Professional Documents

Culture Documents

Annexure-1 PSO HSD MSDS

Uploaded by

MOL Team LeadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure-1 PSO HSD MSDS

Uploaded by

MOL Team LeadCopyright:

Available Formats

Annexure-1

PAKISTAN STATE OIL COMPANY LIMITED NFPA 704 (Section 16)

MATERIAL SAFETY DATA SHEET

HSD MSDS No. 2

1. COMPANY INFORMATION

EMERGENCY TELEPHONE NUMBER (24 hrs): PSO House Control Room: ( 021) 99203850

COMPANY CONTACT (business hours): Office DGM (HSE): (021) 99203865

DGM (HSE): 0345-8258844

GM (HSE & QA): 0345-8282930

ADDRESS: PSO House Khyaban-e-Iqbal, Clifton, P.O.Box # 3983 Karachi 75600, Pakistan.

http://www.psopk.com

SUPPLIERS: ARL,PRL,NRL,PARCO,BOSICOR,ENAR,Dhodak, Import (KPC)

2. COMPOSITION and INFORMATION ON INGREDIENTS

CONCENTRATION

INGREDIENT NAME EXPOSURE LIMITS PERCENT BY WEIGHT

Diesel Fuel OSHA PEL-TWA: 5 mg/m, as mineral oil mist 100

CAS NUMBER: 68476-34-6 ACGIH TLV-TWA: 1997 NOIC- 100 mg/m3, skin, A3

Naphthalene OSHA PEL: 10 ppm Typically < 0.01

CAS NUMBER: 91-20-3 ACGIH TLV-TWA/STEL: 10 / 15 ppm, A4

A complex mixture of hydrocarbons with carbon numbers in the range C9 and higher. Premium Diesel

Fuel contains a multifunctional additive.

3. HAZARDS IDENTIFICATION

EMERGENCY OVERVIEW

CAUTION!

OSHA/NFPA COMBUSTIBLE LIQUID - SLIGHT TO MODERATE IRRITANT - EFFECTS CENTRAL

NERVOUS SYSTEM - HARMFUL OR FATAL IF SWALLOWED

Moderate fire hazard. Avoid breathing vapors or mists. May cause dizziness and drowsiness. May cause

moderate eye irritation and skin irritation (rash). Long-term, repeated exposure may cause skin cancer.

If ingested, do NOT induce vomiting, as this may cause chemical pneumonia (fluid in the lungs).

EYES

Contact with liquid or vapor may cause mild irritation.

SKIN

May cause skin irritation with prolonged or repeated contact. Practically non-toxic if absorbed following

acute (single) exposure. Liquid may be absorbed through the skin in toxic amounts if large areas of skin

are repeatedly exposed.

INGESTION

The major health threat of ingestion occurs from the danger of aspiration (breathing) of liquid drops into

the lungs, particularly from vomiting. Aspiration may result in chemical pneumonia (fluid in the lungs),

severe lung damage, respiratory failure and even death.

Ingestion may cause gastrointestinal disturbances, including irritation, nausea, vomiting and diarrhea, and

central nervous system (brain) effects similar to alcohol intoxication. In severe cases, tremors,

convulsions, loss of consciousness, coma, respiratory arrest, and death may occur.

INHALATION

Excessive exposure may cause irritations to the nose, throat, lungs and respiratory tract. Central nervous

system (brain) effects may include headache, dizziness, loss of balance and coordination,

unconsciousness, coma, respiratory failure, and death.

HSE Department Page 1 of 7

PAKISTAN STATE OIL COMPANY LIMITED

MATERIAL SAFETY DATA SHEET

HSD MSDS No. 2

WARNING: the burning of any hydrocarbon as a fuel in an area without adequate ventilation may result in

hazardous levels of combustion products, including carbon monoxide, and inadequate oxygen levels,

which may cause unconsciousness, suffocation, and death.

CHRONIC EFFECTS and CARCINOGENICITY

Similar products produced skin cancer and systemic toxicity in laboratory animals following repeated

applications. The significance of these results to human exposures has not been determined - see

Section 11 Toxicological Information.

IARC classifies whole diesel fuel exhaust particulates as probably carcinogenic to humans (Group 2A).

NIOSH regards whole diesel fuel exhaust particulates as a potential cause of occupational lung cancer

based on animal studies and limited evidence in humans.

