Professional Documents

Culture Documents

DEP 31.10.00.10 Material Control and Verification (PMI)

Uploaded by

MN VenkatesanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DEP 31.10.00.10 Material Control and Verification (PMI)

Uploaded by

MN VenkatesanCopyright:

Available Formats

DEP SPECIFICATION

MATERIAL CONTROL AND VERIFICATION FOR

PRESSURIZED EQUIPMENT

Copyright Shell Group of Companies. No reproduction or networking permitted without license from Shell. Not for resale

DEP 31.10.00.10-Gen.

February 2017

ECCN EAR99

DESIGN AND ENGINEERING PRACTICE

DEM1

© 2017 Shell Group of companies

All rights reserved. No part of this document may be reproduced, stored in a retrieval system, published or transmitted, in any form or by any means, without the prior

written permission of the copyright owner or Shell Global Solutions International BV.

This document contains information that is classified as EAR99 and, as a consequence, can neither be exported nor re-exported to any country which is under an

embargo of the U.S. government pursuant to Part 746 of the Export Administration Regulations (15 C.F R. Part 746) nor can be made available to any national of such

country. In addition, the information in this document cannot be exported nor re-exported to an end-user or for an end-use that is prohibited by Part 744 of the Export

Administration Regulations (15 C.F.R. Part 744).

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 2

PREFACE

DEP (Design and Engineering Practice) publications reflect the views, at the time of publication, of Shell Global Solutions

International B.V. (Shell GSI) and, in some cases, of other Shell Companies.

These views are based on the experience acquired during involvement with the design, construction, operation and

maintenance of processing units and facilities. Where deemed appropriate DEPs are based on, or reference international,

regional, national and industry standards.

The objective is to set the standard for good design and engineering practice to be applied by Shell companies in oil and

gas production, oil refining, gas handling, gasification, chemical processing, or any other such facility, and thereby to help

achieve maximum technical and economic benefit from standardization.

The information set forth in these publications is provided to Shell companies for their consideration and decision to

implement. This is of particular importance where DEPs may not cover every requirement or diversity of condition at each

locality. The system of DEPs is expected to be sufficiently flexible to allow individual Operating Units to adapt the

information set forth in DEPs to their own environment and requirements.

When Contractors or Manufacturers/Suppliers use DEPs, they shall be solely responsible for such use, including the

quality of their work and the attainment of the required design and engineering standards. In particular, for those

requirements not specifically covered, the Principal will typically expect them to follow those design and engineering

practices that will achieve at least the same level of integrity as reflected in the DEPs. If in doubt, the Contractor or

Manufacturer/Supplier shall, without detracting from his own responsibility, consult the Principal.

The right to obtain and to use DEPs is restricted, and is typically granted by Shell GSI (and in some cases by other Shell

Companies) under a Service Agreement or a License Agreement. This right is granted primarily to Shell companies and

other companies receiving technical advice and services from Shell GSI or another Shell Company. Consequently, three

categories of users of DEPs can be distinguished:

1) Operating Units having a Service Agreement with Shell GSI or another Shell Company. The use of DEPs by these

Operating Units is subject in all respects to the terms and conditions of the relevant Service Agreement.

2) Other parties who are authorised to use DEPs subject to appropriate contractual arrangements (whether as part of

a Service Agreement or otherwise).

3) Contractors/subcontractors and Manufacturers/Suppliers under a contract with users referred to under 1) or 2)

which requires that tenders for projects, materials supplied or - generally - work performed on behalf of the said

users comply with the relevant standards.

Subject to any particular terms and conditions as may be set forth in specific agreements with users, Shell GSI disclaims

any liability of whatsoever nature for any damage (including injury or death) suffered by any company or person

whomsoever as a result of or in connection with the use, application or implementation of any DEP, combination of DEPs

or any part thereof, even if it is wholly or partly caused by negligence on the part of Shell GSI or other Shell Company. The

benefit of this disclaimer shall inure in all respects to Shell GSI and/or any Shell Company, or companies affiliated to these

companies, that may issue DEPs or advise or require the use of DEPs.

Without prejudice to any specific terms in respect of confidentiality under relevant contractual arrangements, DEPs shall

not, without the prior written consent of Shell GSI, be disclosed by users to any company or person whomsoever and the

DEPs shall be used exclusively for the purpose for which they have been provided to the user. They shall be returned

after use, including any copies which shall only be made by users with the express prior written consent of Shell GSI. The

copyright of DEPs vests in Shell Group of companies. Users shall arrange for DEPs to be held in safe custody and Shell

GSI may at any time require information satisfactory to them in order to ascertain how users implement this requirement.

All administrative queries should be directed to the DEP Administrator in Shell GSI.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 3

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................ 4

1.1 SCOPE ....................................................................................................................... 4

1.2 DISTRIBUTION, INTENDED USE AND REGULATORY CONSIDERATIONS ......... 4

1.3 DEFINITIONS ............................................................................................................. 4

1.4 CROSS-REFERENCES ............................................................................................. 6

1.5 SUMMARY OF MAIN CHANGES............................................................................... 6

1.6 COMMENTS ON THIS DEP ....................................................................................... 7

1.7 DUAL UNITS............................................................................................................... 7

1.8 NON NORMATIVE TEXT (COMMENTARY) .............................................................. 7

2. GENERAL .................................................................................................................. 8

3. MATERIAL CONTROL AND VERIFICATION PROGRAMME MAIN

ELEMENTS ................................................................................................................ 8

4. MATERIAL VERIFICATION ....................................................................................... 9

4.1 ALLOY COMPONENTS AND ALLOY WELDS SUBJECT TO PMI ........................... 9

4.2 WELDING CONSUMABLE CONTROL AND VERIFICATION ................................... 9

4.3 CARBON STEEL COMPONENTS SUBJECT TO MATERIAL VERIFICATION ...... 10

4.4 ALTERNATE PMI PROGRAMS ............................................................................... 10

4.5 ALLOYING ELEMENTS REQUIRED TO BE EVALUATED DURING PMI .............. 10

4.6 MATERIALS AND COMPONENTS NOT SUBJECT TO PMI .................................. 11

4.7 TIMING AND LOCATION OF PMI/VERIFICATION CHECKS ................................. 11

4.8 GENERAL REQUIREMENTS FOR MATERIAL CERTIFICATIONS........................ 11

5. EXAMINATION EQUIPMENT/TEST METHOD ....................................................... 12

6. MATERIAL IDENTIFICATION ................................................................................. 12

6.1 TRACEABILITY ........................................................................................................ 12

6.2 MARKING ................................................................................................................. 13

6.3 COLOUR CODING ................................................................................................... 13

6.4 COMPONENT IDENTIFICATION ............................................................................. 14

6.5 REJECTED MATERIAL ............................................................................................ 14

7. PMI INSPECTION REPORT .................................................................................... 15

8. REFERENCES ......................................................................................................... 16

APPENDICES

APPENDIX A COMPONENTS SUBJECT TO PMI............................................................... 17

APPENDIX B PMI FOR INSTRUMENTATION COMPONENTS .......................................... 20

APPENDIX C ALLOYING ELEMENTS REQUIRED FOR PMI ............................................ 21

APPENDIX D MATERIAL IDENTIFICATION CODES ......................................................... 23

APPENDIX E LOCATION OF PMI IDENTIFICATION MARKS FOR PIPING

(EXAMPLES)................................................................................................... 24

APPENDIX F PIPING COMPONENT MARKING SPECIFICATIONS ................................. 25

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 4

1. INTRODUCTION

1.1 SCOPE

This DEP specifies requirements and gives recommendations for material control and

verification (MC&V) of alloy and carbon steel that needs to be applied during all phases of a

project or repair/replacement work, to guard against the installation of rogue materials for

pressurized equipment.

