Januari 2020

PORNo. 01-ASME! POR 08

‘Supporting WPS No, O1/ ASME! WPS/ 08

Welding Process GTAW + SMAW

Type MANUAL

[JOINTS ( aW-402 ) POSITION ( QW. 405 )

ey eae ise

WEE qe Postion of Groove = PLATE -

I

3a Welding Progression : [zJUp tt [Jom ti

|BASE METAL ( QW-403 ) |PREHEAT ( QW-406 )

PN st toPNo ' Preheat Temp. (Min) —: None

IThickness 49 mm Pipe Dia. 26 iach rteress Temp. (Max): 118%

FILLER METALS ( QW.408 ) pwar ( aw-407 )

|weising Process craw swaw — [Temperature Gas (ES): None

F No 6 [Time Range None

la No. 1 1

Sia of Electrode : adinm {GAS (@W-408), ELECTRICAL (aW-409)

lOrFiter Metals 24mm a hela ‘Aegon $9,994

[SFA Speciation SFABIB sras1 [Backing 4

[AWS Clasfcation ER 70 £7018 _|Curert Type Ponty DCEN (GTAW), DCE (SMAW)

Tayer(S) | Process | Size(mm) [Curentand Polerly | Ampere(A) | Votage (V) [Speed (mminin)] Other

Root GTAW [24mm CEN 75-100 70-20 | 60-700

Fite —[-Gran_| 2.4mm CEN 75=100 10-20] 60-100

Capping [SWAN | 3.2mm OGEP 75-110 40-20 | 60-100

Viswl Test Resa Recepied

Penetvant Test Resi Accepted

Fenetrant Test Report No sai PT! ooH

Note ‘Approved by Jacobs |

‘Test kupon disiapkan, dilas dan diuj!sesual

‘dengan persyaratan Standar ASME Section IX

[Document No = FN-223

Revi on

[Revised on _: 26 Apr. 2008

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

Tasha ase FT TAVOSRAR NA TOOaE Pre, TEE

eoree aee em cower

waar wr atten arian

pane casera

Srey svn We ts aaah

wourgpece Taq Sma FOR ar PROVAL

om ‘aaa

JOINTS ( QW-402 ) |POSITION ( QW. 405)

en rosionet cow: PRE 00

YE] Tae IPositio of Groove: PLATE -

t

poe

SBF [Welding Progression : [Z]Up Hal [JDown Ha

IBASE METAL ( QW-403 ) |PREHEAT ( QW.406 )

PN. st tP Neo M [Preheat Temp. (Min): None

[Thickness :49 mm Pipe Dia © inch nterpass Temp. (Max): 115°C

FILLER METALS ( aWw.408 ) |PWHT ( QW-407 )

|Welsing Process Taw swaw [Temperature Gas (ES) = None

F No. 8 4 fTime Range None

la No 1 4

ISizecfElecrode =: . 32mm [GAS (QW-408), ELECTRICAL (QW_409)

lor Filer Metals 24mm - ‘Argon 99.99%

[SFA Speciation SFA518 SFASA -

[AWS Ciasication ER70S £7018 _ [Current Type Polarly __: DCEN (GTAW), DCEP (SMAWW)

Layer(S) | Process | Size(mm) [OurentandPolarty [ Ampere (A) | Votge(V) [Speed (mmimin)] Other

Root | GTAW | —_ 24mm DOEN 75-100 70-20 | 60-100

Filer [Taw | 24mm GEN 75-100 70-20 | 60-100

Capping | SMAW [9.2 mm CEP, 75-110 70-20[ 60-100

Visual Test Resut ‘Aecopied

Penorant Test Result ‘Accepted

Penetrent Test Report No (5.4/PT/ 00%

Note proved by Jacobs Inspected by PT Taiyo Sinar

‘Test kupon disiapkan, dilas dan diuji sesuat

‘dengan persyaratan Standar ASME Section IX fh

Date: (0106

[Document Ne : F233

Revision

[Revised on _: 26 Apr. 2008

ot

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

Vaniairdshine “PT TANO SNARRAVATERE ihe monroe

Wielerenene yok Anan Redo O54 PGT 08

Meter wea Dror ext hee

Pon aS aR

Serrong WPS No, ASME! WPS 0

Metng Pens GTAW+ SHAW

re MANUAL

JOINTS ( QW-402) |POSITION ( QW- 405 )

Ce posinsicone : PRE 66

wy t c [Position of Groove: PLATE -

ER fe f |Welding Progression : [v]Up Hit []Down Hit

BASE METAL ( QW-403 ) PREHEAT ( QW-406 )

fines 49 nm Poem 8 ch —_—_itopm Tor. (Har): 15

FILLER METALS (@W-08) ener (awe)

ety Pree cram saw —_fFonprr ar (ES) = Now

rte 8 mokono "ote

late dtElouiude : 32mm {GAS (QW-408), ELECTRICAL (QW-409)

rears 24am denis seen 98%

Seepeteion FASTA sass [sing :

ans Catan ims ers _[ewow'yporseay __ ocen,crawy ocer ou

Layer(S) | Process | Size(mm) |Current and Polarity Ampere (A) Voltage (V)_|Speed (mm/min )} Other

foot araw | san —| BOER Teton —[-—1osz0 wove

Fe —Terai| —zann—[ bce Testor [10-20] a,

Geese Siw [26mm | Doe? faze [10-20 | —@5- 10

a som Ted

Porta eho Aeceped

Pera Tent Rapo tT Sarre

Note:

