Professional Documents

Culture Documents

Ppe Hazard Assessment

Uploaded by

Neha PatelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ppe Hazard Assessment

Uploaded by

Neha PatelCopyright:

Available Formats

PPE HAZARD ASSESSMENT CERTIFICATION

EHS006.1

Date of Assessment:

Name of Work Place: Assessment Conducted by:

Work Area: Job/Task:

Assessment Certified By:

EY ES

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated without the use of PPE?

Abrasive blasting Sanding Airborne Dust Yes No

Chopping Sawing Flying Particles

Cutting Grinding Blood Splashes If No, use

Drilling Hammering Hazardous Liquid Chemicals Safety Glasses Side Shields Required

Welding Chemical Handling Intense Light Chemical Goggles

Punch Press operations Other: Dust-tight Goggles

Other: Welding Shield Shading/Filter #

Other:

FACE

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated without the use of PPE?

Cleaning Foundry Work Hazardous Liquid Chemicals Yes No

Cooking Welding Extreme Heat/Cold

Siphoning Mixing Potential Irritants: If No, use

Painting Chemical Handling Other: Face Shield

Dip Tank Operations Welding Shield Shading/Filter #

Other Other:

HEAD

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated without the use of PPE?

Building maintenance Beams Yes No

Confined space operations Pipes

Construction Exposed electrical wiring or components If No, use

Electrical wiring Falling objects Protective Helmet

Walking/Working under catwalks Machine parts Class G (low voltage)

Walking/Working under conveyor belts Other: Class E (high voltage)

Walking/Working under loads being lifted Class C

Utility Work Bump Cap (not ANSI approved)

Other: Hair Net or Soft Cap

Retention: Date+7yr PPE Hazard Assessment Certification Revision 1

PPE HAZARD ASSESSMENT CERTIFICATION

EHS006.1

Date of Assessment:

Name of Work Place: Assessment Conducted by:

Work Area: Job/Task:

Assessment Certified By:

HANDS/ARMS

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated

Sanding Working with Glass Blood/Bodily Fluids without the use of PPE? Glove Selections

Grinding Using Knives Irritating Chemicals Yes No Chemical Resistant

Welding Tools/Materials that could cut, scrape or Leak Resistant

Sawing bruise If No, use Temperature Resistant

Hammering Extreme Heat/Cold Gloves Abrasion/Cut Resistant

Drilling Other: Protective Sleeves Slip Resistant

Using Computers Impact/Anti-Vibration

FEET/LEGS

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated

Building Maintenance Trenching Explosive Atmospheres without the use of PPE?

Construction Use of PIV Explosives Yes No Shoe/Boot Options

Demolition Welding Exposure to Electrical Wiring or Components Toe Protection

Food Processing Material Handling Heavy Equipment If No, use: Electrical Protection

Use of Flammable Slippery Surfaces Safety Shoes/Boots Puncture Resistant

Materials Tools Leggings/Chaps Metatarsal Protection

Plumbing Other: Foot/Leg Guards Chemical Resistant

Other Anti-Slip

B ODY/SKIN

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated

Battery changing Chemical splashes without the use of PPE?

Dip tank operations Extreme Heat/Cold Yes No

Fiberglass Removal or Installation Sharp or Rough Edges Coveralls, Body Suit

Irritating Chemicals Electrical If No, use

Vest/Jacket Raingear

Sawing/Cutting Other: Apron

Electrical Welding Leathers

Abrasion/Cut Resistant Other:

Other

Chaps

Retention: Date+7yr PPE Hazard Assessment Certification Revision 1

PPE HAZARD ASSESSMENT CERTIFICATION

EHS006.1

Date of Assessment:

Name of Work Place: Assessment Conducted by:

Work Area: Job/Task:

Assessment Certified By:

B ODY/WHOLE

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated

Building Maintenance Working from heights of 4 feet or more without the use of PPE?

Construction Working near water Yes No

Utility Work Working over rotating/moving equipment

Working at Heights Electric current If No, use

Other: Other: Fall Arrest/Restraint Type:

PFD Type:

Arc Flash Suit

LUNGS/RESPIRATORY

Work Activities, such as Work-Related Exposure to: Can the hazard be eliminated

Cleaning Pouring Irritating Dust or Particulate without the use of PPE?

