Professional Documents

Culture Documents

ESCALATOR-Bk Gulf Only

Uploaded by

SHARAFUDHEEN TKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESCALATOR-Bk Gulf Only

Uploaded by

SHARAFUDHEEN TKCopyright:

Available Formats

م.م.

الــفـــريــــق الســتــشــــارات الســـالمــــة ذ

TEAM SAFETY CONSULTANTS L.L.C

004-IB

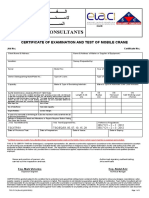

CERTIFICATE OF EXAMINATION AND TEST OF ESCALATOR

Job No.

Type of Inspection

Certificate No.

Client Name

Address

Equipment ID/Manufacturing or

Environment

Serial No.

Manufacturer Degree of Inclination

Year Manufactured/Installed Step Dimension

Main Driving Mechanism &

Rise/Height

Handrail Driving Mechanism

Direction of Travel (Floor

Theoretical Capacity

Served)

Rated Speed Attending Maintenance Co.

Date Of Previous Inspection & Test Date Of Inspection & Test Date of Issue Next Inspection & Test Due On Or Before

TSC Test Method No. TSC Test Equipment No. Standard Reference & Regulation

TSC/ITP/07 TSC/EQ/05, 07, 13, 16, 20, 21, 27 BS EN 115-1:2017

*Certificate becomes invalid, if any alteration/major repair/modernization made on the Escalator in which case it must be re-examined and re-tested.

THIS IS TO CERTIFY THAT the Undersigned, a competent representative, did, attend to examine this equipment in accordance to the aforementioned standard to

ascertain its safe working load and that the examination indicated that the said equipment has no indigenous injury or sighted deformation and the safe working load of

the said equipment as either identified or test proof loaded is shown. The equipment is satisfactory for its intended use within the limits specified and at the time of re-

inspection was found to be satisfactory for further use, provided there is continuous maintenance applied, implementation of our remarks & recommendations and

qualified operators employed.

Name and position of person who Authorized signatory authenticating

carried out the inspection and test: :this certificate

Eng. Umar Nazurudeen Eng. Kunhi Krishnan

Inspection Engineer Dy. Senior Inspector

CERTIFICATE is granted subject to the condition that is understood and agreed that nothing herein contained shall be deemed to relieve any designer,

manufacturer, seller, supplier, repairer or operator of any warranty, express or implied. This inspection is not intended as guarantee against failure or

malfunction. Team Safety Consultants will not be held responsible for any damage to the equipments or parts after examination or accident due to improper

use. No liability for use, operation and for any hidden defects or information related to the equipment and inspection done is assumed by the inspector or Team

Safety Consultants. Any person not a party to the contract pursuant to which this document is delivered may not assert claims against Team Safety Consultants

for any liability arising out of errors or omissions which may be contained in said document and in connection with any activities for which it may provide. This

certificate shall not be reproduced except in the full without written approval of the Team Safety Consultants and the receiving client.

TEAM SAFETY CONSULTANTS L.L.C, TRADE LICENSE NO. 500714, AL-GARHOUD, P. O. BOX: 112349, DUBAI -UAE,

TEL: 04-2828868,FAX: 04-2865265 EMAIL: info@tsc-uae.ae, WEBSITE: https://www.tsc-uae.ae/

TSC-F-17F (Rev.27) (28/01/2023) Page 1 of 3

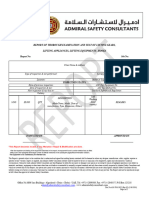

Continuation of Job No.: Certificate No.:

ITEMS CHECKED

A- Satisfactory B- See remarks/recommendation C- Not applicable STATUS A- Satisfactory B- See remarks/recommendation C- Not applicable STATUS

Machinery Space (Driving and Return Station) A B C External A B C

Last inspection report/certificate Inclination

Maintenance records Adequate lighting at landings

Manufacturer instruction / operational manual Landing plates condition

Security of inspection covers and floor plates Warning/advisory signs and notices are in placed

Access to machinery spaces (driving and return) is safe and easy Balustrades panel condition

Machinery spaces light intensity sufficient Skirt panel condition

Provision for ventilation of machinery space Deck panel cover fitted properly and secured

Warning/advisory signs and notices are in placed Step/pallets condition

Stop switch function correctly Handrails condition

Main switch function and security condition Comb plate condition

Lighting and socket outlet power supplies arrangement correct. Skirt deflector devices properly installed and in good condition

