Professional Documents

Culture Documents

SPERRE XW150 备件册

Uploaded by

EMMA0 ratings0% found this document useful (0 votes)

29 views3 pagesThe document provides an overview of service procedures and kits for an air compressor model XW150. It includes a table outlining recommended service intervals and procedures based on running hours or years. Another table lists various service and maintenance kits associated with letters on an illustration, along with their ordering numbers and relevant chapters in the manual. The technical data is the basis for an onboard planned maintenance system, and Sperre should be contacted for the digital version.

Original Description:

SPERRE.XW150

Original Title

SPERRE.XW150.备件册

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides an overview of service procedures and kits for an air compressor model XW150. It includes a table outlining recommended service intervals and procedures based on running hours or years. Another table lists various service and maintenance kits associated with letters on an illustration, along with their ordering numbers and relevant chapters in the manual. The technical data is the basis for an onboard planned maintenance system, and Sperre should be contacted for the digital version.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views3 pagesSPERRE XW150 备件册

Uploaded by

EMMAThe document provides an overview of service procedures and kits for an air compressor model XW150. It includes a table outlining recommended service intervals and procedures based on running hours or years. Another table lists various service and maintenance kits associated with letters on an illustration, along with their ordering numbers and relevant chapters in the manual. The technical data is the basis for an onboard planned maintenance system, and Sperre should be contacted for the digital version.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

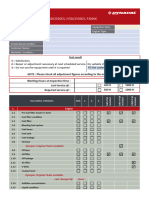

3.

4 Service procedures overview

Service procedure A B C B D B C B E Chap.

Running hours 250 1500 3000 4500 6000 7500 9000 10500 12000

Running years 0,5 1,5 3 4,5 6 7,5 9 10 12

Oil change X X X X X X X X X 4.2

Oil filter replacement X X X X X X X X X 4.2

Air filter replacement X X X X X X X X X 4.3

Valve LP replacement X X X X 4.7

Valve HP replacement X X X X 4.8

Gudgeon bearing + pin X 4.11

X

replacement 4.12

Non return valve replacement X X 4.18

Drain / unload valve HP + coil X

X 4.19

replacement

Bearing crank replacement X X 4.14

Bearing fan side replacement X X 4.13

Piston ring LP replacement X 4.11

Piston ring HP replacement X 4.12

Bearing motor side X 4.17

replacement

Valve LP check* X* X* X* X* 4.7

Valve HP check* X* X* X* X* 4.8

Gudgeon bearing + pin 4.11

X** X**

check** 4.12

Bearing crank check** X** X** 4.14

Air cooler LP check*** X*** X*** 4.5

Air cooler HP check*** X*** X*** 4.6

Flexible tubes check**** X**** X****

Safety valve LP check***** X***** 4.4

Safety valve HP check***** X***** X***** 4.4

* Please check the valve LP and HP condition, and if there is carbon deposit, the valve(s) must be replaced. Sperre recommend for

this compressor valve check every 1.500 hours.

** Please check the gudgeon bearing and the crank bearing condition, and if worn or damaged complete bearing(s) must be

replaced. Sperre recommend for this compressor bearing check every 3.000 hours.

****Please check the cooler condition, and if the cooler have particles in the airflow area inlet, the cooler must be replaced. Sperre

recommends for this compressor cooler check every 6.000 hours.

**** Please check all flexible tubes for wear and aging every 6.000 hours. Refer to standard BS 5244 for details regarding testing

and checking.

***** Please check safety valves and change if necessary (see chapter 4.4).

Compressor serial number must be provided when ordering!

