Professional Documents

Culture Documents

UBE E 102 Heat Exchangers

Uploaded by

john carterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UBE E 102 Heat Exchangers

Uploaded by

john carterCopyright:

Available Formats

UBE GROUP (THAILAND)

ENGINEERING SPECIFICATION

FOR

HEAT EXCHANGERS

ES NO. UBE-E-102

0 Original 16 Sep. ’13 NPT P.PISANU

Rev. Description Date Prepare Check Approve

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 1 of 16

TABLE OF CONTENTS

1. GENERAL

1.1 Scope 3

1.2 Specific Job Requirements 3

1.3 Codes and Standards 3

1.4 Purchaser's Drawings and Specifications 4

1.5 Vendor's Drawings and Documents 4

2. DESIGN

2.1 General 5

2.2 Design Pressure 6

2.3 Design Temperature 6

2.4 Design Loads 7

2.5 Corrosion Allowance 7

2.6 Material 7

2.7 Tolerances 7

2.8 Strength Calculation 8

3. DETAILED DESIGN

3.1 Shells and Channels 8

3.2 Tubes and Tube Bundles 9

3.3 Tubesheet 9

3.4 Expansion Joint 10

3.5 Nozzle and Opening Reinforcement 10

3.6 Bolts and Nuts 11

3.7 Gaskets 11

3.8 Supports 12

3.9 Fittings for Assembly and Disassembly 12

4. FABRICATION

4.1 Plate Layout 12

4.2 Forming 12

4.3 Welding 13

4.4 Heat Treatment 13

5. INSPECTION AND TESTING 15

6. NAMEPLATE, PAINTING AND MARKING

6.1 Nameplate 16

6.2 Painting 16

6.3 Marking 16

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 2 of 16

7. PACKING AND SHIPPING

7.1 General 16

7.2 Packing and Preparation for Shipping 16

7.3 Shipping 16

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 3 of 16

1. GENERAL

1.1 Scope

This specification together with the requisitions, purchase order/inquiry, attached drawings,

and data sheets covers the requirements to be met by Vendor in the design, fabrication"

inspection, testing, and supply of shell and tube heat exchangers.

This specification shall not be apply to such pressure vessels and heat exchangers that are

normally designed under the manufacturer's standard; i.e. pressure vessels which belong to

packaged unit, pressure vessels which are attached to turbines, engines, pumps, compressors

and other mechanical equipment, etc. However, the manufacturer's specifications are Subject

to Owner's approval.

1.2 Specific Job Requirements

Specific Job Requirements which are attached to this specification cover modifications to this

specification, Customer's special or local requirements as well as specific job data pertinent to

this specification.

Where Specific Job Requirements are in contradiction to this specification, Specific Job

Requirements shall govern.

1.3 Codes and Standards

1.3.1 The following Codes and Standards shall be applied as the minimum requirement

For pressure parts design : ASME Section VIII Div.1 & 2, 2010 Edition

For shell & tube heat exchanger : TEMA Class B-9th Edition (2007)

For material of pressure part : ASTM, AWS, JIS, DIN

Manufacturer's Country of Origin with OWNER's approval

For flange : ASME B16.5 (Refer to Table U-3 of ASME Section

VIII Div. 1)

For screw thread of bolt and nut : ASME B 1.1 for ASME Flanges

IS0-261 for others

For welding qualification : ASME sect IX, 2010 EDITION

For expansion joint : Tube sheet by ASME Expansion joint by EJMA

or

Tube sheet by TEMA Expansion joint by TEMA

1.3.2 It shall be the responsibility of Vendor that all aspects of the design, fabrication,

inspection and testing conform to the requirements of the specified codes and

standards, and legal requirements.

1.3.3 Where there are conflicts between Purchaser's drawings/ specifications and the

specified codes/standards or legal requirements, such conflicts shall be promptly

referred to Purchaser.

1.3.4 Combined stress calculation for vertical vessels shall be carried out in accordance with

JPI-7R-35-2004."Design of Vertical Vessels Supported by Skirt" or BS 5500, against

wind and earthquake shall be referred to Basic Engineering Design Data. Wind load

shall be calculated in accordance with Sect 3.9 of Engineering Specification for Design

Loadings UBE-A-100.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 4 of 16

1.4 Purchaser's Drawings and Specifications

1.4.1 Purchaser will furnish Vendor with the drawings as indicated in Purchaser's requisition

sheets.

1.4.2 Either Formal Sketches or Engineering Drawings will be furnished to Vendor as

Purchaser's drawings.

(1) Formal Sketches (hereinafter referred to as Sketches) which are prepared based

on Purchaser's basic design work, contain such information as the shape, basic

dimensions, design conditions, materials for primary parts, and nozzle

specifications as required by the Vendor to accomplish his mechanical design of

the heat exchanger.

(2) Engineering Drawings (hereinafter referred to as Eng. Dwg's) contain, in

addition to the above information on Sketches, some constructional details

based on mechanical design of the vessels, as well as engineering information

necessary for planning, piping and foundation design of the heat exchanger.

1.4.3 Eng. Dwg's will be issued in the following steps. And at each step additional

information and/or revisions will be provided. Vendor shall proceed with his work in

accordance with purpose of each issue.

(1) Preliminary or for Information

(2) For Inquiry or for Approval

(3) Approved for Material Purchase only

(4) Approved for Construction (AFC)

(5) Final

1.4.4 Purchaser's Vessel Standards are to supplement Eng. Dwg's and Sketches, and

applicable standards sheets will be indicated on Eng. Dwg's or Sketches.

1.4.5 The related engineering specification to supplement this specification are as follows.

These specifications, when indicated on purchaser's requisition sheets shall form an

integral part of the purchase order.

(1) UBE-D-112 "Marking for vessels & Heat Exchangers"

(2) UBE-D-202 "Inspection and Tests for Vessels & Heat Exchangers"

(3) UBE-D-301 "Painting Works"

(4) UBE-R-453 "Shipping and Packing Instructions"

(5) - “Basic Engineering Design Data”

(6) UBE-L-101 "Thermal Insulation Design"

(7) UBE-A-100 "Design Loadings"

(8) UBE-D-100 "Vessel Standard"

1.4.6 Where requirements in Purchaser's drawings or specifications are not acceptable by

Vendor, suggested alternatives shall promptly be referred to Purchaser for approval.