Protection on openings in machinery provided Step demarcation provided and in good order

Protection guard for moving and rotating parts fitted and effective Dimension and operational clearance in order

Control cabinet components are labeled & protected Anti-climbing devices on outer decking in good condition

Lubrication or lubrication system adequate Protection guards adjacent to handrails/building structure

Cleanliness Barriers to prevent access of carts/luggage fitted and secure

Emergency stop buttons function

Drive Unit and Braking System A B C Alarm function

Driving machine condition Key-switch function and condition

Operational brake in working order

Drive brake condition

Auxiliary brake operation, if any, in working order Electrical Safety Devices A B C

Over-speed protection device Safety contact on access doors/traps/covers function

Protection for motor in condition and in working order Landing plate detection device in working order

Main drive chain condition Skirt Obstruction device

Hand winding device easy and safe to operate Step sagging device

Operating instruction (hand winding) available Step chain safety device

Missing/low step detector device

Electrical Installations and Appliances A B C Handrail entry device

Insulation resistance condition Broken handrail safety device

Earthing continuity Comb plate obstruction safety device

Electrical wiring method of installation and protection Drive chain safety device

Portable inspection control provided and in working order Phase protection device

Flexible cable of portable inspection control in good condition

Dynamic Test A B C

Internal A B C Hand rail speed: Left: m/min Right: m/min

Step chain condition Step Speed: m/min

Chain wheel axles condition Stopping Distance measured @ unloaded condition: mm

Chain wheel tires/roller condition Dubai Municipality Requirement Circular No.1 (2017)

Up thrust track condition Protection guard provided, adequate measurement and gap

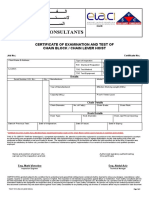

Continuation of Job No.: Certificate No.:

TSC-F-17F (Rev.27) (28/01/2023) Page 2 of 3

FINDINGS SECTION

Findings Target Date:

A. The following items found that needs to be rectified and/or arranged:

1.

B. At the time of installation there was no requirement with reference to a specific standard. For improving the safety of the existing

escalator, referring to the current standard BS EN 115, it is strongly recommended to consider adopting safety measures at least on

the following items below:

1.

Supplementary:

a. Periodic maintenance required as per the manufacturer instruction.

b. If any abnormal condition / sound observed from the equipment during the time of operation, the concerned person should be informed to the maintenance provider, client, building

maintenance and safety personnel.

Note:

a.Certificate becomes invalid in case of any major repair, modification and/or alteration on the design of the equipment; in which case it must be re-inspected and re-tested.

b.It is imperative that action be taken on the items mentioned in the subsequent pages and provides continuous preventive maintenance according to maker’s instruction.

c.In accordance with EIAC-RQ-IB-001, conditional based validity certificate is issued, Certificate become invalid in case of not rectify the finding within target date, in which case it must be

inspection again.

d.Thisis the client responsibility shall be respond / inform to TSC for the Re-inspection or submit the evidence within the target date given in the inspection certificate.

e.Thisis the client responsibility to adhere the supplementary points at all the time but not limited.

TSC-F-17F (Rev.27) (28/01/2023) Page 3 of 3

You might also like

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Elevator (MR) Certificate Standard FormatDocument2 pagesElevator (MR) Certificate Standard FormatAkhil100% (1)

- EscalatorDocument2 pagesEscalatorSHARAFUDHEEN TKNo ratings yet

- ELEVATOR ConstructionDocument2 pagesELEVATOR ConstructionSHARAFUDHEEN TKNo ratings yet

- ElevatorDocument2 pagesElevatorSHARAFUDHEEN TKNo ratings yet

- Earth Moving Equipment Safety TestDocument2 pagesEarth Moving Equipment Safety TestSHARAFUDHEEN TKNo ratings yet

- CERTIFICATE FOR EXAMINATION OF BACKHOE LOADERDocument2 pagesCERTIFICATE FOR EXAMINATION OF BACKHOE LOADERotega Cyril0% (1)

- SAG - Automotive Servicing NC IDocument3 pagesSAG - Automotive Servicing NC IOne And All Tech SchoolNo ratings yet

- ELECTRIC VEHICLE INSPECTION CHECKLISTDocument2 pagesELECTRIC VEHICLE INSPECTION CHECKLISTyonatan solomon100% (1)