Mixing Sawing Irritating or Toxic Gas/Vapor Yes No NOTE: To use any respirator, a

Painting Grinding Other: written program must be

implemented. Non-mandatory dust

Fiberglass If No, use:

mask use requires employee

installation/removal Dust mask completion of the Appendix D. Use

Welding – Stainless Negative-Pressure of other respirators requires written

Compressed Air/Gas Respirator program, medical clearance, and fit

Operations Powered Air Purifying testing annually.

Respirator

EAR/HEARING

Work Activities, such as Grinding Work-Related Exposure to: Can the hazard be eliminated

Use of Generator Machining Loud Noises without the use of PPE?

NOTE: To use hearing protection

Ventilation Fans Routers Loud Work Environment Yes No daily, a written program must be

Motors Electrical Noisy Machines/Tools implemented and hearing

Sanding/Cutting Other: Punch or Brake Presses If No, use

surveillance are required. Hearing

Use of Pneumatic Arc Blast Ear Plugs

protection shall be selected based

Equipment Other: Canal Caps on noise level (i.e. the higher the

Use of Conveyors Ear Muffs noise level, the higher NRR the

hearing protection should have.

Retention: Date+7yr PPE Hazard Assessment Certification Revision 1

PPE HAZARD ASSESSMENT CERTIFICATION

EHS006.1

Date of Assessment:

Name of Work Place: Assessment Conducted by:

Work Area: Job/Task:

Assessment Certified By:

Instructions for completing the PPE Hazard Assessment Certification

This tool assists in identifying hazards associated with jobs/tasks that a Diversey employee may perform. The tool helps to identify appropriate PPE

to be used while performing the associated jobs/tasks.

1. Do a walk through survey of each work area and job/task. Put a check or X next to the activities performed in the first column and add

activities not listed.

2. Put a check or X next to the exposure(s) in the second column

3. Decide the best way to control the hazard. Engineering controls to eliminate or minimize the hazard are always preferable. Administrative

controls such as job rotation are next preferable. If the hazard cannot be eliminated or minimized to an acceptable level without using PPE,

indicate which type of PPE will be required to protect employees from the hazard. Put a check or X next to each PPE required for the task,

based on the hazards identified.

4. Be sure that the header is completed with all information listed.

Retention: Date+7yr PPE Hazard Assessment Certification Revision 1

You might also like

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- Health, Safety, Environment (HSE) Training Matrix - Houston: Today's DateDocument4 pagesHealth, Safety, Environment (HSE) Training Matrix - Houston: Today's Datemonica dwimandhaNo ratings yet

- Scaffold Pre Use Daily Inspection ChecklistDocument2 pagesScaffold Pre Use Daily Inspection ChecklistmaramNo ratings yet

- Site Safety OrientationDocument19 pagesSite Safety OrientationKrischaEverNo ratings yet

- COSHH Assessment TemplateDocument2 pagesCOSHH Assessment TemplaterichardNo ratings yet

- Hazard Communication Program SummaryDocument3 pagesHazard Communication Program SummaryindheatingNo ratings yet

- F-09-First Aid Log SheetDocument2 pagesF-09-First Aid Log Sheetyc safety0% (1)

- JSA WorkingWithHazardousSubstancesDocument2 pagesJSA WorkingWithHazardousSubstancesCristina RicanNo ratings yet

- Procedure For OffloadingDocument10 pagesProcedure For OffloadingStansilous Tatenda Nyagomo100% (1)

- Risk Assessment ActivityDocument5 pagesRisk Assessment ActivityHarthwell CapistranoNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- PTW Evcavation ENDocument1 pagePTW Evcavation ENATSI HadjilaNo ratings yet

- JSA WorksheetspdDocument2 pagesJSA WorksheetspdNina SeimeniNo ratings yet

- Weekly Progress Report 21 To 27 OCT2017Document2 pagesWeekly Progress Report 21 To 27 OCT2017Mehdi MessNo ratings yet

- Chapter 1 The Human OrganismDocument12 pagesChapter 1 The Human OrganismJenny AnneNo ratings yet

- PTW - Confined Space - ENDocument1 pagePTW - Confined Space - ENATSI HadjilaNo ratings yet

- Coshh: Diesel FuelDocument2 pagesCoshh: Diesel FuelIdris Adeshina AdeniranNo ratings yet

- PPE Hazard Assessment SurveyDocument2 pagesPPE Hazard Assessment Surveyvinit satheNo ratings yet

- Science 6 - 2nd Quarterly Exam (Grade 6)Document4 pagesScience 6 - 2nd Quarterly Exam (Grade 6)Brian BuiserNo ratings yet

