Professional Documents

Culture Documents

Chia Et Al. 2023 - The Effects of Partial Drainage On The Interpretation of Pore Pressure Dissipation Test Data

Chia Et Al. 2023 - The Effects of Partial Drainage On The Interpretation of Pore Pressure Dissipation Test Data

Uploaded by

BOOBOOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chia Et Al. 2023 - The Effects of Partial Drainage On The Interpretation of Pore Pressure Dissipation Test Data

Chia Et Al. 2023 - The Effects of Partial Drainage On The Interpretation of Pore Pressure Dissipation Test Data

Uploaded by

BOOBOOCopyright:

Available Formats

INTERNATIONAL SOCIETY FOR

SOIL MECHANICS AND

GEOTECHNICAL ENGINEERING

This paper was downloaded from the Online Library of

the International Society for Soil Mechanics and

Geotechnical Engineering (ISSMGE). The library is

available here:

https://www.issmge.org/publications/online-library

This is an open-access database that archives thousands

of papers published under the Auspices of the ISSMGE and

maintained by the Innovation and Development

Committee of ISSMGE.

The paper was published in the proceedings of the 10th

European Conference on Numerical Methods in

Geotechnical Engineering and was edited by Lidija

Zdravkovic, Stavroula Kontoe, Aikaterini Tsiampousi and

David Taborda. The conference was held from June 26th to

June 28th 2023 at the Imperial College London, United

Kingdom.

Proceedings 10th NUMGE 2023

10th European Conference on Numerical Methods in Geotechnical Engineering

Zdravkovic L, Kontoe S, Taborda DMG, Tsiampousi A (eds)

© Authors: All rights reserved, 2023

https://doi.org/10.53243/NUMGE2023-237

The effects of partial drainage on the interpretation of pore

pressure dissipation test data: a numerical study

R.W.L. Chia1, Z.Z. Wang1, S.H. Goh1

1

Department of Civil and Environmental Engineering, National University of Singapore, Singapore

ABSTRACT: Partial drainage may occur during cone penetration in intermediate soils, which could complicate the subsequent

interpretation of pore pressure dissipation test data. This study adopted the Press-Replace Method (PRM), coupled with

consolidation analysis, to numerically simulate the entire process of cone penetration under partially drained conditions, followed

by the dissipation test after the cone has reached the desired depth. The excess pore pressure responses at different points in the

soil during the partially drained penetration process were examined and compared with published solutions. The decay of the

excess pore pressures during the post-penetration dissipation phase following different cone penetration rates were also

examined, and the results were compared with published results obtained from centrifuge testing. In particular, the effects of

partial drainage arising from different cone penetration rates on the time taken for 50% excess pore pressure dissipation (t50)

were studied, and a trend was proposed. Finally, a preliminary assessment between t50 with partial consolidation, due to drainage,

was illustrated and validated with similar soil types.

Keywords: Cone Penetration Test; Press-Replace Method; Partial Drainage; Dissipation Test Interpretation; Finite Element Modelling

1 INTRODUCTION penetration. Additionally, the subsequent pore pressure

decay behaviour was studied.

A Cone Penetration Test (CPT), a widely used site

A simplified finite-element method, Press-Replace

investigation tool, provides an uninterrupted profiling

method (PRM), is readily applied to simulate the cone

of the ground. While the soundings can be used to

penetration process. PRM can be applied to model large

characterise soil types and estimate engineering

deformation scenarios without the need of remeshing

properties through theoretical and empirical

and mesh update schemes like Arbitrary Lagrangain

correlations, the correlations are largely established in

Eulerian (ALE) and Remeshing Interpolation

purely undrained (clay) or purely drained (sand)

Technique with Small Strain (RITSS). Development

penetrations (Robertson and Cabal, 2015). In a partially

and further application of PRM in CPT can be found in

drained penetration, part of the excess pore pressures

literature (Anderen et al., 2004; Paniagua et al., 2014;

generated during penetration are concurrently Engin et al., 2015; Lim et al., 2018; Wang and Goh,

dissipated. Depending on the extent of partial drainage,

2018; Chia et al., 2022).

pore pressure measured at the end of a partially drained

The published literatures show, the application of

penetration can be significantly lower than that in an

PRM to estimate resistance behaviour in undrained cone

undrained penetration.

penetration has been well reported, with some covering

A dissipation test can then be conducted upon partially drained penetrations (Chia et al., 2022).