Pressurized equipment refers to standard or common types of equipment used in most

assets. Unique or specialized equipment for subsea, pipelines or other parts of the

business are addressed in the DEPs for these specific applications as the material control

and verification requirements in this DEP might not be enough to provide proper controls

and assurance.

This DEP is based on having a procurement system in place that obtains materials and

fabricated equipment from vendors that have been through a review and approval process

similar to that recommended in EEMUA 224.

The material control elements in this DEP apply to bulk and specialty components, and to

fabricated piping and equipment.

This DEP defines the minimum required sample (percentage), elemental analysis

requirements and other verification steps based on the material of construction and the

component type. It includes material traceability to source as part of the process.

This DEP contains mandatory requirements to mitigate process safety risks in accordance

with Design Engineering Manual (DEM) 1 - Application of Technical Standards.

This is a revision of the DEP of the same number dated September 2013; see (1.5)

regarding the changes.

1.2 DISTRIBUTION, INTENDED USE AND REGULATORY CONSIDERATIONS

Unless otherwise authorised by Shell GSI, the distribution of this DEP is confined to Shell

companies and, where necessary, to Contractors and Manufacturers/Suppliers nominated

by them. Any authorised access to DEPs does not for that reason constitute an

authorisation to any documents, data or information to which the DEPs may refer.

This DEP is intended for use in facilities related to oil and gas production, gas handling, oil

refining, chemical processing, gasification, distribution and supply/marketing. This DEP

may also be applied in other similar facilities.

When DEPs are applied, a Management of Change (MOC) process shall be implemented;

this is of particular importance when existing facilities are to be modified.

If national and/or local regulations exist in which some of the requirements could be more

stringent than in this DEP, the Contractor shall determine which of the requirements are the

more stringent and which combination of requirements will be acceptable with regards to

the safety, environmental, economic and legal aspects. In all cases, the Contractor shall

inform the Principal of any deviation from the requirements of this DEP which is considered

to be necessary in order to comply with national and/or local regulations.

This DEP is consistent with API RP 578 Material Verification programme for New and

Existing Alloy Piping Systems.

1.3 DEFINITIONS

1.3.1 General definitions

The Contractor is the party that carries out all or part of the design, engineering,

procurement, construction, commissioning or management of a project or operation of a

facility. The Principal may undertake all or part of the duties of the Contractor.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 5

The Manufacturer/Supplier is the party that manufactures or supplies equipment and

services to perform the duties specified by the Contractor.

The Principal is the party that initiates the project and ultimately pays for it. The Principal

may also include an agent or consultant authorised to act for, and on behalf of, the

Principal.

The word shall indicates a requirement.

The capitalised term SHALL [PS] indicates a process safety requirement.

The word should indicates a recommendation.

The word may indicates a permitted option.

1.3.2 Specific definitions

Term Definition

Alloy Material Any metallic material (including welding filler materials) that contain

alloying elements that are intentionally added to enhance mechanical or

physical properties and corrosion resistance, or a combination thereof,

(e.g., Chromium, Nickel, or Molybdenum). The term alloy includes

special grades of carbon steel such as those used in low temperature

(LT) and sour services.

Fabricator One who fabricates piping systems or portions of a piping system as

defined by ASME B31.3, or process pressure equipment,

instrumentation or machinery.

Heat (of A batch of metal made at the same time, that can be traced from its

Material) original constituents and manufacturing process.

Inspection Lot A group of items or materials of the same type from a common source

from which a sample is to be drawn for examination. An inspection lot

does not include items from more than one heat.

Inspection Test A step by step plan outlining special inspection steps that should occur

Plan (ITP) during the fabrication/assembly process.

Level of The specified percentage of the number of components (or weldments

Examination when specified) to be examined in an inspection lot.

Lot Size The number of items available in the inspection lot at the time a

representative sample is selected.

Material A documented quality assurance program used to control and verify that

Control and the materials installed on a project meet the requirements.

Verification

Program

Material An organization that performs or supervises and directly controls one or

Manufacturer more of the operations that affect the chemical composition or

mechanical properties of a metallic material.

Material Non- A material that does not meet specified requirements.

conformance

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 6

Term Definition

Material An organization that supplies material furnished and certified by a

Supplier material Manufacturer, but does not perform any operation intended to

alter the material properties required by the applicable material

specification. Material Manufacturer and Supplier may be the same

party if the Manufacturer supplies directly to the shop fabricator, field

fabricator, or Principal.

MESC Material and Equipment Standards and Code. Provides material and

final product minimum certification requirements and specifications.

Mill Test A certified document that permits each component to be identified

Report(MTR) according to the original heat of material from which it was produced

and identifies the applicable material specification (including

documentation of all test results required by the material specification).

MTRs are not a substitute for PMI tests.

Positive A physical evaluation or test of a material using an analyzer to confirm

Material that it is consistent with the selected or specified alloy material

Identification designated by the Principal. Evaluations or tests can provide either

(PMI) quantitative information to verify alloy composition in weight percent or

qualitative information that identifies the grade of the material.

Pressure- Items that form the pressure-containing envelope of the operating

Containing components and piping systems. This includes on-line instrumentation

Components up to and including the first isolation valve of off-line instrumentation.

Random Selection process by which choices are made in an arbitrary and

unbiased manner.

Representative One or more items selected at random from the inspection lot that are to

Sample be examined to determine the acceptability of the inspection lot.

Rogue Material Equipment or piping components installed in a specific alloy (or special

carbon steel) system that do not meet the material specification for that

system. This includes welding consumables.

Standard Sample materials for which laboratory chemical analysis data are

Reference available and are used in demonstrating test instrument accuracy and

Materials reliability.

Traceability The ability to match an installed component to its source.

1.4 CROSS-REFERENCES

Where cross-references to other parts of this DEP are made, the referenced section or

clause number is shown in brackets ( ). Other documents referenced by this DEP are listed

in (8).

1.5 SUMMARY OF MAIN CHANGES

This DEP is a revision of the DEP of the same number dated September 2013. The

changes are too extensive to list individually. The following are the main, non-editorial

changes.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 7

Section/Clause Change

Title Changed from “Positive Material Identification Program” to

“Material Control and Verification” to better reflect the entire

process.

General Separated which carbon steel components receive PMI and

which receive material verification through traceability.

General Changed the PMI of weld overlay to a surface verification since

the weld procedure is verified at the proper depth.

General Clarified when PMI testing is to be performed.

General Allowed the use of alloy identification instead of element

identification for PMI of “Standard” materials.

1.6 COMMENTS ON THIS DEP

Comments on this DEP may be submitted to the Administrator using one of the following

options:

Shell DEPs Online Enter the Shell DEPs Online system at

https://www.shelldeps.com

(Users with access to

Select a DEP and then go to the details screen for

Shell DEPs Online)

that DEP.

Click on the “Give feedback” link, fill in the online

form and submit.

DEP Feedback System Enter comments directly in the DEP Feedback

System which is accessible from the Technical

(Users with access to

Standards Portal http://sww.shell.com/standards.

Shell Wide Web)

Select “Submit DEP Feedback”, fill in the online form

and submit.

DEP Standard Form Use DEP Standard Form 00.00.05.80-Gen. to record

feedback and email the form to the Administrator at

(other users)

standards@shell.com.

Feedback that has been registered in the DEP Feedback System by using one of the above

options will be reviewed by the DEP Custodian for potential improvements to the DEP.

1.7 DUAL UNITS

This DEP contains both the International System (SI) units, as well as the corresponding

US Customary (USC) units, which are given following the SI units in brackets. When

agreed by the Principal, the indicated USC values/units may be used.

1.8 NON NORMATIVE TEXT (COMMENTARY)

Text shown in italic style in this DEP indicates text that is non-normative and is provided as

explanation or background information only.

Non-normative text is normally indented slightly to the right of the relevant DEP clause.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 8

2. GENERAL

1. A material control and verification programme (MC&V) approved by the Principal

SHALL [PS] be in place for the installation of all new components of pressure retaining

equipment and piping.

