Professional Documents

Culture Documents

Astm D 4806

Uploaded by

MaryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm D 4806

Uploaded by

MaryCopyright:

Available Formats

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles

for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4806 − 19a

Standard Specification for

Denatured Fuel Ethanol for Blending with Gasolines for Use

as Automotive Spark-Ignition Engine Fuel1

This standard is issued under the fixed designation D4806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* mendations issued by the World Trade Organization Technical

1.1 This specification covers nominally anhydrous dena- Barriers to Trade (TBT) Committee.

tured fuel ethanol intended to be blended with unleaded or 2. Referenced Documents

leaded gasolines at 1 % to 15 % by volume for use as automo-

tive spark-ignition engine fuel covered by Specification D4814 2.1 ASTM Standards:2

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

as well as other fuel applications or specifications involving D86 Test Method for Distillation of Petroleum Products and

ethanol. The significance of this specification is shown in Liquid Fuels at Atmospheric Pressure

Appendix X1. D381 Test Method for Gum Content in Fuels by Jet Evapo-

ration

1.2 Jurisdictions may vary in their regulatory requirements D1298 Test Method for Density, Relative Density, or API

for the allowable or prohibited types of denaturants, chemical Gravity of Crude Petroleum and Liquid Petroleum Prod-

composition of the denaturant or concentration of denaturant ucts by Hydrometer Method

needed to denature the ethanol. The user is advised to check D1613 Test Method for Acidity in Volatile Solvents and

with the national and regional regulatory agencies where the Chemical Intermediates Used in Paint, Varnish, Lacquer,

ethanol is denatured and used. and Related Products

1.2.1 Specific regulatory requirements for denatured fuel D1688 Test Methods for Copper in Water

ethanol and acceptable denaturants from various jurisdictions D2622 Test Method for Sulfur in Petroleum Products by

are given in Appendixes for information. Wavelength Dispersive X-ray Fluorescence Spectrometry

1.3 The values stated in SI units are to be regarded as D3120 Test Method for Trace Quantities of Sulfur in Light

standard. Liquid Petroleum Hydrocarbons by Oxidative Microcou-

1.3.1 Exception—Values given in parentheses are provided lometry

for information only. Non-SI units are shown in the Appendix D4052 Test Method for Density, Relative Density, and API

if they are in a direct quotation from government regulations. Gravity of Liquids by Digital Density Meter

In most cases, U.S. federal regulations specify non-SI units. D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.4 The following safety hazards caveat pertains only to the

D4175 Terminology Relating to Petroleum Products, Liquid

method modification in 8.7 of this specification: This standard

Fuels, and Lubricants

does not purport to address all of the safety concerns, if any,

D4177 Practice for Automatic Sampling of Petroleum and

associated with its use. It is the responsibility of the user of this

Petroleum Products

standard to establish appropriate safety, health, and environ-

D4306 Practice for Aviation Fuel Sample Containers for

mental practices and determine the applicability of regulatory

Tests Affected by Trace Contamination

limitations prior to use.

D4814 Specification for Automotive Spark-Ignition Engine

1.5 This international standard was developed in accor-

Fuel

dance with internationally recognized principles on standard-

D5453 Test Method for Determination of Total Sulfur in

ization established in the Decision on Principles for the

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel

Development of International Standards, Guides and Recom-

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence

D5501 Test Method for Determination of Ethanol and

Methanol Content in Fuels Containing Greater than 20%

1

This specification is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

2

Subcommittee D02.A0.02 on Oxygenated Fuels and Components. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 15, 2019. Published September 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2019 as D4806 – 19. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4806-19A. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS Markit under license with ASTM

1Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

Ethanol by Gas Chromatography 3. Terminology

D5580 Test Method for Determination of Benzene, Toluene, 3.1 For general terminology, refer to Terminology D4175.

