Professional Documents

Culture Documents

Controlador de Rampa Manual

Uploaded by

Nelson RaulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controlador de Rampa Manual

Uploaded by

Nelson RaulCopyright:

Available Formats

MFZ Antriebe GmbH & Co.

KG

Neue Mühle 4

D-48739 Legden

Operation Instructions RS200L EN

EN 1 Contents

1 Contents 2

2 Key to symbols 2

3 General safety instructions 2

4 Overview of products 3

5 Initial Operation - General instructions 5

6 Initial Operation 5

7 Protection against uncontrolled movements 6

8 Overload protection 7

9 Error messages and rectification 7

10 Technical data 7

2 Key to symbols

Danger of personal injury!

The safety instructions must be observed!

Warning! Danger to property!

The safety instructions must be observed!

Information

Special information OR

Reference to other sources of information

3 General safety instructions

Guarantee

The function and safety of the equipment is only guaranteed if the warning and safety instructions

included in these operating instructions are adhered to.

MFZ Antriebe GmbH & Co. KG is not liable for any personal injury or damage to property that occurs as a

result of the warning and safety instructions being disregarded.

Using the equipment for its intended purpose

The RS200L controls are designed only for dock levellers with hinged lip.

Target group

Only qualified and trained electricians may connect, program and service the controls.

Qualified and trained electricians meet the following requirements:

• knowledge of the general and specific safety and accident prevention regulations,

• knowledge of the relevant electrical regulations,

• trained in the use and care of appropriate safety equipment,

• capable of recognising the dangers associated with electricity.

Instructions for installation and connection

• The controls must be disconnected from the electricity supply before carrying out electrical works. It

must be ensured that the electricity supply remains disconnected during the works.

• Local protective regulations must be complied with.

RS200L / Rev.A 02 Page 2 of 8

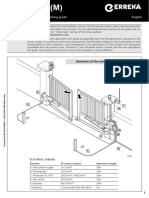

4. Overview of products - housing EN

EN

Key

A: Button leveller up

B: mains switch

Page 3 of 8 RS200L / Rev.A 02

EN 4.2 Overview of products - PCB

Key:

L1, L2, L3, N, PE:

terminal block

mains connection

S1 … S6:

connection mains switch

230 / 400

U, V, W, PE: terminal block

hydraulic unit

3, 4, 5: terminal block interlock

LE1 door - leveller

1,2: terminal block valve

S5/S6

S1: socket for push button

leveller up

S3/S4

230/400: terminal block

adjustment of mains voltage

S1

S1/S2 K1 : Relay valve

NO

J1

NC

K2 : Contactor

hydraulic unit

1 2 3 4 5 F1-F3: overload protection

U V W PE PE L1 L2 L3 N

F4 : Resettable PTC

TR1: Transformer

RS200L / Rev.A 02 Page 4 of 8

5 Initial Operation – general instructions EN

EN

Warning!

To guarantee that the equipment functions properly, the following points must be

ensured:

- The dock leveller is installed and operational.

- The command and safety devices are installed and ready for operation.

- The control housing with the RS200 is installed..

Information:

For the installation of the dock leveller, the hydraulic unit and the command and

safety devices, the relevant manufacturer’s instructions are to be adhered to.

Mains connection

Danger!

To guarantee that the controls function properly, the following points must be ensured:

- The mains voltage must correspond to the voltage stated on the type plate.

- For a three-phase current, a clockwise rotating field is required.

- For a three-phase connection, only 3-way automatic circuit breakers (10A) may be

used.

Warning!

Before switching on the controls for the first time, a check must be carried out after

completing the wiring to ensure that all the motor connections at the motor and at the

controls are securely fixed. All control voltage inputs are galvanically isolated from the

supply.

6 Initial Operation

Mains voltage adjustment X5 X4 X3 X5 X4 X3

A wrong adjustment of the mains

voltage can destroy the control.

230V

400V

230V

400V

Factory setting 400V

Mains supply PE PE L1 L2 L3 N1

400V 3~/PE

230V 3~/PE

Mains switch

L1'

L2'

L3'

S2 S4 S6

S1 S3 S5

L1

L2

L3

Page 5 of 8 RS200L / Rev.A 02

EN

Connection dock leveller

PE

PE

1 2 3 4 5 U V W

U, V, W, PE: hydraulic unit

For a three-phase current, a clockwise

Y1

rotating field is required.

