Professional Documents

Culture Documents

Ref. 020764 - 400V - 3φ: Description

Uploaded by

Sidou BelmahdjoubOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ref. 020764 - 400V - 3φ: Description

Uploaded by

Sidou BelmahdjoubCopyright:

Available Formats

SPOT-WELDING GYSPOT INVERTER BP.

LCX-S7

EQUIPMENT

Ref. 020764 - 400V - 3φ

The Gyspot INVERTER BP.LCX-S7 product is a real advance in the field of spot-welding equipment. This machine is the

ideal answer to the welding requirements of high strength steels (UHSS/boron steel), with 550 daN electrode arms

force at 8 bars and 13 000 Amps welding current. The GYSPOT BP.LCX-S7 is equipped with 2 clamps (X and C). It is

a multifunctional welder, thanks to its water cooling system on both clamps. This machine is fully compliant with the

European Directive 2004/40/EC.

Description

• Ideal X and C clamps for all types of metal works

NUFACTUR

• Lightweight and easy to handle X and C clamps: Weight 5 kg MA

13 000A

ER

R

• Single-sided gun with 3 meter cable: spot hammer welding,

CA

S

stud/rivet/ring welding, carbon shrinking 550 daN

• Accessories box

• Support cable bracket with a telescopic arm AP

P R O VA L

• Control display 6’’

• Remote control on the clamp

Performance

• Welding current:

- High welding current 13 000 A

- Digital display of the actual current value

- Sound alert if the welding current is too low

- Constant current control

• Electrode force :

- Electrode force control

- Digital display of the actual electrode arms force

- C clamp electrode force: 550 daN with at 8 bars

- X clamp electrode force: 550 daN with arms 120 mm at 8 bars Included :

- Liquid-cooled arms up to the tips - X1 & C1 Arm

- Sound alert if the actual clamp force is too low - single sided gun

- earth cable

Machine interface

• The AUTO MODE allows welding without entering any parameter in the machine.

• 7 modes available to answer the requirements of both end users and car manufacturers

BP BODYPROTECT

G

• User friendly: Large display (6”), with intuitive menus TECHNOLOGY 2013/35/UE

• Saving of user welding parameters UNIQUE ELECTRO-MAGNETIC FIELD PROTECTION by GYS

The « BODYPROTECT » concept protects the user against

Tracability electro-magnetic fields. The machine is compliant with the

directive 2004/40/CE.

• Record on SD card of the characteristics of each welding spot performed

• Restoration on any PC of the reports saved on the SD card

ACCESSORIES.

X (Ø 25mm) + Caps Ø 13mm

150

200 mm 115 449

97 350 mm

200 mm 120

C1 8 bar/550 daN

019140

89 430 049253 051614

450 Support & Handle

included 050549 051607

050501 050532

C7 8 bar/550 daN

210 55 mm 020009

C4 8 bar/550 daN

45 C2 8 bar/550 daN

019133 118

019164 310 115

223

131

Arm Panel

396

Arm Panel

X4A (x2) + X5 + X2

177 mm 020702 022324

177

050518

205 mm 202

C11 8 bar/550 daN 59 396

053649

C3 8 bar/550 daN

85

019157

57 C8 8 bar/550 daN

020016

020719

35

67 60 mm

167 mm

141 C2 + C3 050587 20 396

C5 8 bar/550 daN + C4

30 019294 C6 8 bar/300 daN Ref 051614

019126

019775 C10 4 bar/150 daN 020726

051638

Cables

100%

I RMS U0 CU

50/60hz Liquid / Air

m Ø mm²

Cooled

Liquid 2.5 200

32A (D)

65x80x205 180

400V 40A (D) 13 000A 16V 3+3+3 1.5+3 Air 2.5 150 OK

cm kg

50A (D) 4x6

- 8 H07RNF

04/03/2020 - EN 60974-1 MADE in FRANCE

www.gys.fr

Intuitive GYSPOT INVERTER BP.LCX-S7

Menus

SPOT 7 TECHNOLOGY

STANDARD MODE

1 The machine determines the welding parameters from the thickness of the

sheets to be welded and the type of steel.

MANUAL MODE

Direct programming of the welding parameters

2 - welding current

- welding time

- electrode force

MULTI MODE

The thickness of the sheets to be welded, as well as the type of steel, is

3

specified for each sheet in the assembly. The machine determines the

welding parameters.

GYSTEEL MODE

The hardness measurement obtained with the GYSTEEL Vision device can be

4

entered directly in this menu in order to specify the type of steel. The

machine determines the welding parameters.