- Certificate Escalator Final 1-06-2019Document2 pagesCertificate Escalator Final 1-06-2019AkhilNo ratings yet

- RollerDocument2 pagesRollerengr.haseebbalochNo ratings yet

- Tooo': oOO OO.Document28 pagesTooo': oOO OO.ediasianagriNo ratings yet

- Ocef Relay TestingDocument6 pagesOcef Relay TestingPandrayar MaruthuNo ratings yet

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenNo ratings yet

- Machine Guarding ChecklistDocument4 pagesMachine Guarding Checklistadam rizkiNo ratings yet

- Engine Generator TestDocument2 pagesEngine Generator TestSHARAFUDHEEN TKNo ratings yet

- Vehicle LiftDocument2 pagesVehicle LiftSHARAFUDHEEN TKNo ratings yet

- Certificate of Examination and Test of Engine Generator: Certificate No.:DG/C1 Job No.: ASC-18N-0262Document2 pagesCertificate of Examination and Test of Engine Generator: Certificate No.:DG/C1 Job No.: ASC-18N-0262RavijNo ratings yet

- Vehicle LiftDocument2 pagesVehicle LiftSHARAFUDHEEN TKNo ratings yet

- Concrete Truck Pre-Acceptance ChecklistDocument3 pagesConcrete Truck Pre-Acceptance ChecklistMohamed El NasharNo ratings yet

- Concrete PumpsDocument2 pagesConcrete PumpsSHARAFUDHEEN TKNo ratings yet

- Report Escalator Final 12-05-2019Document3 pagesReport Escalator Final 12-05-2019AkhilNo ratings yet

- Method of Statement For Transformer Diff Protection: Owner/Client Consultant ContractorDocument6 pagesMethod of Statement For Transformer Diff Protection: Owner/Client Consultant ContractorPandrayar Maruthu100% (1)

- Mobile CraneDocument2 pagesMobile CraneSHARAFUDHEEN TKNo ratings yet

- WHEEL LOADER (SHOWEL) FRONT2Document2 pagesWHEEL LOADER (SHOWEL) FRONT2engr.haseebbalochNo ratings yet

- 1a. Crawler CraneDocument2 pages1a. Crawler CraneSHARAFUDHEEN TKNo ratings yet

- Truck Crane Inspection FormDocument3 pagesTruck Crane Inspection FormAdhy Darmawan100% (1)

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Hooks-Report UpdatedDocument2 pagesHooks-Report UpdatedAkhilNo ratings yet

- Forklift Safety CertificateDocument2 pagesForklift Safety CertificateSHARAFUDHEEN TKNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- 63 Leak TesterDocument6 pages63 Leak Testersystacare remediesNo ratings yet

- Report - 2024-02-16T115011.731Document2 pagesReport - 2024-02-16T115011.731waseem hallakNo ratings yet

- Standard Commissioning Procedure For Building Exhaust Fans: General NotesDocument9 pagesStandard Commissioning Procedure For Building Exhaust Fans: General NotesAbdul Mohid SheikhNo ratings yet

- 3.hot Water GeneratorDocument3 pages3.hot Water GeneratorSHARAFUDHEEN TKNo ratings yet

- 41-1220 S & Y Crane ServicesDocument1 page41-1220 S & Y Crane Servicessamisaeed300No ratings yet

- Boom Placer ChecklistDocument3 pagesBoom Placer ChecklistAlves Edattukaran100% (3)

- A World Class Lifting Equipment CompanyDocument29 pagesA World Class Lifting Equipment CompanyLuthfi ArdiansyahNo ratings yet

- Method of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorDocument9 pagesMethod of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorPandrayar MaruthuNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- EscalatorDocument9 pagesEscalatorHarris ShehzadNo ratings yet

- JH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistStansilous Tatenda NyagomoNo ratings yet

- Lift Elevator Test QCDD FormDocument2 pagesLift Elevator Test QCDD FormSamir AminNo ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- Circuit Breaker TestingDocument6 pagesCircuit Breaker TestingPandrayar MaruthuNo ratings yet

- Chain Block & Lever HoistDocument8 pagesChain Block & Lever HoistHarris ShehzadNo ratings yet

- Report - 2024-02-16T114954.680Document2 pagesReport - 2024-02-16T114954.680waseem hallakNo ratings yet

