Professional Documents

Culture Documents

Check List For 33 KV Transmission Pole Line

Check List For 33 KV Transmission Pole Line

Uploaded by

Shrikanth SolaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List For 33 KV Transmission Pole Line

Check List For 33 KV Transmission Pole Line

Uploaded by

Shrikanth SolaCopyright:

Available Formats

Doc. No.

: EEPL/ELE/33 KV/F-2

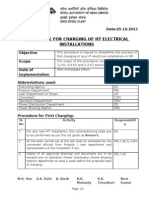

CHECK LIST FOR 33KV TRANSMISSION POLE LINE Rev No. 00

Date: 30.04.2023

Project Name : Date:

Package Name: Drawing No:

Contractor Name: Customer Name:

Scope: 33 kV Electrical Line Erection (Internal/ External) Name of Feeder:

From Location: To Location: Length of the Line inspected:

Total No of Poles: No of CPs: No of SPs/ PPs:

Sr. Type of Checks Pole- 1 Pole- 2 Pole- 3 Pole- 4 Pole- 5 Pole- 6 Pole- 7 Pole- 8 Pole- 9 Pole- 10

Description of Checks

No

Pole type

Pre-Erection

Carryout the dimensional checks of poles, channels,

angles, conductors, insulators, hardware's &

Visual/ Measurements/

1 accessories before erection & ensure correct supply

as per work order/ approvals Test Reports

Check no damages, dent, bend, rust for line

2 materials Visual

Check Bitumen paint done at bottom, 1/6th of the

3 pole length (If mentioned in approved drawings) Visual/ Measurements

Check peg marking of poles as per survey

4 Visual

drawing/points

Check the Pole bore depth & diameter as per

5 approved drawing Visual/ Measurements

Check if water found in bore, dewatering should be

6 done before concreting Visual

Pole Erection

Check dia of base round plates & fixing

Visual/

1 arrangement done at bottom of poles before

concreting (As per drawing) Measurements

Check for pole positioning with min.cover from all Visual/

2

sides & vertical alignment Measurements

Check concreting grade & work done as per Uniformity, No cracks/

3 drawing

damages

Check during concreting, poking rod used for

4 compaction Uniform and compacted

Check Pole coping & Muffing done as as per Visual/

5 drawing

Measurements

Check white wash done for pole copping if

6 mentioned in drawing Visual

7 Check curing of pole concreting Visual

Check distance between the poles as per

8 Visual/Measurements

survey/drawing

Hardware Fitting

Check mounting, fixing of pole channels, cross-

arms, angles, conductors, insulators, hardware's &

Visual/

1 other accessories done as per approved drawing

Measurements

Check for stay concreting,

2 stay sets rigidness, fitment & tightness Visual

Check all the bolted joints should be tightened

properly by providing suitable size GI bolts, nuts,

3 with flat & spring washers Visual

Check rating, fixing, binding & tighness of insulators

4 with accessories are done properly Visual

Span Stringing work

Check the Surface condition of conductor for any

1 damages/ untwisting Visual

Check the size & type of stringing conductor as per Visual/

2

drawing/specification Measurements

Check the conductors shall be continuously

observed for loose or broken strands during

stringing.

3 Repair of conductors shall be carried out with Visual

repair sleeves & not more than one repair sleeve

will be used in one span

Check the mid span joints on the conductor shall be

compression type & check no joints shall be made

4 in spans crossing over main roads, railway line and Visual

small river spans

Check for proper tensioning & sag of line span

5 Visual

Check for proper Phase to Phase/Phase to Ground Visual/

6

clearance as per drawing Measurement

Check Jumpering done as per drawing with suitable

7 hardware/clamps Visual

fitments & tightess of nut, bolts

Check for pole earthing done as per drawing

8 Visual

Check tree cutting & tree trimming done through

9 entire route of line Visual

Accessories Works

Check and ensure for Guarding work at road/ line

1 Visual

crossing

Check fixing of anti climbing device

(min 1.2M length), Danger board, Bird guard, Phase Visual/

2

plates,Bird Reflector as per drawing Measurement

3 Check for Pole & Feeder numbering Visual

Pre-Commissioning

Check completeness of line for pre-commissioning

1 Visual

2 Check IR test for completed line Measurement

Comments/Remarks:

Contractor ER-Project ER-Quality Customer

Signature

Name & Designation

Name of Company

Date

You might also like

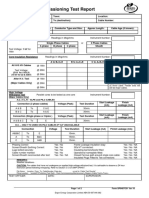

- Site Test Procedure and Report For Bus Duct: Commissioning FormDocument7 pagesSite Test Procedure and Report For Bus Duct: Commissioning Formimrankhan zNo ratings yet

- Electrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Document5 pagesElectrical Notes & Articles: Minimum Electrical Clearance As Per BS:162Shrikanth Sola100% (1)

- Procedure For First Charging Oh HT InstallationDocument7 pagesProcedure For First Charging Oh HT InstallationMadhu KrishnaNo ratings yet

- Saudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 ElectDocument7 pagesSaudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 Electkarthi51289No ratings yet

- SAP 8000 Registry For Contractor/Sub-Contractor QC PersonnelDocument2 pagesSAP 8000 Registry For Contractor/Sub-Contractor QC PersonnelMudabbir HussainNo ratings yet

- Cable Test Sheet After InstallationDocument1 pageCable Test Sheet After InstallationAhmad DagamsehNo ratings yet

- 1.6 Kva Transformer Testing ReportDocument5 pages1.6 Kva Transformer Testing ReportVikrant DeshmukhNo ratings yet

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- KRA KPI DepartmentDocument6 pagesKRA KPI DepartmentShrikanth Sola100% (1)

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth SolaNo ratings yet

- 2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTDocument25 pages2022-07-14 - D - Approved Tunnel Earthing Plan For Package-3 - MRTBhawani NayakNo ratings yet

- IPBD Instruction Manual PDFDocument41 pagesIPBD Instruction Manual PDFrobinknit2009No ratings yet

- Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Electkarthi51289No ratings yet

- Cable Gland, Cable & Wire Installation ProcedureDocument14 pagesCable Gland, Cable & Wire Installation ProcedureIsaalexNo ratings yet

- QCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)Document15 pagesQCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)arockiyathassNo ratings yet

- 10 - Test Format For Metering Instruments TestingDocument3 pages10 - Test Format For Metering Instruments TestingGajendran SriramNo ratings yet

- Method Statement of HV TestDocument4 pagesMethod Statement of HV TestRavi Kumar80% (5)

- Cable Gland Seal & Conduit Seal InstallationDocument19 pagesCable Gland Seal & Conduit Seal InstallationTariqMalikNo ratings yet

- Saudi Aramco Test ReportDocument3 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 pagesCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarNo ratings yet

- SP0407C01 HV Cable Commissioning Test ReportDocument2 pagesSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantNo ratings yet

- MV Cable Hi-Pot Test ShetDocument1 pageMV Cable Hi-Pot Test ShetAhmad Dagamseh100% (1)

- ACB ChecklistDocument3 pagesACB ChecklistShan TanuNo ratings yet

- Requirements For 69kV Transmission Line LatestDocument1 pageRequirements For 69kV Transmission Line LatestCatrina FedericoNo ratings yet

- Earth Pit Test ReportDocument2 pagesEarth Pit Test ReportKOSAKA LABNo ratings yet

- 8BK88PLUSDocument8 pages8BK88PLUSSwapnil PatilNo ratings yet

- MS of 220 KV Switchyard EquipmentDocument8 pagesMS of 220 KV Switchyard EquipmentFareh KhanNo ratings yet

- Operation Manual For Electrical EquipmentDocument86 pagesOperation Manual For Electrical EquipmentGunawan sitinjakNo ratings yet

- Package-A: Supply & Erection Schedule (R1) : New 33 KV Overhead Line by Panther Conductor - Total Qty. 412 CKMDocument55 pagesPackage-A: Supply & Erection Schedule (R1) : New 33 KV Overhead Line by Panther Conductor - Total Qty. 412 CKMAkd DeshmukhNo ratings yet

- PR 15D ManualDocument5 pagesPR 15D ManualJonathan GarcésNo ratings yet

- 11 KV VCB - BrihoDocument95 pages11 KV VCB - BrihobanuNo ratings yet

- Modutec IEC 61439 Asta Bonanza - ABBDocument23 pagesModutec IEC 61439 Asta Bonanza - ABBRamani ManiNo ratings yet

- SAT PROCEDURE FOR MV SWGR PANELS - PdfToWordDocument4 pagesSAT PROCEDURE FOR MV SWGR PANELS - PdfToWordAmr ElkadyNo ratings yet

- Chloride FP 40r Ds en GL 0616 Rev6Document2 pagesChloride FP 40r Ds en GL 0616 Rev6Tanveer Ahmed100% (1)

- Inspection and Test Plan: Project NameDocument2 pagesInspection and Test Plan: Project NameehteshamNo ratings yet

- Erection Procedure For Control Battery - LatestDocument12 pagesErection Procedure For Control Battery - LatestAnmohieyNo ratings yet

- Erection Procedure For 6.6 KV Bus DuctDocument7 pagesErection Procedure For 6.6 KV Bus DuctAnmohieyNo ratings yet