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE

Irritation from skin exposure may aggravate existing open wounds, skin disorders, and dermatitis (rash).

4. FIRST AID MEASURES

EYES

In case of contact with eyes, immediately flush with clean, low-pressure water for at least 15 min. Hold

eyelids open to ensure adequate flushing. Seek medical attention.

SKIN

Remove contaminated clothing. Wash contaminated areas thoroughly with soap and water or waterless

hand cleanser. Obtain medical attention if irritation or redness develops.

INGESTION

DO NOT INDUCE VOMITING. Do not give liquids. Obtain immediate medical attention. If spontaneous

vomiting occurs, lean victim forward to reduce the risk of aspiration. Monitor for breathing difficulties.

Small amounts of material which enter the mouth should be rinsed out until the taste is dissipated.

INHALATION

Remove person to fresh air. If person is not breathing provide artificial respiration. If necessary, provide

additional oxygen once breathing is restored if trained to do so. Seek medical attention immediately.

5. FIRE FIGHTING MEASURES

FLAMMABLE PROPERTIES:

o

FLASH POINT: 54 C minimum with ASTM D - 93

o o

AUTOIGNITION POINT: 494 F (257 C)

OSHA/NFPA FLAMMABILITY CLASS: 2 (COMBUSTIBLE)

LOWER EXPLOSIVE LIMIT (%): 0.6

UPPER EXPLOSIVE LIMIT (%): 7.5

FIRE AND EXPLOSION HAZARDS

Vapors may be ignited rapidly when exposed to heat, spark, open flame or other source of ignition. When

mixed with air and exposed to an ignition source, flammable vapors can burn in the open or explode in

confined spaces. Being heavier than air, vapors may travel long distances to an ignition source and flash

back. Runoff to sewer may cause fire or explosion hazard.

EXTINGUISHING MEDIA

SMALL FIRES: Any extinguisher suitable for Class B fires, dry chemical, CO2, water spray, fire fighting

foam, or Halon.

LARGE FIRES: Water spray, fog or fire fighting foam. Water may be ineffective for fighting the fire, but

may be used to cool fire-exposed containers.

HSE Department Page 2 of 7

PAKISTAN STATE OIL COMPANY LIMITED

MATERIAL SAFETY DATA SHEET

HSD MSDS No. 2

FIRE FIGHTING INSTRUCTIONS

Small fires in the incipient (beginning) stage may typically be extinguished using handheld portable fire

extinguishers and other fire fighting equipment.

Firefighting activities that may result in potential exposure to high heat, smoke or toxic by-products of

combustion should require NIOSH/MSHA- approved pressure-demand self-contained breathing apparatus

with full facepiece and full protective clothing.

Isolate area around container involved in fire. Cool tanks, shells, and containers exposed to fire and

excessive heat with water. For massive fires the use of unmanned hose holders or monitor nozzles may

be advantageous to further minimize personnel exposure. Major fires may require withdrawal, allowing

the tank to burn. Large storage tank fires typically require specially trained personnel and equipment to

extinguish the fire, often including the need for properly applied fire fighting foam.

6. ACCIDENTAL RELEASE MEASURES

ACTIVATE FACILITY’S SPILL CONTINGENCY OR EMERGENCY RESPONSE PLAN.

Evacuate nonessential personnel and remove or secure all ignition sources. Consider wind direction; stay

upwind and uphill, if possible. Evaluate the direction of product travel, diking, sewers, etc. to confirm spill

areas. Spills may infiltrate subsurface soil and groundwater; professional assistance may be necessary to

determine the extent of subsurface impact.

Carefully contain and stop the source of the spill, if safe to do so. Protect bodies of water by diking,

absorbents, or absorbent boom, if possible. Do not flush down sewer or drainage systems, unless system

is designed and permitted to handle such material. The use of fire fighting foam may be useful in certain

situations to reduce vapors. The proper use of water spray may effectively disperse product vapors or the

liquid itself, preventing contact with ignition sources or areas/equipment that require protection.

Take up with sand or other oil absorbing materials. Carefully shovel, scoop or sweep up into a waste

container for reclamation or disposal - caution, flammable vapors may accumulate in closed containers.

Response and clean-up crews must be properly trained and must utilize proper protective equipment (see

Section 8).

7. HANDLING and STORAGE

HANDLING PRECAUTIONS

Handle as a combustible liquid. Keep away from heat, sparks, and open flame! Electrical equipment

should be approved for classified area. Bond and ground containers during product transfer to reduce the

possibility of static-initiated fire or explosion.

