Professional Documents

Culture Documents

Z73B I2 R0 English

Uploaded by

阿康0 ratings0% found this document useful (0 votes)

11 views1 pageZ73B_I2_R0_English

Original Title

Z73B_I2_R0_English

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentZ73B_I2_R0_English

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageZ73B I2 R0 English

Uploaded by

阿康Z73B_I2_R0_English

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Z73B

Medium acrylonitrile (ACN) Hydrogenated Nitrile Butadiene Rubber (HNBR)

Description

Z73B is a Copolymer of acrylonitrile and butadiene with a medium ACN

content of 30 - 45%.

HNBR materials typically provide superior heat resistance, excellent

mechanical properties, combined with exceptional resistance to oils,

hydrogen sulphide, amines present in crude oil, high energy radiation,

ozone and weathering.

Z73B is accepted by the UK Ministry of Defence (MOD) to Defence

Standard 02-337 part 1, issue 2 (NES 337) for use on naval ships and

submarines.

Available in any sized O-ring (fully moulded up to 2.5m/8ft internal

diameter) and custom designed components.

Typical Material Properties

Key Attributes Property ASTM ISO Value

Excellent chemical resistance Material Type HNBR HNBR Copolymer

Excellent wear resistance and mechanical properties

Colour Black

Accepted by M.O.D. to Def. Stan. NES 337

Meets ASTM D2000/SAE J200 line call-out M4DH716, A26, B36, Hardness: (°IRHD) D1415 ISO48 70

EO16, EO36, F17. Tensile Strength (MPa) D412 ISO37 16.3

Elongation at break (%) D412 ISO37 250

Typical Applications Compression Set:

D395 ISO815 12%

Naval ships and submarines 24 hrs @ 135°C (275°F)

Oilfield applications Minimum Operating -30°C

Temperature (Dynamic) (-22°F)

Other NES337 materials available Minimum Operating -40°C

Medium ACN Nitrile materials in 60, 70, 80 and 90 hardness Temperature (Static) (-40°F)

High ACN Nitrile materials in 60, 70, 80 and 90 hardness Maximum Operating +180°C

HNBR materials in 80 and 90 hardness Temperature (+356°F)

V72G FKM fluoroelastomer (green) 70 hardness Heat Ageing:

70 hrs @ 150°C (302°F) D573 ISO188

PPE O-ring parts are listed on the ISIS system under NCAGE reference number U6183.

Hardness change (points) D1415 ISO48 +3 IRHD

Tensile strength change D412 ISO37 +10%

Elongation at break change D412 ISO37 -10%

Low temperature

resistance: -30°C

Non-brittle after 3mins at

SPECIAL NOTE: This information is to the best of our knowledge accurate and reliable. However, Precision

Polymer Engineering Ltd makes no warranty, expressed or implied, that parts manufactured from this material

will perform satisfactorily in the customer's application. It is the customer's responsibility to evaluate parts

prior to use, especially in applications where their failure may result in injury and/or damage. It should also be

noted that all elastomeric parts have a finite life. Therefore a regular programme of inspection and

replacement is strongly recommended.

Low temperature operating parameters are based on SAE AMS 7379-2008.

The material properties above should not to be used for specification purposes.

Quotation's and Order's you can send to: sales@oring.su

Official web site: www.oring.su

You might also like

- Z95X I5 R0 EnglishDocument1 pageZ95X I5 R0 English阿康No ratings yet

- Z85L I4 R2 EnglishDocument1 pageZ85L I4 R2 English阿康No ratings yet

- Z70F I4 R0 EnglishDocument1 pageZ70F I4 R0 English阿康No ratings yet

- Z70B I2 R4 EnglishDocument1 pageZ70B I2 R4 English阿康No ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- Z75L I2 R2 EnglishDocument1 pageZ75L I2 R2 English阿康No ratings yet

- Z85B I1 R4 EnglishDocument1 pageZ85B I1 R4 English阿康No ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- F1 Model Block: Technical DatasheetDocument2 pagesF1 Model Block: Technical DatasheetRafael ObiciNo ratings yet