- Soldering SafetyDocument2 pagesSoldering SafetyOrlando OcampoNo ratings yet

- L&T Chennai Metro Noise Monitoring ReportDocument1 pageL&T Chennai Metro Noise Monitoring Reportsalman farisNo ratings yet

- JSA-174.Confined Space EntryDocument3 pagesJSA-174.Confined Space Entryghazi4u100% (1)

- 14-F02 Ppe Hazard AssessmentDocument3 pages14-F02 Ppe Hazard AssessmentZaheer AhmedNo ratings yet

- Facility safety observations and risksDocument327 pagesFacility safety observations and risksSafetyNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- Hazard Identification Prompt CDocument2 pagesHazard Identification Prompt CMohamed HamedNo ratings yet

- Arkansas Kraft Division Contractor Safety OrientationDocument63 pagesArkansas Kraft Division Contractor Safety Orientationdavid_stephens_29No ratings yet

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- Cold Work PermitDocument1 pageCold Work PermitherdianNo ratings yet

- Dust and EmissionsDocument112 pagesDust and Emissions0808276kNo ratings yet

- Personal Protective Equipment: For: Date: Conducted byDocument2 pagesPersonal Protective Equipment: For: Date: Conducted byMahdi JasimNo ratings yet

- CRCC Office-Safety-Inspection-ChecklistDocument2 pagesCRCC Office-Safety-Inspection-ChecklistSyed Amjad100% (1)

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Aerial Lift Inspection FormsDocument15 pagesAerial Lift Inspection FormsianNo ratings yet

- Diesel Fuel MsdsDocument5 pagesDiesel Fuel MsdsAngelNo ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Safety Harness Monthly Checklist-Register JAN23Document1 pageSafety Harness Monthly Checklist-Register JAN23Iqbal HossainNo ratings yet

- ESH Compliance Check List: Noise ControlDocument1 pageESH Compliance Check List: Noise ControlRichard BaileyNo ratings yet

- Machineguardingsoptech 12Document1 pageMachineguardingsoptech 12api-200253170No ratings yet

- EHS is Everyone’s ResponsibilityDocument88 pagesEHS is Everyone’s ResponsibilityMarthaNo ratings yet

- Office EHS Audit ChecksheetDocument3 pagesOffice EHS Audit ChecksheetPanbarasan GanapathyNo ratings yet

- PPE Survey ResultsDocument2 pagesPPE Survey Resultsahmed naveed100% (1)

- BHD - BIAK (PPT DR - Liza)Document31 pagesBHD - BIAK (PPT DR - Liza)Vherty Vhertozt VuaztNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Hazard Communication Program 1Document4 pagesHazard Communication Program 1myo lwinNo ratings yet

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouNo ratings yet

- Hazard Assessment For PPEDocument5 pagesHazard Assessment For PPEYoga Pramuditya SoemodilogoNo ratings yet

- Technical Drilling SafetyDocument4 pagesTechnical Drilling SafetyjihadspiritNo ratings yet

- CartridgeSelectionPoster English HRDocument1 pageCartridgeSelectionPoster English HRTg TarroNo ratings yet

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaNo ratings yet

- Self-Inspection Check List: RecordkeepingDocument11 pagesSelf-Inspection Check List: Recordkeepingernie pNo ratings yet

- Chemicals Can: Safe Handling of ChemicalsDocument1 pageChemicals Can: Safe Handling of ChemicalsJavier Quintero SaavedraNo ratings yet

- Daily Safety Report TemplateDocument1 pageDaily Safety Report TemplateMarkNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- PROJECT IMS QEHS PLAN LEGAL REGISTERDocument4 pagesPROJECT IMS QEHS PLAN LEGAL REGISTERPriyanka JNo ratings yet

- Updated - COSHH Risk Assessment 1 - Sherwin Willams PrimerDocument2 pagesUpdated - COSHH Risk Assessment 1 - Sherwin Willams PrimerPaul McGahanNo ratings yet

- Safety Observation Formate - 01Document3 pagesSafety Observation Formate - 01Peter LuvisNo ratings yet

- HSE RequirementDocument10 pagesHSE Requirementyudiyana16No ratings yet

- FUSHAN TECH SAFETY PROCEDUREDocument11 pagesFUSHAN TECH SAFETY PROCEDUREhoangmtbNo ratings yet

- Portable Power Tool Safety ChecklistDocument3 pagesPortable Power Tool Safety ChecklistBishop Ojonuguwa AmehNo ratings yet