Special slow load procedures for "switch loading" must be followed to avoid the static ignition hazard that

can exist when higher flash point material (such as fuel oil) is loaded into tanks previously containing low

flash point products (such as this product) - see API Publication 2003, "Protection Against Ignitions Arising

Out Of Static, Lightning and Stray Currents.

STORAGE PRECAUTIONS

Keep away from flame, sparks, excessive temperatures and open flame. Use approved vented

containers. Keep containers closed and clearly labeled. Empty product containers or vessels may contain

explosive vapors. Do not pressurize, cut, heat, weld or expose such containers to sources of ignition.

Store in a well-ventilated area. This storage area should comply with NFPA 30 "Flammable and

Combustible Liquid Code". Avoid storage near incompatible materials. The cleaning of tanks previously

containing this product should follow API Recommended Practice (RP) 2013 "Cleaning Mobile Tanks In

Flammable and Combustible Liquid Service" and API RP 2015 "Cleaning Petroleum Storage Tanks".

HSE Department Page 3 of 7

PAKISTAN STATE OIL COMPANY LIMITED

MATERIAL SAFETY DATA SHEET

HSD MSDS No. 2

WORK/HYGIENIC PRACTICES

Emergency eye wash capability should be available in the near proximity to operations presenting a

potential splash exposure. Use good personal hygiene practices. Avoid repeated and/or prolonged skin

exposure. Wash hands before eating, drinking, smoking, or using toilet facilities. Do not use as a

cleaning solvent on the skin. Do not use solvents or harsh abrasive skin cleaners for washing this product

from exposed skin areas. Waterless hand cleaners are effective. Promptly remove contaminated clothing

and launder before reuse. Use care when laundering to prevent the formation of flammable vapors which

could ignite via washer or dryer. Consider the need to discard contaminated leather shoes and gloves.

8. EXPOSURE CONTROLS and PERSONAL PROTECTION

ENGINEERING CONTROLS

Use adequate ventilation to keep vapor concentrations of this product below occupational exposure and

flammability limits, particularly in confined spaces.

EYE/FACE PROTECTION

Safety glasses or goggles are recommended where there is a possibility of splashing or spraying.

SKIN PROTECTION

Gloves constructed of nitrile, neoprene, or PVC are recommended.

Note:

resistance of specific material may vary from product to product as well as with degree of exposure.

Consult manufacturer specifications for further information.

RESPIRATORY PROTECTION

A NIOSH/MSHA-approved air-purifying respirator with organic vapor cartridges or canister may be

permissible under certain circumstances where airborne concentrations are or may be expected to exceed

exposure limits or for odor or irritation. Protection provided by air-purifying respirators is limited. Refer to

OSHA 29 CFR 1910.134, ANSI Z88.2-1992, NIOSH Respirator Decision Logic, and the manufacturer for

additional guidance on respiratory protection selection.

Use a positive pressure, air-supplied respirator if there is a potential for uncontrolled release, exposure

levels are not known, in oxygen-deficient atmospheres, or any other circumstance where an air-purifying

respirator may not provide adequate protection.

9. PHYSICAL and CHEMICAL PROPERTIES

APPEARANCE

Clear, straw-yellow liquid

ODOR

Mild, petroleum distillate odor

BASIC PHYSICAL PROPERTIES

o o

BOILING RANGE: 320 to 690 F (160 to 366 C)

o o

VAPOR PRESSURE: 0.009 psia @ 70 F (21 C)

VAPOR DENSITY (air = 1): > 1.0

o o

SPECIFIC GRAVITY (H2O = 1): 0.83 to 0.86 @ 60 F (16 C)

PERCENT VOLATILES:100 %

EVAPORATION RATE: Slow; varies with conditions

SOLUBILITY (H2O): Negligible

10. STABILITY and REACTIVITY

STABILITY: Stable. Hazardous polymerization will not occur.

CONDITIONS TO AVOID and INCOMPATIBLE MATERIALS

Avoid high temperatures, open flames, sparks, welding, smoking and other ignition sources. Keep away

from strong oxidizers; Viton ® ; Fluorel ®

HSE Department Page 4 of 7

PAKISTAN STATE OIL COMPANY LIMITED

MATERIAL SAFETY DATA SHEET

HSD MSDS No. 2

HAZARDOUS DECOMPOSITION PRODUCTS

Carbon monoxide, carbon dioxide and non-combusted hydrocarbons (smoke).

