Professional Documents

Culture Documents

RIX OilSkimmer - Catalog - Eng

Uploaded by

mohdshakir bahariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RIX OilSkimmer - Catalog - Eng

Uploaded by

mohdshakir bahariCopyright:

Available Formats

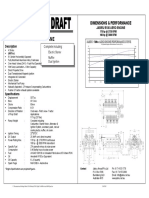

ミ Specifications ミ Schematic Dimensions

X

Screw Type SLS-

Depth(A)

Dimension A

150

Symbol

SB- OP Spiral Type MOS-

Depth(A)

Dimension A

200

Symbol

- G3P-200V-BT Ø140

Innovative

OIL SKIMMERS

150mm 150 150mm 150

200mm 200 200mm 200

300mm 300 300mm 300

X view

Motor Motor

B

Specification Cable Diameter Symbol Specification Cable Diameter Symbol 85 OIL SKIMMERS for Machining Centers

Induction motor, Induction motor,

3 phases, 200V Ø6.8~8.6mm None G3P-

3 phases, 200V Ø6.8~8.6mm

200V

95

Induction motor, 3 phases, Ø6.8~8.6mm

140

200V with terminal cover (cover dia.Ø22 mm) OP

Induction motor,

Motor conduit G3P-

3 phases, 200V with

diameter G1/2 200V-BT Oil collecting tank

Induction motor, 3 phases, Motor conduit terminal box

200V with terminal box diameter G1/2 BT

A

Induction motor, 54 Yview

Ø6.8~8.6mm 100

single phase, 100V

Motor Shape

Screw Type

(All oil skimmers are sold without cable in EU.)

Oil Skimmer

ミ Available Models

1 2

Y

Saving (pat.)

Screw Type Oil Skimmer Spiral Type Oil Skimmer

Model

Dimension (mm)

A B

Motor

Connection

Diagram

Weight

Shape (kg)

Capacity

(ml/hr) Model

Dimension (mm)

A B

Motor

Connection

Diagram

Weight

Shape (kg)

Capacity

(ml/hr)

Advantages at:

SLS-150SB* 352 ① MOS-150- 350 ①

G3P-200V*

SLS-150SB-OB* 150 354 a) ② 3.7 150 a) 4.0 3

SLS-150SB-BT* 392 ③

MOS-150-

G3P-200V-BT*

390 ③ - Maintenance costs

MOS-200-

SLS-200SB 352 ① G3P-200V

200

350

a)

①

4.1 100

- Liquid disposal costs

SLS-200SB-OP 200 354 a) ② 3.8 MOS-200- 390 ③

SLS-200SB-BT 392 ③

G3P-200V-BT - Running costs

850 MOS-300- 350 ①

G3P-200V

SLS-300SB 352 ①

MOS-300-

300 a)

③

4.2 (Height tolerance A and B : ± 5 mm) - Space

SLS-300SB-OP 300 354 a) ② 4.3 390

G3P-200V-BT Dimensions for Installation

③ 4-M6

SLS-300SB-BT 392 Cutout

Flange dimension

Waste oil collection

SLS-150SB-100* 150 3.7

100

120

140

SLS-200SB-100 200 352 b) ① 3.8

port side

SLS-300SB-100 300 4.3 65 10

* The 150 mm models are exclusively sold in Japan. In case you are interested in this types please let us know. 70

(Actual performance may vary depending on use conditions and environment.)

85

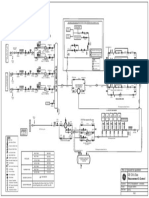

ミ Connection Diagrams (Induction Motor)

Flange dimension

a) 3 Phases AC200V 6W b) Single Phase AC100V 5W c) Single Phase AC220/230V 6W

Rated current :0.09A/50Hz Rated current:0.25A/50Hz Rated current :0.10A/50Hz

0.08A/60Hz 0.25A/60Hz 0.09A/60Hz

R (U)

U

1 Z2

S (V) L 2 Motor L U2 Motor

V Motor

T

(W) N 3 N U1

W

PE Capacitor PE Capacitor PE SLS-20

SLS -200SB

0SB

Rotation direction should be the same as the arrow mark on the

nameplate (clockwise looking from the top). Motor rotation Rotation direction should be the same as the arrow mark Rotation direction should be the same as the arrow mark

direction can be reversed by interchanging any two lines. on the nameplate (clockwise looking from the top). on the nameplate (clockwise looking from the top).