M

1/2: Y1 valve

push button leveller up S1

interlock door – leveller: 1 2 3 4 5 1 2 3 4 5

J1 J1

potential-free switch NO NO

NC NC

+ IN - + IN -

NO or NC switches can be used alternatively.

If the jumper J1 is in position J1=NC and no

switch is connected, the input must be

bridged (+ to IN).

interlock door – leveller: 1 2 3 4 5 1 2 3 4 5

J1 J1

Sensor PNP open collector NO NO

NC NC

+ IN - + IN -

NO or NC sensors can be used alternatively.

brown

brown

If the jumper J1 is in position J1=NC and no

black

black

blue

blue

sensor is connected, the input must be Sensor NC Sensor NO

pnp open collector pnp open collector

bridged (+ to IN).

RS200L / Rev.A 02 Page 6 of 8

7. Protection against uncontrolled movements EN

EN

The control RS200L possesses an integrated protection circuit against uncontrolled movements. It is

activated if during normal operation an emergency stop signal is given to the dock leveller or if voltage

supply is interrupted. After release of the emergency stop or power up, the dock leveller the valve stay

closed, until the push button leveller up button is activated.

8. Overload protection

The control RS200L possesses an integrated overload circuit for the hydraulic unit. Each phase is

examined for overload. As soon as this is the case, the contactor switches automatically off. Further the

circuit is secured against phase failure. Both errors are signalled by the red LED LE1.

.

9. Error messages and rectification / LED

Error messages Cause Rectification

System does not respond No mains power Check mains power to control box

Leveller is not raising when interlock door – leveller is Check interlock contact

the UP button is operated. activated

Leveller is not raising when Field rotation is wrong Swap two phase wires of the

the UP button is operated, hydraulic unit

although motor is running

Red LED ON Overload protection is Check hydraulic unit, cabling and

activated fuses

10 Technical Data

Mains supply 3~ 400VAC, 50 Hz, +/- 10%

3~ 230VAC, 50 Hz, +/- 10%

Fuse supply voltage F1-F3 3 x 3,15A T at 400VAC

3 x 5A T at 230 VAC

Mains fuses 10A K- characteristic

Control voltage 24 VDC max. 0,9 A

Fuse control voltage (F4) Resettable fuse 1,6 A

Maximal loads Max 2,2 KW 6 A

Hydraulic unit

Valve 24 VDC +/- 10%, 0,6 A / 100%

Mounting Vertical on the wall , min. height 100 cm

Housing dimensions 215 mm x 275 m x 190 mm

Ambient temperature -10° C … +55°C

Storage temperature -20°C … +85°C

Isolation class IP 65

Weight 5,5 Kg

Page 7 of 8 RS200L / Rev.A 02

EN

RS200L / Rev.A 02 Page 8 of 8

#1700010413

#140777

You might also like

- SF Circuit - Breaker GL314 With Spring Operating Mechanisms FK3 - 1Document208 pagesSF Circuit - Breaker GL314 With Spring Operating Mechanisms FK3 - 1Hùng MeloNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Tosvert Vf-As1/Ps1: Commercial Power Supply Backup and Commercial Power Supply/Inverter Switching Instruction ManualDocument10 pagesTosvert Vf-As1/Ps1: Commercial Power Supply Backup and Commercial Power Supply/Inverter Switching Instruction Manualdenis dennisNo ratings yet

- 7400 eGPU Parts ListDocument10 pages7400 eGPU Parts ListJulio BaldoyNo ratings yet

- FM 2721 - SM 4Document24 pagesFM 2721 - SM 4VladVeselovskyNo ratings yet

- Remote Mimic Panel: Manual Revisions ListDocument17 pagesRemote Mimic Panel: Manual Revisions ListAleksei PodkopaevNo ratings yet

- Electric Sistem SCHOTTELDocument106 pagesElectric Sistem SCHOTTELmisaelandres1100% (5)

- Lab 2 - Motor Stater - SignedDocument13 pagesLab 2 - Motor Stater - SignedShashitharan PonnambalanNo ratings yet