Ethylbenzene, p/m-Xylene, o-Xylene, C9 and Heavier

Aromatics, and Total Aromatics in Finished Gasoline by NOTE 1—The user is advised that the definitions used by various

industries, marketers, and regulatory bodies can differ from those specific

Gas Chromatography

to this specification. It is the responsibility of the user to ensure that the

D5854 Practice for Mixing and Handling of Liquid Samples terms used in a particular context are clearly understood.

of Petroleum and Petroleum Products

3.2 Definitions:

D6423 Test Method for Determination of pHe of Denatured

3.2.1 denaturants, n—materials added to ethanol to make it

Fuel Ethanol and Ethanol Fuel Blends

unsuitable for beverage use under a formula approved by a

D6550 Test Method for Determination of Olefin Content of

regulatory agency to prevent the imposition of beverage

Gasolines by Supercritical-Fluid Chromatography

alcohol tax.

D7039 Test Method for Sulfur in Gasoline, Diesel Fuel, Jet

3.2.1.1 Discussion—Denaturants are only those materials

Fuel, Kerosine, Biodiesel, Biodiesel Blends, and

added by the denaturer to comply with the approved formula;

Gasoline-Ethanol Blends by Monochromatic Wavelength

any materials absorbed later are not denaturants.

Dispersive X-ray Fluorescence Spectrometry

D7318 Test Method for Existent Inorganic Sulfate in Ethanol 3.2.2 denatured fuel ethanol, n—fuel ethanol made unfit for

by Potentiometric Titration beverage use by the addition of denaturants under formula(s)

D7319 Test Method for Determination of Existent and Po- approved by the applicable regulatory agency to prevent the

tential Sulfate and Inorganic Chloride in Fuel Ethanol and imposition of beverage alcohol tax.

Butanol by Direct Injection Suppressed Ion Chromatog- 3.2.3 ethanol, n—ethyl alcohol, the chemical compound

raphy CH3CH2OH.

D7328 Test Method for Determination of Existent and Po- 3.2.4 fuel ethanol, n—a grade of ethanol with other compo-

tential Inorganic Sulfate and Total Inorganic Chloride in nents common to its production (including water) that do not

Fuel Ethanol by Ion Chromatography Using Aqueous affect the use of the product as a component for automotive

Sample Injection spark-ignition engine fuels.

D7347 Test Method for Determination of Olefin Content in

Denatured Ethanol by Supercritical Fluid Chromatogra- 3.2.4.1 Discussion—The common components do not in-

phy clude denaturant.

D7576 Test Method for Determination of Benzene and Total 3.2.5 gasoline, n—a volatile mixture of liquid

Aromatics in Denatured Fuel Ethanol by Gas Chromatog- hydrocarbons, generally containing small amounts of

raphy additives, suitable for use as a fuel in spark-ignition, internal

D7757 Test Method for Silicon in Gasoline and Related combustion engines. D4814

Products by Monochromatic Wavelength Dispersive 3.2.6 gasoline blendstock, n—a liquid hydrocarbon compo-

X-ray Fluorescence Spectrometry nent suitable for use in spark-ignition engine fuels.

D7795 Test Method for Acidity in Ethanol and Ethanol

Blends by Titration 3.2.6.1 Discussion—Examples of gasoline blendstock in-

D7923 Test Method for Water in Ethanol and Hydrocarbon clude natural gasoline, raffinate, reformate, conventional gaso-

Blends by Karl Fischer Titration line blendstock for oxygenate blending (CBOB), and reformu-

E29 Practice for Using Significant Digits in Test Data to lated gasoline blendstock for oxygenate blending (RBOB).

Determine Conformance with Specifications 3.2.7 gasoline-ethanol blend, n—a fuel consisting primarily

E203 Test Method for Water Using Volumetric Karl Fischer of gasoline along with a substantial amount (more than 0.35 %

Titration by mass oxygen) of denatured fuel ethanol.