ENERGY

AUTO MODE ** New ** DYNAMIC

Automatic detection : CONTROL

- of the metal type

5

- of the metal sheet thickness

- of presence of glue

- of presence of insulating material between the metal sheets

CAR MANUFACTURER MODE ** New **

This mode allows recalling, in a welding spot list, pre-recorded welding spots

6

from car manufacturer repair instructions. The welding parameters are

automatically effective.

ENERGY MODE ** New **

This mode allows controlling the energy transferred during the welding spot.

7 Only the welding current (A) and the energy (kWs) can be set in order to

make the welding spot. This mode has been designed for test laboratories

and car manufacturers, for approval purposes.

04/03/2020 MADE in FRANCE

www.gys.fr

You might also like

- Especificaciones Nbcv5 5.0Document40 pagesEspecificaciones Nbcv5 5.0delioNo ratings yet

- Product Features: AC131-1A AC131-2C AC131-3C AC131-6CDocument1 pageProduct Features: AC131-1A AC131-2C AC131-3C AC131-6Cdusan cincarNo ratings yet

- Nasarc Technologies REVOVER The Power of Spin 1695300632Document6 pagesNasarc Technologies REVOVER The Power of Spin 1695300632VVan TanNo ratings yet

- ZB ZBV IC 10 enDocument2 pagesZB ZBV IC 10 enRaluca HutanuNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesraselNo ratings yet

- Nertazip Plasma CuttersDocument7 pagesNertazip Plasma CuttersrascalkajeeNo ratings yet

- C&K ZMA Series Subminiature Snap-Acting Switches: Features/Benefits Typical ApplicationsDocument3 pagesC&K ZMA Series Subminiature Snap-Acting Switches: Features/Benefits Typical ApplicationsBoris ȚepeșNo ratings yet

- ZMA00A080L04L - DatasheetDocument3 pagesZMA00A080L04L - DatasheetPușcă MartinNo ratings yet

- C&K ZMA Series Subminiature Snap-Acting Switches: Features/Benefits Typical ApplicationsDocument3 pagesC&K ZMA Series Subminiature Snap-Acting Switches: Features/Benefits Typical ApplicationsPușcă MartinNo ratings yet

- (Susol ACB) UL Type Catalog en 202105Document104 pages(Susol ACB) UL Type Catalog en 202105LUATNo ratings yet

- 6KW Fire Station SLDDocument1 page6KW Fire Station SLDB . G STUDIONo ratings yet

- C and K USA Pushbutton Switch E121 E020 - 5jan12-14673Document9 pagesC and K USA Pushbutton Switch E121 E020 - 5jan12-14673abcNo ratings yet

- Dimensions: 0714EN July 2014Document2 pagesDimensions: 0714EN July 2014EngTyranNo ratings yet

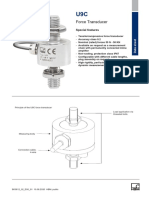

- U9C-50 KNDocument8 pagesU9C-50 KNGMAR ComercializadoraNo ratings yet

- SK 02Document3 pagesSK 02ASDNo ratings yet

- 12 - A95 - A96 Siamese ConnectionDocument3 pages12 - A95 - A96 Siamese ConnectionmikNo ratings yet

- 8500 Series Subminiature Pushbutton Switches: Features/Benefits Typical ApplicationsDocument5 pages8500 Series Subminiature Pushbutton Switches: Features/Benefits Typical ApplicationsJaime ArroyoNo ratings yet

- X-Ray DongmunDocument3 pagesX-Ray DongmunCarlos TorralbaNo ratings yet

- L011516 - EMG-10APB Servo MotorDocument3 pagesL011516 - EMG-10APB Servo MotorReginaldo KrothNo ratings yet

- IEICOS Machine Tool Dynamometer BrochureDocument5 pagesIEICOS Machine Tool Dynamometer Brochurerajan_dunNo ratings yet

- 09 InstructivoDocument24 pages09 InstructivoDavid Ian Gaytan CeronNo ratings yet

- #EMKA-PACIFIC 2023 Catalogue - 1107S##U3-IND-B-333-PADDocument1 page#EMKA-PACIFIC 2023 Catalogue - 1107S##U3-IND-B-333-PADandriNo ratings yet

- KS760 Series: KCC Co., LTDDocument4 pagesKS760 Series: KCC Co., LTDYosmell Fritzan Paz UrbizagasteguiNo ratings yet

- Gage and Absolute Pressure Transducers: Special FeaturesDocument4 pagesGage and Absolute Pressure Transducers: Special Featuresaemis2010No ratings yet

- Tsubaki Power Lock Ad N SeriesDocument5 pagesTsubaki Power Lock Ad N SeriesRizal IephoNo ratings yet