2. The MC&V programme shall cover the minimum required sample (percentage), the

elemental analysis requirements and other material verification steps contained in this

DEP, based on the alloys of construction and the component type.

3. The programme shall include MC&V of non-pressure retaining components that are

integral to the pressure equipment.

3. MATERIAL CONTROL AND VERIFICATION PROGRAMME MAIN ELEMENTS

1. The elements covered by the MC&V programme for pressurized equipment shall

include the following:

a. Levels of examination, including alloy elements required for PMI;

b. PMI equipment and methods;

c. Materials, components and fabricated assemblies (e.g., pipe spools) subject to

PMI;

d. Marking and identification of components on which PMI has been performed (i.e.,

the stamping and colour coding systems);

e. PMI of welding consumables and gaskets;

f. Material traceability during fabrication and machining, the timing and location of

PMI in accordance with the Inspection and Test Plan (ITP), including transfer of

identification markings (e.g., heat numbers) and colour coding;

g. PMI Inspection reports as defined in (7).

2. The MC&V programme shall include the following controls at both the fabrication and

construction sites:

a. Receipt of Materials – controls for segregation and storage of materials, material

test report validation and PMI and component identification from the

Manufacturers/Suppliers per the scope of this specification.

b. Issue of Materials – Controls for the issue and tracking of materials and

components and welding consumables during fabrication. This includes the

following:

i. Controls during fabrication, such as the segregation of materials, materials

traceability and identification including matching of heat numbers to MTRs

during the fabrication process;

ii. Segregation of tools where applicable to prevent contamination.

c. Surplus Materials – the control and traceability of surplus materials.

d. Rejected Materials – the control and traceability of rejected materials, including

the return and/or replacement.

e. Carbon steel materials – the control and traceability of carbon steel materials

where mill test report verification is the means of verifying the correct material

was installed.

3. The MC&V programme shall include auditable material traceability records including

the following:

a. Transmittal of the records as part of the handover documentation packages;

b. Final field verification on completed systems.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 9

4. MATERIAL VERIFICATION

4.1 ALLOY COMPONENTS AND ALLOY WELDS SUBJECT TO PMI

1. The extent of PMI examination SHALL [PS] be according to the tables in (APPENDIX

A) and (APPENDIX B) according to the following classifications:

a. Standard: Common materials for general corrosion resistance where a smaller

sample size is representative of the Inspection Lot.

b. Full: Higher alloy or specifically selected materials for degradation resistance or

strength requirements where 100% of the components are verified to meet the

requirements of the intended service.

c. Standard: For all grades of Type 304 stainless steel (i.e., 304L, 304, and 304H).

d. Full: For alloy materials other than Type 304 stainless steel, including all grades

of Type 316 stainless steel, for both base material and welds.

Some weld rods have the alloying elements contained in the flux, and do not

meet the alloy specification until welded. PMI of weld metal (e.g., deposited

weld metal or undiluted weld “buttons”) is a permissible alternative to PMI of an

electrode, TIG wire, or wire sample.

4.2 WELDING CONSUMABLE CONTROL AND VERIFICATION

1. Verification and control of welding consumables shall include the following:

a. Controlled storage, handling, quarantining, issuing of welding consumables and

return of unused consumables.

b. PMI of welding consumables based on testing of a heat/lot.

c. Intermediate controls after the consumables have been issued, i.e., before,

during, and after the welding process including inspection and testing, quality

control and assurance measures.

d. Non-conformance identification and marking, tracking and corrective action

measures.

2. When welding is conducted, one electrode or wire sample from each lot or heat of

alloy weld rod shall be positively identified.

a. The remainder of the lot should be compared to the sample to verify that the

markings of the wires/electrodes are correct.

b. Weld rods that have the alloying elements contained in the flux and do not meet

the alloy specification until welded shall require PMI of the deposited weld metal

(e.g., deposited weld metal or undiluted weld buttons).

3. For weld overlay used to provide corrosion protection, analysis of the overlay

SHALL [PS] be performed as follows to verify the specified alloy chemical composition

and that the degree of alloy dilution is acceptable:

a. Qualify the weld procedures for overlay per DEP 30.10.60.18-Gen. or

DEP 30.10.60.32-Gen., as applicable.

b. During production weld overlay, carry out the following as a minimum:

i. perform PMI on the surface once per shift per welder or operator;

ii. perform PMI including a copper sulphate test on any areas of overlay that

have been ground (e.g., for bundle clearance);

iii. verify the weld overlay thickness.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 10

4. For weld overlay used to only assure product purity, analysis of the overlay shall be

performed as follows to verify the specified alloy chemical composition and that the

degree of alloy dilution is acceptable:

a. Qualify the weld procedures for overlay per DEP 30.10.60.18-Gen. or

DEP 30.10.60.32-Gen., as applicable

b. During production weld overlay, carry out the following as a minimum:

i. perform PMI on the surface once per shift per welder or operator;

ii. perform PMI including a copper sulphate test on any areas of overlay that

have been ground (e.g., for bundle clearance);

iii. verify the weld overlay thickness.

4.3 CARBON STEEL COMPONENTS SUBJECT TO MATERIAL VERIFICATION

1. In Hydrofluoric acid service, carbon steel materials with restricted carbon content and

residual element requirements SHALL [PS] be verified by full (100%) PMI including

material verification by matching heat numbers of components to the mill test reports.

2. An Optical Emission Spectrometer (Arc/Spark) shall be used for PMI of carbon steel

materials with restricted carbon content and residual element requirements in

Hydrofluoric acid service.

3. Materials in the following process services SHALL [PS] be verified by matching heat

numbers of components to the mill test reports:

a. Where Hydrogen Induced Cracking (HIC) resistant material or maximum

hardness levels are specified.

b. Where materials for Wet Hydrogen Sulphide (H2S) services are specified;

c. Where materials with minimum silicon (Si) content critical to corrosion resistance

are specified;

d. Where low temperature enhanced mechanical properties are specified (e.g.,

impact tested material) or drop weight tear tests for pipelines.

4. PMI or material verification for carbon steels in services other than (4.3, Item 3) shall

be as specified by the Principal.

5. Specialty carbon steel (such as impact tested, HIC resistant and for HF service) shall

be stored and fabricated in an area separated from regular grade carbon steel in order

to avoid mixing of materials and welding electrodes.

a. colour coding or unique material tagging shall be applied to specialty carbon steel

materials see (6.3).

4.4 ALTERNATE PMI PROGRAMS

Implementation of an alternative PMI programme that defines the extent of PMI based

on risk might be permitted. Since many of the elements of a PMI programme are DEM1

mandated, an alternate programme would be subject to the approval of the Principal and

the TA1 Principal's Technical Authority (TA1).

For speciality components (e.g., sub-sea blocks), material controls and material

traceability and/or destructive testing can be used in lieu of full PMI if agreed with the

Principal’s Technical Authority (TA1).

4.5 ALLOYING ELEMENTS REQUIRED TO BE EVALUATED DURING PMI

1. For the “Full” level of PMI testing, a quantitative alloy assay mode shall determine the

percent by weight of elements in accordance with (APPENDIX C).

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 11

For the “Standard” level of PMI testing, a semi-quantitative material identification

mode is acceptable.

4.6 MATERIALS AND COMPONENTS NOT SUBJECT TO PMI

1. Unless otherwise specified by the Principal, the following materials should not be

subject to PMI:

a. All grades of carbon steel except as specified in (4.3).

b. Internal valve components that are standard from the Manufacturer/Supplier.

c. All standard cast 304 and 316 machinery components.

d. Internal parts of machinery and pumps made of type 304, 316 stainless steel or

brass.

e. Instrumentation as detailed in (APPENDIX B).

f. All cast brass valves.

g. Machinery lube oil systems, hydraulic systems, steam tracing and steam turbine

gland vacuum systems.

h. Standard type 304 and 316 stainless steel spiral wound gaskets.

i. All standard cast 304 and 316 valves.

j. All other materials for both cast and forged valves where the material marking

on both the body and bonnet components are executed in high relief

(stamping or embossing is not considered as high relief) as an integral part of

the component and are not obscured by painting or coating.