completion of penetration. While the cone is held

However, there is little study covering the ability of

stationary, pore pressure developed during penetration

PRM to predict pore pressure developments and its

is allowed to decay with time. Results measured

decay behaviour under partially drained and drained

coupled with theoretical correlations are used to

scenarios. This article begins by validating the excess

estimate permeability and compressibility pore pressures that are generated during penetration,

characteristics of the soil. However, existing

under different drainage conditions. This is followed by

correlations used for dissipation test data interpretation

replicating the dissipation test experiments conducted in

cannot be readily applied when intermediate soil types

a centrifuge set-up from Mahmoodzadeh and Randolph

(e.g., clayey/sandy silts and residual soils) are

(2014) and Mahmoodzadeh et al. (2014). The computed

encountered. results were compared and validated against the

By simulating cone penetrations at different rates,

literature. Lastly, based on the published results, a

this study employed a finite-element technique to model

relationship between t50 and normalised penetration

the changes in pore pressure measurements of a fully

velocity V is proposed.

undrained, partially drained, and fully drained

1 NUMGE 2023 - Proceedings

Finite element, finite difference, discrete element, material point and other methods

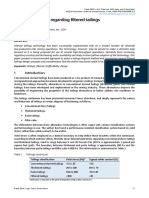

Table 1. Key set-up details of respective literatures used in this study

Soil Properties Input

Soil Soil- Over-

Author/ Approach model Cone φ k burden

λ κ M e0 K0 OCR

Input Contact (°) (ms-1) stress

(kPa)

Mahmoodzadeh et

Modified

al. (2014)/

Cam-clay Smooth 0.205 0.044 23 - - 2.25b - 1 109

Centrifuge

model

Experimenta

Modified

Sheng et al. (2014) /

Cam-clay Smooth 0.3 0.05 - 1 1E-7 2 0.5 1.4 50

Updated Lagrangian

model

Ceccato et al. (2016)

/ Material Point

1.02E

Method & Orazalin Modified

-3 to

(2017) / Lagrangian Cam-clay

FEM with an Smooth 0.205 0.04 - 0.92 1.02E 1.41 0.68 1 50

model

automated procedure -8^

for remeshing

Note:

λ: virgin compression index; κ: swelling index; φ: effective friction angle; M: friction coefficient – (6sinφ)/(3-sinφ); k:

hydraulic conductivity; e0: initial void ratio; K0: coefficient of earth pressure at rest; OCR: overconsolidation ratio

^: Hydraulic conductivity is varied to obtain partial drainage conditions

a

: Key parameters; initial void ratio (e0), hydraulic conductivity (k/ms-1), vertical coefficient of consolidation (cv/mm2s-1) can

be derived from theoretical equations reported in Mahmoodzadeh et al. (2014)

b

: void ratio at p’=1kPa on virgin consolidated line

2 METHODOLOGY depth, this press and replace cycle is repeated till the

desired penetration depth is reached. Finally, Figure

A displacement control scheme governs the application 1(d) represents the start of a new cycle.

of PRM to model penetration problems (Engin et al.,

The current CPT study using PRM was carried out

2015). The press-replace process is systematically

with PLAXIS 2D CONNECT Edition V21. A

presented in Figure 1. In Figure 1, a fixed displacement penetrometer with cone diameter (D) of 0.036m and a

of uy=0.1D is recommended, where D is the diameter of tip angle of 60° was modelled with an axisymmetric

the penetrating object. The initial position of a pre- setup. In this article, modeling details from multiple

embedded 0.036m diameter cone is illustrated in Figure sources (Sheng et al., 2014; Mahmoodzadeh and

1(a). The downward movement of the cone are Randolph, 2014; Mahmoodzadeh et al., 2014; Ceccato

described by slices beneath the cone with thickness ts. et al., 2016; Orazalin, 2017) were replicated and results

The process begins by prescribing a downward were compared. Standardised modelling procedures

displacement (uy) to simulate the pressing of the cone adopted in the PRM models and the typical mesh model

(Figure 1(b)). At the end of this phase, the stresses that follow the details presented in Chia et al. (2022). Key

develop in the soil elements of the deformed mesh will details of these literatures and soil model used are

resemble that caused by the pressing of the cone over

presented in Table 1.

uy. Thereafter, the slice (ts = 0.1D) beneath the cone is

replaced by the cone material (Figure 1(c)). In practice,

Figures 1(b) and (c) represent the incremental 3 VALIDATION RESULTS

penetration of the cone. To increase the penetration

3.1 During CPT penetration

3.1.1 Comparison with Sheng et al. (2014)

Following the simulation example in Sheng et al.