- NeedleValves ALCOVALVESDocument11 pagesNeedleValves ALCOVALVESFercomil S.A.SNo ratings yet

- Leaky Wave Cable Installation: Falcon Autotech Pvt. Ltd. - ConfidentialDocument27 pagesLeaky Wave Cable Installation: Falcon Autotech Pvt. Ltd. - ConfidentialytdvshuvnkdNo ratings yet

- PTS645 Series6 MM Tact SwitchesDocument6 pagesPTS645 Series6 MM Tact Switcheshgg2kNo ratings yet

- Osl / Osls: Low Height Jacks - Plain Ram, Single Acting, Plain / Spherical Saddle (Type - Spring Return)Document1 pageOsl / Osls: Low Height Jacks - Plain Ram, Single Acting, Plain / Spherical Saddle (Type - Spring Return)VIN PATNo ratings yet

- Color Television Receiver: Chassis: KS1C (P) Model: CS21A9W2QS/MURDocument40 pagesColor Television Receiver: Chassis: KS1C (P) Model: CS21A9W2QS/MURSomnath KarmakarNo ratings yet

- Mine-Cap Family DatasheetDocument14 pagesMine-Cap Family DatasheetValentinIonescuNo ratings yet

- EPAD 4x5-S 1Document1 pageEPAD 4x5-S 1engr.santosmichaelNo ratings yet

- Over-Head Level Indicators: O O O O O O O ODocument11 pagesOver-Head Level Indicators: O O O O O O O Oanon_975837510No ratings yet

- Aplab High Voltage DC Lab 300V 5000V 1Document1 pageAplab High Voltage DC Lab 300V 5000V 1drvikaasNo ratings yet

- Product Features Product Features: AC150-1A AC150-2C AC150-3C AC150-6CDocument1 pageProduct Features Product Features: AC150-1A AC150-2C AC150-3C AC150-6CYesenia Jaime RoaNo ratings yet

- Enerpac WHC WHR Series CatalogDocument1 pageEnerpac WHC WHR Series CatalogTitanplyNo ratings yet

- Optig 161 - Welder: FeaturesDocument1 pageOptig 161 - Welder: FeaturesNicoNo ratings yet

- (Susol Compact ACB) - Catalog - EN - 202007Document92 pages(Susol Compact ACB) - Catalog - EN - 202007Ekanit ChuaykoedNo ratings yet

- ST Ep DR 86a 1Document2 pagesST Ep DR 86a 1Sergio Trujillo CerroNo ratings yet

- Assured Automation R-SeriesDocument2 pagesAssured Automation R-SeriesBrandon TrocNo ratings yet

- 91751Document27 pages91751Inam Ul HaqNo ratings yet

- Sta-Kon Rings, Forks and Locking Forks: Ring TerminalsDocument2 pagesSta-Kon Rings, Forks and Locking Forks: Ring TerminalssoayNo ratings yet

- OMEGA LeafletDocument6 pagesOMEGA LeafletDev ShahNo ratings yet

- Amphenol 7-16 RF ConnDocument4 pagesAmphenol 7-16 RF ConnShaunVermaakNo ratings yet

- Caterpillar Operation and Maintenance Manual Sr4b Generators (85 93)Document9 pagesCaterpillar Operation and Maintenance Manual Sr4b Generators (85 93)AlexNo ratings yet

- Brochure Tilt SwitchDocument2 pagesBrochure Tilt SwitchricardobonillaavilesNo ratings yet

- Track Master: Festoon SystemsDocument32 pagesTrack Master: Festoon SystemsRenwick69No ratings yet

- Three-Way Switches Dimensional Data 115 - 230 KV, Type 3G and 3GLDocument4 pagesThree-Way Switches Dimensional Data 115 - 230 KV, Type 3G and 3GLbloodpointerNo ratings yet

- Cobra 7250EXM Datasheet 8.28.14Document2 pagesCobra 7250EXM Datasheet 8.28.14FarmaceuticaNo ratings yet

- SI-E122 AcbDocument110 pagesSI-E122 AcbshantoNo ratings yet

- PCS100 - 250 - 500 - 630 DatasheetDocument2 pagesPCS100 - 250 - 500 - 630 DatasheetKCB TechnologiesNo ratings yet

- Tomacarga CHANCEDocument18 pagesTomacarga CHANCEBenjamin HidalgoNo ratings yet

- 100989-01 InstructivoDocument24 pages100989-01 Instructivoclodomiro aliaga malpartidaNo ratings yet

- Klein SaleDocument1 pageKlein SaleShamrock SupplyNo ratings yet

- (Susol Compact ACB) Catalog en 202010Document92 pages(Susol Compact ACB) Catalog en 202010raiNo ratings yet