4.7 TIMING AND LOCATION OF PMI/VERIFICATION CHECKS

1. PMI, material verification and marking shall be performed during the construction

phase at one of the following stages of the project:

a. During receiving inspection when components or materials arrive at site.

b. Prior to storage in the warehouse or delivery to the on-site fabrication shop or to

the field.

c. At a Manufacturer/Supplier’s facility prior to delivery to the site.

d. At the welding shop prior to dispensing consumables for use.

e. During assembly, machining, or fabrication per the ITP, e.g., at the fabrication

shop.

f. On existing piping at tie-ins of new piping to existing prior to welding in the field.

g. On completed piping systems (including welds), after field installation of pipe

spools at the appropriate stage of turnover of systems (e.g., final punch listing).

2. The PMI or material verification shall be performed prior to the application of paint.

4.8 GENERAL REQUIREMENTS FOR MATERIAL CERTIFICATIONS

The requirements in this section are in addition to the material and final product

minimum certification requirements and specifications in the pertinent MESC and the

applicable DEPs.

1. Mill test reports shall comply with ASME SA-20 and ISO 10474 or EN 10204.

2. The language used in mill test reports shall be English or, if in another language,

accompanied by an endorsed, stamped and dated English translation of the original

report.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 12

3. Reports for final products (such as welded fittings) shall include certification of the

base material and a copy of the welding procedure specification (WPS) applied.

4. For final products, if the Manufacturer/Supplier of a semi-finished product and the

Manufacturer/Supplier of the base material are not the same, the report shall consist

of two documents covering both stages of the manufacturing process.

5. A copy of the material certificate may be supplied as long as the

Manufacturer/Supplier has a traceable system of the transfer of data from the original

material certificate to the copy.

5. EXAMINATION EQUIPMENT/TEST METHOD

1. Alloy analysers used for PMI shall be capable of producing quantitative measurements

(i.e., percentage by weight) for the alloying elements listed in (APPENDIX C).

2. Alloy analysers shall be one of the following technology types (in order of preference):

a. X-ray Tube Equipment (Handheld Analyser)

b. X-Ray Florescence Equipment (Handheld Analyser)

c. Optical Emission Spectrometers (Arc/Spark)

3. The type of analyser and alloy analyser calibration records and results shall be

documented in the PMI Inspection Report.

4. PMI shall be performed by a trained and competent technician.

a. Qualifications of the PMI machine operator, including make and type of PMI

Machine the Operator was trained and has worked with should be submitted for

review and approval by the Contractor.

5. Examination for determining the elements shall not be carried out with sorting methods

such as chemical spot testing or methods that use eddy current, triboelectric testing,

electromagnetic, or thermoelectric tests.

6. Chemical spot testing techniques for dilution such as using copper sulphate to test

areas where grinding has been performed on weld overlay are acceptable.

6. MATERIAL IDENTIFICATION

6.1 TRACEABILITY

1. Alloy components and carbon steel components per (4.3) shall be traceable to their

source from procurement through final installation as follows:

a. The heat numbers on completed piping spools shall be 100 % verified prior to

release of the spools for painting and/or field installation.

b. The heat numbers shall be copied onto the relevant shop fabrication

isometric/weld map, written on a tag applied to the spool, or hard stamped (when

permitted).

c. Verification of heat numbers and heat number transfer shall be included as a hold

point on the piping Inspection and Test Plan (ITP).

d. The heat number shall be transferred before materials are cut.

e. Verification in the field that the components have been installed per

requirements.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 13

6.2 MARKING

1. All piping bulk materials shall be delivered with the original Manufacturer/Supplier’s

markings and be as follows:

a. Clearly readable.

b. Compliant with the relevant material specification (e.g., ISO, ASTM).

c. Include the Manufacturer/Supplier’s applicable identification symbol, matching the

identification shown on the applicable mill test reports.

d. Be preserved when piping materials are ordered in the blasted and primed

condition (e.g., straight length pipes).

e. Supplemented by markings applied by stock personnel and

Manufacturers/Suppliers (e.g., PO numbers or MESC codes) if needed.

2. All components that require machining shall be traceable through the machining

process by transfer of the heat number to the component.

3. Completed shop fabricated pipe spools shall be fitted with an identification tag

identifying at a minimum the Isometric number and spool number.

6.3 COLOUR CODING

6.3.1 General

1. colour coding of piping bulk materials shall be applied on alloy or special carbon steel

systems per the scope defined in (4) unless marked as specified in 6.4.1.

a. The box or container shall be colour coded once the PMI sampling results verify

the material markings on the studs and nuts.

2. colour coding shall be the responsibility of the group performing the PMI (e.g.,

Manufacturer/Supplier, warehouse receiving).

3. PMI on pre-fabricated piping spools shall be completed prior to blasting and painting.

The re application of colour coding is not necessary after the components have

been painted.

4. Refer to (APPENDIX F) for piping component marking specifications.

5. Piping components in which identification markings or colour coding are maintained

through pipe spool fabrication may be released for painting as long as all components

have been welded on and all relevant NDE, including PMI, is complete.

a. The spool shall then be tracked by the spool tagging number and isometric.

6.3.2 Colour standard

1. The following colour standards may be applied:

a. Pipe Fabrication Institute - PFI ES-22.

b. British Standards Institution BS 381C.

c. A suitable identification system or colour standard as approved by the Principal.

2. colour coding paint shall be selected to last until fabrication is complete and the spools

are ready for blasting and coating.

3. Paints and markers shall be selected such that they will not cause degradation to the

base material (e.g., no zinc-containing paint/marker on stainless steel base material,

no chloride-containing paint/marker on stainless steel base material).

4. Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) documentation and

paint data sheets shall be available for review by the Principal.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 14

6.4 COMPONENT IDENTIFICATION

6.4.1 General

1. Components on which PMI is performed shall be identified with a PMI indicator stating

the material identification codes applied by means of a low-stress steel stamp (stencil)

or paint/marker as prescribed in this DEP, in accordance with (7.2) and (APPENDIX

D).

2. Vibro-etching may be used for thin wall materials or if the configuration of the

component does not permit stamping.

3. The “PMI” letters shall be circled as shown in the examples in (APPENDIX E).

4. Pressure equipment (e.g., vessel, heat exchanger) subject to PMI shall have a PMI

stamp on the nameplate (Reference standard drawing S 10.114).

a. An additional nameplate for the PMI stamp may be welded on or adjacent to the

code nameplate.

b. Heat exchanger nameplate PMI stamping shall identify the tube side and shell

side separately.

c. Pressure vessel and heat exchanger internals, cladding, and cladding welds shall

be marked with paints or markers identifying the PMI that was performed on each

component, provided sufficient documentation is in place for the PMI of all

components.

5. All piping welds subject to PMI shall be PMI stamped on the final weld pass (where

allowed by code) or next to the weld, applied by means of a low-stress tool.

6.4.2 Material Identification Codes

1. Material identification codes shall be at least 6 mm (1/4 in) high.

2. Material identification codes shall be located below the letters “PMI” within the same

circle as shown in the examples in (APPENDIX E).

3. Material identification codes given in (APPENDIX D) shall be in addition to those

required by the applicable material specification (e.g., ASTM).

6.5 REJECTED MATERIAL

1. Rejected material shall be identified by marking or tagging and segregated from

acceptable material.

2. The Manufacturer/Supplier, shop Fabricator, or field Fabricator, as applicable, shall

submit a non-conformance report (NCR) per the project quality procedures.