PMS input

The technical data above is the basis for the onboard planned maintenance system. Contact Sperre for the digital version for direct

implementation.

www.sperre.com Service Manual XW150 Version 03 13

3.5 Kit overview

The letters on the illustration below refer to service and maintenance kits for the compressor, listed in the table on next page, and

described in chapter 3.4.

www.sperre.com Service Manual XW150 Version 03 14

Ordering number Chapter

Letter Kit Name

Service Maintenance Recommended kit Service Procedures

Kit kit

- Service Kit A XAW120-150 50008 3.4

- Service Kit B XAW120-150 50045 3.4

- Service Kit C XAW120-150 50074 3.4

- Service Kit D XW120-150 50114 3.4

- Service Kit E XW150 50175 3.4

MR Kit XW150 XW150-MR 3.4

CR Kit XW150 XW150-CR 3.4

MK Compressor gasket XW150 50915 3.4

a MK Cylinder head LP XW120-150 50345 3.4 4.7

b MK Cylinder head HP XW120-150 50375 3.4 4.8

c MK Valve LP XAW120-150 50438 3.4 4.7

d MK Valve HP XAW120-150 50468 3.4 4.8

e MK Cylinder LP XAW150 50568 3.4 4.9

f MK Cylinder HP XAW120-150 50608 3.4 4.10

g MK Piston rings LP XAW150 50638 3.4 4.11

h MK Piston rings HP XAW120-150 50668 3.4 4.12

i MK Piston LP XAW150 50708 3.4 4.11

j MK Piston HP XAW120-150 50738 3.4 4.12

k MK Connecting rod LP XAW120-150 50775 3.4 4.14

l MK Connecting rod HP XAW120-150 50845 3.4 4.14

m MK Crankshaft XAW120-150 50815 3.4 4.17

Sperre Tool Box XAW120-150 50968

Starter kit 48-65/65/230-K 59216

Starter kit 48-65/65/115-K 59246

Starter kit 30-40/65/230-K 59322

Starter kit 30-40/65/115-K 59372

Soft starter kit 57-75/80A/1-2-S 59430

Soft starter kit 9-47/47A/2-S 59446

Soft starter kit 9-47/47A/1-S 59466

Aux relay 3NO+2NC 230V 66720

Aux relay 3NO+2NC 115V 66725

Control kit XW120-150 59936

* Safety valve HP / LP 4.4

* Air cooler LP 4.5

* Air cooler HP 4.6

* Compressor serial number must be provided when ordering!

www.sperre.com Service Manual XW150 Version 03 15

You might also like

- Crawler Excavator Inspection ListDocument5 pagesCrawler Excavator Inspection ListSoubhik BagchiNo ratings yet

- Scania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLDocument3 pagesScania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLramsey2220% (1)

- Uploads Media Document BAC Rigging-VXI RVXIv15ENDocument28 pagesUploads Media Document BAC Rigging-VXI RVXIv15ENsidsaleemNo ratings yet

- JIG Standards Session G ODonnell N MasonDocument40 pagesJIG Standards Session G ODonnell N Masonsamson anyumbaNo ratings yet

- Bard - Wall Mount W R410A 1.5@2 TR, PartsDocument8 pagesBard - Wall Mount W R410A 1.5@2 TR, PartsGabriel Ortiz MNo ratings yet

- Recondition Engine DCEC 4BTA ThriveniDocument9 pagesRecondition Engine DCEC 4BTA ThriveniRegi HermawanNo ratings yet

- Air Compressor Maintenance GuideDocument3 pagesAir Compressor Maintenance Guideredvalor0% (1)

- Digmax Parts CatalogeDocument630 pagesDigmax Parts CatalogeChirag BansalNo ratings yet

- 2010 HD Buell Service IntervalsDocument20 pages2010 HD Buell Service IntervalsEugenio CandrevaNo ratings yet

- Turbonetics 350Z Turbo Kit Installation Manual 15134-tDocument35 pagesTurbonetics 350Z Turbo Kit Installation Manual 15134-tTHMotorsports.netNo ratings yet

- Maintenance Schedule For HIMOINSA GeneratorDocument1 pageMaintenance Schedule For HIMOINSA GeneratorAnar HajiyevNo ratings yet

- Big Pavers - Service ChecklistDocument15 pagesBig Pavers - Service Checklistjhay agtalaoNo ratings yet

