Professional Documents

Culture Documents

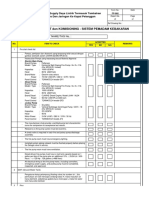

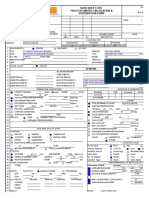

(Form-GNQ-18) Cornell Ammonia Pump Pre-Commissioning Checklist

Uploaded by

eugene mejidanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Form-GNQ-18) Cornell Ammonia Pump Pre-Commissioning Checklist

Uploaded by

eugene mejidanaCopyright:

Available Formats

GNQ INDUSTRIAL &

Date Prepared: ___________

CONTRACTING CORPORATION

Project:

Client Name: AMMONIA PUMP

Page __1__ of ____ page/s

PRE-COMMISSIONING CHECKLIST

Unit Designation: End User Name:

Project Name: Contact Number:

Project Number: Address:

Pump Motor

Model HP/KW Phase

Make FLA Make

Serial No: Motor No: Model

TDH (FT): Voltage Frequency (Hz)

Flow rate: Speed (RPM) Efficiency (%)

Mechanical Check Remarks

1. Check the external cleanliness of the pumps, remove and clean replace all strainers

2. Check that flow direction is correct

3. Check that all components, bolts, fixing, tie bars, etc., are secured

4. Check that the impellers are free to rotate

5. Check the level and plumb of pump and motor shaft and slide rails; (direct drive pumps

require particular attention in this respect)

6. Check the anti-vibration mountings for correct deflection

7. Check that the correct drivers are fitted

8. Check that the pipe work imposes no strain on the pump connections

Operational Check

9. Check pump-separator elevation.

10. Check actual motor load is lower than FLA rating

Starting The Pump

Adjust the valves in following order:

1. Close drain valve

2. Open vent valve

3. Open valve in discharge line one quarter.

4. Slowly open valve in suction line fully.

5. Open suction vent valve (if present) fully.

6. Fill pump with liquid.

7. Open valve in bypass line.

8. Check wiring of motor and heater. Make sure that once liquid is admitted to pump,

Prepared by: __ s T Accepted by:

GNQ Representative Owner / Representative

(Signature of Over Printed Name) (Signature of Over Printed Name)

Ammonia Pump Pre-commissioning Checklist Form-GNQ-18 Rev 1

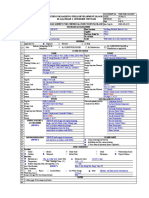

GNQ INDUSTRIAL &

Date Prepared: ___________

CONTRACTING CORPORATION

Project:

Client Name: AMMONIA PUMP

Page __1__ of ____ page/s

PRE-COMMISSIONING CHECKLIST

heater is on.

9. Allow pump to cool down for approximately one hour.

On any subsequent start-up of the pump, after it has been shut down for one or more days,

The oil reservoir should be vented of any vapor accumulation, and oil should be added as

necessary.

10. Start the Pump.

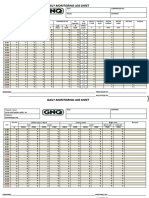

START-UP DATA

Insulation Testing Rotation

G-L1 G-L2 G-L3 L1-L2 L2-L3 L1-L3 Clockwise Counter Clockwise

Prepared by: __ s T Accepted by:

GNQ Representative Owner / Representative

(Signature of Over Printed Name) (Signature of Over Printed Name)

Ammonia Pump Pre-commissioning Checklist Form-GNQ-18 Rev 1

You might also like

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- (Form GNQ 19) Pump Pre Commissioning Checklist 1Document2 pages(Form GNQ 19) Pump Pre Commissioning Checklist 1eugene mejidanaNo ratings yet

- (Form GNQ 16) Evaporative Condenser Pre Commissioning ChecklistDocument2 pages(Form GNQ 16) Evaporative Condenser Pre Commissioning Checklisteugene mejidanaNo ratings yet

- (Form GNQ 17) Aircoolers Pre Commissioning Checklist 1Document140 pages(Form GNQ 17) Aircoolers Pre Commissioning Checklist 1eugene mejidanaNo ratings yet

- (Form GNQ 15A) FrickCompPrestartChecklistDocument7 pages(Form GNQ 15A) FrickCompPrestartChecklisteugene mejidanaNo ratings yet

- Buyer: OwnerDocument27 pagesBuyer: OwnerDaniel TostaNo ratings yet

- (Form GNQ 20) AHU Pre Commissioning Checklist 1Document2 pages(Form GNQ 20) AHU Pre Commissioning Checklist 1eugene mejidanaNo ratings yet