3. If an item from a representative sample is rejected, the following additional testing

shall be carried out:

a. Examine 100 % of the remaining components of the lot from which the sample

was taken;

b. Examine 100 % of the same component types from the next delivery from the

same Manufacturer/Supplier;

c. Return the level of examination to the originally specified level if examination of

the next lot does not identify any similar non-conformance.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 15

7. PMI INSPECTION REPORT

1. The PMI Inspection Report shall be submitted to the Principal and include the

following for each inspection lot examined:

a. Manufacturer/Fabricator's name.

b. Date(s) of testing.

c. Name of person and company performing the test.

d. Method of examination (laboratory or field analyser).

e. Analyser used for the examination.

f. Material specification of the material to be tested.

g. Material Manufacturer/Supplier, MTR number, heat number and lot number, as

applicable.

h. Inspection lot size and number of pieces or items examined.

i. Results of the test and resolution of non-conformance material.

j. Chemical elements verified by PMI and the percentage of the elements in

accordance with (APPENDIX C).

i. Reports downloaded from the alloy analyser are acceptable.

2. For fabricated items with multiple components and welds, the PMI Inspection Report

shall also include the following:

a. Each component receiving PMI by the Manufacturer/Supplier.

b. Each piece of equipment (with item number) receiving PMI by the shop

Fabricator, including a test location map.

c. Each pipe line (with line number and pipe spec, including the spool or fabrication

drawing) showing the locations of PMI by the shop/field Fabricator or field

Constructor.

d. Existing piping PMI results for field welds of new to existing piping.

3. PMI Inspection Reports shall become part of the permanent record included in the

final data package or equipment file folders.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 16

8. REFERENCES

In this DEP, reference is made to the following publications:

NOTES: 1. Unless specifically designated by date, the latest edition of each publication shall be used, together

with any amendments/supplements/revisions thereto.

2. The DEPs and most referenced external standards are available to Shell staff on the SWW (Shell

Wide Web) at http://sww.shell.com/standards/.

SHELL STANDARDS

DEP feedback form DEP 00.00.05.80-Gen.

Evaluation of pipeline and pressure vessel steels for resistance to DEP 30.10.02.16-Gen.

hydrogen-induced cracking (amendments/supplements to

NACE TM0284)

Wet H2S requirements for downstream process equipment and piping DEP 30.10.02.17-Gen.

Welding of metals (amendments/supplements to API RP 582) DEP 30.10.60.18-Gen.

Welding of metals, based on ISO standards DEP 30.10.60.32-Gen.

Shell HSSE & SP Control Framework, Design Engineering Manual DEM1

(DEM) 1 – Application of Technical Standards

https://eu001-

sp.shell.com/sites/AAAAA8432/CF/Web/Design Engineering Manual 1 DEM1.aspx

STANDARD DRAWINGS

Nameplate with bracket for vessel and heat exchanger equipment S 10.114

AMERICAN STANDARDS

Material verification programme for new and existing alloy piping API RP 578

systems

Process piping ASME B31.3

Standard specification for alloy-steel and stainless steel bolting for ASTM A193

high temperature or high pressure service and other special purpose

applications

Petroleum, petrochemical and natural gas industries – metallic NACE MR0103

materials resistant to sulfide stress cracking in corrosive petroleum

refining environments

Recommended Practice for colour Coding of Piping Materials PFI ES-22

Issued by: Pipe Fabrication Institute

BRITISH STANDARDS

Specification for colours for identification, coding and special purposes BS 381C

EUROPEAN STANDARDS

A Guide to Risk Based Procurement EEMUA 224

Metallic products - types of inspection documents EN 10204

INTERNATIONAL STANDARDS

Steel and steel products - Inspection documents ISO 10474

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 17

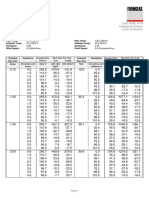

APPENDIX A COMPONENTS SUBJECT TO PMI

Component Full Standard

Piping

Pipe 100 % 10 % (1,11)

Corrosion resistant alloy (CRA) lined or clad pipe 100 % 10 % (1,11)

Fittings 100 % 10 % (1,11)

Valves (7) 100 % 10 % (1,11)

Expansion joints and special items 100 % 10 % (1,11)

Heat exchangers, boilers and fired heaters

Heater tubes 100 % 10 % (1)

Heat exchanger tubes 2 % (2) 1 % (2)

Tubesheets 100 % 10 % (4, 11)

Fittings 100 % 10 % (1, 11)

Solid, jacketed or spiral wound gaskets 100 % 10 % (1)

Expansion joints 100 % 10 % (4)

Non-pressure retaining bundle components: e.g., 10 % (1) 10 % (1, 11)

Baffles, tie-rods, seal strips.

Channels 100 % 10 % (4, 11)

Furnace tube hangers 100 % 10 % (1)

Furnace tube supports 100 % 10 % (1)

Air cooled heat exchanger header plugs and gasket 100 % 10 % (1)

Corrosion resistant alloy (CRA) lined or clad 100 % 10 % (1,11)

components

Pressure retaining components of pressure vessels

Shell 100 % 10 % (4, 11)

Heads 100 % 10 % (4, 11)

Nozzles 100 % 10 % (1, 11)

Fittings 100 % 10 % (1, 11)

Flanges 100 % 10 % (1, 11)

Corrosion resistant alloy (CRA) lined or clad 100 % 10 % (1, 11)

components

Non-pressure retaining components of pressure vessels

Tray components, downcomers, reactor bed 10 % (1) 10 % (1)

internals

Pressure retaining components of machinery

Pump casing 100 % 100 %

Compressor casing 100 % 100 %

Solid, jacketed or spiral wound casing gaskets 100 % 100 %

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 18

Bulk material

ASTM A193 bolts other than B7/B7M (11) 5 % (3, 12) 5 % (3)

Spiral wound gaskets other than 304SS and 316SS 5 % (10) 5 % (10)

Solid metal, metal jacketed & ring-type joint gaskets 100 % 10 % (1)

Welds

Welds (pressure equipment) 100 % (5, 6) 5 % (8, 9,11)

Welds (repairs) 100 % (5, 6) 5 % (8, 9, 11)

Welds (piping) 100 % (5, 6) 5 % (5, 9, 11)

Weld overlay 100 % (6, 8, 9) 5 % (5, 8, 9, 11)

Weld - dissimilar 100 % (6, 13) 100 % (6, 13)

Pressure relieving equipment

Bellows 100 % 100 %

Body 100 % 100 %

Bonnet 100 % 100 %

Rupture disc 100 % 100 %

NOTES:

1. Examine 10 % of all the purchased components. If any given sample of components has fewer

than 10 items, examine a minimum of one item.

2. 1 % representative sample of the total number of tubes from each heat, lot and material

specification of tubes.

3. Examine 5 % of bolts supplied in bulk or two bolts per box, and per heat and lot, whichever is

greater.

a. Bolts to be examined shall be selected randomly by the Principal.

4. One examination per heat of material

5. Examine one spot on every cap pass of every pressure retaining weld or one cap pass per

weld procedure per spool of piping per Table 1.

6. For the buttering welding technique, the extent of PMI to be determined by the Principal.

7. Valve body and bonnet only:

a. Non-standard, high alloy valve trim may be PMId at the discretion of the Principal.

b. PMI testing in the modification shop should be carried out on non-standard, high alloy trim

upgrades such as Alloy 400.

c. Internal bonnets as found on “power seal” type valves are considered internal components

as they typically cannot be accessed by PMI analysers.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 19

8. Take one analysis per weld procedure of the base filler material or overlay finished weld per

shift (e.g., covering a base metal weld or joining the cladding of clad plates), on each major

longitudinal and circumferential weld seam as well as the following:

a. For nozzles and components lined with alloy weld metal overlay, one analysis per nozzle.

b. For sleeve lined nozzles, one analysis for the flange face overlay and one analysis of the

shell tie-in overlay.

c. Alloy Air Cooler Header Boxes: one analysis for each welding procedure used for long

seams, end plates, and nozzles.

d. Machined components: the PMI analysis of the finished machined components.