1.5 Vendor's Drawings and Documents

1.5.1 Vendor shall submit to Purchaser drawings and documents as called for in Purchaser's

requisition sheets.

1.5.2 All drawings and documents shall give the name of the client (end user), Purchaser's

Job No., Item No., and name of the commodity.

1.5.3 Drawings and documents to be submitted shall be in metric, Celsius and kilogram unit.

As a rule, drawings shall be prepared to scale and in third angle projection.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 5 of 16

1.5.4 When Sketches are provided, Vendor shall prepare Eng. Dwg's covering the same

contents as specified in Par. 1.4.2 (2). Such drawings may be used as Vendor's

assembly drawings with necessary information that may be added by him for his work.

1.5.5 Vendor's shop drawings shall contain:

(1) Title block (Purchaser's Job No., Item No., and name of the commodity)

(2) Design data (conforming to Purchaser's drawings)

(3) Material list (material specifications and quantities for all parts including spare

parts)

(4) Nozzle list (conforming to Purchaser's drawings)

(5) All welded seams, and weld and surface finish symbols

(6) Detailed dimensions and thicknesses

1.5.6 Vendor's strength calculations shall cover:

(1) All pressure holding parts

(2) Opening reinforcements

(3) Expansion bellows

(4) Supports

(5) Pass partition plate when specified

(6) Flow induced vibration of bundle when specified

(7) Local stress analysis when specified

1.5.7 For heat exchangers fabricated and/or assembled at job site, Vendor shall submit the

instructions for the work. Packing specifications and sketches shall also be provided.

1.5.8 Purchaser's approval for Vendor's drawings and documents shall not relieve Vendor of

his responsibility to meet all requirements of the purchase order.

2. DESIGN

2.1 General

2.1.1 Shell and tube exchanger shall be designed according to

(a) TEMA Class "B" when handling fouling fluid;

(b) TEMA Class “C" when handling clean fluid. (ff < 0.0002 m2 hr oC/kcal)

If for process reason other design may be applied by the Owner/Contractor under his

design criteria and experience.

2.1.2 Overall heat transfer coefficient (U) calculation divided by Overall heat transfer

coefficient (U) design shall be more than 1.10 in additional to design margin which is

specified by the Process Licensor.

2.1.3 Fouling fluid shall be in tube side. If for process reason the fouling fluid can be in shell

side and the floating head type shall also be provided.

2.1.4 U-tube designs are not allowed when the tube side fouling factor is greater than

0.0002 m2 hr oC/kcal

2.1.5 Major equipment shall be designed for 25 years operating life. However, for corrosive

or erosive areas where material can easily be replaced, a minimum service life of 10

years is acceptable.

2.1.6 Cooling water velocity shall not lower that than 1.5 m/s or higher than 2.5 m/s. If its

velocity is out of that range, list of heat exchanger, shall be submitted to Owner for

approval during engineering period.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 6 of 16

2.1.7 Heat exchangers and reboilers with fixed tubesheets, with or without an expansion

bellow in the shell, or exchangers with longitudinal baffles may be applied by the

Contractor under his design criteria and experience and shall be approved by the

Owner prior to fabrication.

2.1.72.1.8 Each exchanger shall be at least defined by the following data:

- The thermal duty or enthalpies curves of fluids.

- The physical and thermodynamic conditions of the fluids at the inlet and outlet.

- The hydraulic conditions such as viscosity, velocity, pressure drop.

- The number of passes for each fluid.

- The corrosion allowances.

- The diameter, length and arrangement of the tubes, the diameter of the shell,

the exchange surface, the layout of the baffles and the TEMA type.

- The fouling factor and total heat transfer-coefficient.

- The design conditions (temperature and pressure).

- The materials and their ASTM references.

- The weight both empty and filled with water and the weight of the bundle alone.

- The data shall be presented in the form of Standard Specifications sheet of

TEMA. Each sheet shall defined exchanger by using TEMA nomenclature with

specific features proposed. The heat transfer surface shall be net effective

transfer surface.

2.1.9 For each exchanger circuit, for each operating run, start-up, normal shutdown and

emergency shutdown, the maximum temperature and pressure conditions duty and

fluid conditions shall be issued for each operating case.

2.1.10 The design shall take account the configuration of the piping, the presence of block

valves, the maximum discharge pressure of compressors and pumps and the pressures

at which safety valves are set.

2.2 Design Pressure

2.2.1 The design pressure shall be as indicated on purchaser's drawings.

2.2.2 Parts subjected to both shell and tube side fluids shall be designed to withstand the

pressure on shell side only and tube side only, and the most severe combination of the

pressure unless Purchaser's drawings explicitly require other design conditions.

2.2.3 When design pressure is specified as full vacuum (F.V) in Purchaser's drawings

specifications, Pressure vessels shall be designed for extema1 pressure of 1.033

kg/cm2 and internal pressure of 2.0 kg/cm2G and design internal pressure, as indicated

on Purchaser’s drawing whichever is the greater.

2.3 Design Temperature

2.3.1 The design temperature shall be as indicated on purchaser's drawings.

In case of the design temperature indicated on Purchaser's drawings/specifications

higher than the minimum ambient temperature for mechanical design basis specified

on "Basic Engineering Design Data", the minimum design metal temperature is the

Minimum Ambient Temperature

2.3.2 Parts in contact with both fluids having different temperatures shall be designed for

the higher temperature of the two. When operating temperatures are 15oC or less,

they shall be designed for the lower temperature of the two.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 7 of 16

2.4 Design Loads

2.4.1 Exchangers and their supports shall be designed for the erection, operating, test

conditions and maintenance.

Exchangers and their support and foundation shall be designed so as to bear the field

hydrostatic test load under the installed condition.

The exchanger design must thus take the static head of liquid, whilst the foundation

and supports should take the additional weight of liquid, into consideration. Allowance

shall also be made for attached piping.

2.4.2 Fixed supports and anchor bolts shall be designed to withstand a minimum horizontal

force equal the bundle weight multiplied by 1.5.