- Manual KWG Iso5 en v10 2018Document11 pagesManual KWG Iso5 en v10 2018TTIBCCANo ratings yet

- Quick Installation Guide VIVO-M201 Control Panel PDFDocument4 pagesQuick Installation Guide VIVO-M201 Control Panel PDFShaik SajeedNo ratings yet

- 1.1 Switch Status (Transmitted) : Auxiliary Input / Output Status 1Document4 pages1.1 Switch Status (Transmitted) : Auxiliary Input / Output Status 1ass manNo ratings yet

- SF6 Circuit Breaker Instruction ManualDocument386 pagesSF6 Circuit Breaker Instruction ManualiraqnewNo ratings yet

- Ap2101 2111Document14 pagesAp2101 2111Ahmad gozaliNo ratings yet

- Installation manual for E1T control panelDocument12 pagesInstallation manual for E1T control panelDinezJdNo ratings yet

- Panasonic KX t7730 KX t7730 BDocument35 pagesPanasonic KX t7730 KX t7730 BKusnadiNo ratings yet

- Sper 1c1 Supervision Relay User S ManualDocument16 pagesSper 1c1 Supervision Relay User S Manualhassan karimiNo ratings yet

- Light Control Switch Circuit: Wiring DiagramDocument3 pagesLight Control Switch Circuit: Wiring DiagramPhang KumwingNo ratings yet

- BUK208-50Y BUK213-50Y: 1. Product ProfileDocument17 pagesBUK208-50Y BUK213-50Y: 1. Product ProfileEdson CostaNo ratings yet

- PT150 Mini Inverter ManualDocument36 pagesPT150 Mini Inverter ManualCarlos BenitesNo ratings yet

- BUK213Document16 pagesBUK213Nemesys TOFNo ratings yet

- Functional Description: Q Q Q Q QDocument6 pagesFunctional Description: Q Q Q Q QAgus YulfizarNo ratings yet

- ML8511-00FC: REFERENCE BOARD Manual For UV Sensor (QFN)Document8 pagesML8511-00FC: REFERENCE BOARD Manual For UV Sensor (QFN)ali alasdyNo ratings yet

- A005F520020-Basic Equipment (L0L) From July 2016A5Document1,795 pagesA005F520020-Basic Equipment (L0L) From July 2016A5Dmitriy GevkoNo ratings yet

- O1 Prisma Fox Door Drive PDFDocument11 pagesO1 Prisma Fox Door Drive PDFfirasalthiyabyNo ratings yet

- Eaton 216376 M22 K10 en - GBDocument6 pagesEaton 216376 M22 K10 en - GBEmmanuel Astaroth PaizaNo ratings yet

- ABB MicroFlex e150 Installation GuideDocument74 pagesABB MicroFlex e150 Installation Guidehome madeNo ratings yet

- tmp15 InstallationDocument2 pagestmp15 InstallationMohammad Nabil AbdullahNo ratings yet

- Directional High Response Valve 4wrte With Obe Re29083Document24 pagesDirectional High Response Valve 4wrte With Obe Re29083Kiagus Abdul HadiNo ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveSandi AslanNo ratings yet

- Eaton 107898 M22 CK20 en - GBDocument4 pagesEaton 107898 M22 CK20 en - GBAchafi Moussa MahamatNo ratings yet

- APL-2N Series Limit Switch Box ManualDocument4 pagesAPL-2N Series Limit Switch Box ManualJustin LiNo ratings yet

- RRU !remote Relay UnitDocument2 pagesRRU !remote Relay UnitOussama ChriguiNo ratings yet

- Moog DINBufferAmplifier G123825001 TechnicalNote enDocument4 pagesMoog DINBufferAmplifier G123825001 TechnicalNote enMauricio GuanellaNo ratings yet

- 45 - 60055 - EE512 - 2015 - 5 - 2 - 1 - Experiment 2 PLC PDFDocument7 pages45 - 60055 - EE512 - 2015 - 5 - 2 - 1 - Experiment 2 PLC PDFkrishnandrkNo ratings yet

- EM312SR input/output module technical specificationsDocument2 pagesEM312SR input/output module technical specificationsyoussefNo ratings yet