- Parts and Service Interval DD90HF M@SH PDFDocument2 pagesParts and Service Interval DD90HF M@SH PDFjrincon26No ratings yet

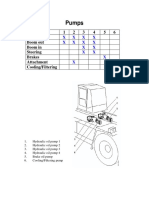

- Pumps: 1 2 3 4 5 6 Lift Boom Out Boom in Steering Brakes Attachment Cooling/FilteringDocument2 pagesPumps: 1 2 3 4 5 6 Lift Boom Out Boom in Steering Brakes Attachment Cooling/FilteringSyed Kamal Quadri AdiNo ratings yet

- Dp1600i t3 Maintenance Planner Combo EnglishDocument2 pagesDp1600i t3 Maintenance Planner Combo Englishsoledad alvis arotaipeNo ratings yet

- Bac - VXC - Operating and Maintenance InstructionsDocument36 pagesBac - VXC - Operating and Maintenance InstructionsLuis Alejandro VásquezNo ratings yet

- Model CBLE 100-800 HP Boilers: Figure A1-14. Model CB-LE Gas Train ComponentsDocument4 pagesModel CBLE 100-800 HP Boilers: Figure A1-14. Model CB-LE Gas Train ComponentssebaversaNo ratings yet

- Vxi 9Document38 pagesVxi 9Ritche Lim BragaisNo ratings yet

- 2 Stroke Maintenance SchedulesDocument3 pages2 Stroke Maintenance SchedulesGeo PalNo ratings yet

- TOYOTA RAV4 Dashboard Warning LightsDocument1 pageTOYOTA RAV4 Dashboard Warning LightsMarco Yarasca RomeroNo ratings yet

- Series 2000 Stocking ListDocument14 pagesSeries 2000 Stocking ListGerman O.No ratings yet

- Heating, Ventilation, and Air ConditioningDocument148 pagesHeating, Ventilation, and Air ConditioningGeo AdmNo ratings yet

- Harley-Davidson: and Buell Service IntervalsDocument16 pagesHarley-Davidson: and Buell Service IntervalsPeluzitaNo ratings yet

- Isl 721F 821F & 921FDocument3 pagesIsl 721F 821F & 921FGarcia CruzNo ratings yet

- OM - B20D - 6X4 - & - 6X6 - ADT - MK - III - CHP - 10 - & - CHP - 11Document14 pagesOM - B20D - 6X4 - & - 6X6 - ADT - MK - III - CHP - 10 - & - CHP - 11PeetNo ratings yet

- 3-179 Scheduled Maintenance ProgramDocument4 pages3-179 Scheduled Maintenance ProgramMariano Cal GarciaNo ratings yet

- VX40-55 (M) S sheet+rev04+ENDocument12 pagesVX40-55 (M) S sheet+rev04+ENIonut GrozaNo ratings yet

- 2011 Yamaha YZF-R1 Specifications+ComparisonDocument1 page2011 Yamaha YZF-R1 Specifications+ComparisonRodrigo CruzNo ratings yet

- Maintenance Schedule: S.No. Items of Work KM MonthDocument1 pageMaintenance Schedule: S.No. Items of Work KM MonthErnan ConisllaNo ratings yet

- BAC Maintenance-VXI MVXIv17EN-SADocument34 pagesBAC Maintenance-VXI MVXIv17EN-SAEurotech Tra TranNo ratings yet

- Harley Davidson Service IntervalsDocument5 pagesHarley Davidson Service Intervalsdneprmt1No ratings yet

- Harley-Davidson and Buell Service IntervalsDocument15 pagesHarley-Davidson and Buell Service IntervalsCleverson SantosNo ratings yet

- Preventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSDocument1 pagePreventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSSeif AlbaghdadyNo ratings yet

- 1.3 Maintenance Schedule: GeneralDocument2 pages1.3 Maintenance Schedule: GeneralÉder Oliveira NicolletiNo ratings yet

