Professional Documents

Culture Documents

Kluber Unisilkon L 250 L Special Lubricating Grease Ptfe Datasheet

Uploaded by

High Tech KatlaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kluber Unisilkon L 250 L Special Lubricating Grease Ptfe Datasheet

Uploaded by

High Tech KatlaneCopyright:

Available Formats

Product information

UNISILKON L 250 L

Special lubricating grease for drinking water, beverage and heating valves and

fittings

Benefits for your application

– Proven effective in valves and fittings as well as adjusting mechanisms in the drinking water, beverage, sanitary and

heating sectors

– Certified acc. to international standards for valves and fittings, e.g. BWGL-KTW (UBA- guideline), WRAS, ACS, AS

4020, NSF/ANSI/CAN 61 and NSF H1

– Long-term protection of seals and bearings owing to the lubricant’s good resistance to numerous media like

disinfectants, cleaning agents, water, steam

Description temperatures, UNISILKON L 250 L allows constant

actuating forces within the whole cold/hot water range of

UNISILKON L 250 L is a special lubricant based on silicone oil e.g. single-lever mixer taps.

and PTFE with high thermal stability. UNISILKON L 250 L offers

good penetration ability in small lubrication gaps and lube – valves and fittings of heating installations (e.g.

points of difficult access. Owing to its relatively high viscosity, thermoregulators, tap cocks, pressfit seals)

adhesion is improved even in case of unfavourable geometries. UNISILKON L 250 L has also proven effective as assembly aid

UNISILKON L 250 L is resistant to cold and hot water, for radial shaft seals and packings in contact with cold or hot

superheated steam up to approx. 130 °C as well as industrial water and steam.

cleaning agents and disinfectants. UNISILKON L 20 L is also

resistant to pumpable foodstuffs and beverages like fruit juices,

beer or milk products. UNISILKON L 250 L is not resistant to Application notes

organic solvents or strong acid and alkaline solutions.

UNISILKON L 250 L is neutral towards most metals,

UNISILKON L 250 L is NSF H1 registered and therefore thermoplastics and elastomers. Owing to the many different

complies with FDA 21 CFR § 178.3570. The lubricant was elastomer and plastic compositions their compatibility should be

developed for incidental contact with products and packaging checked prior to series applications. UNISILKON L 250 L can

materials in the food-processing, cosmetics, pharmaceutical or be applied by means of spatula, brush, usual metering devices

animal feed industries. The use of UNISILKON L 250 L can or the tampon printing method. Please observe the material

contribute to increase reliability of your production processes. safety data sheet.

We nevertheless recommend conducting an additional risk

analysis, e.g. HACCP.

Application Material safety data sheets

UNISILKON L 250 L is used as lubricating and sealing grease Material safety data sheets can be requested via our website

for www.klueber.com. You may also obtain them through your

contact person at Klüber Lubrication.

– domestic valves & fittings for drinking water, (e.g. ceramic

discs and piston cartouches, thermo regulators). As the

lubricant’s viscosity is rather independent of service

Pack sizes UNISILKON L 250 L

Tube 60 g +

Cartridge 500 g +

Can 750 g +

Bucket 30 kg +

UNISILKON L 250 L,Prod. 022102,en

Edition 14.07.2021 [replaces edition 21.05.2021]

Product information

UNISILKON L 250 L

Special lubricating grease for drinking water, beverage and heating valves and

fittings

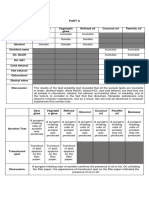

Product data UNISILKON L 250 L

Article number 022102

NLGI grade, DIN 51818 3

NSF-H1 registration 141 714

Chemical composition, type of oil methyl silicone oil

Chemical composition, solid lubricant PTFE

Lower service temperature -45 °C / -49 °F

Upper service temperature 160 °C / 320 °F

Colour space white

Texture fibrous

Texture homogeneous

Density at 20 °C approx. 1.25 g/cm³

Worked penetration, DIN ISO 2137, 25 °C, lower limit value 220 x 0.1 mm

Worked penetration, DIN ISO 2137, 25 °C, upper limit value 250 x 0.1 mm

Shear viscosity at 25 °C, shear rate 300 s-1, equipment:rotational viscometer approx. 13 000 mPas

Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 25 °C approx. 1 350 mm²/s

Copper corrosion, DIN 51811, (lubricating grease), 24h/100°C 1 - 100 corrosion degree

Water resistance, DIN 51807 pt. 01, 3 h/90 °C, rating <= 1 - 90

Minimum shelf life from the date of manufacture - in a dry, frost-free place and in the unopened 36 months

original container, approx.

Klüber Lubrication München SE & Co. KG /

Geisenhausenerstraße 7 / 81379 München / Germany /

Klüber Lubrication – your global specialist phone +49 89 7876-0 / fax +49 89 7876-333.

Innovative tribological solutions are our passion. Through The data in this document is based on our general experience and knowledge at

the time of publication and is intended to give information of possible applications

personal contact and consultation, we help our customers to be to a reader with technical experience. It constitutes neither an assurance of

successful worldwide, in all industries and markets. With our product properties nor does it release the user from the obligation of performing

ambitious technical concepts and experienced, competent staff preliminary field tests with the product selected for a specific application. All data

are guide values which depend on the lubricant's composition, the intended use

we have been fulfilling increasingly demanding requirements by and the application method. The technical values of lubricants change depending

manufacturing efficient high-performance lubricants for more on the mechanical, dynamical, chemical and thermal loads, time and pressure.

than 80 years. These changes may affect the function of a component. We recommend

contacting us to discuss your specific application. If possible we will be pleased to

provide a sample for testing on request. Klüber products are continually improved.

Therefore, Klüber Lubrication reserves the right to change all the technical data in

this document at any time without notice.

Publisher and Copyright: Klüber Lubrication München SE & Co. KG. Reprints,

total or in part, are permitted only prior consultation with Klüber Lubrication

München SE & Co. KG and if source is indicated and voucher copy is forwarded.

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Isoflex Lds 18 Special A: Product InformationDocument4 pagesIsoflex Lds 18 Special A: Product InformationSimty AkterNo ratings yet

- CONSTANT GL 2000 EN enDocument2 pagesCONSTANT GL 2000 EN enSiska JozefNo ratings yet

- BARRIERTA L 25 DL EN enDocument2 pagesBARRIERTA L 25 DL EN enSiska JozefNo ratings yet

- Syntheso Proba 270 330-EnDocument1 pageSyntheso Proba 270 330-EnmiftahNo ratings yet

- AMBLYGON TA 30-1, TA 30-2: Special Greases For Long-Term Lubrication and High TemperaturesDocument2 pagesAMBLYGON TA 30-1, TA 30-2: Special Greases For Long-Term Lubrication and High TemperaturesErick AvilaNo ratings yet

- Polylub Ga 352 PDocument2 pagesPolylub Ga 352 PMuhammad Samsul HasanNo ratings yet

- Kluebersynth LR 44 21 GB enDocument2 pagesKluebersynth LR 44 21 GB enkarthik venkatachalamNo ratings yet

- Unisilkon TK 017/200 Therm, TK 017/500 ThermDocument1 pageUnisilkon TK 017/200 Therm, TK 017/500 Thermspurwito46No ratings yet

- Isoflex Topas L 32Document2 pagesIsoflex Topas L 32c108No ratings yet

- Syntheso Proba 270 enDocument2 pagesSyntheso Proba 270 entoughridin88No ratings yet

- Molylub GoldTex T 32 KnittingDocument1 pageMolylub GoldTex T 32 KnittingismoyoNo ratings yet

- Wolfrakote Top PasteDocument2 pagesWolfrakote Top PasteWillian BrandãoNo ratings yet