- 3.roller Compactor ChecklistDocument2 pages3.roller Compactor ChecklistSuresh Praba PNo ratings yet

- Work Instruction VCBDocument3 pagesWork Instruction VCBTAHIR HUSAINNo ratings yet

- water tanker Front1Document2 pageswater tanker Front1engr.haseebbalochNo ratings yet

- Window CradleDocument10 pagesWindow CradleHarris ShehzadNo ratings yet

- Daily_Pre_Use_Checklist_Mobile_CraneDocument3 pagesDaily_Pre_Use_Checklist_Mobile_Craneahmad muzakkir mohamadNo ratings yet

- Attachment - I: Pre Start-Up Safety Review Checklist - 1Document15 pagesAttachment - I: Pre Start-Up Safety Review Checklist - 1HamzaNoumanNo ratings yet

- HelmetDocument2 pagesHelmetSHARAFUDHEEN TKNo ratings yet

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- Elevator ChecklistDocument2 pagesElevator ChecklistHarris ShehzadNo ratings yet

- OQ Analytical BalanceDocument8 pagesOQ Analytical BalanceMohsin AliNo ratings yet

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistDocument2 pagesConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattahNo ratings yet

- Chain BlockDocument2 pagesChain BlockSHARAFUDHEEN TKNo ratings yet

- Operation and Qualification of Stability Chamber IVDocument21 pagesOperation and Qualification of Stability Chamber IVsystacare remedies100% (1)

- Earth PitDocument2 pagesEarth PitSHARAFUDHEEN TKNo ratings yet

- Belay DevicesDocument2 pagesBelay DevicesSHARAFUDHEEN TKNo ratings yet

- Chain BlockDocument2 pagesChain BlockSHARAFUDHEEN TKNo ratings yet

- Bumper CarDocument2 pagesBumper CarSHARAFUDHEEN TKNo ratings yet

- EQUIPMENT or MACHINERYDocument1 pageEQUIPMENT or MACHINERYSHARAFUDHEEN TKNo ratings yet

- LadderDocument2 pagesLadderSHARAFUDHEEN TKNo ratings yet

- HelmetDocument2 pagesHelmetSHARAFUDHEEN TKNo ratings yet

- LPG DetectorDocument2 pagesLPG DetectorSHARAFUDHEEN TKNo ratings yet

- Lifting GearDocument2 pagesLifting GearSHARAFUDHEEN TKNo ratings yet

- Thermic Fluid Heater InspectionDocument2 pagesThermic Fluid Heater InspectionSHARAFUDHEEN TKNo ratings yet

- 10.engine GeneratorDocument2 pages10.engine GeneratorSHARAFUDHEEN TKNo ratings yet

- Steam Dryer Inspection ReportDocument1 pageSteam Dryer Inspection ReportSHARAFUDHEEN TKNo ratings yet

- Pat TestDocument1 pagePat TestSHARAFUDHEEN TKNo ratings yet

- 3.hot Water GeneratorDocument2 pages3.hot Water GeneratorSHARAFUDHEEN TKNo ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- Expansion TankDocument2 pagesExpansion TankSHARAFUDHEEN TKNo ratings yet

- Expansion TankDocument2 pagesExpansion TankSHARAFUDHEEN TKNo ratings yet

- Concrete PumpsDocument2 pagesConcrete PumpsSHARAFUDHEEN TKNo ratings yet

- Thermic Fluid Heater InspectionDocument2 pagesThermic Fluid Heater InspectionSHARAFUDHEEN TKNo ratings yet

- Steam DryerDocument1 pageSteam DryerSHARAFUDHEEN TKNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Engine Generator TestDocument2 pagesEngine Generator TestSHARAFUDHEEN TKNo ratings yet

- 3.hot Water GeneratorDocument3 pages3.hot Water GeneratorSHARAFUDHEEN TKNo ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- Pat TestDocument2 pagesPat TestSHARAFUDHEEN TKNo ratings yet

- Lifting GearDocument2 pagesLifting GearSHARAFUDHEEN TKNo ratings yet

- Pressure VesselDocument2 pagesPressure VesselSHARAFUDHEEN TKNo ratings yet

- Vehicle LiftDocument2 pagesVehicle LiftSHARAFUDHEEN TKNo ratings yet

- DS2 Series 380V Servo Drive: Fast Reference ManualDocument43 pagesDS2 Series 380V Servo Drive: Fast Reference Manualspectra-tw100% (1)