- High Pot Test ProcedureDocument5 pagesHigh Pot Test Procedurebookbum100% (1)

- INSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVDocument6 pagesINSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanNo ratings yet

- 01-MCC310 Single Line Diagram For UCD4 MCC of TLM PlantDocument17 pages01-MCC310 Single Line Diagram For UCD4 MCC of TLM PlantVidiya NovelinNo ratings yet

- Motor Check ListDocument7 pagesMotor Check ListPrateek Kumar SinghNo ratings yet

- Lightning Protection System Installation Works Inspection ChecklistDocument1 pageLightning Protection System Installation Works Inspection ChecklistReda HamedNo ratings yet

- 2nd Floor MDC - CONTINUITY - TEST - FORM - (PRE - AND - POST - ENER) FR-06-EMCD-A-EE-001-rev0Document2 pages2nd Floor MDC - CONTINUITY - TEST - FORM - (PRE - AND - POST - ENER) FR-06-EMCD-A-EE-001-rev0Kris Tolentino100% (2)

- LV Cable TEST ON REELDocument2 pagesLV Cable TEST ON REELMalik MalikNo ratings yet

- Field Test PlanDocument8 pagesField Test PlanMohammed TauseefNo ratings yet

- Motors Solo Run TestDocument2 pagesMotors Solo Run TestSureshYarlagaddaNo ratings yet

- Aux Transformer TestDocument4 pagesAux Transformer TestEngr Fahimuddin QureshiNo ratings yet

- HV Power Cable TestDocument9 pagesHV Power Cable TestMohammad Nasar100% (1)

- Spec EarthingDocument9 pagesSpec EarthingsbpathiNo ratings yet

- 007 LV & Control Cable Pre-CommissioningDocument6 pages007 LV & Control Cable Pre-CommissioningMohamed KasemNo ratings yet

- Broucher First Training of NEC 2023 at NITS NoidaDocument6 pagesBroucher First Training of NEC 2023 at NITS Noidaambadi.ma1955No ratings yet

- Mechanical Completion L.V. Power, Control and Telecomm / Instrument CablesDocument4 pagesMechanical Completion L.V. Power, Control and Telecomm / Instrument CablesJalal AlbadriNo ratings yet

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- QCS 2014 - Colours of Ducts Pipes Cables and Marker Warning TapesDocument2 pagesQCS 2014 - Colours of Ducts Pipes Cables and Marker Warning TapesBalaji Naik100% (1)

- 16139-Cable TraysDocument4 pages16139-Cable TraysNATHANNo ratings yet

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 pagesInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoNo ratings yet

- Quality Plan and Checklist (Electrical Condut & Raceways) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (Electrical Condut & Raceways) - Sandvik G BlockParasNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument and Control CablesDocument2 pagesSaudi Aramco Pre-Commissioning Form: Instrument and Control Cableszahid1078No ratings yet

- 11kV Switchgear SchemesDocument17 pages11kV Switchgear SchemesEdciel EbuenNo ratings yet

- Certificate of Calibration and Conformance: OmicronDocument1 pageCertificate of Calibration and Conformance: OmicronNadiaNo ratings yet

- Interoffice Memorandum: 11411E1111Iitah 0iiii Gas 13,.V, Co 'Document4 pagesInteroffice Memorandum: 11411E1111Iitah 0iiii Gas 13,.V, Co 'will bill100% (1)

- A7 CSI Ku Module EL Inspection SpecificationDocument12 pagesA7 CSI Ku Module EL Inspection SpecificationShrikanth SolaNo ratings yet

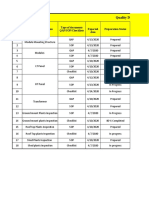

- SL - No SL - No Action ItemsDocument3 pagesSL - No SL - No Action ItemsShrikanth SolaNo ratings yet

- Generation Detail of Last One Year-19Document232 pagesGeneration Detail of Last One Year-19Shrikanth SolaNo ratings yet

- Project DetailsDocument1,325 pagesProject DetailsShrikanth SolaNo ratings yet

- Trafo Oil Testing TypesDocument10 pagesTrafo Oil Testing TypesShrikanth SolaNo ratings yet

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- Quality Department Document StatusDocument3 pagesQuality Department Document StatusShrikanth SolaNo ratings yet

- Transformer Oil & Its EvolutionDocument7 pagesTransformer Oil & Its EvolutionShrikanth SolaNo ratings yet

- Cell-To-Module Conversion Loss Simulation For Shingled-Cell ConceptDocument5 pagesCell-To-Module Conversion Loss Simulation For Shingled-Cell ConceptShrikanth SolaNo ratings yet