(2014), a fully undrained and drained penetration were

associated with penetration rates (v) of 2 m/s and

0.000002 m/s. A validation study of cone resistance at

different rates were reported in Chia et al. (2022).

Figure 1. PRM process for cone penetration.

2 NUMGE 2023 - Proceedings

The effects of partial drainage on the interpretation of pore pressure dissipation test data: a numerical study

Figure 2. Pore pressure development at 10H/D

Figure 4. Radial profile of Δu2/σ’v0 at 6R (11cm) penetra-

tion depth from ground surface.

3.1.2 Comparison with Ceccato et al. (2016) and

Orazalin (2017)

Results from an identical cone penetration set-up in

normally consolidated kaolin clay were reported in

Ceccato et al. (2016) and Orazalin (2017). Both

publications adopted different numerical techniques and

modified cam-clay (MCC) soil model to model the

same penetration process. The numerical methods are

Material Point Method (MPM) and Lagrangian finite

element with automated remeshing, respectively. To

simulate partially drained behaviour, a constant

Figure 3. Variation of Δumax with v/k of present study and penetration rate v = 0.020 m/s was used, and hydraulic

results from Sheng et al. (2014) conductivity k (ms-1) was varied. Subsequently, the

extent of consolidation due to drainage was quantified

A monitoring location at depth 10H/D (from ground using the normalised velocity term V=vD/cv (Randolph

surface) and radial distance R (from centre of cone) was and Hope, 2004), where cv is the consolidation

chosen, where, H and D are, respectively, the coefficient of the soil given in Equation (1), λ denotes

penetration depth and cone diameter. At this location, the virgin compression index, e0 is the initial void ratio,

the pore pressure development during penetration was σ’v0 is the effective vertical stress, and γw is the unit

monitored. Figure 2 illustrates the pore pressure weight of water.

development for v (m/s) = 2, 0.2, 0.02, 0.002, 0.0002

and 0.00002. When the x-axis value is 0, the cone tip 𝑘∙(1+𝑒0 )

coincides with the monitoring point. 𝑐𝑣 = ∙ 𝜎′𝑣0 (1)

𝛾𝑤 ∙𝜆

The peak excess pore pressure was observed when

the cone tip was at a depth of 0.86D below the monitor- The following V values were used: V=1200

ing point. At this instance, the cone shoulder position (undrained respond), V=12 & 1.2 and V=0.012 (drained

(u2) coincides with the monitoring point. For an response). Figure 4 plots the normalised excess pore

undrained penetration, PRM estimates a maximum pore pressure (Δu2/σ’v0) radial profile of the cone at 6R depth

pressure of 158kPa, a 2% difference from results from ground surface. Included in Figure 4 are the

reported in Sheng et al. (2014). reported results (Orazalin, 2017) for V=502.1

Figure 3 shows the pore pressure backbone curve (undrained response) and V=12. For points very close to

obtained by plotting Δumax (from Figure 2) against the cone shaft, the present PRM study predicts slightly

normalised penetration rate (v/k), where k denotes the larger Δu2/σ’v0 values compared to Orazalin’s results.

hydraulic conductivity of the soil. Figure 3 also Beyond the normalized distance of about 2R from the

includes reported results from Sheng et al. (2014). cone shaft, the PRM results and Orazalin’s results show

There is good results from Sheng et al. (2014). A good good agreement.

agreement between the PRM results and those

published in the literature.