- Iomrmpxxxx00 GBDocument27 pagesIomrmpxxxx00 GBSuranNo ratings yet

- MACPUAR S.A. Order DetailsDocument22 pagesMACPUAR S.A. Order DetailsBjorn De BenNo ratings yet

- MV Protection RelayDocument200 pagesMV Protection RelayAnonymous 6IaYAICNo ratings yet

- Troubleshooting A Power Supply Cover Opened ErrorDocument7 pagesTroubleshooting A Power Supply Cover Opened ErrorMohammad A. BawtagNo ratings yet

- Range Rover - 1995 - 4th EditionDocument569 pagesRange Rover - 1995 - 4th EditionJorge TeixeiraNo ratings yet

- Catalogo General BTDocument416 pagesCatalogo General BTwfjerrNo ratings yet

- Sheet Alignment ControlDocument13 pagesSheet Alignment Controlمحمد محمودNo ratings yet

- FRENIC-Ace Instruction ManualDocument36 pagesFRENIC-Ace Instruction ManualFlorin Tarziu100% (1)

- A22ne-Pd A22ne-P A22e A263-E1 20 13 csm1265Document58 pagesA22ne-Pd A22ne-P A22e A263-E1 20 13 csm1265Zaenal ArifinNo ratings yet

- XE125 Product BriefDocument19 pagesXE125 Product BriefCem VardarNo ratings yet

- 45 - 60055 - EE512 - 2015 - 5 - 2 - 1 - Experiment 3 PLCDocument6 pages45 - 60055 - EE512 - 2015 - 5 - 2 - 1 - Experiment 3 PLCAnonymous DLJu4uzL100% (2)

- Instruction Manual (Supplementary) Totally-Enclosed Box Type InverterDocument8 pagesInstruction Manual (Supplementary) Totally-Enclosed Box Type InverterDoni WandoniNo ratings yet

- OMRON MK3P Relay-1Document13 pagesOMRON MK3P Relay-1Antonio TancevNo ratings yet

- Pasos para Implementar Un Proyecto en RSLOGIX 500Document8 pagesPasos para Implementar Un Proyecto en RSLOGIX 500Raul Rigoberto RoqueNo ratings yet

- Speed Dome InstaDocument2 pagesSpeed Dome InstaJoy Son100% (1)

- Danfoss Pressure SwitchDocument10 pagesDanfoss Pressure SwitchRoshan JaiswalNo ratings yet

- ABS551T Service ManualDocument48 pagesABS551T Service ManualvovchickNo ratings yet

- TL431A, B Series, NCV431A, B Series, SCV431A Programmable Precision ReferencesDocument18 pagesTL431A, B Series, NCV431A, B Series, SCV431A Programmable Precision ReferencesmarcokersulrodriguesNo ratings yet

- Inverter Powerflex 525 IntroductionDocument28 pagesInverter Powerflex 525 IntroductionsonNo ratings yet

- E-STOP Relays, Safety Gate MonitorsDocument9 pagesE-STOP Relays, Safety Gate MonitorsRuro LaudaNo ratings yet

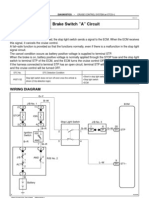

- DTC P0571/52 Brake Switch "A" CircuitDocument4 pagesDTC P0571/52 Brake Switch "A" CircuitErln LimaNo ratings yet

- Modular Installation Devices: Catalog ET B1.T 2002Document154 pagesModular Installation Devices: Catalog ET B1.T 2002Victor Manuel BonettoNo ratings yet

- 4/3-Way Servo Solenoid Directional Control Valves, Pilot Operated, With Electrical Position Feedback (LVDT DC/DC 10V)Document16 pages4/3-Way Servo Solenoid Directional Control Valves, Pilot Operated, With Electrical Position Feedback (LVDT DC/DC 10V)Robert PowerNo ratings yet

- 155 เครน32ตันDocument95 pages155 เครน32ตันOos Tk100% (2)

- Fokker 50-Electrical System PDFDocument33 pagesFokker 50-Electrical System PDFRichard R M ThodéNo ratings yet

- BP 305 Range Product Information en A2017Document2 pagesBP 305 Range Product Information en A2017Anonymous RcxX0FcNo ratings yet

- Rpm/Rate Indicator With Alarms: SpecificationsDocument2 pagesRpm/Rate Indicator With Alarms: SpecificationsArun GuptaNo ratings yet