- Molylub GoldTex T 22 KnittingDocument1 pageMolylub GoldTex T 22 KnittingismoyoNo ratings yet

- Molylub GoldTex T 46 KnittingDocument1 pageMolylub GoldTex T 46 KnittingismoyoNo ratings yet

- Isoflex Topas NB 5051Document2 pagesIsoflex Topas NB 5051jcapancho.pertuaNo ratings yet

- Klüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain BearingsDocument4 pagesKlüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain Bearingsphucdc095041No ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- Olio KluebersynthDocument2 pagesOlio KluebersynthAlessandro PatanèNo ratings yet

- Kluber - 50C Pour VSNU Isoflex LDS 18 Special ADocument2 pagesKluber - 50C Pour VSNU Isoflex LDS 18 Special AsbyeNo ratings yet

- TURMOGREASE BIO LC 1301 EngDocument1 pageTURMOGREASE BIO LC 1301 EngStrange AhadNo ratings yet

- MICROLUBE GL 261 GL 262 EN enDocument4 pagesMICROLUBE GL 261 GL 262 EN enVendy KurniawanNo ratings yet

- WOLFRACOAT C FLUID 099118 PI GB enDocument2 pagesWOLFRACOAT C FLUID 099118 PI GB enwajahat ali KhanNo ratings yet

- BARRIERTA GTE 403 EN enDocument2 pagesBARRIERTA GTE 403 EN enSiska JozefNo ratings yet

- Additex SW 22, SW 32, SW 46: Textile Machine OilDocument2 pagesAdditex SW 22, SW 32, SW 46: Textile Machine OilRonald Mario Kupa AnticonaNo ratings yet

- 9 PCC Synthetic Lubricants LDPE S NetDocument6 pages9 PCC Synthetic Lubricants LDPE S Net34-coreNo ratings yet

- Turmotemp II 400 Rs 00 Ti enDocument1 pageTurmotemp II 400 Rs 00 Ti enKoushar MechanictcNo ratings yet

- Tds Beslux Luder 220 (05.05.11)Document1 pageTds Beslux Luder 220 (05.05.11)Vaidas BartkevičiusNo ratings yet

- Isoflex Topas NB 52 NB 1521 PDFDocument4 pagesIsoflex Topas NB 52 NB 1521 PDFc108No ratings yet

- Lukoil Stabio DDocument2 pagesLukoil Stabio DRoberto Alfaro EspinozaNo ratings yet

- Birkosit Now With Stands 900 Deg C Temp and 3600 Psi PressureDocument1 pageBirkosit Now With Stands 900 Deg C Temp and 3600 Psi PressureProject Sales CorpNo ratings yet

- Isoflex Topas Nca 52: Product InformationDocument2 pagesIsoflex Topas Nca 52: Product InformationnghiaNo ratings yet

- Klubersynth UH1 14 31Document2 pagesKlubersynth UH1 14 31kadiremreturan12No ratings yet

- Asonic HQ 72-102 - EnglishDocument2 pagesAsonic HQ 72-102 - EnglishCleiton Luiz CordeiroNo ratings yet

- Bpxe 8Z56LRDocument2 pagesBpxe 8Z56LRVusal HasanovNo ratings yet

- Product Information: Multi-Silicone GreaseDocument3 pagesProduct Information: Multi-Silicone Greasekamalkraj4002No ratings yet

- 503hoja-tecnica-MOLYKOTE® 44 MediumDocument2 pages503hoja-tecnica-MOLYKOTE® 44 MediumeariesilvapcNo ratings yet

- Aceite MR520Document4 pagesAceite MR520capc.asesoriasNo ratings yet

- Isoflex Lds 18 Special A PDFDocument4 pagesIsoflex Lds 18 Special A PDFNorbertoRGNo ratings yet

- ISOFLEX LDS 18 SPECIAL A 004013 PI GB enDocument2 pagesISOFLEX LDS 18 SPECIAL A 004013 PI GB endenisNo ratings yet