E300 Practice for Sampling Industrial Chemicals 3.2.8 oxygenate, n—an oxygen-containing, ashless, organic

E1064 Test Method for Water in Organic Liquids by Coulo- compound, such as an alcohol or ether, which may be used as

metric Karl Fischer Titration a fuel or fuel supplement. D4814

2.2 Government Regulations: 3.2.9 pHe, n—a measure of the acid strength, defined by

United States Code of Federal Regulations, Title 27, Parts Test Method D6423, of ethanol-hydrocarbon blends. D6423

19, 20, and 213 3.2.9.1 Discussion—This measurement is sometimes

United States Code of Federal Regulations, Title 40, Part 80 thought to be analogous to the traditional pH measurement of

California Code of Regulations, CCR Title 13, §2260 – hydrogen ion activity in aqueous systems but the measure-

§22984 ments done in Test Method D6423 are in a nearly anhydrous

environment.

3.3 Abbreviations:

3

A printed copy of the Code of Federal Regulations may be purchased from the 3.3.1 CCR—California Code of Regulations

U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St.,

NW, Mail Stop: SDE, Washington, DC 20401 or the online store at http:// 3.3.2 CFR—U.S. Code of Federal Regulations

bookstore.gpo.gov/. The Code of Federal Regulations may be browsed online at 3.3.3 DFE—Denatured Fuel Ethanol

http://www.gpoaccess.gov/cfr/index.html.

4

California regulations are available online at http://government.westlaw.com. 3.3.4 EPA—The U.S. Environmental Protection Agency

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

2Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

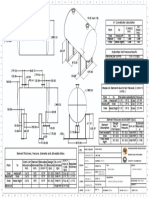

TABLE 1 Performance Requirements

Property Limit Method

Ethanol, % by volume, min 92.1 D5501

Methanol, % by volume, max 0.5 D5501

Solvent-washed gum content, mg/100 mL, max 5 D381

Water, % by volume (% by mass), max 1.0 (1.26) D7923, E203, or E1064

Inorganic Chloride, mg/kg (mg/L), max 6.7 (5) D7319 or D7328

Copper, mg/kg, max 0.1 D1688

Acidity (as acetic acid CH3COOH) mg/kg, (% by mass) [mg/L], max 70 (0.0070) [56] (Note 2) D7795

pHe 6.5 to 9.0 D6423

Sulfur, mg/kg, max 30. D2622, D3120, D5453, or D7039

Existent sulfate, mg/kg, max 4 D7318, D7319, or D7328

3.3.5 IRS—U.S. Internal Revenue Service 5.1.1.1 This specification is specific to denatured fuel etha-

3.3.6 RBOB—reformulated blendstock for oxygenate blend- nol as a blendstock in spark-ignition engine fuel. Denaturants

ing that could provide satisfactory performance for other uses

could cause damage to spark-ignition engines. The fuel ethanol

3.3.7 RIN—Renewable Identification Number

formulas approved by the alcohol regulatory agency for fuel

3.3.8 TTB—The Alcohol and Tobacco Tax and Trade Bureau use could include denaturing materials which are not allowed

of the U.S Department of Treasury by this ASTM specification. It is the denaturer’s responsibility

to consult the regulations to ensure legal denaturing of the fuel

4. Performance Requirements (Table 1) ethanol and to ensure compliance with this specification with

4.1 Denatured Fuel Ethanol—After fuel ethanol is dena- regard to allowed denaturants.

tured as specified in Section 5, it shall conform to the following 5.1.2 The natural gasoline, gasoline blendstock, or unleaded

requirements at the time of blending with gasoline. gasoline used as denaturant should not contain materials at

NOTE 2—Denatured fuel ethanol may contain additives, such as

concentrations that can separate from solution at the expected

corrosion inhibitors and detergents, that can affect the titratable acidity temperatures of blending, storage, and use. If drag reducing

(acidity as acetic acid) of the finished denatured fuel ethanol. Although the agent (additive) (DRA) is used in the distribution system, it

base fuel ethanol may meet the acidity specification, the effect of these should not be present in the product delivered to be used as a

additives can produce an apparent high titratable acidity of the finished denaturant at a concentration or shear condition that can

product. Contact the ethanol supplier if there is a question regarding the

titratable acidity of the denatured fuel ethanol to verify that the base fuel

separate from the denatured fuel ethanol under those condi-

ethanol meets the acidity requirements in Table 1. tions.