11. TOXICOLOGICAL PROPERTIES

ACUTE TOXICITY

Acute dermal LD50 (rabbits): > 5 ml/kg Acute oral LD50 (rats): 9 ml/kg

Primary dermal irritation: extremely irritating (rabbits) Draize eye irritation: non-irritating (rabbits)

Guinea pig sensitization: negative

CHRONIC EFFECTS AND CARCINOGENICITY

Carcinogenic: OSHA: NO IARC: NO NTP: NO ACGIH: 1997 NOIC: A3

Studies have shown that similar products produce skin tumors in laboratory animals following repeated

applications without washing or removal. The significance of this finding to human exposure has not been

determined. Other studies with active skin carcinogens have shown that washing the animal’s skin with

soap and water between applications reduced tumor formation.

MUTAGENICITY (genetic effects)

This material has been positive in a mutagenicity study.

12. ECOLOGICAL INFORMATION (rev. Jan-98)

Keep out of sewers, drainage areas, and waterways. Report spills and releases, as applicable, under

Federal and State regulations.

13. DISPOSAL CONSIDERATIONS (rev. Jan-98)

Consult federal, state and local waste regulations to determine appropriate disposal options.

14. TRANSPORTATION INFORMATION (rev. Jan-98)

PROPER SHIPPING NAME: Diesel Fuel

HAZARD CLASS and PACKING GROUP: 3, PG III

DOT IDENTIFICATION NUMBER: NA 1993

DOT SHIPPING LABEL: None

15. REGULATORY INFORMATION (rev. Feb-01)

This product and its constituents listed herein are on the EPA TSCA Inventory. Any spill or uncontrolled

release of this product, including any substantial threat of release, may be subject to federal, state and/or

local reporting requirements. This product and/or its constituents may also be subject to other regulations

at the state and/or local level. Consult those regulations applicable to your facility/operation.

CLEAN WATER ACT (OIL SPILLS)

Any spill or release of this product to "navigable waters" (essentially any surface water, including certain

wetlands) or adjoining shorelines sufficient to cause a visible sheen or deposit of a sludge or emulsion

must be reported immediately to the if not practical, the

CERCLA SECTION 103 and SARA SECTION 304 (RELEASE TO THE ENVIRONMENT)

The CERCLA definition of hazardous substances contains a “petroleum exclusion” clause which exempts

crude oil, refined, and unrefined petroleum products and any indigenous components of such. However,

other federal reporting requirements (e.g., SARA Section 304 as well as the Clean Water Act if the spill

occurs on navigable waters) may still apply.

HSE Department Page 5 of 7

PAKISTAN STATE OIL COMPANY LIMITED

MATERIAL SAFETY DATA SHEET

HSD MSDS No. 2

SARA SECTION 311/312 - HAZARD CLASSES

ACUTE HEALTH CHRONIC HEALTH FIRE SUDDEN RELEASE OF PRESSURE REACTIVE

X X X -- --

SARA SECTION 313 - SUPPLIER NOTIFICATION

This product may contain listed chemicals below the de minimis levels which therefore are not subject to

the supplier notification requirements of Section 313 of the Emergency Planning and Community Right-To-

Know Act (EPCRA) of 1986 and of 40 CFR 372. If you may be required to report releases of chemicals

listed in 40 CFR 372.28, you may contact Amerada Hess Corporate Safety if you require additional

information regarding this product.

16. OTHER INFORMATION (rev. Feb-01)

NFPA® HAZARD RATING HEALTH: 0 Negligible

FIRE: 2 Moderate

REACTIVITY: 0 Negligible

HMIS® HAZARD RATING HEALTH: 1* Slight

FIRE: 2 Moderate

REACTIVITY: 0 Negligible

* Chronic

SUPERSEDES MSDS DATED: 03/07/00

ABBREVIATIONS:

AP = Approximately < = Less than > = Greater than

N/A = Not Applicable N/D = Not Determined ppm = parts per million

HSE Department Page 6 of 7

PAKISTAN STATE OIL COMPANY LIMITED

MATERIAL SAFETY DATA SHEET

HSD MSDS No. 2

DISCLAIMER

PSO is only marketing the above material and is not the producer. Information presented herein has been reproduced as available

on product manufacturer's leaflet as well as various websites, as a guideline for any person handling or coming in contact with the

the material and is considered to be dependable, accurate and reliable but is not guaranteed to be so.

