Professional Documents

Culture Documents

Needle Mat

Uploaded by

Bruce FerreiraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Needle Mat

Uploaded by

Bruce FerreiraCopyright:

Available Formats

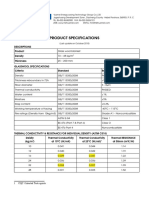

CrossFilm™ 2105 Expansion Joint Material

NEEDLE-MAT

DESCRIPTION

NEEDLE-MAT is manufactured to conform with the requirements of Military Specification MIL-1-16411 Type II, ASTM-C-1086-96 and

Coast Guard Specification for Incombustible Materials #164.009 and MIL-I-24244. TEMP-MAT is a fiberglass mat composed of 100%

“E” type glass fibers which are put into web form and mechanically needles together without chemical binders.

ADVANTAGES

NEEDLE-MAT is an effective low cost replacement for asbestos mats, millboard, ceramic or refractory fiber paper, mat and

sheets, and mineral fiber boards. It is used as a thermal insulation and gasket material in home and industrial furnaces, package boiler

and for special piping applications where heat resistance, flexibility and low special air and liquid chemical and thermal resistance are

mandatory.

NEEDLEMAT PROPERTIES

________________________________________________________________________________________________________

Weight Density

Thickness English Metric English Metric Service Temperature

________________________________________________________________________________________________________

2 2

1/4” (0.635cm) 3 oz./ft. 915.6g/m 9 lbs./cu.ft. 144.2 kg/cu.m Up to 1200oF (6490C)

.2 2

1/2” (1.27 cm) 6 oz./ft. 1831.2 g/m 9 lbs./cu.ft. 144.2 kg/cu.m Up to 1200oF (649oC)

3/4” (1.91 cm) 9 oz./ft..2 2746.8 g/m2 9 lbs./cu.ft. 144.2 kg/cu.m Up to 1200oF (649oC)

1” (2.54 cm) 15 oz./ft.2 4578 g/m2 11 lbs./cu.ft. 176.2 kg/cu.m Up to 1200oF (649oC)

* All four needle-Mat styles have extremely good fire resistance and are incombustible, have negligible moisture absorption, but

o

will experience up to a 2% weight loss at continuous use at 1200F (649oC).

THERMAL CONDUCTIVITY ACOUSTICAL RATINGS

“K” Value for 1 Inch Thick Frequency

“K” BTU-Inch/Hour-ft.2-oF (Hz) 1/4" 1/2" 1"

Mean Temperatures 250 .04+ - .02 .07 +- .02 .15 +- .04

500 .12 +- .01 .24 +- .01 .80 +- .03

75oF ( 24oC) 0.29 1000 .29 +- .01 .55 +- .01 1.02 +- 02

300oF (149oC) 0.40

500oF (260oC) 0.50 2000 .51 +-.01 .79 +- .02 1.08 +- 02

700oF (371oC) 0.65 4000 .85 +- .01 .91 +- .02 .92 +- .02

Noise

reduction 0.25 0.40 0.70

Coefficient

DATA SHEET #13412 REV. H DATE: 9/05/12

*All values are nominal unless otherwise specified

Specializing in marine, aerospace, automotive and commercial fabrics for thermal and industrial applications.

All statements herein are expressions of opinion that we believe to be accurate and reliable, but are presented without guaranty or

responsibility on our part. Statements concerning possible use of our products are not intended as recommendations for their use

alone or in combination with any materials or elements to infringe any patents. No patent warranty of any kind, express or implied, is

made or intended.