- Turmosynthgrease A 1002-EngDocument1 pageTurmosynthgrease A 1002-EngOmin PostingNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- MOLYKOTE 44 - MediumDocument2 pagesMOLYKOTE 44 - MediumCesar AlejandroNo ratings yet

- Kluberplex BEM 41 132Document4 pagesKluberplex BEM 41 132Maryasa RobedNo ratings yet

- Pi Oks 252 113701 enDocument2 pagesPi Oks 252 113701 enGokulNo ratings yet

- TDS 化学技术说明书Document2 pagesTDS 化学技术说明书adam sumardinataNo ratings yet

- Pi Oks 476 113678 enDocument2 pagesPi Oks 476 113678 enSophia RoseNo ratings yet

- P004916 Commercial Vehicle Multi Purpose Grease K2K 20 15 en - GBDocument1 pageP004916 Commercial Vehicle Multi Purpose Grease K2K 20 15 en - GBSaeed QahremaniNo ratings yet

- Pala 652 e 02 15Document3 pagesPala 652 e 02 15Carmen LinaresNo ratings yet

- Turmosynthgrease Al 4602 Ti enDocument1 pageTurmosynthgrease Al 4602 Ti enOmin PostingNo ratings yet

- Molykote G-2003Document2 pagesMolykote G-2003Luz Angela GuerreroNo ratings yet

- CONSTANT OY K Oils EN enDocument4 pagesCONSTANT OY K Oils EN enSiska JozefNo ratings yet

- Klüberquiet BQH 72-102: Product InformationDocument4 pagesKlüberquiet BQH 72-102: Product Informationduy tanNo ratings yet

- E1738-1609-ATT.20 Sellador OTTOSEALDocument3 pagesE1738-1609-ATT.20 Sellador OTTOSEALmarcosNo ratings yet

- Birkosit India +91-98851-49412Document19 pagesBirkosit India +91-98851-49412Project Sales CorpNo ratings yet

- Bpxe 9Q932NDocument2 pagesBpxe 9Q932NArthur Sanda LayukNo ratings yet

- Product Information: High-Temperature Grease For Food Processing TechnologyDocument2 pagesProduct Information: High-Temperature Grease For Food Processing TechnologyFelipe OsorioNo ratings yet

- Sealing Compounds From Project Sales CorpDocument34 pagesSealing Compounds From Project Sales CorpProject Sales CorpNo ratings yet

- Klüberquiet BQ 72-72 EN enDocument4 pagesKlüberquiet BQ 72-72 EN enaligholiNo ratings yet

- A10011-ASM-T61-EN-Spec-X-Serie S - DMSDocument68 pagesA10011-ASM-T61-EN-Spec-X-Serie S - DMSHigh Tech KatlaneNo ratings yet

- SIPLACE Explorer Eng 10-2012Document18 pagesSIPLACE Explorer Eng 10-2012High Tech Katlane100% (1)

- 1688 - 7 - 88618 - 1635767930 - ASM Service - Elearning - ENDocument1 page1688 - 7 - 88618 - 1635767930 - ASM Service - Elearning - ENHigh Tech KatlaneNo ratings yet

- 1607 - 7 - 88618 - 1635774016 - ASM Service - Elearning - ENDocument1 page1607 - 7 - 88618 - 1635774016 - ASM Service - Elearning - ENHigh Tech KatlaneNo ratings yet

- M64 XIV - Savr Tehnol I Privr Raz - Leskovac 2021 Miladinovic Et Al 2021Document5 pagesM64 XIV - Savr Tehnol I Privr Raz - Leskovac 2021 Miladinovic Et Al 2021Olivera StamenkovicNo ratings yet

- Class 10 Science Answer Key 2024 SET 31 - 5 - 3Document5 pagesClass 10 Science Answer Key 2024 SET 31 - 5 - 3SarthakNo ratings yet

- Cremophor ELPDocument4 pagesCremophor ELPMd.ali-bin-saifullah50% (2)