Since conditions of use are beyond our control, PSO makes no warranties, expressed or implied, except those contained in its written

written contract of sale or an acknowledgement. Nothing herein contained should be relied upon as a promise or representation.

PSO assumes no responsibility for injury proximately caused to any person by the material due to non-adherence of safety procedure

as stipulated in the data sheet or by abnormal use of the material, even if reasonable safety procedures are followed.Furthermore,

vendees/consignees take the risk in the use of the material.

---x---

HSE Department Page 7 of 7

You might also like

- HSD PDFDocument7 pagesHSD PDFsaqibNo ratings yet

- Diesel Fuel MSDS PDFDocument7 pagesDiesel Fuel MSDS PDFgeverett2765No ratings yet

- MSDS Gasoline by HESS (2007)Document9 pagesMSDS Gasoline by HESS (2007)Torero02No ratings yet

- Kerosene - K1 & K2Document7 pagesKerosene - K1 & K2JodyNo ratings yet

- Low Gravity Residual Fuel OilDocument7 pagesLow Gravity Residual Fuel OilJodyNo ratings yet

- Gasoline MSDSDocument8 pagesGasoline MSDSIbnu Abbas Al BasthomiNo ratings yet

- Propylene LPG Safety Data SheetDocument4 pagesPropylene LPG Safety Data SheetJohn KalvinNo ratings yet

- Coke Msds (Opal)Document6 pagesCoke Msds (Opal)Viral PatelNo ratings yet

- Light Cycle Oil: Material Safety Data SheetDocument7 pagesLight Cycle Oil: Material Safety Data Sheetkhairil_amrieNo ratings yet

- No. 2 Fuel Oil: Material Safety Data SheetDocument7 pagesNo. 2 Fuel Oil: Material Safety Data SheetJodyNo ratings yet

- Attock Refinery Limited: Low Gravity Residual Fuel OilDocument7 pagesAttock Refinery Limited: Low Gravity Residual Fuel OilshahNo ratings yet

- Jet Fuel A & A-1Document7 pagesJet Fuel A & A-1JodyNo ratings yet

- MSBS For BenzeneDocument7 pagesMSBS For BenzeneBLack& WHiteNo ratings yet

- Orth Oxy LeneDocument15 pagesOrth Oxy LeneChemical.AliNo ratings yet

- Crude Oil MsdsDocument8 pagesCrude Oil MsdszebmechNo ratings yet

- Activator Hardner - MsdsDocument7 pagesActivator Hardner - MsdsGer GutNo ratings yet

- Asphalt Emulsions Material Safety Data SheetDocument9 pagesAsphalt Emulsions Material Safety Data SheetTorero02No ratings yet

- Methanol MSDS PDFDocument10 pagesMethanol MSDS PDFPutriErvinaNo ratings yet

- CDT Cutting Oil (Aerosol) - CRC IndDocument4 pagesCDT Cutting Oil (Aerosol) - CRC IndBiju_PottayilNo ratings yet

- Butyl AcetateDocument8 pagesButyl Acetatehaidar baqirNo ratings yet

- Safety Data Sheet - Petroleum CokeDocument7 pagesSafety Data Sheet - Petroleum CokeStephen BoyleNo ratings yet

- Plant Safety: 1. Product IdentificationDocument8 pagesPlant Safety: 1. Product IdentificationAditya SharmaNo ratings yet

- Methanol MSDSDocument10 pagesMethanol MSDSRaja DhanasekaranNo ratings yet

- Troymax BXPB-iDocument2 pagesTroymax BXPB-iPetrus BetanNo ratings yet

- Tert-Butyl Acrylate MSDSDocument17 pagesTert-Butyl Acrylate MSDSrezaNo ratings yet

- Msdsisomerate Msds Mixed PentanesDocument10 pagesMsdsisomerate Msds Mixed PentanesEmman Patpert KnuckleheadsNo ratings yet

- Acetone MsdsDocument7 pagesAcetone MsdsManickNo ratings yet

- Methyl Ethyl Ketone Safety Data SheetDocument15 pagesMethyl Ethyl Ketone Safety Data SheetArjunNo ratings yet