Flextra Engineered Products (PTY) LTD | Supplier of High-Performance Fluoropolymer Films, Laminates, and Composites

366 Northlands Business Park, Randburg, JHB PHONE: (011) 462 7291 FAX: (086) 669-3324 www.Flextra.co.za

You might also like

- ASTM F2516-Standard-Test-Method-for-Tension-Testing-of-Nickel-Titanium-Superelastic-Materials PDFDocument6 pagesASTM F2516-Standard-Test-Method-for-Tension-Testing-of-Nickel-Titanium-Superelastic-Materials PDFTiagoNo ratings yet

- Table of Content Flow of Fluids Excel Workbook PDFDocument17 pagesTable of Content Flow of Fluids Excel Workbook PDFLOKESHNo ratings yet

- Ae1402 Composite Materials and StructuresDocument23 pagesAe1402 Composite Materials and Structuresrakhi_chenNo ratings yet

- Ineos Typical Engineering Properties of HdpeDocument3 pagesIneos Typical Engineering Properties of HdpePhát Lê TiếnNo ratings yet

- Renolin ThermDocument1 pageRenolin ThermFarhan TamjidNo ratings yet

- Rockwool Rocktech Section Pipe Insulation: General Product InformationDocument4 pagesRockwool Rocktech Section Pipe Insulation: General Product Informationramy abazaNo ratings yet

- Data Sheet Schott® Borofloat: Chemical PropertiesDocument2 pagesData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- Afico Duct LinerDocument3 pagesAfico Duct LinerChris SolonNo ratings yet

- Rockwool-Rocktech-Spi en Ds 202007Document4 pagesRockwool-Rocktech-Spi en Ds 202007pisun chumsriNo ratings yet

- Fryquel EHC PlusDocument4 pagesFryquel EHC PlusZuli Nur CahyoNo ratings yet

- Easy Flow Polystyrene Material DatasheetDocument3 pagesEasy Flow Polystyrene Material DatasheetAlbert FortunatoNo ratings yet

- Specifications & Properties for Motiva Base OilsDocument1 pageSpecifications & Properties for Motiva Base OilsMassimiliano VolaNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Our Products: General PropertiesDocument1 pageOur Products: General PropertiesManjunathNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Block InsulationDocument2 pagesBlock Insulation1repsaperuNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- ATA Heet: LSS Chipper KnifeDocument2 pagesATA Heet: LSS Chipper KnifeX800XL100% (1)

- SF-600 TDS 2023Document1 pageSF-600 TDS 2023Rajneesh RallanNo ratings yet

- Typical Engineering Properties of High Density Polyethylene: General Properties English Units SI UnitsDocument2 pagesTypical Engineering Properties of High Density Polyethylene: General Properties English Units SI UnitsAnil AmrawanshiNo ratings yet

- TCS-Geotechnics-Terram-T Series-Standard Nonwoven Geotextile-Data SheetDocument1 pageTCS-Geotechnics-Terram-T Series-Standard Nonwoven Geotextile-Data SheetBerat DalyabrakNo ratings yet

- Rockwool Rocktech WM en DsDocument4 pagesRockwool Rocktech WM en DsZain Al AbidinNo ratings yet

- LIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONDocument8 pagesLIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONPhan LongNo ratings yet

- Monel 400 Alloy Properties & ApplicationsDocument5 pagesMonel 400 Alloy Properties & Applicationsraja ENo ratings yet

- BNZ Materials Castable Data SheetDocument4 pagesBNZ Materials Castable Data SheetLeo CrisuNo ratings yet

- WWW Matweb Com Search Datasheet Print Aspx Matguid E30d1d103Document3 pagesWWW Matweb Com Search Datasheet Print Aspx Matguid E30d1d103Vijay PalNo ratings yet

- FRF Slabs: Thermal Insulation for Buildings and Industrial ApplicationsDocument16 pagesFRF Slabs: Thermal Insulation for Buildings and Industrial ApplicationsAmal RajNo ratings yet

- Momentive RTV 630 TDS 2019Document7 pagesMomentive RTV 630 TDS 2019crushergaming1804No ratings yet

- 210 SuperlonFR Insulation BrochureDocument8 pages210 SuperlonFR Insulation BrochurealexNo ratings yet

- PA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingDocument2 pagesPA66-G30 Glass Fiber Reinforced Polyamide 66 Properties Applications ProcessingVinoth SekarNo ratings yet