3 NUMGE 2023 - Proceedings

Finite element, finite difference, discrete element, material point and other methods

Figure 5 plots the variation of Δu2/Δu2undrained at the to 8, with the excess pore pressure (Δu2) showing a

cone shoulder with increasing dimensionless velcocity slight increase initially (at very small values of the

V (Randolph and Hope, 2004), in which Δu2 is the normalized time) before decreasing monotonically with

excess pore pressure at the cone shoulder measured at time. Non-standard decay curves were observed and

varying penetration rates and Δu2undrained the excess pore adjusted via the root time method (Taylor, 1948). A

pressure from an undrained penetration. Included in detailed execution of this method has been explained in

Figure 5 are the results taken from Ceccato et al. (2016) Mahmoodzadeh and Randolph (2014). Dissipation

and Orazalin (2017). It can be seen that the PRM results results from the undrained penetration case were

show good agreement with those obtained using processed using the theoretical solution of Equation (3)

different numerical techniques (Ceccato et al., 2016; (Teh and Houlsby, 1991) to obtain a ch value of 5.2 x

Orazalin, 2017). 10-7 m2s-1. Thereafter, the modified time factor T* (Teh

A backbone curve describing the change in and Houlsby, 1991) corresponding to t(s) were

Δu2/Δu2undrained with the normalised penetration rate V calculated using Equation (4), where ch denotes the

was fitted following Equation (2) (DeJong and coefficient of consolidation calculated from dissipation

Randolph, 2012; Ceccato et al., 2016), whereby V50 test, and Ir is the rigidity index of the soil.

denotes the normalised velocity required to mobilize an 𝑐ℎ 𝑡50

excess pore pressure that is 50% of the fully undrained 𝑑2 √𝐼𝑟

= 0.06125 (3)

condition and c is the maximum rate of change of

𝑐ℎ 𝑡

Δu2/Δu2undrained with V. For this simulation V50=3 and 𝑇∗ = (4)

𝑑2 √𝐼𝑟

c=1.1.

For each penetration rate (V=78.5, 11.8, 3.5, 1.2 and

∆𝑢2 1 0.35), the Δu2 value from the dissipation test is

=1− 𝑐 (2)

∆𝑢2𝑢𝑛𝑑𝑟𝑎𝑖𝑛𝑒𝑑 1+(

𝑉

) normalised by Δu2initial (obtained via root time method)

𝑉50

and plotted against T*, as shown in Figures 6-8 for T*

corresponding to V=78.5, 3.5 and 0.35. Included in

Figures 6 to 8 are results reported from Mahmoodzadeh

et al. (2014). The minor differences observed might be

attributed to different cone diameter (D) used in the

present PRM study and Mahmoozadeh et al. (2014),

although this difference has, in principle, been

accounted for through the dimensional velocity V and

modified time factor T*.

Figure 5. Variation of normalised excess pore pressure

(Δu2/Δu2undrained) with V.

3.2 During dissipation tests

Figure 6. Normalised excess pore pressure decay curve

PRM analyses were also performed to simulate the with T*, V=78.5 (undrained)

centrifuge CPT experiments reported in

Mahmoodzadeh and Randolph (2014) and

Mahmoodzadeh et al. (2014). The penetrations were

conducted at corresponding dimensionless velocity V

values of 78.5 (undrained), 11.8, 3.5, 1.2 and 0.35. The

cone was held stationary upon penetration to a depth of

16H/D, and the excess pore pressures that developed

were allowed to dissipate. The pore pressure dissipation

response from the PRM simulations were plotted and

compared with the results reported in Mahmoodzadeh

and Randolph (2014). The dissipation curves generally

exhibit the reverse S-shaped profile shown on Figures 6 Figure 7. Normalised excess pore pressure decay curve

with T*, V=3.5 (Partially drained)

4 NUMGE 2023 - Proceedings

The effects of partial drainage on the interpretation of pore pressure dissipation test data: a numerical study

The experimental results of Mahmoodzadeh et al.

(2014) show that dissipation tests conducted following

penetration at different rates would result in a rightward

shift of the dissipation curve. This observation is

illustrated in Figure 9, which shows the decay behaviour

of excess pore pressure generated from different rates of

penetration. It is clearly seen that the t50 value (from the

dissipation test) increases as the rate of penetration

decreases. Consequently, the variation of t50 (s) caused

by different penetration rates would result in multiple

interpretations of the ch value if the conventional ch

Figure 8. Normalised excess pore pressure decay curve interpretation (Teh and Houlsby, 1991) is applied

with T*, V=0.35 (drained)

Overall, there is good agreement between the

dissipation curves obtained numerically in this study

and the centrifuge results reported by Mahmoodzadeh

et al. (2014). In this respect, PRM is shown to be a

viable method to simulate the cone penetration process

at different rates as well as the excess pore pressure

response during the subsequent dissipation test.