5.1.3 Prohibited Denaturants—This specification prohibits

4.2 Other Properties—Limits more restrictive than those

the use of hydrocarbons with an end boiling point higher than

specified above, or the specification of additional properties

225 °C as determined by Test Method D86, although they may

such as color, may be agreed upon between the supplier and the

be permitted by some regulations. Some kerosines, for

purchaser.

instance, promote piston scuff in automotive engines. Specific

4.3 For purposes of determining conformance with the mention must be made of some materials that have extremely

specified limits in Table 1, an observed value or a calculated adverse effects on fuel stability, automotive engines, and fuel

value shall be rounded “to the nearest unit” in the last righthand systems. These materials shall not be used as denaturants for

digit used in expressing the specification limit, in accordance fuel ethanol under any circumstances. They are as follows:

with the rounding method of Practice E29, unless otherwise methanol, pyrroles, turpentine, ketones, and tars (high-

specified. molecular weight pyrolysis products of fossil or nonfossil

vegetable matter). Ketone denaturants tend to degrade fuel

5. Denaturant and Regulatory Information stability or increase the tendency of a gasoline-ethanol blend to

5.1 General Requirements—This specification provides corrode metals and attack elastomers. These effects become

general information for the denaturants to be used in denatured more serious if the concentration of a ketone such as 4-methyl

fuel ethanol and the concentration of denaturant to be added. pentanone (methyl isobutyl ketone) exceeds one part by

Jurisdictions may vary in their regulatory requirements for the volume per 100 parts by volume of fuel ethanol. There is no

allowable or prohibited types of denaturants, chemical compo- information available on the effects of denaturants other than

sition of the denaturant or concentration of denaturant needed those mentioned above. Therefore, the only denaturants that

to denature the ethanol. shall be used are those listed in 5.1.1.

5.1.1 Allowable Denaturants—The only denaturants al- 5.1.4 Denaturant Level—A buyer may ask the denaturer to

lowed for the denatured fuel ethanol defined by this specifica- denature within a specific range (for example, 1.96 % to 2.5 %

tion are natural gasoline, gasoline blendstocks, or unleaded by volume). A buyer may also ask the denaturer to certify the

gasoline. Small amounts of the same or similar hydrocarbons range used for the denaturant addition. A buyer or distributor

absorbed by the denatured fuel ethanol as it moves through the may commingle receipts certified within the same range and

distribution system is not denaturant. A jurisdiction can main- provide a certification of conformance with the product from

tain approved formulas to denature alcohol for fuel use. that commingling. The blender may use this certification of

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

3Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

conformance for the product to demonstrate compliance with 7.3 The correct sample volume and appropriate container

the denaturant limits. If the product is shipped directly from a selection are important decisions that can impact test results.

denaturer to a blender, the initial certification from the dena- Refer to Practice D4306 for aviation fuel container selection

turer may be used to demonstrate compliance. Compliance for tests sensitive to trace contamination. Refer to Practice

with the denaturant limit cannot be determined analytically. D5854 for procedures on container selection and sample

Compliance shall be based on the information from the original mixing and handling. All sampling and storage containers

denaturer. The maximum concentration of denaturant allowed should be evaluated for durability, compatibility, and contami-

in this specification is 5 % by volume. nation of denatured fuel ethanol prior to use. If samples must

5.2 Regulatory Information for Denaturants and Denatured be collected in metal containers, do not use soldered metal

Fuel Ethanol: containers. Soldering flux in the containers and the lead in the

5.2.1 Users of this specification are advised to consult with solder can contaminate the sample.

the applicable regulatory agency for specific requirements for 7.4 Sample Size—A minimum of about 1 L is recommended.

