100% found this document useful (3 votes)

306 views34 pagesPID Controller Fundamentals and Applications

The document discusses different types of feedback controllers used in process control loops, including proportional (P), proportional-integral (PI), and proportional-integral-derivative (PID) controllers. It explains how each type of controller works, including how they calculate their output based on the error between the setpoint and measured process variable. It also covers concepts like controller gain, proportional band, direct vs reverse action, and the advantages and disadvantages of P, PI, and PID control.

Uploaded by

Mohd AizadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

306 views34 pagesPID Controller Fundamentals and Applications

The document discusses different types of feedback controllers used in process control loops, including proportional (P), proportional-integral (PI), and proportional-integral-derivative (PID) controllers. It explains how each type of controller works, including how they calculate their output based on the error between the setpoint and measured process variable. It also covers concepts like controller gain, proportional band, direct vs reverse action, and the advantages and disadvantages of P, PI, and PID control.

Uploaded by

Mohd AizadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction

- Process Control Loop

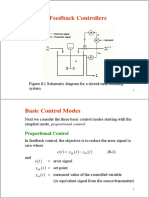

- Feedback Controllers

- Action of Controllers

- Type of Feedback Controllers

- Conventional Block Diagram Representation

- Proportional Control

- Integral Control

- Derivative Control

- Proportional-Integral-Derivative (PID) Control

- Controller Comparison

- Feedback Control Systems Response

- Application Questions