9. Analyse the base filler metal or final closure weld seams of internally clad or weld overlaid

components at locations determined by the Principal's designated Inspector.

10. Examine 5% of spiral wound gaskets when the windings or ID ring are alloys other than 304,

304L, 304H, 316, 316L or 316H stainless steels.

a. The PMI to be of the area at the ends where there is no filler or, if provided, the inner ring.

11. Equipment and piping fabricated of alloy material (including welds) solely to maintain product

purity (to avoid contamination of the product by corrosion products) is subject to 10% PMI.

a. Equipment and piping fabricated of 304, 304L, 304H or 316, 316L and 316 H solely to

maintain product purity are exempt from PMI unless otherwise specified by the Principal.

12. Examine 100% of B7M bolting for HFA and for sour service (if applicable) for hardness as a

part of the PMI program.

13. Complete PMI on four quadrants of the final closure weld for dissimilar metal welds.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 20

APPENDIX B PMI FOR INSTRUMENTATION COMPONENTS

Instruments No PMI Standard Full

(10 %) (100 %)

Orifice plate 304/304L and Higher alloy (3)

316/316L SS

Thermowell, other type insertion 304/304L and Higher alloy (1, 2, 3)

type instruments and positive 316/316L SS

displacement meters (analyser

probes, FCI meters and vortex

meters

Instrument tubing including 304/304L and Higher alloy (1, 2, 3)

insertion type 316/316L SS

Control valve (3),(4) Cast 316 SS bulk Higher alloy (3) or all

produced CV Custom Cast

Valve trim Standard trim from the High alloy trim upgrades at

Manufacturer valve modification shops

Displacer, magnetic level 304/304L and Higher alloy (1, 2, 3)

gauges and level chamber 316/316L

SS components and

welds

Coriolis meters 304/304L and Higher alloy (1, 2, 3)

316/316L

SS components and

welds

Fabricated meter runs and 304/304L and Higher alloy (1, 2, 3)

fabricated venturies (pressure 316/316L

retaining parts only) SS components and

welds

NOTES:

1. The scope of this includes:

a. Venturis (external portion only), level bridles, Coriolis meter, magnetic level, displacer

and other instruments installed in pressure retaining service upstream of the primary

block valve.

b. Only the accessible welds to be tested in the field.

c. Insertion type instruments of alloys higher than 304/316 austenitic stainless.

2. This scope excludes:

a. Insertion type instruments (such as thermowells, annubars, capacitance probes, FCI

flow meters) made of 304/316 austenitic stainless steels because of the low stress level

and standard stainless construction.

b. ,Items that are not pressure retaining.

c. Items that are not in-line instruments upstream of the primary block valve, such as

pressure transmitters.

3. Higher alloy is 321SS, 347SS, all chrome alloys and high nickel alloy.

4. Valve body and bonnet only:

a. Non-standard, high alloy valve trim may be PMId at the discretion of the Principal.

b. PMI testing in the modification shop should be carried out on non-standard trim

upgrades using high alloy material such as Alloy 400 trim.

c. Internal bonnets as found on “power seal” type valves are considered internal

components as they typically cannot be accessed by PMI analysers.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 21

APPENDIX C ALLOYING ELEMENTS REQUIRED FOR PMI

Chemical element (3)

Alloy

C Cr Ni Mo Nb Ti Cu Co Al Zn Sn Pd V

AISI 8630 X X X

AISI 8620 X X X

AISI 4130 X X

1Cr–1/2Mo X X

1-1/4Cr–1/2Mo X X

2-1/4Cr–1Mo X X

2-1/4Cr–1Mo– X X X

1/4V

5Cr–1/2Mo X X

9Cr –1Mo X X X

9Cr-1Mo modified X X X

13Cr–4Ni X X

13Cr–4Ni /CA6NM X X X X

12Cr/CA15 X X X X X

304 (1) X X

308 (1) X X

309 (1) X X

310 (1) X X

316 (1) X X X

317 (1) X X X

321 (1) X X X

347 (1) X X X

405 X X X

410 (2) X X X X

430 X X

Duplex (1) X X X

Super Duplex (1) X X X

SMO 254 X X X

F6NM X X X

CD4Mcu X X X X

Alloy 20 (1) X X X X X

6 Mo Alloys (1) X X X

Alloy C-276 X X X

Alloy 400 (5) X X X

Alloy 600 X X

Alloy 625 X X X X X

Alloy 625 LCF X X X X X

Alloy 800 X X X

Alloy 825 X X X X

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 22

Chemical element (3)

Alloy

C Cr Ni Mo Nb Ti Cu Co Al Zn Sn Pd V

90/10 CuNi X X

70/30 CuNi X X

Stellites X X X

304L (1, 6) X X X

304H (1) X X X

308L (1, 6) X X X

309L (1, 6) X X X

410S (2) X X X X X

316L (1, 6) X X X X

316H (1) X X X X

317L (1, 6) X X X X

321H (1) X X X X

347H (1) X X X X

Tantalum (3)

Titanium Gr 2 X

Titanium Gr 7 X

Titanium Gr 12 X

Titanium Gr 16 X X

Zirconium (3)

Admiralty brass X X X

Naval brass X X X

Weld Overlayed

Surfaces(to match

specified

chemistry)

CS in HFA Service X X X X

(4)

NOTES: 1. All welds in this metallurgy to have the ferrite controlled to the value specified in the

associated welding DEP (DEP 30.10.60.18-Gen. or DEP 30.10.60.32-Gen.).

a. The sample percentage for ferrite testing to match the same level as the base

material unless a specific sample size / testing rate is given in the welding DEP.

2. 0.5 % to 0.75 % max Ni in base material and <1.1 % Ni for weld deposits. 0.1 % to

0.3 % Al.0.2 % to 0.5 % Ti.

3. Check alloying elements meet the ASTM specification.

4. Carbon steel in HF acid service is limited to the following criteria: Cu + Ni < 0.15 wt%

(C> 0.18 wt%).

a. Where the minimum required carbon is not met, chromium is included in the

formula as: Cu + Ni + Cr < 0.15 wt%.

5. Alloy 400 weld consumables to contain Ti < 2.2 %wt. and Fe < 5 %wt. in Hydrofluoric

acid service.

6. Examination results for the welds to meet the same composition limits as the

corresponding base plate, and clad materials except that carbon maximum of

0.045 % is acceptable in a deposit joining L grade austenitic stainless steel cladding.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 23

APPENDIX D MATERIAL IDENTIFICATION CODES

Alloy UNS number Material Alloy UNS number Material

Identification Code Identification Code

1¼ Cr ½ Mo K11597 1 CR 430 S43000 430

2¼ Cr 1 Mo K21590 2 CR Duplex S31803 and 2205

S32205

2¼ Cr 1 Mo K31835 2CR V Super Duplex S32750 and 2507

¼V S32760

5 Cr ½ Mo K41545 5 CR Alloy 20 N08020 20

9 Cr 1 Mo S50400 9 CR 6 Mo Alloys N08367 and 6 Mo

N08925

13 Cr-4Ni, or J91540 CA6NM Alloy B2 N10665 B2

CA6NM

12 Cr, or J91150 CA 15 Alloy C-276 N10276 276

CA15

304 S30400 304 Alloy 600 N06600 600

304L S30403 304L Alloy 625 N06625 625

304H S30409 304H Alloy 625LCF N06626 626

308 S30408 308 Alloy 800 N08800 800

308L S30883 308L Alloy 825 N08825 825

309 S30900 309 90/10 CuNi C70600 90/10

309L S30983 309L 70/30 Cu/Ni C71500 70/30

310 S31000 310 Alloy 400 N04400 400

316 S31600 316 Nickel 200 N02200 200

316L S31603 316L Titanium Gr 2 R50400 T-2

316H S31609 316H Titanium Gr 7 R52400 T-7

317 S31700 317 Titanium Gr 12 R53400 T-12

317L S31703 317L Titanium Gr 16 R52402 T-16

321 S32100 321 Zirconium 702 R60702 Z-702

321H S32109 321H Zirconium 705 R60705 Z-705

347 S34700 347 Tantalum R05210 R05210

347H S34709 347H Tantalum 40 % R05240 R05240

Nb

405 S40500 405 Admiralty C44x00 C44x00

Brass x = 3,4 or 5 x = 3,4 or 5

410 S41000 410 Naval Brass C46x00 C46x00

x = 5,6 or 7 x = 5,6 or 7

410S S41008 410S

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 24

APPENDIX E LOCATION OF PMI IDENTIFICATION MARKS FOR PIPING

(EXAMPLES)

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

ECCN EAR99 DEP 31.10.00.10-Gen.