- K Relay-E9 Lowres 26-28 enDocument3 pagesK Relay-E9 Lowres 26-28 enAnonymous CRQ100No ratings yet

- Mohilo 0143SDDocument6 pagesMohilo 0143SDDexter PoliNo ratings yet

- Resistance Spot Welder: Unique, New Generation WelderDocument2 pagesResistance Spot Welder: Unique, New Generation WelderFranklin GonzálezNo ratings yet

- 4 InstructivoDocument24 pages4 InstructivoUlises Antonio Hernández GarciaNo ratings yet

- A Guidebook - Indicator of Sustainable For Tourism DestinationDocument9 pagesA Guidebook - Indicator of Sustainable For Tourism DestinationFajar Muhammad RahmanNo ratings yet

- BLOOD On The DOORPOSTS by William and Sharon SchnoebelenDocument220 pagesBLOOD On The DOORPOSTS by William and Sharon SchnoebelenDennis e kaluwe100% (3)

- Manual de Usuario Honda Civic 2006 PDFDocument307 pagesManual de Usuario Honda Civic 2006 PDFmorispNo ratings yet

- LEHNER SuperVario Brochure Engl 3 2023Document4 pagesLEHNER SuperVario Brochure Engl 3 2023Jefferson MagalhaesNo ratings yet

- Solar Power PlantDocument23 pagesSolar Power Plantmadhu_bedi12No ratings yet

- Case Folder GuideDocument94 pagesCase Folder GuideFrancis Mon DulayNo ratings yet

- Multiple Choice Questions - Answers PDFDocument2 pagesMultiple Choice Questions - Answers PDFSedat Korkmaz75% (4)

- Whitepaper Evaluate Data Centers With ConfidenceDocument19 pagesWhitepaper Evaluate Data Centers With ConfidenceAnoop PattatNo ratings yet

- A Elementary PDFDocument83 pagesA Elementary PDFPhilBoardResultsNo ratings yet

- DoterraDocument20 pagesDoterraLAURA GLORIANo ratings yet

- CV For The Post of Rover Operator - Jetties Abdul Rahman Rover Operatopr-JettiesDocument2 pagesCV For The Post of Rover Operator - Jetties Abdul Rahman Rover Operatopr-JettiesAbdul RahmanNo ratings yet

- 16PF Questionnaire DatasheetDocument2 pages16PF Questionnaire DatasheetEqraChaudhary67% (3)

- Fire Alarm Systems - LX Sounder Beacons ConventionalDocument3 pagesFire Alarm Systems - LX Sounder Beacons ConventionalLuiyi Lazcano MontalvoNo ratings yet

- Common Sexting CodesDocument7 pagesCommon Sexting CodesBrightonNo ratings yet

- Operation & Maintenance Manual d260 S3a-En Okt. 2014Document166 pagesOperation & Maintenance Manual d260 S3a-En Okt. 2014DrBollapu Sudarshan50% (2)

- ED 205 Module FinalDocument151 pagesED 205 Module FinalGene Bryan SupapoNo ratings yet

- Procreation - Socialization of The Family MemberDocument3 pagesProcreation - Socialization of The Family Memberkazelle GentallanNo ratings yet

- Template HOC Online - April 2017Document41 pagesTemplate HOC Online - April 2017Dalvin PratamaNo ratings yet

- Passive Voice ExercisesDocument4 pagesPassive Voice ExercisesInês CachaçoNo ratings yet

- Effect SizesDocument32 pagesEffect SizesdashNo ratings yet

- Macario Biology W1Document6 pagesMacario Biology W1Roberto MendozaNo ratings yet

- Install of Grounding ModulesDocument10 pagesInstall of Grounding Modulesolegprikhodko2809No ratings yet

- Gender Advocacy and SelfDocument4 pagesGender Advocacy and SelfkhimpotchingNo ratings yet

- UK National Guideline For The Management of Pelvic Inflamatory DiseaseDocument18 pagesUK National Guideline For The Management of Pelvic Inflamatory Diseasealejandro perez sanchezNo ratings yet

- Aumund TCBM V001Document29 pagesAumund TCBM V001umutNo ratings yet

- 5-Child Guidance ClinicsDocument13 pages5-Child Guidance ClinicsSwati LalNo ratings yet

- All Tied UpDocument27 pagesAll Tied Upalmaclois2100% (1)

- Water Cement RatioDocument11 pagesWater Cement RatioMyrell NaguiatNo ratings yet

- For Example in Case of - WCDocument8 pagesFor Example in Case of - WCSUCHETA DASNo ratings yet

- Ogunbiyi - ThesisDocument149 pagesOgunbiyi - ThesisOgunbiyi David OluwabukunmiNo ratings yet