- InsulationDocument23 pagesInsulationFabio TemporiniNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- DUPAC-0521®: DescriptionDocument6 pagesDUPAC-0521®: DescriptionPablo TorresNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Superwool Plus HT Pyroblocmodules EngDocument2 pagesSuperwool Plus HT Pyroblocmodules Engมิตร อันมาNo ratings yet

- 500ºf Electrically Resistant EpoxyDocument1 page500ºf Electrically Resistant Epoxy李聪No ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Saint Gobain Norfrax RBDocument1 pageSaint Gobain Norfrax RBJavier Enrique Toro YentzenNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Tds Tasnee 100 Black Revised in 2022Document2 pagesTds Tasnee 100 Black Revised in 2022Amir NawazNo ratings yet

- Datasheet MomentiveDocument5 pagesDatasheet Momentivehuynh thi y viNo ratings yet

- TDS Turbonycoil TN600 1E19Document2 pagesTDS Turbonycoil TN600 1E19Emad The EnthusiastNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- datasheet-saf-2205-en-v2021-10-07 13_05 version 1Document8 pagesdatasheet-saf-2205-en-v2021-10-07 13_05 version 1simone.mauriNo ratings yet

- Qais Alrawi & Sons CompanyDocument1 pageQais Alrawi & Sons Companykariem noweerNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Contact Material Beryllium Nickel Be NiStrip360 PDFDocument4 pagesContact Material Beryllium Nickel Be NiStrip360 PDFImags GamiNo ratings yet

- Alloy 360 Data SheetDocument4 pagesAlloy 360 Data SheetImags GamiNo ratings yet

- Technical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketDocument2 pagesTechnical Data Sheet: Ceramic Wool Mattress /ceramic Fiber BlanketMohamed KhaledNo ratings yet

- Vötsch VCL Benchtop Temperature and Climatic Chambers BrochureDocument4 pagesVötsch VCL Benchtop Temperature and Climatic Chambers BrochureAlbert IonutNo ratings yet

- 316 Stainless Steel, Anneal...Document3 pages316 Stainless Steel, Anneal...Moisés Vázquez ToledoNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- CPM Magnacut - Technical Data: Your in Specialty MetalsDocument2 pagesCPM Magnacut - Technical Data: Your in Specialty MetalscpNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- Vitralit 1650 English Tds Panacol AdhesiveDocument4 pagesVitralit 1650 English Tds Panacol Adhesivetito3007No ratings yet

- Alloy304-304L-APR2013Document3 pagesAlloy304-304L-APR2013J A S JASNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Fuel Air Ratio Commissioning Boiler Control Min 1Document1 pageFuel Air Ratio Commissioning Boiler Control Min 1Bruce FerreiraNo ratings yet

- Tech Tip Checking EmissionsDocument3 pagesTech Tip Checking EmissionsBruce FerreiraNo ratings yet

- Tech Tip Boiler Leakage TipDocument1 pageTech Tip Boiler Leakage TipBruce FerreiraNo ratings yet

- CDB ReportDocument9 pagesCDB ReportBruce FerreiraNo ratings yet

- Lessons Learned Template 04Document7 pagesLessons Learned Template 04Bruce FerreiraNo ratings yet

- Lessons Learned Template 10Document3 pagesLessons Learned Template 10Bruce FerreiraNo ratings yet

- CA2022 Brochure r05 FinalDocument4 pagesCA2022 Brochure r05 FinalBruce FerreiraNo ratings yet

- Lessons Learned Template 22Document10 pagesLessons Learned Template 22Bruce FerreiraNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document4 pages3-Pre-Lift Checklist Rev A 06302015Bruce FerreiraNo ratings yet

- Lessons Learned Template 20Document1 pageLessons Learned Template 20Bruce FerreiraNo ratings yet

- Addis Ababa Plastic CrusherDocument144 pagesAddis Ababa Plastic Crusheryeabsira gashawNo ratings yet