February 2017

Page 25

APPENDIX F PIPING COMPONENT MARKING SPECIFICATIONS

Component Marking

(1),(2)

Pipe Each length of pipe shall be painted over the entire length with a 12 mm (0.5 in)

to a 40 mm (1.6 in) wide stripe, depending on the pipe size.

Fittings (1),(2) a) Each socket weld fitting, swage or pipe nipple shall be dabbed with a spot

of paint 12 mm (0.5 in) to 25 mm (1 in) in diameter.

b) The entire length of each butt weld fitting shall be painted on the outside

surface with a 12 mm (0.5 in) to 40 mm (1.6 in) wide stripe, depending on

size.

Flanges (1),(2) a) The outer peripheral edge of each flange shall be painted with a spot of

paint on the outer surface.

Plate (1),(2) A stripe shall be painted across from corner to corner.

Valves (1),(2) a) Each welded or flangeless (wafer type) valve shall be dabbed with a spot of

paint 12 mm (0.5 in) to 25 mm (1 in) in diameter.

b) Each flanged valve shall be dabbed with a spot of paint 12 mm (0.5 in) to

25 mm (1 in) in diameter on the top side of one flange.

c) For flanges thicker than 25 mm (1 in), the width of the band may be limited

to 25 mm (1 in).

Bolts (1),(2) Each stud bolt shall be dabbed with a spot of paint on each end.

Notes: 1. Identifying paint is not applied to the following:

a. inside surfaces of pipe, flanges or fittings;

d. threads;

e. weld bevels;

f. symbols or markings which would obliterate identification;

g. gasket seating surface.

2. Apply colour codes to specialty carbon steels.

This document has been supplied under license by Shell to:

Robt. Stone LLC venu@robtstone.ae 03/09/2019 13:17:16

You might also like

- Coating Requirements For Bolts and Nuts (Amendments/Supplements To Astm B 841)Document12 pagesCoating Requirements For Bolts and Nuts (Amendments/Supplements To Astm B 841)behzad mohammadi100% (1)

- MESC - SPE - 85-203 February 2018 PDFDocument9 pagesMESC - SPE - 85-203 February 2018 PDFNIKESHNo ratings yet

- Standard Drawings IndexDocument34 pagesStandard Drawings IndexWael ChouchaniNo ratings yet

- Spec - 2017-02 - A00 - METALLIC MATERIALS - SELECTED STANDARDSDocument101 pagesSpec - 2017-02 - A00 - METALLIC MATERIALS - SELECTED STANDARDSAL Rajhi Zakaria100% (2)

- Machining Rule of ThumbDocument2 pagesMachining Rule of ThumbKamlesh DalavadiNo ratings yet

- Flange Insulation Sets: Technical SpecificationDocument6 pagesFlange Insulation Sets: Technical SpecificationNor Azlan AwangNo ratings yet

- 76 - 200Document11 pages76 - 200rajaNo ratings yet

- Mesc Spe 74 014 2016 PDFDocument15 pagesMesc Spe 74 014 2016 PDFSalahuddin FarooquiNo ratings yet

- Tubular Heat ExchangerDocument4 pagesTubular Heat Exchangerprashant_dc_inNo ratings yet

- 571 Study Guide - 1000+ QADocument112 pages571 Study Guide - 1000+ QABilal Ghazanfar100% (15)

- Shell Dep 2Document16 pagesShell Dep 2Vivek JoshiNo ratings yet

- Spec 2021-02 A00Document47 pagesSpec 2021-02 A00Anoop GokhaleNo ratings yet

- DEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesDocument30 pagesDEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesMoin AltafNo ratings yet

- 76 204 16Document7 pages76 204 16finiteinjusticeNo ratings yet

- MESC SPE 74-009 - 2010 - Stainless Steel Pipe To Astm A358Document8 pagesMESC SPE 74-009 - 2010 - Stainless Steel Pipe To Astm A358sathi11189No ratings yet

- General-Purpose Steam Turbines (Amendments/Supplements To Api 611)Document27 pagesGeneral-Purpose Steam Turbines (Amendments/Supplements To Api 611)BiswasNo ratings yet

- Spec SCAPSA Metallic Material Selected StdsDocument107 pagesSpec SCAPSA Metallic Material Selected StdsSwath M MuraliNo ratings yet

- 76 202Document8 pages76 202wawanNo ratings yet

- MESC SPE 85-103 Feb 2014 PDFDocument8 pagesMESC SPE 85-103 Feb 2014 PDFaleeimeran100% (1)

- Spe 76-202 Sep 2012Document8 pagesSpe 76-202 Sep 2012akashdruva892100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PeraneeshjokayNo ratings yet

- 76-040 - 2012 Orifice Meter RunsDocument7 pages76-040 - 2012 Orifice Meter RunspradeepNo ratings yet

- Gate, Globe and Check Valves (Amendments/Supplements To Iso 15761)Document13 pagesGate, Globe and Check Valves (Amendments/Supplements To Iso 15761)윤규섭100% (1)

- 77-103 - 2012 Globe ValvesDocument13 pages77-103 - 2012 Globe ValvespradeepNo ratings yet

- M-501 Rev 5 Surface Prep & CoatingDocument24 pagesM-501 Rev 5 Surface Prep & Coatingmareepierre003No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- API Standard 660: Shell-and-Tube Heat ExchangersDocument3 pagesAPI Standard 660: Shell-and-Tube Heat ExchangersJessy Prior0% (2)

- 74-002 Carbon Steel Pipe To Astm A106 2021 MESC 14DDocument9 pages74-002 Carbon Steel Pipe To Astm A106 2021 MESC 14Dkuttub28No ratings yet

- Spe 76-201 Sep 2012Document9 pagesSpe 76-201 Sep 2012akashdruva892No ratings yet

- Mesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Document17 pagesMesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Dwayne YiiNo ratings yet

- Dep 31.38.01.13-Compilation of Bill of Material For Piping IsometricsDocument12 pagesDep 31.38.01.13-Compilation of Bill of Material For Piping Isometricssudeep9666No ratings yet

- Spe 76-031Document9 pagesSpe 76-031manuneedhi0% (1)

- Materials SelectionDocument1 pageMaterials SelectionAnonymous P9TMWcGNo ratings yet

- 76 - 033Document6 pages76 - 033rajaNo ratings yet

- Uha 32-2Document1 pageUha 32-2Lipika GayenNo ratings yet

- MESC SPE 77-211 Nov 2012 PDFDocument6 pagesMESC SPE 77-211 Nov 2012 PDFaleeimeranNo ratings yet

- Ut in Lieu of RT For Code Construction of Pressure EquipmentDocument16 pagesUt in Lieu of RT For Code Construction of Pressure EquipmentbmkaleNo ratings yet