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 pagesAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilNo ratings yet

- UntitledDocument5 pagesUntitledJuan Bautista Rojas VillegasNo ratings yet

- Win Progress.,Co - LTD (Pharkant Branch) : D13A Engine Receiving/Delivering Inspection FormDocument26 pagesWin Progress.,Co - LTD (Pharkant Branch) : D13A Engine Receiving/Delivering Inspection FormLinzaw OoNo ratings yet

- 3.1 Oil Filled Power TransformersDocument32 pages3.1 Oil Filled Power TransformersThameemul BuhariNo ratings yet

- Appendix 11F: Operational ChecklistsDocument15 pagesAppendix 11F: Operational Checklists许爱文No ratings yet

- Data Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG ODocument4 pagesData Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG Ogabriel riveroNo ratings yet

- Annexure To Be AttachedDocument12 pagesAnnexure To Be AttachedAnonymous vspGaH8No ratings yet

- CK-E73 H - Generator Set Detroit Diesel - Series 71 In-Line2Document5 pagesCK-E73 H - Generator Set Detroit Diesel - Series 71 In-Line2Edward SchenkNo ratings yet

- 7 Auto Transformer Test ReportsDocument11 pages7 Auto Transformer Test ReportsCOVER VERIFICACIONES ELECTRICAS, S.A.No ratings yet

- Silo D-PumpDocument2 pagesSilo D-PumpMithun Singh RajputNo ratings yet

- DH3-31MA-T-ITP-0001 ITP For Commissioning of Complete-Set Startup of Steam Turbine REV.0Document12 pagesDH3-31MA-T-ITP-0001 ITP For Commissioning of Complete-Set Startup of Steam Turbine REV.0Lan RungNo ratings yet

- E39 Ahsop 06Document11 pagesE39 Ahsop 06Sanjit SinghNo ratings yet

- 6000-TWC-413 (CHW Hydraulic Balnce)Document21 pages6000-TWC-413 (CHW Hydraulic Balnce)darrenNo ratings yet

- Diesel Engine Generator Set Site Acceptance Test Procedure 48 JamDocument7 pagesDiesel Engine Generator Set Site Acceptance Test Procedure 48 Jambambang ismail100% (4)

- Aquacat c79Document53 pagesAquacat c79NebojsaNo ratings yet

- Check List Start Up and Comissioning of Fire Pumps 2Document6 pagesCheck List Start Up and Comissioning of Fire Pumps 2ismail_khansNo ratings yet

- Check List - Fire Protection Inspection Untuk KomisioningDocument4 pagesCheck List - Fire Protection Inspection Untuk KomisioningRudy Harahap100% (1)

- SABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingDocument15 pagesSABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingAbdelaziz EldeebNo ratings yet

- DH01 M E 0007 - Mechanical Datashet For TankDocument4 pagesDH01 M E 0007 - Mechanical Datashet For TankDuy NamNo ratings yet

- Sea Sovereign: Test Specification and Protocol FOR Fuel Oil SystemDocument4 pagesSea Sovereign: Test Specification and Protocol FOR Fuel Oil SystemPT INDORAD MEGA BINTANGNo ratings yet

- Hydraulic Pump, InstallingDocument4 pagesHydraulic Pump, InstallingCEVegaONo ratings yet

- Tear Down Inspection Report Engine PERKINS DG-04 PHEWMODocument5 pagesTear Down Inspection Report Engine PERKINS DG-04 PHEWMOKhoirul UmamNo ratings yet

- Check List Test Dan Komisioning - Sistem Pemadam Kebakaran: Equipment Name/Tag No.Document8 pagesCheck List Test Dan Komisioning - Sistem Pemadam Kebakaran: Equipment Name/Tag No.Rudy HarahapNo ratings yet

- Comp No.5 (-10) PrestartchecklistDocument7 pagesComp No.5 (-10) PrestartchecklistEujan MejidanaNo ratings yet

- Comment - Tubrine Performance Test Rev 07Document7 pagesComment - Tubrine Performance Test Rev 07guzfistekNo ratings yet

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- CRS MAR 23 001 - Chilled Water PumpsDocument3 pagesCRS MAR 23 001 - Chilled Water PumpsThiraviam AyyappanNo ratings yet

- Inspection Unit PC 200Lc - 8moDocument28 pagesInspection Unit PC 200Lc - 8moBima AditamaNo ratings yet