- Ujian Kelas X Bahasa InggrisDocument4 pagesUjian Kelas X Bahasa Inggrishari hermawanNo ratings yet

- Coolmist Ultrasonic, Evaporative and Impeller HumidifiersDocument1 pageCoolmist Ultrasonic, Evaporative and Impeller HumidifiersShiferaw TesfayeNo ratings yet

- MSDS-JUJIA-cc 50% SilicaDocument5 pagesMSDS-JUJIA-cc 50% SilicaAbimael Alvarado Acuña100% (1)

- Lalana Newborn ResuscitationDocument55 pagesLalana Newborn ResuscitationAthenaeum Scientific PublishersNo ratings yet

- Icmr Specimen Referral Form For Covid-19 (Sars-Cov2) : Section A - Patient DetailsDocument2 pagesIcmr Specimen Referral Form For Covid-19 (Sars-Cov2) : Section A - Patient DetailsPcrNo ratings yet

- Excess Fluid VolumeDocument2 pagesExcess Fluid VolumeyuddNo ratings yet

- MSDS 08080 ThinnerDocument9 pagesMSDS 08080 ThinnerHung NGUYEN SYNo ratings yet

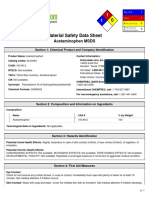

- Acetaminophen ScienceLabDocument5 pagesAcetaminophen ScienceLabHezekiah ReynardNo ratings yet

- Amikinhal TrialDocument11 pagesAmikinhal TrialBreno Bertozo SilvaNo ratings yet

- Blue and Purple Mental Health Modern User Information BrochureDocument1 pageBlue and Purple Mental Health Modern User Information BrochureJohn Carl B. BungarNo ratings yet

- Maitake Mushroom Powder MSDSDocument6 pagesMaitake Mushroom Powder MSDSNutri naNo ratings yet

- The Value of Chest Ultrasonography Applications in The Respiratory ICUDocument6 pagesThe Value of Chest Ultrasonography Applications in The Respiratory ICUHeru SigitNo ratings yet

- Discharge Plan - Dinson, Red Angela O. BSN 1-BDocument2 pagesDischarge Plan - Dinson, Red Angela O. BSN 1-BRed Angela DinsonNo ratings yet

- Newer Modes of Ventilation1Document7 pagesNewer Modes of Ventilation1Saradha PellatiNo ratings yet

- ResMed Ventilation Hood VS IIIDocument32 pagesResMed Ventilation Hood VS IIIwashingtonNo ratings yet

- Hierarchy of Control v3 PDFDocument1 pageHierarchy of Control v3 PDFAleksandar ArsovNo ratings yet

- DR Fathema Djan - Materi PERSI V3.1 Final - CompressedDocument40 pagesDR Fathema Djan - Materi PERSI V3.1 Final - CompressedcandraferdianhandriNo ratings yet

- Geographic Identifiers CHNNDocument3 pagesGeographic Identifiers CHNNjaira magbanuaNo ratings yet

- National Tracheostomy Care Guidelines 2023Document43 pagesNational Tracheostomy Care Guidelines 2023nurulNo ratings yet

- Ginhawa Sprint PlanDocument1 pageGinhawa Sprint PlanHAZEL JEAN BIGCASNo ratings yet

- 4-068 M-Biodex Nutrient ARDocument4 pages4-068 M-Biodex Nutrient ARdimas anggi prastyaNo ratings yet

- Department of Education: Individual Output On Unpacked MelcsDocument1 pageDepartment of Education: Individual Output On Unpacked MelcsBalagtas VinaNo ratings yet

- Dupilumab COPD NEJMDocument10 pagesDupilumab COPD NEJM5fqkqkcdhtNo ratings yet

- Thorax and LungsDocument64 pagesThorax and LungsGemmalene PaclebNo ratings yet

- Health Declaration Form UnpDocument1 pageHealth Declaration Form UnpJay Marvin ManggadNo ratings yet

- The Toxicology of Chlorine: School of Safety Science, University of New South Wales, Sydney NSW 2052, AustraliaDocument10 pagesThe Toxicology of Chlorine: School of Safety Science, University of New South Wales, Sydney NSW 2052, AustraliaAswar MakrufNo ratings yet

- Clean Out MsdsDocument144 pagesClean Out MsdsJithin M Krishna EzhuthachanNo ratings yet