- Development and Improvement of Warm-Mix Asphalt Technology PDFDocument194 pagesDevelopment and Improvement of Warm-Mix Asphalt Technology PDFBaran BaranyNo ratings yet

- CHEM1PH Lec Midterms QUESTIONNAIREDocument4 pagesCHEM1PH Lec Midterms QUESTIONNAIREIvy Rose OrozcoNo ratings yet

- Chemistry - Test ElectrochemistryDocument12 pagesChemistry - Test Electrochemistrypolamraju100% (1)

- Proteins 1Document456 pagesProteins 1pareehan salmanNo ratings yet

- 10cordination CompDocument22 pages10cordination Compaleena'No ratings yet

- Rastogi and Pospisil 2010Document7 pagesRastogi and Pospisil 2010anshuslsNo ratings yet

- Module 8 - BIOCHEM LABDocument5 pagesModule 8 - BIOCHEM LABStarrrNo ratings yet

- PPH Catalog UnlockedDocument24 pagesPPH Catalog UnlockedAlfa PumpsNo ratings yet

- Insecticides: S.No Technical Name Formulation Trade NamesDocument13 pagesInsecticides: S.No Technical Name Formulation Trade NamesRamkannan Parasumanna Chandrasekaran75% (16)

- Cross-Specialization Training For Grades 7-10 Science TeachersDocument13 pagesCross-Specialization Training For Grades 7-10 Science TeachersJen DescargarNo ratings yet

- Use of Water Reducers To Impove Grindability and Performance of PC Clinker PDFDocument10 pagesUse of Water Reducers To Impove Grindability and Performance of PC Clinker PDFTran Huynh NamNo ratings yet

- Meat Packaging PDFDocument39 pagesMeat Packaging PDFhabteyes abateNo ratings yet

- Lesson 2 Uses and Sources of EnergyDocument3 pagesLesson 2 Uses and Sources of EnergyLyn Hani AlojadoNo ratings yet

- Tata Steel - Colorcoat HPS200 UltraDocument19 pagesTata Steel - Colorcoat HPS200 UltraGabriel CamargoNo ratings yet

- Project Ethyl Benzene .. 2019-20 .. Jay RSDocument100 pagesProject Ethyl Benzene .. 2019-20 .. Jay RSBhatu DevareNo ratings yet

- Chemistry Lab Manual 2Document21 pagesChemistry Lab Manual 2Nischay SanjayNo ratings yet

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Document8 pagesIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationNo ratings yet

- Lecture-2 Crude Oil Composition - Fall 2023Document37 pagesLecture-2 Crude Oil Composition - Fall 2023MrHemFunNo ratings yet

- Is 253 1985Document35 pagesIs 253 1985MonirNo ratings yet

- Determination of Sulphate As Barium Sulphate Using Gravimetry With Drying of ResidueDocument4 pagesDetermination of Sulphate As Barium Sulphate Using Gravimetry With Drying of ResidueKojo Eghan83% (12)

- An Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalDocument5 pagesAn Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalKhin Aung ShweNo ratings yet

- Trimec: Chemical Compatibility ChartDocument12 pagesTrimec: Chemical Compatibility ChartMandiriNo ratings yet

- Marking MAR 4461 20090428Document41 pagesMarking MAR 4461 20090428sensor_versionNo ratings yet

- Hardfacing For Valves - Materials and ProcessesDocument1 pageHardfacing For Valves - Materials and ProcessesPA PlantNo ratings yet

- Casting Standards PDFDocument1 pageCasting Standards PDFamaestrelNo ratings yet

- MTU Off-Highway Coolant: Performance and LongevityDocument4 pagesMTU Off-Highway Coolant: Performance and Longevityjesus_rs01No ratings yet

- CID A-A-344B - Lacquer (Clear Gloss), With Notice 1Document4 pagesCID A-A-344B - Lacquer (Clear Gloss), With Notice 1エドワードNo ratings yet