2.4.3 In case of stacked shells of two or more exchangers the support system shall be

adequate to accommodate the loads of the upper shells without distortion and to resist

the axial load from pulling the upper bundles. No buckling shall be allowed.

2.5 Corrosion Allowance

2.5.1 The corrosion for the shell shall be specified by Purchaser for 25 years operation life of

the vessels. Anyhow, the minimum corrosion allowance for carbon steel and low allow

steel shall not be less than 1.6 mm.

Unless otherwise specified in Purchaser's drawings/specifications, corrosion allowance

for shell & tube type heat exchangers shall be in accordance with TEMA class 'B'.

2.5.2 Unless otherwise specified in the drawings, the corrosion allowances are not required

for tubes, backing devices and non-pressure parts such as baffles, supports,

impingement baffles, pass partition plates, etc.

2.5.3 The corrosion allowance shall not be required for external surfaces of exchangers.

2.5.4 When the service conditions are such that it is not practicable to provide corrosion

allowances by added base metal, a solid corrosion resistant material, or lining,

cladding, deposit or coating of the corrosion resistant material shall be used. The

minimum thickness shall be 2 mm for lining and cladding, and 3 mm for weld deposit

after machining. The minimum thickness of cladding on tube sheet shall be 8 mm.

2.5.5 Total corrosion allowance of 1.0 mm on the diameter of the bolt shall be considered for

foundation bolts.

For external surface of vessels and external accessories such as platforms skirts lugs

and setting bolts, no corrosion allowance is provided.

2.6 Material

2.6.1 The materials for primary parts shall be as specified on Purchaser’s drawings.

2.6.2 Materials of the parts not specified on Purchaser's drawings or vessel standards shall

be decided by vendor and shall be submitted by showing on the Vendor's drawings for

Purchaser's approval.

2.6.3 Vendor may propose the use of alternative materials. Such alternatives shall be clearly

indicated on his proposal giving the official material designation or the chemical

composition and physical properties for such materials having only a trade or supplier

designation, and shall be submitted for Purchaser's approval.

2.7 Tolerances

2.7.1 Unless otherwise specified, tolerances shall be in accordance with Engineering

Specification UBE-D-202, Inspections & Tests of Vessels and Heat Exchangers.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 8 of 16

2.7.2 The thickness after forming of any pressure holding parts shall not be less than the

design minimum thickness.

2.8 Strength Calculation

2.8.1 The thicknesses indicated on Purchaser's drawings are those proposed by Purchaser.

Vendor shall check and confirm under his guarantee that such thicknesses provide the

proper strength under the specified conditions. Any lesser thickness considered by

Vendor shall immediately be referred to purchaser, but in no case will any proposed

thickness be decreased without Purchaser's prior approval, even if it has an extra

margin beyond the required thickness.

2.8.2 Connecting dimensions shall not be changed by Vendor, even if such change is

required resulting from the strength calculation. However, if nozzles, reinforcement

pads, and main seams should interfere with each other, these dimensions may be

changed upon Purchaser's approval.

2.8.3 Stresses induced on shell by support saddles shall be checked according to JPI-7R-52-

76 or zick method, if necessary. Analysis for local stress caused by nozzle and

attachment reaction under operation conditions and lifting lug for equipment shall be

conducted in accordance with WRC 107 and 297, if necessary.

2.8.4 Combined stress calculation for vertical vessels shall consider (under corroded

condition) the hydrostatic test condition after installation at the plant site. However,

the seismic load shall not be considered for design of vertical vessels during

hydrostatic test at the plant site.

2.8.5 Unless otherwise specified, the following weight for equipment shall be included into

erection weight for calculation under erection condition.

- Platform and ladders

- Piping

- Insulation

- Tray and other internals, except packing and catalyst

- Accessories

2.8.6 Corrosion resistance lining shall not be considered as contributing to the strength.

3 DETAILED DESIGN

3.1 Shells and Channels

3.1.1 The angle of a conical section of kettle type exchangers shall be in general 30o

(degrees).

3.1.2 For fixed tubesheet construction Vendor shall determine the necessity of expansion

bellows according to the ASME Section VIII Div.1 Part UHX standard. The metal

temperatures of shell and tubes will be specified on purchaser's drawings. Subtract

20oC from those temperatures in calculation in general.

Unless otherwise specified, expansion joints, if required, shall be bellows type and

rated for 3,000 cycles at full design movement in accordance with EJMA.

3.1.3 Strength calculation on channel covers shall conform to the requirement of the ASME

Section VIII Div.1.

3.1.4 Girth flanges shall have a confined gasketed joint to hold the gasket in place during

assembly.

3.1.5 In general all girth flanges shall be of welding neck construction, except that slip-on

flanges shall be used when exchangers are made of high alloy steels or nonferrous

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 9 of 16

metals or when design pressure is 20 kg/cm2G or less, and design temperature 350oC

and less.

3.1.6 Vent and drain holes of approx. 6 mm in diameter shall be provided at the highest and

lowest points of each pass partition plate.

3.2 Tubes and Tube Bundles

3.2.1 The length specified on Purchaser's drawings shall be end-to end length for straight

tubes, and for U-tubes the length measured from end to return bend tangent.

3.2.2 Tube thicknesses will be specified on purchaser's drawings as the minimum

thicknesses.

3.2.3 Each U-tube shall be formed from a single length and mean radius of U-tube bend

shall not be less than 2 times the tube outside diameter.

3.2.4 If strength welded tube-to-tubesheet joints are impracticable and/or impossible,

expanded tube-to tubesheet joints with two square edged groove may be applied.

3.2.5 Strength welded and light expanded tube-to-tubesheet joints are considered as

standards. Vendor shall submit the welding procedure, welding methods and inspection

methods for purchaser's approval.

3.2.6 Baffles and support plates shall be tied together with rods and spacers, and for

horizontal exchangers they shall be provided with notches at the lowest point to permit

full drainage of the shell.

3.2.8 For exchangers those do not require baffles, support plates of 45% vertical cut shall

generally be provided. Support plates need not be cut for kettle type exchangers.