- Dự Án Lọc Dầu Nghi SơnDocument418 pagesDự Án Lọc Dầu Nghi Sơneagleonsky100% (1)

- Omni Antenna HG2408U-NF - 2DDocument1 pageOmni Antenna HG2408U-NF - 2DedgarNo ratings yet

- Flexible Electronic Skin: Akhil Raj G A GuideDocument27 pagesFlexible Electronic Skin: Akhil Raj G A GuideSwaroop NNo ratings yet

- Debugging Solaris Using OBPDocument59 pagesDebugging Solaris Using OBPzeekndtroyNo ratings yet

- 300MW Coal Power Plant in Davao Inaugurated PDFDocument5 pages300MW Coal Power Plant in Davao Inaugurated PDFAlan P. MangalimanNo ratings yet

- Automatic Payment Program Run F110 - SAP TutorialDocument20 pagesAutomatic Payment Program Run F110 - SAP TutorialVenkateswarlu vNo ratings yet

- RRB Alp Tech. CBT 2 Master Question Paper Electrician Trade Date 22 1 2019 Shift 1Document58 pagesRRB Alp Tech. CBT 2 Master Question Paper Electrician Trade Date 22 1 2019 Shift 1arpitrockNo ratings yet

- ECA Task Force CCS GuidelineDocument54 pagesECA Task Force CCS Guidelineto van trung100% (3)

- 22LS350S, 350T, 359S, 359T, 3500, 3510, 3590Document52 pages22LS350S, 350T, 359S, 359T, 3500, 3510, 3590Kiran VeesamNo ratings yet

- Service Manual: Compact Disc ReceiverDocument44 pagesService Manual: Compact Disc ReceiverJorge Fernando de TivantaNo ratings yet

- Goz - Study of The Numerical Instabilities in Lagrangian Tracking of Bubbles and Particles in Two Phase FlowDocument7 pagesGoz - Study of The Numerical Instabilities in Lagrangian Tracking of Bubbles and Particles in Two Phase FlowguilhermehsssNo ratings yet

- Chap 03Document54 pagesChap 03ServicefuchsNo ratings yet

- STAMPEX Soap PressDocument6 pagesSTAMPEX Soap PressL'ambassadeur de lamourNo ratings yet

- Paper - Update On Subsea LNG Pipeline TechnologyDocument11 pagesPaper - Update On Subsea LNG Pipeline TechnologyfralgiugiaNo ratings yet

- Brittle Coating and Strain GaugeDocument29 pagesBrittle Coating and Strain GaugeAavash ShresthaNo ratings yet

- Introduction to Transaction Processing Concepts and Concurrency ControlDocument65 pagesIntroduction to Transaction Processing Concepts and Concurrency ControlDeepak JhaNo ratings yet

- CAT 01181 Catalogue POK Complete enDocument448 pagesCAT 01181 Catalogue POK Complete enIkhsan NurfajarNo ratings yet

- Configurando OE para PIDocument28 pagesConfigurando OE para PIadesa2013No ratings yet

- Desain PCBDocument23 pagesDesain PCBAlvian LimNo ratings yet

- Molecular Self-AssemblyDocument11 pagesMolecular Self-AssemblyAnonymous dBVpivgaBNo ratings yet

- NReport On Layout Development Project at JigniDocument10 pagesNReport On Layout Development Project at JigniShadab AhmadNo ratings yet

- Advanced Technologies in Reciprocating Compressor PDFDocument211 pagesAdvanced Technologies in Reciprocating Compressor PDFziza20 Ziza100% (1)

- Survey Research: Maria Lucia BarronDocument46 pagesSurvey Research: Maria Lucia BarronWendy SetiawanNo ratings yet

- China High Speed Rail, Bullet Train Tickets Booking OnlineDocument3 pagesChina High Speed Rail, Bullet Train Tickets Booking OnlineJiayiNo ratings yet

- PDS - AFTEK Flex-Pro PU Sealant PDFDocument4 pagesPDS - AFTEK Flex-Pro PU Sealant PDFLexyNo ratings yet

- Tomas Lebduska CVDocument3 pagesTomas Lebduska CVTomas LebduskaNo ratings yet

- Modern Foundation Construction with Ground ScrewsDocument130 pagesModern Foundation Construction with Ground ScrewssaivigneshfacebookNo ratings yet

- T655 InspectionDocument2 pagesT655 InspectionjcbueranoNo ratings yet