- Fuid End PDFDocument2 pagesFuid End PDFKaleem UllahNo ratings yet

- Preventative Maintenance Task Sheet: Plant/Equipment: Job IDDocument29 pagesPreventative Maintenance Task Sheet: Plant/Equipment: Job IDJaveria KhanNo ratings yet

- Fire Pump PRE-START UP CHECK LISTDocument3 pagesFire Pump PRE-START UP CHECK LISTMark Louie Guinto100% (1)

- Gen Set Service ReportDocument1 pageGen Set Service ReportReman MarykanNo ratings yet

- Job Completion Report Presentation - Conventional RigDocument16 pagesJob Completion Report Presentation - Conventional Rigmnscsc713321No ratings yet

- Piper Aircraft Corporation: Haven, Pennsylvania, U.S.ADocument2 pagesPiper Aircraft Corporation: Haven, Pennsylvania, U.S.AmaximeNo ratings yet

- Hydraulic Piston Pump Start-Up ProcedureDocument3 pagesHydraulic Piston Pump Start-Up ProcedureSami NcirNo ratings yet

- ENGINE LRUs STATUS REPORTDocument5 pagesENGINE LRUs STATUS REPORTImran SalehNo ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- Diesel TankDocument1 pageDiesel TankRejo AbrahamNo ratings yet

- SOP OperationDocument68 pagesSOP OperationPamela Bradley100% (1)

- DatasheetDocument71 pagesDatasheetRhadityo Shakti BudimanNo ratings yet

- Materi Pengenalan Pengoperasian Dan Perawatan Fire PumpDocument48 pagesMateri Pengenalan Pengoperasian Dan Perawatan Fire PumpBALLYNo ratings yet

- CC ITP Sample PDFDocument4 pagesCC ITP Sample PDFMRezaNo ratings yet

- 08-SOP of ASH SLURRY PUMPDocument5 pages08-SOP of ASH SLURRY PUMPMithun Singh RajputNo ratings yet

- DAILY CHECK LIST Tyre Mounted CraneDocument1 pageDAILY CHECK LIST Tyre Mounted CraneAditya Enterprise100% (1)

- Epri Turbine A Vapeur PDFDocument53 pagesEpri Turbine A Vapeur PDFamarmissoum100% (3)

- (Form GNQ 15B) FrickCompPrestartChecklistDocument2 pages(Form GNQ 15B) FrickCompPrestartChecklisteugene mejidanaNo ratings yet

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaNo ratings yet

- Quote Labor PartsDocument2 pagesQuote Labor PartsOno Jr ArazaNo ratings yet

- Check ListDocument6 pagesCheck ListSikandar Khan0% (1)

- P8217 Checklist Fire Pump PDFDocument7 pagesP8217 Checklist Fire Pump PDFQuynh NguyenNo ratings yet

- 7 CompressorDocument2 pages7 CompressorMithun Singh RajputNo ratings yet

- VP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Document18 pagesVP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Vasilica BArbarasaNo ratings yet

- (Form GNQ 15C) FrickCompPrestartChecklist 1Document1 page(Form GNQ 15C) FrickCompPrestartChecklist 1eugene mejidanaNo ratings yet

- (Form GNQ 15B) FrickCompPrestartChecklistDocument2 pages(Form GNQ 15B) FrickCompPrestartChecklisteugene mejidanaNo ratings yet

- (Form GNQ 20) AHU Pre Commissioning Checklist 1Document2 pages(Form GNQ 20) AHU Pre Commissioning Checklist 1eugene mejidanaNo ratings yet

- FormDocument1 pageFormeugene mejidanaNo ratings yet

- Abi Elsalvador ReportDocument6 pagesAbi Elsalvador Reporteugene mejidanaNo ratings yet

- Quantum Retrofit Panel RECO COMPESSORDocument2 pagesQuantum Retrofit Panel RECO COMPESSOReugene mejidanaNo ratings yet

- COMPRESSOR MonitoringDocument2 pagesCOMPRESSOR Monitoringeugene mejidanaNo ratings yet

- SMBI - IN.FI12 REV02 Motor Insulation Resistance Test ReportDocument3 pagesSMBI - IN.FI12 REV02 Motor Insulation Resistance Test Reporteugene mejidana100% (1)

- Manual SAJ R5-0.7-8K-S1-S2-15Document70 pagesManual SAJ R5-0.7-8K-S1-S2-15Dieldson RibeiroNo ratings yet