- V80D I4 R0 EnglishDocument1 pageV80D I4 R0 English阿康No ratings yet

- PP TDSDocument2 pagesPP TDSsribachaNo ratings yet

- Molykote 3402Document2 pagesMolykote 3402Dicky PratamaNo ratings yet

- Tds Infinam Ti 3100 LDocument2 pagesTds Infinam Ti 3100 LKacperNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- OptDocument1 pageOptDarkedgeNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- N70F I3 R0 EnglishDocument1 pageN70F I3 R0 English阿康No ratings yet

- Technicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022Document2 pagesTechnicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022pmf engineering limitedNo ratings yet

- Ficha Técnica Nylon MolyDocument1 pageFicha Técnica Nylon MolyHector ArciniegasNo ratings yet

- Durafide 6165A6 TDSDocument6 pagesDurafide 6165A6 TDSCassianNo ratings yet

- Datasheet SaphirAF 2016 EN v1Document2 pagesDatasheet SaphirAF 2016 EN v1André CardosoNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Technical Data Sheet Sapfoam 323D-M: Polyurethane Spray SystemDocument3 pagesTechnical Data Sheet Sapfoam 323D-M: Polyurethane Spray SystemAbidNo ratings yet

- TECAPEEK CF30 Black 7 PDFDocument1 pageTECAPEEK CF30 Black 7 PDFHARSHANo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Solar Roll PE55 PDFDocument2 pagesSolar Roll PE55 PDFLong TomahawkNo ratings yet

- Dupont DelrinDocument3 pagesDupont DelrinIjaz AhmedNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- F70C I2 R0 EnglishDocument1 pageF70C I2 R0 English阿康No ratings yet

- Sustatron Pps GF 40: Technical Data SheetDocument1 pageSustatron Pps GF 40: Technical Data SheetyatheendravarmaNo ratings yet

- Econamid FL 6M20 - Pa6 M2oDocument1 pageEconamid FL 6M20 - Pa6 M2omuthuNo ratings yet

- Titanvene ll0209sr Product Data SheetpdfDocument1 pageTitanvene ll0209sr Product Data SheetpdfHanry WRNo ratings yet

- ProductFile 131206155656Document1 pageProductFile 131206155656Michael HajzerNo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- Propertie NilonDocument3 pagesPropertie Nilonmuhammad daffaNo ratings yet

- TDS Tremco CPG APAC TREMguard LLM 2023Document2 pagesTDS Tremco CPG APAC TREMguard LLM 2023CHEONG WEI HAONo ratings yet

- HD M5306 PDFDocument2 pagesHD M5306 PDFmohamed1303No ratings yet

- Duracon M25-44Document5 pagesDuracon M25-44AVLight AutomotivesNo ratings yet

- Sikadur®-42 MP Slow - PDS - GCC - AE - (07-2016) - 1 - 1Document5 pagesSikadur®-42 MP Slow - PDS - GCC - AE - (07-2016) - 1 - 1邢焕震No ratings yet

- Nusil CV2-2646 - 29017393Document3 pagesNusil CV2-2646 - 29017393Joaquin Sanchez MagariñosNo ratings yet

- Virgin PTFE G400 Extruded - Rev.06Document1 pageVirgin PTFE G400 Extruded - Rev.06Alessio Di BellaNo ratings yet

- Nyco Grease GN 22 Air4222Document1 pageNyco Grease GN 22 Air4222muhammad_andinovaNo ratings yet

- Tasnee LD 4025as Polyethylene: DescriptionDocument2 pagesTasnee LD 4025as Polyethylene: Descriptiontrần hải namNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- Zytel HTN52 G35 HSLDocument5 pagesZytel HTN52 G35 HSLVisan GheorgheNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- HT - Tribol GR 100-2PDDocument3 pagesHT - Tribol GR 100-2PDRomulo Davila GarciaNo ratings yet

- Tecatron Gf40 Black en All 201711Document2 pagesTecatron Gf40 Black en All 201711JorgeMariscalNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- Datasheet 1332408905 PDFDocument1 pageDatasheet 1332408905 PDFSheikh Tahsina Trading CorporationNo ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- CSP SMC 40774 Data Sheet 2012 PDFDocument1 pageCSP SMC 40774 Data Sheet 2012 PDFBrian García AguirreNo ratings yet

- Ces 3Document5 pagesCes 3LegendaryNNo ratings yet

- TVH Driver SeatsDocument92 pagesTVH Driver SeatsMelwyn FernandesNo ratings yet

- Pojet PPT 1Document39 pagesPojet PPT 1Tushar JainNo ratings yet

- Compressive Strength of SFRCDocument6 pagesCompressive Strength of SFRCsravan_rubyNo ratings yet