- Recip Ignition Starting QuizDocument2 pagesRecip Ignition Starting QuizhygfgNo ratings yet

- Sop For Electrical SafetyDocument3 pagesSop For Electrical Safetyanoushia alviNo ratings yet

- Sace Tmax XT: W S51 Only F-PDocument12 pagesSace Tmax XT: W S51 Only F-Phicham boutoucheNo ratings yet

- Transistors TutorialDocument92 pagesTransistors TutorialAmit Raj100% (18)

- Electrical IP 16-0-0 Section Table of Contents: Changes Shown byDocument2 pagesElectrical IP 16-0-0 Section Table of Contents: Changes Shown byHarold Gutierrez MartinezNo ratings yet

- Datasheet APW7142Document22 pagesDatasheet APW7142José Aparecido BarbosaNo ratings yet

- Pressure Switch For Neutral Gases and LiquidsDocument3 pagesPressure Switch For Neutral Gases and LiquidsDiệp ThắngNo ratings yet

- Defender CircuitDocument32 pagesDefender CircuitjdogoNo ratings yet

- Zlib - Pub Basic ElectronicsDocument629 pagesZlib - Pub Basic ElectronicsJean GoujonNo ratings yet

- Double Layer Super CapacitorDocument10 pagesDouble Layer Super CapacitorAlaa AhmedNo ratings yet

- UX Series User GuideDocument108 pagesUX Series User GuideBEBACANNo ratings yet

- Varta Opzv Range 4 Opzv 200... 24 Opzv 3000: Application InstallationDocument3 pagesVarta Opzv Range 4 Opzv 200... 24 Opzv 3000: Application InstallationJose Rafael Pineda BricenoNo ratings yet

- Documents - MX Battery-EliminatorDocument35 pagesDocuments - MX Battery-EliminatorAliNo ratings yet

- Siemens Polydoros LX 30-50 X-Ray - AdjustmentDocument82 pagesSiemens Polydoros LX 30-50 X-Ray - Adjustmenthaseeb100% (1)

- US Navy Course - Interior Communications Electrician, Volume 1 NAVEDTRA 14120 PDFDocument527 pagesUS Navy Course - Interior Communications Electrician, Volume 1 NAVEDTRA 14120 PDFsubashdahal2No ratings yet

- (2017) PEC Tables - FinalDocument13 pages(2017) PEC Tables - FinalJustin Jay Delos Reyes38% (8)

- A190061Document3 pagesA190061Luis Fernando Llumiquinga OñaNo ratings yet

- General Purpose Transistors BC160 and BC161 DatasheetDocument5 pagesGeneral Purpose Transistors BC160 and BC161 DatasheetpaulomarezeNo ratings yet

- ESC201 UDas Lec16class Diodes - SupplyDocument6 pagesESC201 UDas Lec16class Diodes - SupplyaamnNo ratings yet

- Electrical MachinesDocument2 pagesElectrical MachinesPrashant GautamNo ratings yet

- Susol Ring Main Unit: User GuideDocument67 pagesSusol Ring Main Unit: User GuideM Kashif JunaidNo ratings yet

- VLSI BookDocument6 pagesVLSI BookVinod JagdaleNo ratings yet

- Full Adder Design Using LEDITDocument22 pagesFull Adder Design Using LEDITGaurav Soni0% (1)

- Ground Bounce in Digital VLSI Circuits: Payam Heydari, Member, IEEE, Massoud Pedram, Fellow, IEEEDocument15 pagesGround Bounce in Digital VLSI Circuits: Payam Heydari, Member, IEEE, Massoud Pedram, Fellow, IEEEgzb012No ratings yet

- Product Data Sheet: Tesys Vario - Emergency Stop Switch Disconnector - 32 A - On DoorDocument2 pagesProduct Data Sheet: Tesys Vario - Emergency Stop Switch Disconnector - 32 A - On DoorEdu SilvaNo ratings yet

- Thermocouple GroundingDocument6 pagesThermocouple GroundingNAYEEMNo ratings yet

- APT - Line CB (E3) : Service ManualDocument100 pagesAPT - Line CB (E3) : Service ManualDavid EguezNo ratings yet