Demonstration machines for testing purposes are available for the screw as well as spiral type oil skimmer .

Attention

- This product has been developed for machining centers using water-soluble coolant.

If you intend to use the product for a different process, please contact us or our distributors.

NEW!

- Applicable range of oil viscosity: VG 22 to 68, applicable range of coolant temperature: 10 to 50 °C Spiral type

- Not applicable for vegetable oil-based, water-soluble coolant

- Applicable pH range of coolant : pH4 to pH9 oil skimmer:

- Filter installation is strongly recommended to prevent cutting chips from getting into the coolant tank.

- Do not use this product for detergent or coolant containing debris from machining. Highly resistant to

- This product is not applicable for cleaning solutions and coolants containing abrasive grit.

The best installation position is where the oil gathers and stagnates. cutting chips

- It is recommended to provide enough clearance to the tank bottom to prevent raising sludge.

- For details, please refer to the operation manual.

(pat. pending)

Vjg"urgekÝecvkqpu"ctg"uwdlgev"vq"ejcpig"ykvjqwv"pqvkeg0

MOS-200-G3P-200V

RIX CORPORATION LTD www.rix.co.jp/english/ RIX CORPORATION SEARCH

CAT No.201410

See next page

Advantages of RIX Oil Skimmers Long Seller

Screw Type Oil Skimmer(SLS Model)

High performance Differentiated product range

1 Low Maintenance Costs Max. 850 ml/hr (continuous operation)* Supplying motors with different voltages

Standard Belt Oil Skimmer RIX Oil Skimmer Popularity of our products

RIX oil skimmers have been adopted by well-known automobile

No separation tank

Need for regular required, therefore

and motorcycle manufacturers since its release in 2004

adjustment, change easy installation

and cleaning Since sludge is collected

with the oil, the separation

Squeegee

tank will not function properly

High viscosity oil is lifted by rotating screw

without regular cleaning. Low viscosity coolant is dropped

Separation tank

Belt might

Oil collecting tank

Oil collecting tank NEW

break

Spiral Type Oil Skimmer(MOS Model)

Sludge

Wider range of applications

Finally the coolant flow

cycle does not work. The MOS model is suitable for coolant containing more

sludge and metal cutting chips

Capacity

Max. 100 ml/hr (continuous operation) is enough, because the

oil usage at a machining center is only approx. 2 to 3 l/week*

2 Reduced Waste Liquid

q and Disposal

p Costs Shaft rotates and lifts up oil along a fixed spiral

Sludge and metal cutting chips are dropped

Oil Collection Efficiency Comparison together with low viscosity coolant from spiral

(Oil: Vactra No. 2 VG 68) Nearly exclusively

Standard Belt Oil Skimmer RIX Oil Skimmer oil collected

Coolant 7%

Coolant 49% (Please contact us in case the

coolant contains sludge and/

or metal cutting chips.)

Example of

Installation

Machining center

Oil collected

Oil 51% Oil 93%

by RIX oil skimmer

RIX Oil

(In case of inoperable separation tank) Skimmer

Collecting lubricant

in the coolant tank

Space-saving

p g 4 Low Running Costs

Lubricating oil circulation

3

Approx. 40 % installation space saved compared

to a standard belt or disk oil skimmer Standard Belt Coolant pump

Contents RIX Oil Skimmer

Oil Skimmer

Standard Belt Oil Skimmer RIX Oil Skimmer

1 Belt check & adjustment 1hr/yr None!

2 Squeegee check & adjustment 1hr/yr None! Coolant

circulation

3 Cleaning separation tank 6hrs/yr None!

4 Cleaning oil skimmer 0.5hr/yr

5 Power consumption 25W 6W

Approx. 40 % Lubricants

180×180=

32,400mm2 space reduction Saved space

140×140= Coolant tank

19,600mm2

(Standard belt

oil skimmer size)

*Actual performance may vary depending on use conditions and environment.