4 INTERPRETATION OF DISSIPATION

TEST DATA FOLLOWING PARTIALLY

DRAINED PENETRATIONS

By processing the dissipation results from an undrained

penetration using the theoretical solution of Teh and

Hously (1991), a reasonable estimate of the ch value can Figure 10: Variation of t50/t50,undrained with V/V50 with pub-

be made. Where partial consolidation occurs during lished literatures.

penetration, as a result of different drainage scenarios,

it is difficult to accurately obtain a unique solution. This By processing the experimental dissipation data from

is because the extent of drainage can vary depending on Mahmoodzadeh et al. (2014), a relationship between t50

the penetration rate and the consolidation properties of and V is presented in Figure 10, where t50 is normalised

the soil. However, a framework accounting for by t50,undrained and V by V50 (from Equation (2)). The term

interpretation errors in ch value caused by partially t50,undrained denotes the time taken for 50% excess pore

drained penetrations can be introduced. This is done by pressure dissipation following an undrained

first understanding the relationship between t50 and penetration. For this illustration, V50 = 4.0. Figure 10

dimensionless velocity (V). plots the variation of normalised time (t50/t50,undrained)

with normalised velocity, V/V50. An “inverse-S’ trend

was observed. Also included in Figure 10 are the

processed dissipation results from other published

sources (Schneider et al., 2007; Ceccato and Simonini,

2017).

The processed data in Figure 10 supports the trend

observed between t50/t50,undrained and V/V50. The ratio

t50/t50,undrained remains relatively constant (with slight

variation) as the penetration process approaches the

drained condition. For simplicity, it is assumed that

t50/t50,undrained remains constant.

The trend presented in Figure 10 can be

approximated by the function presented in Equation (5),

whereby t50, limiting is the limiting value that t50

approaches as the penetration rate decreases, and w and

m are fitting constants.

Figure 9: Normalised excess pore pressure decay with

time.

5 NUMGE 2023 - Proceedings

Finite element, finite difference, discrete element, material point and other methods

Ceccato, F., Beuth, L., & Simonini, P. (2016). Analysis of

𝑡

piezocone penetration under different drainage conditions

( 50,𝑑𝑟𝑎𝑖𝑛𝑒𝑑 )−1 with the two-phase material point method. Journal of

𝑡50 𝑡50,𝑢𝑛𝑑𝑟𝑎𝑖𝑛𝑒𝑑

𝑡50,𝑢𝑛𝑑𝑟𝑎𝑖𝑛𝑒𝑑

= (1 + 1+𝑤∙(𝑉⁄𝑉50 )

𝑚 ) (5) Geotechnical and Geoenvironmental

Engineering, 142(12), 04016066.

Ceccato, F., & Simonini, P. (2017). Numerical study of

According to the results plotted in Figure 10, the partially drained penetration and pore pressure dissipation

approximate values of t50,limiting/t50,undrained, w and m are in piezocone test. Acta Geotechnica, 12(1), 195-209.

2.6, 1.2 and 1.1 respectively. Equation (5) can be used Chai, J., Sheng, D., Carter, J. P., & Zhu, H. (2012).

Coefficient of consolidation from non-standard piezocone

to estimate t50,undrained from t50 when the fitted constatnts

dissipation curves. Computers and Geotechnics, 41, 13-

are known. A limitation of Equation (5) is that it cannot 22.

be applied readily to estimate ch. A direct relationship Chia, R. W. L., Wang, Z. Z., & Goh, S. H. (2022). Validating

between ch with t50 needs to be established in Equation cone penetration test in partially drained conditions using

(5). This will be presented and discussed in an a simplified numerical modelling method. In Cone

upcoming publication currently under preparation. Penetration Testing 2022 (pp. 317-324). CRC Press.

Engin, H. K., Brinkgreve, R. B. J., & Van Tol, A. F. (2015).

Simplified numerical modelling of pile penetration–the

5 CONCLUSION press‐replace technique. International Journal for

Numerical and Analytical Methods in

This article adopts a simplified approach, the Press- Geomechanics, 39(15), 1713-1734.