‘Test kupon disiapkan, dilas dan diyji sesuai

‘dengan persyaratan Standar ASME Section IX

Date: (3/03/20 Date

7

eo MIpTAH PARID

NLMAR 2020

INSPECTION RECORD OF

WELDER PERFORMANCE QUALIFICATION TEST ( WPQT )

[Document No = Fua-223

lRevision 01

[Revised on: 26 Apr. 2008

Merufesure’s Name PT. TAIVOSINAR RAYA TEKNIK KTP No: 18010416%2670005,

Wels Name sya Anam Record Ne. :08.4/ WeaTi oot0

Welder No wees Date of Test 11 Marat 2020

PORN o-aswer Pon’ 08 Date of Test =27 Januari2020

Supporting WPS No, -O1 ASME WPS) 08

Weling Process = GTAW

Type MANUAL

somes ( aw.s02) Position ( aw- 405)

— ee feo

Wt Te Posten of Groove: PLATE -

aT f lWelsing Progression = [y]Up Hill [—]Down it

BASE METAL ( QW-403 ) |PREHEAT ( QW-406 )

Pre. 4 PN Preneat Temp. (Min) = None

Thickness :3:1 mm Pediat rch nterpass Temp. Max): 118%

|FILLER METALS ( QW-404 ) |PWHT ( QW-407 )

lweting Process GTAW remperaure Gas (ES) = None

FN. 8 Time Range None

Ja No. 1

size of Elecrode : eee tenoy:

orFiter Weis 24 mm sticking ‘gon 86 90%

cng =

Tayer(S) | Proeess | Size(mm) [Ourertand Poeriy | Ampere (A) | Votege () [Speed inminin)| Other

Root__[ GtaW | 24mm DEN 0-80 10-20 | 20-60

Cepoing [Gta | 24mm CEN 50-60 10-20 [20-60

‘Viual Test Renu ‘ecepied

Penetant Test Resut ‘Accepted

Penetant Test Repo Ne sal PTI 007

Note :

‘Test kupon disiapkan, dilas dan

dengan persyaratan Standar ASME Section IX

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- WPS 19 - Mb-Gtaw-Iv-08Document14 pagesWPS 19 - Mb-Gtaw-Iv-08Dedi KartiwaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Site MaintenanceDocument3 pagesSite MaintenanceDedi KartiwaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Pipe SizeDocument1 pagePipe SizeDedi KartiwaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 010 MSDS - Toilon (IXPE - Foam)Document3 pages010 MSDS - Toilon (IXPE - Foam)Dedi KartiwaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- WPS 20 - Mb-Gmaw-Iv-08Document12 pagesWPS 20 - Mb-Gmaw-Iv-08Dedi KartiwaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Aerovent BLI 710 Datasheet - 17645Document1 pageAerovent BLI 710 Datasheet - 17645Dedi KartiwaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- How To Detect Ammonia - 8 Steps (With Pictures) - WikihowDocument4 pagesHow To Detect Ammonia - 8 Steps (With Pictures) - WikihowDedi KartiwaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Sodium Methoxide - WikipediaDocument4 pagesSodium Methoxide - WikipediaDedi KartiwaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Pipe Size Foam WaterDocument1 pagePipe Size Foam WaterDedi KartiwaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- TAG Handout 2022 English 001 48 EzsawDocument1 pageTAG Handout 2022 English 001 48 EzsawDedi KartiwaNo ratings yet

- Color Code For Piping MaterialDocument1 pageColor Code For Piping MaterialDedi KartiwaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- DLR-Series Clamshell Pipe Cutting Beveling Machines EN-USDocument2 pagesDLR-Series Clamshell Pipe Cutting Beveling Machines EN-USDedi KartiwaNo ratings yet

- What Is Cold CuttingDocument5 pagesWhat Is Cold CuttingDedi KartiwaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dimension Material & FabricationDocument10 pagesDimension Material & FabricationDedi KartiwaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Fusion 17 ManualDocument1,511 pagesFusion 17 ManualDedi KartiwaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Pipe Flushing ProcedureDocument2 pagesPipe Flushing ProcedureDedi KartiwaNo ratings yet

- Dimensions of Long Radius Elbows Dimensions of Short Radius ElbowsDocument2 pagesDimensions of Long Radius Elbows Dimensions of Short Radius ElbowsDedi KartiwaNo ratings yet

- Welding Method Joining Bonnet HeadDocument1 pageWelding Method Joining Bonnet HeadDedi KartiwaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Approved Iwm SCR Mec EdsDocument31 pagesApproved Iwm SCR Mec EdsDedi KartiwaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Adhesive 820 MSDSDocument4 pagesAdhesive 820 MSDSDedi KartiwaNo ratings yet

- Adhesive 820 MSDSDocument4 pagesAdhesive 820 MSDSDedi KartiwaNo ratings yet

- Requires Certification From ERICO: Lightning Protection System DesignDocument12 pagesRequires Certification From ERICO: Lightning Protection System DesignDedi KartiwaNo ratings yet

- High Pressure Pigtail Selection Guide: Selecting The Correct Hose Can Improve Your ProcessDocument4 pagesHigh Pressure Pigtail Selection Guide: Selecting The Correct Hose Can Improve Your ProcessDedi KartiwaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Pump and Glycol Tank Nozzle LoadsDocument4 pagesPump and Glycol Tank Nozzle LoadsDedi KartiwaNo ratings yet

- Kustono: //GAIA-m0006821 A - Unloading, Letter //GAIA-m0006821 A - Unloading, LetterDocument6 pagesKustono: //GAIA-m0006821 A - Unloading, Letter //GAIA-m0006821 A - Unloading, LetterDedi KartiwaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)