You might also like

- MPRDC 02-ModelDocument1 pageMPRDC 02-Modelramthakurh12No ratings yet

- CN2 Illustration of the terminal arrangement of the absolute encoderDocument2 pagesCN2 Illustration of the terminal arrangement of the absolute encoderRomain JRNo ratings yet

- Brochure GM IM Sampler MZEA MZED en LowDocument4 pagesBrochure GM IM Sampler MZEA MZED en LowCharlesNo ratings yet

- Powered by ExperienceDocument8 pagesPowered by ExperienceFigo ChengNo ratings yet

- Section of Pier: 42-25 MM Ø BarsDocument1 pageSection of Pier: 42-25 MM Ø Barsshekhar Nath chapagainNo ratings yet

- 5M. Polygonal: Hot Dip Galvanized Pole Model: TUGDocument1 page5M. Polygonal: Hot Dip Galvanized Pole Model: TUGDumitrache IulianNo ratings yet

- Kedbrooke Product CatalogueDocument44 pagesKedbrooke Product CatalogueVr BenioNo ratings yet

- Motros Shaded Pole 52Document2 pagesMotros Shaded Pole 52nicuNo ratings yet

- Ceramic TrapsDocument2 pagesCeramic TrapsxxmarquesmiguelxxNo ratings yet

- Schreder AVENTO Installation Instructions RevbDocument3 pagesSchreder AVENTO Installation Instructions RevbOscarNo ratings yet

- VIAT Catalogue No. VI-C01B-R0Document2 pagesVIAT Catalogue No. VI-C01B-R0vhgiaoNo ratings yet

- MOTOVIBRADORORDocument1 pageMOTOVIBRADORORJulio Vega AngelesNo ratings yet

- 600 Shape DIA LengthDocument1 page600 Shape DIA LengthImranuddin SyedNo ratings yet

- (HL200M) (HL200M) : Skid Trailer Sound AttenuatedDocument2 pages(HL200M) (HL200M) : Skid Trailer Sound AttenuatedhendrynNo ratings yet

- ACO Surface Selector 204Document2 pagesACO Surface Selector 204Miltiades SiopisNo ratings yet

- G-Series servo motors: compact servomotors for all applicationsDocument10 pagesG-Series servo motors: compact servomotors for all applicationsnguyenquocNo ratings yet

- EIM NC2 Test Project Layout ModelDocument1 pageEIM NC2 Test Project Layout ModelAlbertEubra100% (1)

- Structural S 1 PDFDocument1 pageStructural S 1 PDFIbbe CaguiatNo ratings yet

- MITSUMI Stepping Motor M55SP-2K Technical SpecificationsDocument2 pagesMITSUMI Stepping Motor M55SP-2K Technical SpecificationsbLesaLmeNo ratings yet

- BS2400.402HT243 90KW - 400VDocument7 pagesBS2400.402HT243 90KW - 400VorhanNo ratings yet

- OPzV GelDocument1 pageOPzV GelSINES France100% (1)

- 200x150-400 Centrifugal Pump Performance DataDocument1 page200x150-400 Centrifugal Pump Performance DataMuhammad Fadhly AugustamiNo ratings yet

- SS & SC All Gear Lathe MachineDocument2 pagesSS & SC All Gear Lathe MachineMihir Machine Tools Gujarat Pvt LtdNo ratings yet

- P-0172 Manual Fixturlaser PAT Rev CDocument2 pagesP-0172 Manual Fixturlaser PAT Rev CClaudio SotoNo ratings yet

- Engine 2JZ-GEDocument108 pagesEngine 2JZ-GEroy.cheong900% (1)

- SC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out RobotDocument1 pageSC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out Robotbagas prakosoNo ratings yet

- Reinforcement detailing of abutment and dirt wallDocument1 pageReinforcement detailing of abutment and dirt wallshekhar Nath chapagain100% (1)

- Submerged PumpDocument8 pagesSubmerged Pumpbramantiya100% (1)

- Alfa Laval MR 166us 185us 200us Liquid Ring Pump - Ese00233enusDocument4 pagesAlfa Laval MR 166us 185us 200us Liquid Ring Pump - Ese00233enusjonatas.silvaNo ratings yet

- Options: Specification Output TorqueDocument6 pagesOptions: Specification Output Torquezytura2019No ratings yet