- HondapilotmaintDocument2 pagesHondapilotmaintMikayil MammadovNo ratings yet

- 2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTDocument1 page2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTLeonardo PachecoNo ratings yet

- Daily ChecklistDocument2 pagesDaily ChecklistBo BosNo ratings yet

- EngineDocument2 pagesEngineRahmat HidayatNo ratings yet

- VT0 Open Cooling Towers VT1 Open Cooling Tower: Operating and Maintenance InstructionsDocument34 pagesVT0 Open Cooling Towers VT1 Open Cooling Tower: Operating and Maintenance InstructionsoussNo ratings yet

- Datos Tecnicos Hilux 2trfeDocument1 pageDatos Tecnicos Hilux 2trfeIrving Alexander RujanoNo ratings yet

- 2005 HD Buell Service IntervalsDocument12 pages2005 HD Buell Service IntervalsHéctor Alejandro Ayala SolisNo ratings yet

- 2006 HD Buell Service IntervalsDocument12 pages2006 HD Buell Service IntervalsAdrián CasarrubiasNo ratings yet

- VXC Evaporative Condensers: Operating and Maintenance InstructionsDocument36 pagesVXC Evaporative Condensers: Operating and Maintenance InstructionsRafael FerreiraNo ratings yet

- Spek Moment MesinDocument7 pagesSpek Moment MesinIndra WHNo ratings yet

- Articulated Haulers / C Series Models: Description Part No. Qty 250 H 500 H 1000 H 2000 H Notes EngineDocument3 pagesArticulated Haulers / C Series Models: Description Part No. Qty 250 H 500 H 1000 H 2000 H Notes EngineHugo Alejandro Bello ParraNo ratings yet

- G990 S.I.PDocument1 pageG990 S.I.Pأبو خالد الأثرىNo ratings yet

- PSCS Kamaz6520Document3 pagesPSCS Kamaz6520Theo anggara kusumaNo ratings yet

- Mantenimiento Compresor BlackmerDocument10 pagesMantenimiento Compresor BlackmerMarco NoccettiNo ratings yet

- HL Owners Manual 2021Document2 pagesHL Owners Manual 2021Dutchie169No ratings yet

- Manual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFDocument148 pagesManual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFskpppNo ratings yet

- Technical Documentation 19.8895Document142 pagesTechnical Documentation 19.8895YIOUGO WNo ratings yet

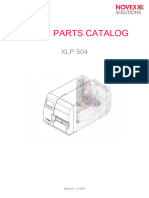

- XLP504 Spare PartsDocument32 pagesXLP504 Spare PartsДоктор КтоNo ratings yet

- B40D Mkii Service Kits PDFDocument4 pagesB40D Mkii Service Kits PDFBassieNo ratings yet

- MGB Workshop ManualDocument417 pagesMGB Workshop ManualjailemeilleurfrereaumondeNo ratings yet

- L20BDocument1 pageL20BМ РNo ratings yet

- 2010-0007 WebDocument32 pages2010-0007 WebAhmed El-ShafeiNo ratings yet

- Concrete Mixer Truck EnglishDocument6 pagesConcrete Mixer Truck EnglishlikNo ratings yet

- Adt e b40 b45 RSG Rev 5Document3 pagesAdt e b40 b45 RSG Rev 5wingchow282828228No ratings yet

- Polo Vivo Online BrochureDocument20 pagesPolo Vivo Online BrochureTandolwethu MaliNo ratings yet

- ATMOSDocument3 pagesATMOSYousfi Tadj EddineNo ratings yet

- Calcul UkDocument5 pagesCalcul UkJeremyNo ratings yet

- Ewf14742 PDFDocument36 pagesEwf14742 PDFbritt1611No ratings yet

- Fowler Ridge Fact SheetDocument2 pagesFowler Ridge Fact Sheetapi-242158334No ratings yet

- Control Theory IntroductionDocument53 pagesControl Theory IntroductionSushmita KujurNo ratings yet