- Domacryl 926: Methacrylate ResinDocument1 pageDomacryl 926: Methacrylate ResinmonrmNo ratings yet

- C15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesDocument2 pagesC15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesPaulo Henrique NascimentoNo ratings yet

- Catalogo CompletoDocument220 pagesCatalogo CompletoWilliam Dante Mescco SaireNo ratings yet

- BS Market SurveyDocument9 pagesBS Market SurveyPratik BiyaniNo ratings yet

- Precios y Cantidades de Recursos Requeridos Por TipoDocument3 pagesPrecios y Cantidades de Recursos Requeridos Por TipoWilder Huaman MuñozNo ratings yet

- D Market Rate Analysis BuildingDocument74 pagesD Market Rate Analysis BuildingSarinNo ratings yet

- Introduction-Iron Carbon Phase DiagramDocument31 pagesIntroduction-Iron Carbon Phase DiagramTHE BBEASTNo ratings yet

- Field Officer Wise Pending Sample Report: To 29-Jul-2022 1-Jan-2017 Report Period FromDocument147 pagesField Officer Wise Pending Sample Report: To 29-Jul-2022 1-Jan-2017 Report Period FromMalakMunirKhanNo ratings yet

- 2022 Electrical Steel NO Catalog - Eng - FinalDocument14 pages2022 Electrical Steel NO Catalog - Eng - Final雨庵우암No ratings yet

- InterliningDocument8 pagesInterliningshimanthNo ratings yet

- Appx B Fluid Series1Document6 pagesAppx B Fluid Series1omveer singhNo ratings yet

- Composite Materials ReportDocument47 pagesComposite Materials ReportPatrickNo ratings yet

- Company Grade Origin Port: Base Oil Grades Imported Into Indian Ports of Mumbai, JNPT & Chennai - January 2004Document6 pagesCompany Grade Origin Port: Base Oil Grades Imported Into Indian Ports of Mumbai, JNPT & Chennai - January 2004georgevoommen100% (1)

- Plastic Deformation & CreepDocument71 pagesPlastic Deformation & CreepifrizaldpNo ratings yet

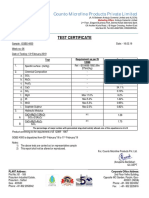

- Test Certificate: Counto Microfine Products Private LimitedDocument1 pageTest Certificate: Counto Microfine Products Private LimitedSiddhesh Kamat MhamaiNo ratings yet

- Sikadur 31 PlusDocument5 pagesSikadur 31 Plusghazi.tcmarineNo ratings yet

- Santoprene Aplication and PerformanceDocument33 pagesSantoprene Aplication and PerformanceAristo OnanNo ratings yet

- Pidicryl XD 4000 - Suggestive Formulation - WhiteDocument1 pagePidicryl XD 4000 - Suggestive Formulation - WhiteCarlos Lizarraga FloresNo ratings yet

- Septon and Hybrar Technical Information KurarayDocument12 pagesSepton and Hybrar Technical Information Kurarayswaggeroni yololoNo ratings yet

- Shore ScleroscopeDocument6 pagesShore ScleroscopeAaliyahNo ratings yet

- Victrex PEEK 450FE20: Conditions Test Method Units Typical ValueDocument2 pagesVictrex PEEK 450FE20: Conditions Test Method Units Typical ValueRohan KulkarniNo ratings yet

- Tugas 10 - Chapter 15Document6 pagesTugas 10 - Chapter 15hana haddadNo ratings yet

- Analisis Kinerja Campuran Aspal Porus Menggunakan Aspal Pen 60/70 Dan Aspal Modifikasi Polimer ElvaloyDocument11 pagesAnalisis Kinerja Campuran Aspal Porus Menggunakan Aspal Pen 60/70 Dan Aspal Modifikasi Polimer ElvaloyKurnia ZandyNo ratings yet

- Geogrid: Secugrid® Q (PES/PET)Document1 pageGeogrid: Secugrid® Q (PES/PET)Yassin Abd El AalNo ratings yet

- Evalene LF20185Document2 pagesEvalene LF20185Oscar Tan IIINo ratings yet