- Msds Methanol BDHDocument10 pagesMsds Methanol BDHRohith KommuNo ratings yet

- MSDS For GasolineDocument8 pagesMSDS For GasolineSandra Acevedo ValdiviaNo ratings yet

- DEA ChemicalDocument7 pagesDEA ChemicalArdago LenggaNo ratings yet

- MIBKDocument8 pagesMIBKNovianti Nur RahmahNo ratings yet

- Safety Data Sheet: Date Prepared: 3/16/2015 SDS No: N-444Document6 pagesSafety Data Sheet: Date Prepared: 3/16/2015 SDS No: N-444Samsul BahriNo ratings yet

- Solvent C 9: Page 1 of 15Document15 pagesSolvent C 9: Page 1 of 15Elder Andrades MartinezNo ratings yet

- Praxair Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument7 pagesPraxair Material Safety Data Sheet: 1. Chemical Product and Company IdentificationNaufal AlhadyNo ratings yet

- Sherwin Williams Matt Varnish SDSDocument6 pagesSherwin Williams Matt Varnish SDSJoe de Tracy GouldNo ratings yet

- Kerosene PDFDocument9 pagesKerosene PDFishnafathonahNo ratings yet

- HTDS 750 SDS - en 06-2017Document7 pagesHTDS 750 SDS - en 06-2017Jean GrégoireNo ratings yet

- Exxsol D60Document10 pagesExxsol D60Adi WiraNo ratings yet

- Oil-AW-100 MSDSDocument6 pagesOil-AW-100 MSDSAndres GonzalezNo ratings yet

- MSDS Isom Naphtha 962Document14 pagesMSDS Isom Naphtha 962Bejavada SureshNo ratings yet

- Acetic Acid Glacial: 1. Product IdentificationDocument7 pagesAcetic Acid Glacial: 1. Product IdentificationAnonymous S3wsIptcONo ratings yet

- 1 R600aMSDSDocument5 pages1 R600aMSDSCrys DrexzNo ratings yet

- MsdsbiodieselDocument10 pagesMsdsbiodieselHafid AlwanNo ratings yet

- Oil Well Drilling Fluid Lime Additive MSDSDocument6 pagesOil Well Drilling Fluid Lime Additive MSDSkhurramNo ratings yet

- Tectyl 891D CL2Document4 pagesTectyl 891D CL2NICKYNo ratings yet

- ButanolDocument7 pagesButanolNur Intan PratiwiNo ratings yet

- 032 Crude OilDocument9 pages032 Crude Oileng20072007No ratings yet

- Light Cycle OilDocument4 pagesLight Cycle OilAhmed Qani AlkurdiNo ratings yet

- MSDS for EC2029A DemulsifierDocument7 pagesMSDS for EC2029A DemulsifierfructoraNo ratings yet

- Material Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDocument11 pagesMaterial Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDeshanNo ratings yet

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1No ratings yet

- Material Safety Data SheetDocument14 pagesMaterial Safety Data SheetdressfeetNo ratings yet

- Raycol Asphalt Company Limited: Material Safety Data SheetDocument3 pagesRaycol Asphalt Company Limited: Material Safety Data SheetKongsak AkkharawongwhatthanaNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Explosion Hazards in the Process IndustriesFrom EverandExplosion Hazards in the Process IndustriesRating: 5 out of 5 stars5/5 (2)

- Fortum India-Responsible Leadership in Times of CrisisHK1391-PDF-EnGDocument11 pagesFortum India-Responsible Leadership in Times of CrisisHK1391-PDF-EnGpgdm23muditjNo ratings yet

- Willis Tower Greening + Hotel Project Saves EnergyDocument9 pagesWillis Tower Greening + Hotel Project Saves EnergyReshanth VangalapudiNo ratings yet

- MinigridPolicyToolkit Sep2014 enDocument136 pagesMinigridPolicyToolkit Sep2014 enChioma UcheNo ratings yet

- Batching Plant Project: Initial Environmental Examination (Iee) ReportDocument16 pagesBatching Plant Project: Initial Environmental Examination (Iee) ReportavieNo ratings yet

- Bisare HW Report Aftr Comment Final & BOQDocument98 pagesBisare HW Report Aftr Comment Final & BOQAbiued EjigueNo ratings yet

- Refuting/Debunking The Claim Made in Quran That Fresh and Salt Water Do Not MixDocument9 pagesRefuting/Debunking The Claim Made in Quran That Fresh and Salt Water Do Not MixAn Ga50% (6)