These support plates shall be so spaced that unsupported tube length does not exceed

the value specified in the TEMA Standard.

3.2.9 Clamp bands shall be installed for kettle type exchangers.

3.2.10 Tube shall be seamless. Circumferential welds in tubes are not acceptable.

3.2.11 Austenitic materials require only the U-bends to be solution annealed beyond the

tangent line after bending. Contractor shall submit the procedure for the Owner's

review. Annealing shall be performed electrically in accordance with the ASTM

standard appropriate to the particular material grade.

3.3 Tubesheet

3.3.1 Tubesheets shall be designed in accordance with the ASME Section VIII Div.1 provided

that calculated thicknesses meet the code requirement.

3.3.2 Tubesheet calculations shall be based on at least to the following conditions in both

corroded and uncorroded state,

- Normal operating conditions.

- Shell side start-up, no fluid tube side.

- Tube side start-up, no fluid shell side; shell at most severe ambient temperature.

- Shell side pressure failure.

- Tube side pressure failure.

- Specified turn-down operating conditions.

- Hydro Test.

- "Steam-Out" or other cleaning procedures, when specified.

3.3.3 When longitudinal baffles are welded to the shell, the welding seams shall not be close

to the longitudinal welded seams of the shell. The Fixed tubesheets shall be provided

with the gasket grooves for the baffles.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 10 of 16

3.3.4 Clad tube sheet is not allowed.

3.4 Expansion Joint

3.4.1 In general, expansion joints are not allowed on exchanger shells. During the design

phase expansion joints may be allowed in a few instances, but only with Owner

approval. Expansion joints shall be the "OMEGA" type unless otherwise approved by

the Owner.

3.4.2 All expansion joints must be capable of withstanding a minimum of 5000 cycles.

3.4.3 "OMEGA" expansion joints must be the same material as the shell, with the same

corrosion allowance. Minimum thickness shall satisfy TEMA requirements.

3.4.4 Bellows type of expansion joints are not allowed in hydrocarbon service.

3.4.5 Design of fixed tubesheet exchangers shall use the most stringent of the following

criteria in determining the need for an expansion joint:

- Normal operating conditions.

- Shell side start-up, no fluid tube side.

- Tube side start-up, no fluid shell side; shell at most severe ambient temperature.

- Shell side pressure failure.

- Tube side pressure failure.

- Specified turn-down operating conditions.

- Hydro Test.

- "Steam-Out" or other cleaning procedures, when specified.

3.4.6 Bellows-type internal expansion joint between the floating head and the shell cover

may be used subject to the following conditions:

- The expansion joint shall be hydraulically-formed corrugated bellow type and

shall be able to withstand the full design and test pressure of either side of the

exchanger.

- The construction shall be such that it can be disassembled without cutting, if

possible, for access to the floating tubesheet, removal of tube bundle, and for

replacement of the bellows and floating head.

3.5 Nozzles and Opening Reinforcement

3.5.1 In general nozzles shall be flanged and 3/4 in. minimum in size. The type, rating and

facing of nozzles flanges and thicknesses of nozzle necks shall be in accordance with

Purchaser's drawings and Vessel Standards.

3.5.2 All high and low points on shell and tube sides of exchangers not otherwise vented or

drained shall be provided with 3/4 in. connections for vent and drain.

3.5.3 When male and female (M&F) or tongue and groove (T&G) type flanges are specified,

the nozzle flange facing of the heat exchangers shall be of female or groove type.

3.5.4 Drain nozzles shall be trimmed flush with the inside surface of the heat exchangers.

3.5.5 Nozzles to be welded directly to the connecting piping will be indicated on Purchaser's

drawings. Caps for pressure testing shall be attached to the nozzles by welding. After

the pressure testing the caps shall be cut off, and the nozzles machined to form the

specified welding edges.

3.5.6 The facing of the intermediate nozzles between the units which are to be stacked shall

be FF or RF type.

3.5.7 Level gauge nozzles of kettle type exchangers shall be supported from the shell.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 11 of 16

3.5.8 Nozzles shall not generally be provided with connections for pressure gauges and

thermometers.

3.5.9 The opening reinforcement shall be so designed as not to limit the maximum allowable

working pressure of the heat exchanger.

3.5.10 The reinforcement for the nozzle opening shall be of integral type, when required by

the applicable codes/standards or where all of the following conditions apply:

(1) Design temperatures exceed 350oC

(2) Design pressures exceed 30 kg/cm2

(3) Plate thicknesses exceed 50 mm

3.5.11 Nozzles sized 2 in. nominal and larger shall generally be provided with reinforcement

plates. Each reinforcement plate shall be provided with at least one tell-tale bole of 1/4

in. NPT thread. The tell-tale bole shall not be provided on the reinforcement plate in

the longitudinal direction of the vessel.

3.5.12 In general, nozzles are subject to external loads. Vendor shall check the strength of

the nozzles and shells against external loads based on Purchaser's information and

shall provide additional reinforcements if required.

3.5.13 Roughness of flange gasket face except ring type face, shall be 125 RMS max. for

vacuum service and 250 RMS max. for others.

3.6 Bolts and Nuts

3.6.1 Unless otherwise specified, all bolting threads to be used for vessels shall be ISO

metric system as set out in VS-23 of Vessel Standard except for ASME standard

flanges.

3.6.2 Threads of bolts and nuts shall be coated before installation with lubricant to prevent

galling of the thread.

3.7 Gaskets

3.7.1 The hardness of metal gaskets shall not exceed the values in the following table.

Gasket Materials Brinell Hardness

Soft Iron, Low Carbon Steel and Nickel 120

5% Cr - ½% Mo Steel 140

Austenitic Stainless 160

3.7.2 All metal and metal jacketed, non-asbestos gaskets shall be confined type with a

double crimped face and of a total thickness at least 3 mm before compression. The

metal envelope shall be 0.6 mm thickness.

3.7.3 For hydrocarbon and hydrogen service, the girth joint gaskets shall be solid metal

type; spiral wound non-asbestos filled type or double jacketed metal asbestos filled

type.

3.7.4 For hydrogen service, the material of gasket shall provide hydrogen protection and

corrosion protection equal or better than minimum requirements on material involves

at joint.