Replace Method (PRM), to model the Cone Penetratiton Lim, Y. X., Tan, S. A., & Phoon, K. K. (2018). Application

Test (CPT). PRM is readily implemented using a small of press-replace method to simulate undrained cone

strain finite element program. In this study, PRM was penetration. International Journal of

adopted to simulate cone penetration in which there is Geomechanics, 18(7), 04018066.

consolidation concurrently taking place. This is done by Mahmoodzadeh, H., & Randolph, M. F. (2014). Penetrometer

testing: effect of partial consolidation on subsequent

applying different rates of cone penetrations. This

dissipation response. Journal of Geotechnical and

paper compares the excess pore pressure response for 4 Geoenvironmental Engineering, 140(6), 04014022.

examples taken from the published literature. Mahmoodzadeh, H., Randolph, M. F., & Wang, D. (2014).

First, consolidation analyses were carried out and the Numerical simulation of piezocone dissipation test in

effects of partial drainage (during penetration) studied clays. Géotechnique, 64(8), 657-666.

and validated. Using published results from Sheng et Orazalin, Z. Y. (2017). Analysis of large deformation

al. (2014), Orazalin (2017), Ceccato et al. (2016), the offshore geotechnical problems in soft clay (Doctoral

PRM pore pressure predictions were validated using dissertation, Massachusetts Institute of Technology).

radial profiles and backbone curves relating the excess Paniagua, P., Nordal, S., & Engin, H. K. (2014). Back

pore pressure behaviour with normalised velocity. Next, calculation of CPT tests in silt by the Press-Replace

technique.

as part of this validation study, a dissipation test using

Randolph, M., & Hope, S. (2004). Effect of cone velocity on

the centrifuge setup reported by Mahmoodzadeh et al. cone resistance and excess pore pressures. Proc. 1st Int.

(2014) and Mahmoodzadeh and Randolph (2014) was Symp. on Engineering Practice and Performance of Soft

simulated using PRM. The predicted profiles of pore Deposits, Osaka, 147–152.

pressure decay with T* compare well with those Robertson, P. K., & Cabal, K. L. (2015). Guide to cone

reported in the published literature. penetration testing for geotechnical engineering. Gregg

As an extension to this study, the effects of partially Drilling & Testing, Inc, 6.

drained penetrations on the subsequent disspation tests Schneider, J. A., Lehane, B. M., & Schnaid, F. (2007).

and ch interpretation errors were highlighted and Velocity effects on piezocone measurements in normally

discussed. A relationship between t50 and V was and over consolidated clays. International Journal of

Physical Modelling in Geotechnics, 7(2), 23-34.

established and illustrated graphically.

Sheng, D., Kelly, R., Pineda, J., & Bates, L. (2014).

Numerical study of rate effects in cone penetration test.

In 3rd international symposium on cone penetration

6 REFERENCES testing (pp. 419-428).

Andersen, K. H., Andresen, L., Jostad, H. P., & Clukey, E. C. Teh, C. I., & Houlsby, G. T. (1991). An analytical study of

(2004, January). Effect of skirt-tip geometry on set-up the cone penetration test in clay. Geotechnique, 41(1), 17-

outside suction anchors in soft clay. In International 34.

Conference on Offshore Mechanics and Arctic Wang, Z. Z., & Goh, S. H. (2018). Spudcan installation and

Engineering (Vol. 37432, pp. 1035-1044). post installation behaviour in soft clay: The press-replace

method. In Numerical Methods in Geotechnical

Engineering IX (pp. 1503-1510). CRC Press

6 NUMGE 2023 - Proceedings

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Arenas Et Al. 2023 - Numerical Assessment of Drilling-Induced Static Liquefaction Triggering of Feijao Dam IDocument7 pagesArenas Et Al. 2023 - Numerical Assessment of Drilling-Induced Static Liquefaction Triggering of Feijao Dam IBOOBOONo ratings yet

- Dose LimitsDocument3 pagesDose LimitsBOOBOONo ratings yet

- Radiation Safety Act 1975 - (04-c0-01)Document60 pagesRadiation Safety Act 1975 - (04-c0-01)BOOBOONo ratings yet

- Sottile Et Al. 2023 - Numerical Study of MT and End Platens Lubrication Effect On Undrained Triaxial TestsDocument7 pagesSottile Et Al. 2023 - Numerical Study of MT and End Platens Lubrication Effect On Undrained Triaxial TestsBOOBOONo ratings yet

- Radiation Safety (Transport of Radioactive Substances) Regulations 2002 - (00-c0-00)Document10 pagesRadiation Safety (Transport of Radioactive Substances) Regulations 2002 - (00-c0-00)BOOBOONo ratings yet