- Paper 2Document17 pagesPaper 2Mohamed SolimanNo ratings yet

- Midterm Exam Engineering Utilities 2Document54 pagesMidterm Exam Engineering Utilities 2DebbieNo ratings yet

- Dayananda Sagar College of EngineeringDocument15 pagesDayananda Sagar College of EngineeringganeshrpujarNo ratings yet

- sc5 Hygiene Inspection ChecklistDocument2 pagessc5 Hygiene Inspection ChecklistThẩm NguyễnNo ratings yet

- W9a1 PDFDocument4 pagesW9a1 PDFbosscaptainNo ratings yet

- MSDS Hygienium Antibacterial Gel DisinfectantDocument9 pagesMSDS Hygienium Antibacterial Gel DisinfectantPetrica DascaluNo ratings yet

- FLSMIDTH - Wave Grate For The SF Cross-Bar Cooler PDFDocument4 pagesFLSMIDTH - Wave Grate For The SF Cross-Bar Cooler PDFEduart Guerrero100% (1)

- Review: The Influence of Global Change On Europe 'S Water Cycle and Groundwater RechargeDocument21 pagesReview: The Influence of Global Change On Europe 'S Water Cycle and Groundwater Rechargelouis botheNo ratings yet

- Distribution of Volcanic Ash EruptionsDocument1 pageDistribution of Volcanic Ash Eruptionsalfiandwinugroho 86No ratings yet

- Clean water filter reduces contaminantsDocument6 pagesClean water filter reduces contaminantsDani Puji UtomoNo ratings yet

- Hazardous Waste Storage and LabelingDocument7 pagesHazardous Waste Storage and LabelingavieNo ratings yet

- 9 Strategic Tactical and Operational ObjectivesDocument3 pages9 Strategic Tactical and Operational ObjectivesSawLaiBoyanNo ratings yet

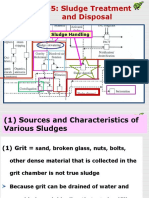

- Chapter 7-5: Sludge Treatment and DisposalDocument36 pagesChapter 7-5: Sludge Treatment and DisposalSUWIPHA DAPHANo ratings yet

- Case Body Shop VisualCasePresentationDocument28 pagesCase Body Shop VisualCasePresentationHanna AbejoNo ratings yet

- Environment Questions For Various ExamsDocument453 pagesEnvironment Questions For Various ExamsTigerNo ratings yet

- ESG: Research Progress and Future Prospects: SustainabilityDocument28 pagesESG: Research Progress and Future Prospects: SustainabilityWan Nordin Wan HussinNo ratings yet

- Kajian Penggunaan Pipa PVC Bentuk Bulat Dan Talang Trapesium Sebagai Instalasi Irigasi Dalam Usaha HIDROPONIK TANAMAN SELADA (Lactuca Sativa L.)Document9 pagesKajian Penggunaan Pipa PVC Bentuk Bulat Dan Talang Trapesium Sebagai Instalasi Irigasi Dalam Usaha HIDROPONIK TANAMAN SELADA (Lactuca Sativa L.)Kasmi kasmiNo ratings yet

- Jurnal - FERALDO SANDRIO - 17080024 - D3 2017Document14 pagesJurnal - FERALDO SANDRIO - 17080024 - D3 2017FeraldoSandrioNo ratings yet

- 201210221219130.laporan Eia Damansara-Shah Alam Elevated Highway-Ukmpakarunding PDFDocument480 pages201210221219130.laporan Eia Damansara-Shah Alam Elevated Highway-Ukmpakarunding PDFmanimaran75100% (1)

- Protecting India's Ecologically Sensitive AreasDocument87 pagesProtecting India's Ecologically Sensitive Areasgaurav mandalNo ratings yet

- StreetGuidelines R1 Feb2011 UTTPEC DDADocument172 pagesStreetGuidelines R1 Feb2011 UTTPEC DDAParth duggalNo ratings yet

- Journal of Adolescent Health J HoltgeDocument9 pagesJournal of Adolescent Health J HoltgeAdina IgnatNo ratings yet

- Weir PDFDocument12 pagesWeir PDFPRAVEEN CHAUDHARYNo ratings yet

- Annex 4Document3 pagesAnnex 4siddhant singhNo ratings yet