3.7.5 For cooling water service, the anti-corrosive compressed non-asbestos is acceptable.

3.7.6 For high-pressure and high-temperature and hydrogen service, the ring type joints or

spiral wounded gaskets with retention ring shall be used (Class 150 rating and higher).

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 12 of 16

3.7.8 For design temperatures above 425oC the material shall be TP 345 or TP 321 or TP

316 stainless steel. Below 400oC stainless steel TP 304 is acceptable.

3.7.9 Copper gasket is not permitted.

3.8 Supports

3.8.1 Units which are to be stacked shall be provided with the required additional

intermediate supports and liners for elevation adjustment.

3.8.2 Lug or saddle supports for the vertical or horizontal vessels/heat exchangers with

design temperatures less than 0o C shall be provided with wooden pillows according to

Vessel Standards.

3.9 Fittings for Assembly and Disassembly

3.9.1 To facilitate breaking gasketed joint of main girth flanges, jack screws or (at the

periphery of the male flange) a cutback of 5 mm to a depth of approximately 30 mm

and width of 30 mm shall be provided.

3.9.2 Guide rails shall be provided for kettle type exchangers and the horizontal exchangers

with the removable bundle weighing 10 tons and over.

3.9.3 Each channel, channel cover and shell cover shall be provided with plate type welded-

on lifting lug with 25 mm diameter hole.

3.9.4 Tapped holes for insertion of eyebolts shall be provided on the outer face of

tubesheets of removable bundles and floating head cover flanges

3.9.5 Alignment marks shall be provided to prevent mis-assembly of channel covers, channel

flanges, shell flanges, shell cover flanges and floating heads.

4 FABRICATION

4.1 Plate Layout

4.1.1 Shell plates shall be laid out so that there will be a minimum of welded seams.

4.1.2 If a reinforcement plate and/or attachments must cover a weld seam, the entire

bidden length plus a distance of 50 mm beyond the attachment weld shall be full

radiographed prior to the attachment of the pad.

4.1.3 Longitudinal welded seams on adjacent shell segments shall be separated by at least 4

times the wall thickness of the thicker plate but not less than 100 mm.

4.1.4 Longitudinal and circumferential welded seams shall be kept out of the internal welds

insofar as practical, and shall be so located that they can be easily inspected with

internals in place.

4.2 Forming

4.2.1 Selection of hot or cold forming of materials may be made by Vendor, but heat

treatment after forming shall conform to Par. 4.4.

4.2.2 Despite Par. 4.2.1, austenitic stainless steel shall generally be subjected to cold

forming. Hot forming shall not be employed unless approval has been obtained from

Purchaser.

4.2.3 A formed head shall generally be made of single plate and shall be formed by cold or

hot press, or hot spinning.

4.2.4 When temporary attachments are required during the forming work, they shall be

welded to the shell plate using the same welding procedures as for the main seams.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 13 of 16

After removing these attachments, the surface shall be ground flush and examined by

either magnetic particle or liquid penetrant method.

4.2.5 When forming of clad steel is required, Vendor shall submit prior to operation, the

procedure for Purchaser's approval.

4.3 Welding

4.3.1 As a rule exchangers shall be welded by the fusion arc process. Electrogas or

electroslag welding shall be subject to Purchaser's approval.

4.3.2 Welders shall be qualified in accordance with the specified codes or standards.

4.3.3 Pressure holding seams shall normally be full penetration double-welded butt joints.

Single-welded butt joints which ensure full penetration may be used, where double

welded butt joints are impractical.

4.3.4 Welding electrodes and wires shall have chemical composition and mechanical

properties equal to or of higher grade than the base material

4.3.5 Stainless steel welding and dissimilar welding of stainless to carbon or low alloy steels

shall be carried out conforming to Vessel Standard

4.3.6 Welding procedures for any dissimilar welds of stainless to carbon or low alloy steels

shall be presented in full detail to purchaser for approval.

4.3.7 Welding procedures shall be selected to minimize the residual stress insofar as

practical.

4.3.8 Preheating shall be carried out for carbon and low alloy steel welding as required. The

preheating temperature shall be kept uniform from the start to the end of welding.

4.3.9 The minimum bead length for low and high alloy steel shall be 80 mm.

4.3.10 As a rule, tubes shall be welded to tubesheet by at least two pass welding when

strength weld are applied.

The welding shall be carried out before expanding tubes to tubesheet.

When manual welding are applied 10 the strength welding, a filler metal on first pass

shall not be used, unless otherwise agreed.

4.4 Heat Treatment

4.4.1 Unless otherwise stated in purchaser's drawings, postweld heat treatments shall be

carried out in accordance with the applicable codes or standards, and the following

additional requirements.

4.4.2 The maximum postweld heat treatment or stress relief temperature shall not exceed

the lower of the following values:

(1) Maximum temperature listed in the applicable codes or standards.

(2) The tempering temperature if tempering was performed.

(3) The following temperatures for the listed materials.

(a) Carbon and 2-1/2 to 3-1/2% Ni Steel : 650 oC

(b) C-1/2% Mo and Mn-Mo Steel : 690 oC

(c) 1/2% Cr-1/2% Mo Steel : 690 oC

For design temperatures of 480oC and over, the postweld heat treatment

shall be in the temperature range of 680 oC to 730 oC for a period of 4

hours minimum,

(d) 3/4 to 9% Cr-Mo Steel : 745 oC

4.4.1 Plates, seamless heads, parts of built-up heads, and similar pressure holding parts

subject to cold or hot bending, forming or forging shall be heat treated as required by

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 14 of 16

Table 1. Annealing, normalizing, and tempering required by Table 1 shall be performed

in accordance with Table 2.

Incase less stringent than ASME. the requirement of Heat Treatment shall be in

accordance with ASME Section VIII Div.1.

4.4.4 Welds with a thickness of 19 mm or greater made by electroslag or single pass

electrogas processes shall be normalized.

4.4.5 No welding shall be performed on vessels after the fina1 postweld heal treatment

4.4.6 When clad steel or dissimilar welded parts are heat treated, the heat treating

procedure shall be submitted for Purchaser's approval.