- Contactors, Thermal Overload Relays & Capacitor ContactorsDocument8 pagesContactors, Thermal Overload Relays & Capacitor ContactorsABDUL GHAFOORNo ratings yet

- DC Electromagnetic Brake Details and SpecificationsDocument1 pageDC Electromagnetic Brake Details and Specificationsakhil100% (1)

- Pampllet 3 FoldDocument6 pagesPampllet 3 FoldFraz AhmedNo ratings yet

- L21 ag lightingDocument1 pageL21 ag lightingyrliimgtluhqqhlxtzNo ratings yet

- Excellence Line Hits Smarter: Factory Installed Rd3 For MyfleetDocument2 pagesExcellence Line Hits Smarter: Factory Installed Rd3 For MyfleetamarpathyNo ratings yet

- PL 500 Technical LeafletDocument2 pagesPL 500 Technical LeafletAsad AijazNo ratings yet

- Cocina PDFDocument1 pageCocina PDFcursorevit439No ratings yet

- Model SSV3: Mechanical Feed and Electronic Control Drill UnitDocument4 pagesModel SSV3: Mechanical Feed and Electronic Control Drill Unitasta seikiNo ratings yet

- Spreader Beam Pc-U Girder: Isomatric ViewDocument1 pageSpreader Beam Pc-U Girder: Isomatric ViewhermonNo ratings yet

- Catalogues - LBC Tower - TCM SeriesDocument12 pagesCatalogues - LBC Tower - TCM Seriesyêu animeNo ratings yet

- Rotary Encoder ENC Series Instruction ManualDocument1 pageRotary Encoder ENC Series Instruction ManualArie Cahyo UtomoNo ratings yet

- 2-Data Us Aa6vm Ra - 91604Document35 pages2-Data Us Aa6vm Ra - 91604suriantoNo ratings yet

- Performance and Specification 1. Performance: Body Electrical - Air Conditioning BE-60Document3 pagesPerformance and Specification 1. Performance: Body Electrical - Air Conditioning BE-60Roma KuzmychNo ratings yet

- Jabiru 5100 Aero Engine Specs & PerformanceDocument1 pageJabiru 5100 Aero Engine Specs & PerformanceG.L. ZortmanNo ratings yet

- NKZ3 D3 C4XXDocument8 pagesNKZ3 D3 C4XXasNo ratings yet

- Elevation: DIMENSIONS (In Centimeters) For Concrete Headwall (Inlet or Outlet)Document1 pageElevation: DIMENSIONS (In Centimeters) For Concrete Headwall (Inlet or Outlet)Jef Atillo RepuldaNo ratings yet

- Global Proposal System 19.0.2 Technical SummaryDocument12 pagesGlobal Proposal System 19.0.2 Technical SummaryKKNo ratings yet

- EVC600i Operation ManualDocument7 pagesEVC600i Operation ManualNatee MongkhonpornNo ratings yet

- Curve 86 EAH - Motor 45kWDocument1 pageCurve 86 EAH - Motor 45kWdaniqoNo ratings yet

- PS2-1800 CS-F4-6: Solar Surface Pump SystemDocument3 pagesPS2-1800 CS-F4-6: Solar Surface Pump SystemPatient BisakabungaNo ratings yet

- Etn 150-400 y 150-450Document1 pageEtn 150-400 y 150-450Carolina Aguirre ANo ratings yet

- Product Data Sheet Damcos BRC 500 en 60338Document4 pagesProduct Data Sheet Damcos BRC 500 en 60338cvfNo ratings yet

- Marine Ejectors PDFDocument11 pagesMarine Ejectors PDFVikk SuriyaNo ratings yet

- GOYKA INTAKE FINAL-ModelDocument1 pageGOYKA INTAKE FINAL-ModeladhirachnaNo ratings yet

- Counter Weight DrawingDocument1 pageCounter Weight Drawingrajaguru20003No ratings yet

- Lorentz Ps2 600 Cs FDocument6 pagesLorentz Ps2 600 Cs FSINES FranceNo ratings yet

- Optimal: Ower-WergeDocument1 pageOptimal: Ower-WergeJury ZanniNo ratings yet

- Metering Skid: Station Outlet 350 250 Psig 600 MMSCFDDocument1 pageMetering Skid: Station Outlet 350 250 Psig 600 MMSCFDshakuntla5bankerNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Resume-Mariam Abdul AzizDocument2 pagesResume-Mariam Abdul Azizmaryam cookNo ratings yet