- F2000 - Afm Sup11 Rev04 - 20100712Document36 pagesF2000 - Afm Sup11 Rev04 - 20100712rjohnson3773No ratings yet

- Module 1Document45 pagesModule 1itsbharath19106No ratings yet

- Validation Report 7.5 MW Lubuk Gadang Small Hydropower Plant at West Sumatera, Indonesia in IndonesiaDocument133 pagesValidation Report 7.5 MW Lubuk Gadang Small Hydropower Plant at West Sumatera, Indonesia in IndonesiaRdy SimangunsongNo ratings yet

- Jump, Loop and Call Instructions: University of Engineering and Technology TaxilaDocument93 pagesJump, Loop and Call Instructions: University of Engineering and Technology TaxilaPraneetha InumarthiNo ratings yet

- DHLDocument20 pagesDHLMohammad Faraz AkhterNo ratings yet

- HCI4F 311 1P TD EN - Rev - A PDFDocument9 pagesHCI4F 311 1P TD EN - Rev - A PDFRenzo zuñiga ahonNo ratings yet

- Iq An DesignDocument395 pagesIq An DesignLê Trường LâmNo ratings yet

- PDTP Ad 2023 24Document1 pagePDTP Ad 2023 24IrfanNo ratings yet

- Hydrodyne Teikoku PRESENTATIONDocument66 pagesHydrodyne Teikoku PRESENTATIONRabin kumar jain100% (1)

- Oracle Database 11g - SQL Fundamentals I Vol3Document62 pagesOracle Database 11g - SQL Fundamentals I Vol3ralucap100% (1)

- Dual Band Radio 4449 B12, B71Document7 pagesDual Band Radio 4449 B12, B71Viren BansalNo ratings yet

- 5991 7367enDocument6 pages5991 7367enAshraf ahmedNo ratings yet

- Open XpsDocument282 pagesOpen Xpsjosefer0716No ratings yet

- Circuit SDMDocument8 pagesCircuit SDMMohammedasifNo ratings yet

- Engineering Economy. IntroductionDocument30 pagesEngineering Economy. IntroductionTushar SinglaNo ratings yet

- Class-XII - Chemistry Worksheet-1 Aldehyde, Ketone and Carboxylic AcidsDocument3 pagesClass-XII - Chemistry Worksheet-1 Aldehyde, Ketone and Carboxylic AcidsSameer DahiyaNo ratings yet

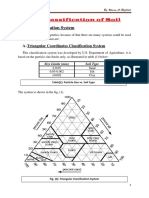

- 4 Classification of SoilDocument8 pages4 Classification of SoilPRAJWAL srNo ratings yet

- Transmission Notes-KLM Mapping in SDHDocument11 pagesTransmission Notes-KLM Mapping in SDHmathurwise100% (1)

- Protecting Ieds With Deviation of Power Frequency: Transmission and DistributionDocument3 pagesProtecting Ieds With Deviation of Power Frequency: Transmission and DistributionGangaDhar100% (1)

- EF132 BEE Lecture 2 & 3Document49 pagesEF132 BEE Lecture 2 & 3Anonymous gdLjDzNo ratings yet

- Connection Steel BCW-01 - 1Document2 pagesConnection Steel BCW-01 - 1duy quang NguyenNo ratings yet

- Automatic Voltage Regulator: C A Pa C I T Y: 1 0 0 0 Va - 5 0 0 0 VaDocument12 pagesAutomatic Voltage Regulator: C A Pa C I T Y: 1 0 0 0 Va - 5 0 0 0 VaNihar RoyNo ratings yet

- Iso 14 1982Document10 pagesIso 14 1982LotharSchmidtNo ratings yet

- Axial Flux PMBLDC Motor DesignDocument8 pagesAxial Flux PMBLDC Motor DesignAvi GuptaNo ratings yet

- ConfigGuide TR-069Document110 pagesConfigGuide TR-069joomlistNo ratings yet