Table 1 Bending, Forming, and Forging Heat Treatment Requirements

Cold Bending or Hot Bending or Forming

Type of Material Forging

Forming (1) (1)

Normalize if heated

C Steel None (2) None

Above 980 OC

C – ½% Mo Steel None (2) None Normalize

½% Cr – ½%

None (2) None Normalize and temper

Mo steel

Normalize and temper to Normalize and temper

1 to 9% Cr – Mo

None (2) conform to mill test report to conform to mill test

Steel

Heat treatment report Heat treatment

AISA types 304,

None Anneal Anneal

316, 321 And 347

2 to 6% Ni Steel None Normalize and temper Normalize and temper

Incoloy None None None

Incoloy,

Solution anneal Solution anneal Solution anneal

AISI type 310

Heat treatment to

Steel enhanced by Heat treatment to

None (2) conform to mill test

heat treatment conform to mill test report

report

Notes:

(1) Bending and forming are defined for ferritic materials as cold when the temperature is below

the maximum temperature permitted by Par. 4.4.2 and hot when above 870oC and for

austenitic materials as cold when the temperature is 593oC or under, and as hot when over

593oC. Bending and forming shall not be performed on ferritic materials at temperatures

between the maximum cold temperature and 870oC

(2) Pressure vessel formed parts having a ratio of thickness to local radius greater than 5% shall

be stress relieved prior to any subsequent operations.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 15 of 16

Table 2 Heat Treating Requirements (3)

Heat Soaking Temp. Method of

Type of Material Holding Time (Hour)

Treatment (OC) Cooling

1 per 25 mm of

AISI types 304, 316,

1,040 to 1,100 thickness but not less

321 and 347

than ½ Water

quench or air

Anneal Incoloy 1150 (1) 1 per 25 mm of

blast

thickness but not less

AISI type 310 1150 than 1

C Steel

C – ½% Mo Steel 900 to 950 1 per 25 mm of

1/2 to 9% Cr – Mo Steel thickness but not less

Normalize than 1/2 Still air

2 to 6% Ni Steel 820 to 845

1/2 to 9% Cr – Mo 1 per 25 mm of

700 to 760 In furnace (2)

Temper Steel thickness but not less

2 to 6% Ni Steel 563 to 650 than 1 Still air

Notes:

(1) The temperature range during heat treatments shall be plus 0, minus 30oC.

(2) After attaining the soaking temperature and maintaining the required holding time, the cooling

time to 430oC shall not be less than one hour.

(3) Procedures listed in this table are Purchaser's proposal. Vendor may adopt alternative

procedure upon Purchaser's prior approval.

4.4.7 Channels, bonnets and floating head shall be stress relieved, when required by TEMA.

4.4.8 The gasket faces of shell and channel girth flanges shall be machined after heat

treatment

4.4.9 The following U-tubes shall be heat treated after bending.

(1) Tubes to be used in the environment of stress corrosion cracking.

(2) Al-killed steel or 3-1/2% Ni steel tubes of which mean bending radius is less

than or equal to 5 times the tube outside diameter.

(3) Cr-Mo steel

4.4.10 When fixed tubesheet exchanger bundles shall be heat treated, the instruction shall be

submitted for Purchaser's approval.

5 INSPECTION AND TESTING

All heat exchangers shall be inspected and tested in accordance with the Engineering

Specification UBE-D-202, Inspection & Tests of Vessels & Heat Exchangers, unless otherwise

specified on purchaser's drawings.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

ENGINEERING SPECIFICATION UBE-E-102

FOR Rev.0 : Sep.16, 2013

UBE GROUP (THAILAND) HEAT EXCHANGERS Pa ge 16 of 16

6 NAMEPLATE, PAINTING AND HARKING

6.1 Nameplate

6.1.1 A nameplate as shown in Vessel Standards shall be mounted on each exchanger.

6.1.2 Location of nameplates will be indicated in purchaser's drawings.

6.2 Painting

6.2.1 Painting material, application and external surface preparation for painting shall be in

accordance with Engineering Specification UBE-O-301.

6.2.2 All flange faces and other machined surfaces shall be coated with a readily removable

rust preventive paint,

6.2.3 Weld bevels on the ends of carbon or low alloy steel nozzles shall be coated two times

on the inside and outside, for a distance of 75 mm from the end of the nozzle, with

Deoxaluminite, Taseto Silver or equivalent.

6.3 Marking

Marking shall be in accordance with Engineering Specification UBE-D-112, Marking for Vessels

and Heat Exchangers.

7 PACKING AND SHIPPING

7.1 General

Packing and shipping shall be in accordance with Engineering Specifications UBE-R-453.

7.2 Packing and preparation for Shipping

7.2.1 All exchangers shall be dry, thoroughly cleaned inside and outside and free of all dirt

and loose foreign materials before shipping.

7.2.2 All flanged openings shall be provided with bolted blinds with gaskets,

7.2.3 All beveled openings shall be covered or capped to protect the inside from rust and

moisture.

7.2.4 When rust preventive measures are required for inside surface of exchangers, these

will be indicated on Specific Job Requirements.

7.2.5 Spare parts shall be packed separately from the exchangers.

7.2.6 Tell-tale holes on the outside of exchangers shall be greased up.

7.2.7 Demisters shall be free of wire pieces in so far as possible.

7.3 Shipping

7.3.1 Templates, foundation boltings, sliding plates and insert plates shall be shipped

separately from the exchangers according to the site schedule.

7.3.2 No exchanger shall be released for shipment from Vendor's shop until it has been

approved by Purchaser's inspector.

ALL RIGHTS RESERVED

THIS DOCUMENT AND ANY DATA AND INFORMATION CONTAINED THEREIN ARE CONFIDENTIAL AND THE PROPERTY OF UBE GROUP. AND

THE COPYRIGHT THEREIN IS VESTED IN UBE GROUP. NO PART OF THIS DOCUMENT, DATA OR INFORMATION SHALL BE DISCLOSED TO

OTHERS OR REPRODUCED IN ANY MANNER OR USED FOR ANY PROPOSE WHATSOEVER, EXCEPT WITH THE PRIOR WRITTEN PERMISSION OF

UBE GROUP.