- Corrego Feijao Thesis Summary-Steve-EmermanDocument3 pagesCorrego Feijao Thesis Summary-Steve-EmermanBOOBOONo ratings yet

- Solans Et Al. 2023 - Impact of Foundation Layer Characteristics On The Seismic Response of A Tailings DamDocument7 pagesSolans Et Al. 2023 - Impact of Foundation Layer Characteristics On The Seismic Response of A Tailings DamBOOBOONo ratings yet

- 1229-Referral-Annexure 3 King Data CVRDDocument69 pages1229-Referral-Annexure 3 King Data CVRDBOOBOONo ratings yet

- The Effect of Salts On The Rate of EvaporationDocument7 pagesThe Effect of Salts On The Rate of EvaporationBOOBOO100% (1)

- Aviles and Pinyol 2023 - The Construction Process With MPMDocument7 pagesAviles and Pinyol 2023 - The Construction Process With MPMBOOBOONo ratings yet

- Tasso Et Al. 2023 - Seismic Liquefaction Potential Assessment by Means of Automated Numerical ModellingDocument7 pagesTasso Et Al. 2023 - Seismic Liquefaction Potential Assessment by Means of Automated Numerical ModellingBOOBOONo ratings yet

- Feijao Dam I Expert Panel Appendix J Glossary ENGDocument9 pagesFeijao Dam I Expert Panel Appendix J Glossary ENGBOOBOONo ratings yet

- 2023 Fees and ChargesDocument3 pages2023 Fees and ChargesBOOBOONo ratings yet

- 37 Édgar Quiroz FINAL PAPER OKDocument19 pages37 Édgar Quiroz FINAL PAPER OKBOOBOO100% (1)

- SIRGAS2000Document15 pagesSIRGAS2000BOOBOONo ratings yet

- Corrego Feijao Safety Audit SummaryDocument3 pagesCorrego Feijao Safety Audit SummaryBOOBOONo ratings yet

- 03b - Applying Dam Breach Analytical ResultsDocument7 pages03b - Applying Dam Breach Analytical ResultsBOOBOONo ratings yet

- 34 Nathalia Costa FINAL PAPER OKDocument9 pages34 Nathalia Costa FINAL PAPER OKBOOBOONo ratings yet

- 25 Jasna Zúñiga FINAL PAPER OKDocument9 pages25 Jasna Zúñiga FINAL PAPER OKBOOBOONo ratings yet

- 26 Osvaldo Aduvire FINAL PAPER OKDocument9 pages26 Osvaldo Aduvire FINAL PAPER OKBOOBOONo ratings yet

- Moon Et Al. 2019 - Advances in Non-Newtonian Dam Break StudiesDocument8 pagesMoon Et Al. 2019 - Advances in Non-Newtonian Dam Break StudiesBOOBOONo ratings yet

- 2-16 Use of CPTuDocument10 pages2-16 Use of CPTuBOOBOONo ratings yet

- 00 AgendaDocument1 page00 AgendaBOOBOONo ratings yet

- 3-09 Effect of Artesian GroundwaterDocument8 pages3-09 Effect of Artesian GroundwaterBOOBOONo ratings yet

- Quelopana 2019 - Released Volume Estimation For Dam Break AnalysisDocument13 pagesQuelopana 2019 - Released Volume Estimation For Dam Break AnalysisBOOBOONo ratings yet

- Quelopana 2016 - Tailings Beach Slope Forecasting - An Empirical ModelDocument14 pagesQuelopana 2016 - Tailings Beach Slope Forecasting - An Empirical ModelBOOBOONo ratings yet

- 00 - Presenter BiosDocument3 pages00 - Presenter BiosBOOBOONo ratings yet

- Ulrich and Coffin 2013 - Considerations For Tailings Facility Design and Operation Using Filtered TailingsDocument10 pagesUlrich and Coffin 2013 - Considerations For Tailings Facility Design and Operation Using Filtered TailingsBOOBOONo ratings yet

- Froehlich - 2016 - Empirical Model of Embankment Dam BreachingDocument9 pagesFroehlich - 2016 - Empirical Model of Embankment Dam BreachingBOOBOONo ratings yet

- Ulrich 2019 - Practical Thoughts Regarding Filtered TailingsDocument10 pagesUlrich 2019 - Practical Thoughts Regarding Filtered TailingsBOOBOONo ratings yet