- Enthalpy ChangesDocument2 pagesEnthalpy Changesapi-296833859100% (1)

- New Technique for Producing 3D Fabrics Using Conventional LoomDocument1 pageNew Technique for Producing 3D Fabrics Using Conventional LoomSujit GulhaneNo ratings yet

- Cement and Concrete Research: Amin Abrishambaf, Mário Pimentel, Sandra NunesDocument13 pagesCement and Concrete Research: Amin Abrishambaf, Mário Pimentel, Sandra NunesJoseluis Dejesus AnguloNo ratings yet

- Consumers Guide To The ExpertsDocument406 pagesConsumers Guide To The ExpertsHassan Younhous Traore KonéNo ratings yet

- Chapter 2 Study Questions Solution ManualDocument12 pagesChapter 2 Study Questions Solution ManualSebastiàn Valle100% (3)

- Growatt Warranty Procedure - 07-09-2020Document9 pagesGrowatt Warranty Procedure - 07-09-2020Design TeamNo ratings yet

- Use of Passive VoiceDocument13 pagesUse of Passive VoiceLuciana DicieroNo ratings yet

- Rubber Conveyor Belt Wear ResistanceDocument5 pagesRubber Conveyor Belt Wear ResistanceBelt Power LLCNo ratings yet

- A Review Paper On Rice Quality Analysis Using Image Processing TechniqueDocument5 pagesA Review Paper On Rice Quality Analysis Using Image Processing TechniqueIJRASETPublicationsNo ratings yet

- International Standard Iso/Iec Software Cycle Processes: Standards SectionDocument16 pagesInternational Standard Iso/Iec Software Cycle Processes: Standards SectionDavid SalgadoNo ratings yet

- Muhammad Farrukh QAMAR - Assessment 2 Student Practical Demonstration of Tasks AURAMA006 V2Document19 pagesMuhammad Farrukh QAMAR - Assessment 2 Student Practical Demonstration of Tasks AURAMA006 V2Rana Muhammad Ashfaq Khan0% (1)

- Proficiency 6Document4 pagesProficiency 6api-508196283No ratings yet

- Medical Services Recruitment Board (MRB)Document20 pagesMedical Services Recruitment Board (MRB)durai PandiNo ratings yet

- Gabriel MarcelDocument6 pagesGabriel MarcelCeciBohoNo ratings yet

- Lamb To The Slaughter EssayDocument5 pagesLamb To The Slaughter Essaypflhujbaf100% (2)

- QMM: Exercise Sheet 8 - Structural Equation Model: Structural RegressionDocument3 pagesQMM: Exercise Sheet 8 - Structural Equation Model: Structural Regressionlaurine.hoyoNo ratings yet

- Cargo Security Awareness - Etextbook - 2nd - Ed - 2016 - TCGP-79Document185 pagesCargo Security Awareness - Etextbook - 2nd - Ed - 2016 - TCGP-79kien Duy Phan80% (5)

- Faktor OrganisasiDocument9 pagesFaktor OrganisasiNur Fatin NabilahNo ratings yet

- WRBS Quarter 1 Modules WEEK-1-8Document32 pagesWRBS Quarter 1 Modules WEEK-1-8Sir Kindred VillaruzNo ratings yet

- 2narrative Essay - My Favorite TeacherDocument9 pages2narrative Essay - My Favorite TeacherHerbertKoh100% (1)

- Marivy Abella ResearchDocument43 pagesMarivy Abella ResearchRo Gi LynNo ratings yet

- G25M R TransmissionDocument29 pagesG25M R TransmissionMaksym VovkNo ratings yet

- Organization-and-Management Q1 LAS Wk1Document5 pagesOrganization-and-Management Q1 LAS Wk1Joyce CelineNo ratings yet

- Small BusinessDocument22 pagesSmall BusinessAngelie Dela CruzNo ratings yet

- Senior Power Apps Engineer JobDocument3 pagesSenior Power Apps Engineer JobMichałNo ratings yet

- Emebet Kebede FINALDocument65 pagesEmebet Kebede FINALTefeNo ratings yet