You might also like

- Norsok Standard P-001: Edition 5, Sep. 2006Document26 pagesNorsok Standard P-001: Edition 5, Sep. 2006Đào_hải_10No ratings yet

- Kettle Type Exchangers PDFDocument13 pagesKettle Type Exchangers PDFrams789No ratings yet

- SAES-E-004 02-18-2018 FinalDocument35 pagesSAES-E-004 02-18-2018 Finalsaleem naheedNo ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- DJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDocument3 pagesDJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDIANTORONo ratings yet

- Webinar FAQ - Shell and Tube Heat ExchangersDocument8 pagesWebinar FAQ - Shell and Tube Heat Exchangersrameshkarthik810No ratings yet

- E PR 810Document41 pagesE PR 810anju2718No ratings yet

- E-Pr-330 COMPRESSED AIR SYSTEMSDocument28 pagesE-Pr-330 COMPRESSED AIR SYSTEMSFabian Andrey DiazNo ratings yet

- Detail DesignDocument67 pagesDetail DesignBHAVISHA GOHILNo ratings yet

- Engineering Standard: IPS-E-PR-340Document22 pagesEngineering Standard: IPS-E-PR-340Sadegh AhmadiNo ratings yet

- Aspen Exchanger Design and Rating Air Cooled V11Document1 pageAspen Exchanger Design and Rating Air Cooled V11HafidzAliyufaNo ratings yet

- Structured Packings GasDocument20 pagesStructured Packings GasBowo Edhi WibowoNo ratings yet

- CHE 165A L11 - Heat Exchanger Design PDFDocument61 pagesCHE 165A L11 - Heat Exchanger Design PDFLi ChNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- HDS Benefits From Plate Heat ExchangersDocument6 pagesHDS Benefits From Plate Heat Exchangerssaleh4060No ratings yet

- Engineering Standard: IPS-E-PR-700Document17 pagesEngineering Standard: IPS-E-PR-700ssureshkumar85100% (1)

- OMN-FAC-263 Shell and Tube ExchangersDocument13 pagesOMN-FAC-263 Shell and Tube Exchangerssumit kumarNo ratings yet

- 6b - Tower DesignDocument25 pages6b - Tower DesignIslam SolimanNo ratings yet

- Heat Transfer Lect 6 (Heat Exchanger)Document45 pagesHeat Transfer Lect 6 (Heat Exchanger)Mostafa SabryNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- Mr. C.H.Park / Project Manager 03-May-06Document30 pagesMr. C.H.Park / Project Manager 03-May-06Ali YassineNo ratings yet

- Biofuels PowerpointDocument27 pagesBiofuels PowerpointIrene Kaye AceroNo ratings yet

- E PR 491Document41 pagesE PR 491aizzuan_1No ratings yet

- Equipment DatasheetDocument3 pagesEquipment DatasheetmdgouseahmedNo ratings yet

- Flare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachDocument8 pagesFlare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachaltruismNo ratings yet

- Saes C 001Document6 pagesSaes C 001jinto joyNo ratings yet

- Safe Chemical Reaction Scale Up: by Dennis C. Hendershot, Aaron SarafinasDocument7 pagesSafe Chemical Reaction Scale Up: by Dennis C. Hendershot, Aaron Sarafinasnitin_kheseNo ratings yet

- RSD/RCD/RCT Series: Coarse/Fine Bubble Aeration DiffuserDocument8 pagesRSD/RCD/RCT Series: Coarse/Fine Bubble Aeration DiffuserArgie AdduruNo ratings yet

- Isolation PhilosophyDocument13 pagesIsolation PhilosophySamir BhongadeNo ratings yet

- E PR 360Document74 pagesE PR 360Hossein Jalali MoghaddamNo ratings yet

- Line Sizing CriteriaDocument5 pagesLine Sizing CriteriaBILAL ILYASNo ratings yet

- PSV-1203 - 3632-I-DS-31001 WorkingDocument1 pagePSV-1203 - 3632-I-DS-31001 Workinganamaria ursuNo ratings yet

- Peggen03 PDFDocument5 pagesPeggen03 PDFMohamedNo ratings yet

- Glycol Dehydration Unit English A4 PDFDocument4 pagesGlycol Dehydration Unit English A4 PDFAjay Kumar GuptaNo ratings yet

- Training Program On Petroleum Refining Technology: Session 5: Fouling - Causes, Consequences and MitigationDocument27 pagesTraining Program On Petroleum Refining Technology: Session 5: Fouling - Causes, Consequences and MitigationAtifNo ratings yet

- S-138777-Activated Energy Analysis Jump Start GuideDocument18 pagesS-138777-Activated Energy Analysis Jump Start Guidegion_ro401No ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- UOP 3-28-6 - Storage Tanks Low PressureDocument3 pagesUOP 3-28-6 - Storage Tanks Low Pressurejev_vdNo ratings yet

- PEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ADocument30 pagesPEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ARokan PipelineNo ratings yet

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocument4 pagesR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRANo ratings yet

- Indra: For ConstructionDocument48 pagesIndra: For Constructionsumit kumarNo ratings yet

- Equipment Design Lecture 11 PDFDocument7 pagesEquipment Design Lecture 11 PDFWidhi AlchemistNo ratings yet

- Castable-Free Fired HeaterDocument4 pagesCastable-Free Fired HeaterchemengseliemNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 pagesAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNo ratings yet

- Inert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringDocument5 pagesInert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringFRANKLIN REVILLANo ratings yet

- New - Lecture 2 Introduction To S&TDocument31 pagesNew - Lecture 2 Introduction To S&TWael ElArinyNo ratings yet

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Document23 pagesGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongNo ratings yet

- A Review On Heat Exchanger Thermal Hydraulic Models For Cryogenic ApplicationsDocument14 pagesA Review On Heat Exchanger Thermal Hydraulic Models For Cryogenic ApplicationsbcshendeNo ratings yet

- TN0001 007 Equipment Surface Protection Published English - 210710 - 160106Document15 pagesTN0001 007 Equipment Surface Protection Published English - 210710 - 160106RJ ROHITNo ratings yet