- 6.DM PlantDocument94 pages6.DM PlantDhilip AnNo ratings yet

- Bussmann Eaton Fuse - 170m6466-Fuse 1250a 690v 3bkn-50 Ar Uc-En - GBDocument1 pageBussmann Eaton Fuse - 170m6466-Fuse 1250a 690v 3bkn-50 Ar Uc-En - GBTerminal TruckNo ratings yet

- AMI Adapter Cables Product LineDocument1 pageAMI Adapter Cables Product LineAnkur PandeyNo ratings yet

- Kim Lighting 12 Volt Landscape Lighting Products Catalog 1977Document16 pagesKim Lighting 12 Volt Landscape Lighting Products Catalog 1977Alan MastersNo ratings yet

- Siprotec 5 DIGSI 5 - Course: Hardware OverviewDocument28 pagesSiprotec 5 DIGSI 5 - Course: Hardware Overviewm kh100% (1)

- DS 80 Manual PDFDocument82 pagesDS 80 Manual PDFIlko PenevNo ratings yet

- Res Slide 1-4Document23 pagesRes Slide 1-4DEEPANo ratings yet

- Procedure UPS CEGDocument2 pagesProcedure UPS CEGsella100% (1)

- Test - Practice On Wiring: Protection From ShockDocument4 pagesTest - Practice On Wiring: Protection From ShockShobu YarlagadaNo ratings yet

- Camflex CF5000-2005 020254Document16 pagesCamflex CF5000-2005 020254isidromundarain67No ratings yet

- Sampling PlanDocument5 pagesSampling PlanMukul JainNo ratings yet

- Airbus A320 ATA 31 EIS PresentationDocument101 pagesAirbus A320 ATA 31 EIS Presentationcacad999No ratings yet

- ARUM192168096BTE5Document4 pagesARUM192168096BTE5ingcivalflhNo ratings yet

- Panasonic ACDocument84 pagesPanasonic ACMicky PlumbNo ratings yet

- Smoke Extract Fan ChecklistDocument10 pagesSmoke Extract Fan Checklistphe zenNo ratings yet

- Copy of Critical Spare List (Revision No 9)Document17 pagesCopy of Critical Spare List (Revision No 9)rajesh sharmaNo ratings yet

- Arba Minch University: DEPARTEMENT OF: Health Informatics Individual AssignmentDocument7 pagesArba Minch University: DEPARTEMENT OF: Health Informatics Individual AssignmentAgegnehu TakeleNo ratings yet

- HD 101 Deluge Valve Model ADocument15 pagesHD 101 Deluge Valve Model APiyush JainNo ratings yet

- DTC B1182/19 Short in D Squib (2Nd Step) Circuit (To Ground)Document4 pagesDTC B1182/19 Short in D Squib (2Nd Step) Circuit (To Ground)Phang KumwingNo ratings yet

- X60349-M01c1-Hvac Schematic Ahus 3, 4 & 4aDocument1 pageX60349-M01c1-Hvac Schematic Ahus 3, 4 & 4aKarthy GanesanNo ratings yet

- HVAC Commissioning Checklist PDF ReportDocument9 pagesHVAC Commissioning Checklist PDF ReportCadz GamingNo ratings yet

- CaDr Schematic V3Document1 pageCaDr Schematic V3Papa Mike MurrayNo ratings yet

- SMC-3, SMC Flex, and SMC-50 Smart Motor Controller SpecificationsDocument168 pagesSMC-3, SMC Flex, and SMC-50 Smart Motor Controller SpecificationsOscar Miño VillaoNo ratings yet

- NCM-WF Installation ManualDocument7 pagesNCM-WF Installation Manualvizion2k4100% (1)

- BICR020 - Live - Report - Assigned - Tasks - by - Resource 00 - 09 - 20Document205 pagesBICR020 - Live - Report - Assigned - Tasks - by - Resource 00 - 09 - 20Phoebe HardingNo ratings yet

- Solar Modules For Rooftop Systems and Solar Parks: EnglishDocument2 pagesSolar Modules For Rooftop Systems and Solar Parks: EnglishSanthosh RameshNo ratings yet

- CAT312 Elastimold Sw10213 1606 TNB Elastimold Switchgear CAT312 FA HRDocument44 pagesCAT312 Elastimold Sw10213 1606 TNB Elastimold Switchgear CAT312 FA HRRaulNo ratings yet

- PA Inverter EDTMT452039-ENDocument132 pagesPA Inverter EDTMT452039-ENPhuNguyenHoangNo ratings yet