- Petronas Technical Standards: Pts Publications and Standard SpecificationsDocument38 pagesPetronas Technical Standards: Pts Publications and Standard SpecificationsadamNo ratings yet

- Hoisting Facilities and Weather Protection For Rotating EquipmentDocument12 pagesHoisting Facilities and Weather Protection For Rotating Equipmentsudeep9666No ratings yet

- Mesc Spec 76/222Document9 pagesMesc Spec 76/222ManoNo ratings yet

- SP-1176 V4.0Document45 pagesSP-1176 V4.0Ghulam HusainNo ratings yet

- Cellular Glass - Thickness CalculationDocument15 pagesCellular Glass - Thickness CalculationPrabha KaranNo ratings yet

- Requisitions IndexDocument13 pagesRequisitions IndexKarnan ThirugnanamNo ratings yet

- DEP 39011012 - Inf - 2018-02 - A01Document67 pagesDEP 39011012 - Inf - 2018-02 - A01g_325899365No ratings yet

- Spe 76-101 Sep 2012Document6 pagesSpe 76-101 Sep 2012akashdruva892No ratings yet

- Mesc Spe 76 030 2015Document6 pagesMesc Spe 76 030 2015Salahuddin FarooquiNo ratings yet

- Tender Document - GAIL - MIJ PDFDocument17 pagesTender Document - GAIL - MIJ PDFVeer GangjiNo ratings yet

- Carbon Steel Forgings (Amendments/Supplements To Astm A 105)Document7 pagesCarbon Steel Forgings (Amendments/Supplements To Astm A 105)manuneedhiNo ratings yet

- HIC Test ChecklistDocument3 pagesHIC Test ChecklistVicky Kumar100% (2)

- 175 023400Document2 pages175 023400Abu Anas M.SalaheldinNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Radiographic Examination Procedure B-QAC-PRO-210-39158Document24 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Radiographic Examination Procedure B-QAC-PRO-210-39158ZaidiNo ratings yet

- MESC SPE 74-019, June 2007 - Nickel Alloy Pipe To ASTM B423Document7 pagesMESC SPE 74-019, June 2007 - Nickel Alloy Pipe To ASTM B423sathi11189100% (1)

- GIS 46-010-New Pressure VesselsDocument87 pagesGIS 46-010-New Pressure VesselsPippo Pippo100% (1)

- Material and Equipment Standard For Large Welded Low Pressure Storage Tanks M-Me-110Document17 pagesMaterial and Equipment Standard For Large Welded Low Pressure Storage Tanks M-Me-110Javeed A. KhanNo ratings yet

- Astm B423Document4 pagesAstm B423pritam sarkarNo ratings yet

- Spe 81 - 002 - 2016Document6 pagesSpe 81 - 002 - 2016Dharmendra Jadeja100% (2)

- Piping - Spec - 요약본 Rev1Document3 pagesPiping - Spec - 요약본 Rev1vangie3339515No ratings yet

- 32.29.20.10-Gen Safeguarding and Instrumented Protective Functions For Rotating EquipmentDocument42 pages32.29.20.10-Gen Safeguarding and Instrumented Protective Functions For Rotating EquipmentPrajeeth Ganesh MosuriNo ratings yet

- Dep 30.10.02.31 2017 Metallic Materials - Prevention of Brittle Fracture in NewDocument18 pagesDep 30.10.02.31 2017 Metallic Materials - Prevention of Brittle Fracture in NewRubén Crespo MartínezNo ratings yet

- Spec 2017-02 A01Document50 pagesSpec 2017-02 A01dnatarajan100% (1)

- Spec 2017-02 A01Document27 pagesSpec 2017-02 A01dnatarajanNo ratings yet

- Spec - 2017-02 - A00 Plate and Frame Heat EchangersDocument20 pagesSpec - 2017-02 - A00 Plate and Frame Heat EchangersabdelhalimNo ratings yet

- Ship DesignDocument247 pagesShip DesignArun Gupta0% (1)

- S2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationDocument7 pagesS2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationvivekpecNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument89 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Specification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Document2 pagesSpecification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Rahul KhoslaNo ratings yet

- Causes of Cracks:: Weld CrackDocument5 pagesCauses of Cracks:: Weld CrackJay R ChivaNo ratings yet

- Aisi 8640Document2 pagesAisi 8640Engineering ProductionNo ratings yet

- ECCS Recommendations For Fatigue Design of Steel StructuresDocument47 pagesECCS Recommendations For Fatigue Design of Steel StructuresCpm102No ratings yet

- Qcs 2010 Part 8 03 Pipes and Fittings Materials PDFDocument23 pagesQcs 2010 Part 8 03 Pipes and Fittings Materials PDFNasih TrNo ratings yet

- st44 2 PDFDocument1 pagest44 2 PDFAraby Gamal GamalNo ratings yet

- General Brochure V2 2023 For WebDocument12 pagesGeneral Brochure V2 2023 For WebMohamad LutfiNo ratings yet

- Journal of Constructional Steel Research: Inas Mahmood Ahmed, Konstantinos Daniel TsavdaridisDocument15 pagesJournal of Constructional Steel Research: Inas Mahmood Ahmed, Konstantinos Daniel TsavdaridisPrapa KaranNo ratings yet

- Effect of Austenitizing Temperature and Cooling Rate On The Structure and Properties of A Ultrahigh Strength Low Alloy SteelDocument10 pagesEffect of Austenitizing Temperature and Cooling Rate On The Structure and Properties of A Ultrahigh Strength Low Alloy SteelMilena StajicNo ratings yet

- Gme Sample Question PaperDocument2 pagesGme Sample Question PaperAbhishek PuriaNo ratings yet

- Development of High Strength Construction RebarsDocument13 pagesDevelopment of High Strength Construction Rebarsosman recai100% (3)

- Astm A6 A6m-08Document62 pagesAstm A6 A6m-08Vũ Nhân HòaNo ratings yet

- 3500 Series Replacement Parts For ASME/ANSI B73.1M PumpsDocument4 pages3500 Series Replacement Parts For ASME/ANSI B73.1M PumpsmetropumpsNo ratings yet

- Visual Welding Inspector Course TopicsDocument40 pagesVisual Welding Inspector Course TopicsJohn Dare100% (2)

- Single Skin Profile Sheets Manufacturers&Suppliers in UAE - A To Z STEELDocument9 pagesSingle Skin Profile Sheets Manufacturers&Suppliers in UAE - A To Z STEELamin alzuraikiNo ratings yet

- Metals Manufacturing: EDEM Application AreasDocument13 pagesMetals Manufacturing: EDEM Application AreasRuben PurcaNo ratings yet

- History of Iron and SteelDocument27 pagesHistory of Iron and SteelHens Christian Fuentes100% (1)

- The Use of Heheat Straightening To Repair Damaged Steel StructuresDocument38 pagesThe Use of Heheat Straightening To Repair Damaged Steel Structuresjeanpaul CAYTANNo ratings yet

- Spirol Pins Bissel Pins Tension Pins SLTP - UsDocument8 pagesSpirol Pins Bissel Pins Tension Pins SLTP - Usstuartj01No ratings yet

- KP Pr056m1 enDocument32 pagesKP Pr056m1 enIgorsNo ratings yet

- SigmathermDocument8 pagesSigmathermHaresh BhavnaniNo ratings yet

- 21 Chemical Elements and Effects On Steel Mechanical PropertiesDocument12 pages21 Chemical Elements and Effects On Steel Mechanical Propertieshaidv254100% (1)

- Metal Stairs and LaddersDocument7 pagesMetal Stairs and Laddersrizkboss8312No ratings yet

- Chaitanya IntroductionDocument7 pagesChaitanya Introductionanon_647217551No ratings yet

- Type of Structural SteelDocument18 pagesType of Structural SteelaltavanoarNo ratings yet