- Erification Omment Heet: ALPHA ECC-Dehydration Skids Package For Tien Hai Thai Binh ProjectDocument2 pagesErification Omment Heet: ALPHA ECC-Dehydration Skids Package For Tien Hai Thai Binh ProjectLê Đức ThiệnNo ratings yet

- Accessen Plate Heat Exchanger Specification SheetDocument1 pageAccessen Plate Heat Exchanger Specification Sheetfakir mohammadNo ratings yet

- Criterios de Diseño - Varios - 1Document116 pagesCriterios de Diseño - Varios - 1wylie01No ratings yet

- Offsites and UtilitiesDocument70 pagesOffsites and Utilitiesankitalalwani100% (1)

- Reaction Technologies: ThreeDocument31 pagesReaction Technologies: ThreeProcess EngineerNo ratings yet

- Heat Exchanger Design Lecture - 07Document24 pagesHeat Exchanger Design Lecture - 07Mohmmad ShaikhNo ratings yet

- Guide Document GE P312 4.1.2 I General ConsiderationsDocument31 pagesGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraNo ratings yet

- Gas Control Valve Sizing: (Masoneilan)Document1 pageGas Control Valve Sizing: (Masoneilan)Tun Naing WinNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument18 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Dickow Pumpen KG: Installation, Operation and Maintenance InstructionsDocument51 pagesDickow Pumpen KG: Installation, Operation and Maintenance InstructionsRoberto FernandezNo ratings yet

- DUQM RefineryDocument56 pagesDUQM RefineryHatrRatNo ratings yet

- Designing For Movement in BrickworkDocument14 pagesDesigning For Movement in BrickworkUgurNo ratings yet

- Yoon 2015Document35 pagesYoon 2015Trushar ParmarNo ratings yet

- HMA Valveco Product OverviewDocument16 pagesHMA Valveco Product OverviewrizalNo ratings yet

- Strip Seal CatalogDocument20 pagesStrip Seal CatalogwalidNo ratings yet

- Приложение по техническим вопросам StenflexDocument23 pagesПриложение по техническим вопросам StenflexОлеся ТвиклерNo ratings yet

- Core Vendor PDFDocument215 pagesCore Vendor PDFSakar EngitechNo ratings yet

- COADE Seminar Notes-Pvelite PDFDocument315 pagesCOADE Seminar Notes-Pvelite PDFDarshJhaNo ratings yet

- Product Index Bridges Other StructuresDocument26 pagesProduct Index Bridges Other StructuresbradenNo ratings yet

- Fatigue Life Testing of Metal Expansion JointsDocument1 pageFatigue Life Testing of Metal Expansion JointsVirjil AycochoNo ratings yet

- CDOT Bridge Design Manual - Section - 11 - 2022Document50 pagesCDOT Bridge Design Manual - Section - 11 - 2022Liu ZhenguoNo ratings yet

- Problems and Solutions With Expansion Joints in Gas Turbine Applications PDFDocument17 pagesProblems and Solutions With Expansion Joints in Gas Turbine Applications PDFJorge Bismarck Jimenez BarruosNo ratings yet

- Vendors Regis2011Document92 pagesVendors Regis2011manjuu47No ratings yet

- Building Seals and Sealants: Standard Terminology ofDocument14 pagesBuilding Seals and Sealants: Standard Terminology ofWaleed MedhatNo ratings yet

- EVR General Product CatalogueDocument16 pagesEVR General Product CatalogueAnthonyNo ratings yet

- Caesar II Modeling ExcisersDocument40 pagesCaesar II Modeling ExcisersBùi Văn Hợp100% (2)

- Expansion Joints: Raison EtreDocument2 pagesExpansion Joints: Raison EtreTAHIR MAHMOODNo ratings yet

- Astm E330-02 PDFDocument7 pagesAstm E330-02 PDFscubricNo ratings yet

- DOPOL® 90 C-Type Cyclone StageDocument37 pagesDOPOL® 90 C-Type Cyclone StageRahmat YusufNo ratings yet

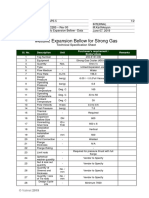

- Strong Gas Cooler - Metallic Expansion Bellow - Data Sheet - Rev 00Document2 pagesStrong Gas Cooler - Metallic Expansion Bellow - Data Sheet - Rev 00Anonymous Ywevve5HNo ratings yet

- 2014-68-EU Guidelines en v2 PEDDocument225 pages2014-68-EU Guidelines en v2 PEDEmmanuelPETITNo ratings yet

- Section A List of Principal Quantities/ Scope of WorksDocument164 pagesSection A List of Principal Quantities/ Scope of WorksKhaled Maddallah50% (2)

- Rehabilitation and Strengthening of Bridges by Using FRP: Niraj S Parsekar (AG21012) Batch 15 Nicmar GoaDocument5 pagesRehabilitation and Strengthening of Bridges by Using FRP: Niraj S Parsekar (AG21012) Batch 15 Nicmar GoadebadityagNo ratings yet

- Pipe Hot Insulation SpecificationDocument34 pagesPipe Hot Insulation Specificationsadeghmsg100% (1)

- Asme Sec Viii D1 Ma App 5Document4 pagesAsme Sec Viii D1 Ma App 5ridho arkanaNo ratings yet

- Refractory Castables by Gunning - Uk PDFDocument10 pagesRefractory Castables by Gunning - Uk PDFdika wahyuNo ratings yet

- Hydroformed Metal Bellows - Design HandbookDocument128 pagesHydroformed Metal Bellows - Design Handbookchipulino100% (1)

- ES - Maurer - Swivel - Joist - DS 480 - DS 560 - Características Del Material PDFDocument2 pagesES - Maurer - Swivel - Joist - DS 480 - DS 560 - Características Del Material PDFmarcoedgNo ratings yet

- A Standard For Asphaltic Plug JointsDocument20 pagesA Standard For Asphaltic Plug JointsbrelightsNo ratings yet

- Estocell: Bitumen Impregnated Fibre BoardDocument2 pagesEstocell: Bitumen Impregnated Fibre BoardcandraNo ratings yet