- ICE-Qatar 18Apr22-Durability Design of Concrete StructuresDocument55 pagesICE-Qatar 18Apr22-Durability Design of Concrete StructuresShokry AlkissyNo ratings yet

- KME PowderDocument4 pagesKME Powderfrankypanky123No ratings yet

- Absorbency and Wicking Properties of Terry Towel Weaving FabricsDocument9 pagesAbsorbency and Wicking Properties of Terry Towel Weaving FabricsmetinNo ratings yet

- TDS Polyvest MA 75Document3 pagesTDS Polyvest MA 75Fairmont Ind Quality DivisionNo ratings yet

- EnDOtec 310Document2 pagesEnDOtec 310EdwinNo ratings yet

- KITSEN IF Fastform Slab Formworks SolutionDocument15 pagesKITSEN IF Fastform Slab Formworks SolutionLuis Gustavo Rodrigues PereiraNo ratings yet

- Advanced Materials Processes CourseDocument1 pageAdvanced Materials Processes CourseSebastián Díaz ConstanzoNo ratings yet

- 101 (2006)Document2 pages101 (2006)Eng-Mahmoud AtiaNo ratings yet

- Casting Defects 6Document36 pagesCasting Defects 6AnuskaNo ratings yet

- Advanced PP 1102KDocument1 pageAdvanced PP 1102KLaxman AhirNo ratings yet

- TDS Polidan TA HF V 1.0 June 2017Document3 pagesTDS Polidan TA HF V 1.0 June 2017valdecirnasatoNo ratings yet

- Mechanical Properties of MetalsDocument13 pagesMechanical Properties of MetalsNicholas Bonn SingNo ratings yet

- SL - No. Name of Test Testing Method: Testing Frequency & Specification (As Per MORTH-5th Revision)Document18 pagesSL - No. Name of Test Testing Method: Testing Frequency & Specification (As Per MORTH-5th Revision)Ashok amlapure100% (1)

- ASTER 12G2F Data Sheet Conveyor BeltDocument1 pageASTER 12G2F Data Sheet Conveyor BeltKoen BidlotNo ratings yet

- Praveen SinghDocument24 pagesPraveen SinghAbhay Kumar PandeyNo ratings yet

- STAINLESS STEEL - Chemical & Mechanical PropertiesDocument3 pagesSTAINLESS STEEL - Chemical & Mechanical PropertiesGregorio KilatonNo ratings yet

- Norms For Consumption of Materials For Building WorksDocument1 pageNorms For Consumption of Materials For Building WorksVishal TiwariNo ratings yet

- Date of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)Document65 pagesDate of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)GaneshNo ratings yet

- PT Gilang Indo Pratama-FINAL DRAWING Concrete Sinker (HL)Document5 pagesPT Gilang Indo Pratama-FINAL DRAWING Concrete Sinker (HL)Pradhipta W NurrobbiNo ratings yet

- Am - Unit 2 - NotesDocument36 pagesAm - Unit 2 - NotesNarender NarruNo ratings yet

- OK Flux 10.62: Classifications: ApprovalsDocument3 pagesOK Flux 10.62: Classifications: ApprovalsJaison JoseNo ratings yet

- Custom House, ChittagongDocument20 pagesCustom House, Chittagongsamrat_77100% (1)

- Conveyor Belt Technical Data Sheet: UF30 - 0/V08P Vcexcon 3R/ 16 W 38 General InformationDocument2 pagesConveyor Belt Technical Data Sheet: UF30 - 0/V08P Vcexcon 3R/ 16 W 38 General InformationDAMIAN QUIMIZNo ratings yet

- Iepg 103Document9 pagesIepg 103Zandrex S. AguillonNo ratings yet

- Rubbond HM72Document1 pageRubbond HM72belas728No ratings yet

- Buildings - Sor: 2011-2012: Government of Andhra PradeshDocument389 pagesBuildings - Sor: 2011-2012: Government of Andhra PradeshsibenduNo ratings yet

- 06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkDocument16 pages06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkJhoNo ratings yet