denaturants (types, composition, and amounts) and denatured If specific gravity is to be determined by a hydrometer method,

fuel ethanol in their jurisdictions. The requirements can be additional volume may be required. This depends on the size of

covered by regulations specific to a jurisdiction or by multiple the hydrometer.

regulations due to overlapping jurisdictions. Appendixes have

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

7.5 Lot Size—A lot shall normally consist of the amount

been developed to provide information for several jurisdictions contained in a tanker compartment or other bulk container in

describing the requirements within the designated jurisdiction: which it is delivered. If this definition does not apply, the

5.2.1.1 Appendix X2, Regulatory Requirements for Califor- definition of a lot must be agreed upon between the supplier

nia. and purchaser.

5.2.1.2 Appendix X3, Regulatory Requirements for the

United States. NOTE 5—See Sections 5, 6, and 7 on Significance, Safety, and

Statistical Considerations, respectively, of Practice E300 for a detailed

discussion of the statistics of sampling.

6. Workmanship

6.1 At the point of custody transfer, the denatured fuel 8. Test Methods

ethanol shall be visually free of sediment, suspended, or

8.1 The scope of some of the test methods listed below do

undissolved matter. It shall be clear and bright at the product

not include denatured fuel ethanol. The precisions of those test

temperature at the point of custody transfer or at a lower

methods can differ from the reported precisions when testing

temperature agreed upon by the purchaser and seller.

denatured fuel ethanol.

NOTE 3—Fuel components should be resistant to phase separation or

undissolved matter at the lowest temperatures to which it is likely to be 8.2 Water—Test Methods D7923, E203, or E1064.

subjected, dependent on the time and place of its intended use. See 8.3 Solvent-Washed Gum Content—Test Method D381, air

Specification D4814 Table X8.1 for guidance. jet apparatus.

NOTE 4—Solubility is temperature dependent. As this fuel component

cools, some high molecular weight additives can become insoluble. 8.4 Acidity—Test Method D7795.

6.2 The product shall be free of any adulterant or contami- 8.5 pHe—Test Method D6423.

nant that can render the material unacceptable for its com-

8.6 Inorganic Chloride—Test Methods D7319 or D7328.

monly used applications.

6.2.1 Manufacturers, importers, and others denaturing fuel 8.7 Copper—Modification of Test Methods D1688, Test

ethanol shall avoid ethanol (for example, improperly recycled Method A.

ethanol) or denaturants contaminated by silicon-containing 8.7.1 The modifications of Test Methods D1688, Test

materials, or both. Silicon contamination of gasoline- Method A (atomic absorption, direct) consists of mixing

oxygenate blends has led to fouled vehicle components (for reagent-grade ethanol (which can be denatured in accordance

example, spark plugs, exhaust oxygen sensors, catalytic con- with TTB Formula 3A or 30) in place of water as the solvent

verters) requiring parts replacement and repairs. Test Method or diluent for the preparation of reagents and standard solu-

D7757 is a procedure for determining silicon content but no tions. However, this must not be done to prepare the stock

specification limits have been established for this silicon. copper solution described in the section on Copper Solution,

Stock in Test Method D1688. Because a violent reaction can

7. Sampling, Containers, and Sample Handling occur between the acid and the ethanol, use water, as specified,

7.1 The user is strongly advised to review all intended test in the acid solution part of the procedure to prepare the stock

methods prior to sampling to understand the importance and copper solution. Use ethanol for the rinse and final dilution

effects of sampling technique, proper containers, and special only.

handling required for each test method. 8.7.2 The precision of this modified method has not been

determined, but it is expected to be similar to the precision of

7.2 Correct sampling procedures are critical to obtain a Test Method D1688, Test Method A.

sample representative of the lot intended to be tested. Use

appropriate procedures in Practice D4057 or Practice E300 for 8.8 Ethanol and Methanol—Test Method D5501.

manual method sampling and in Practice D4177 for automatic 8.9 Sulfur—Test Methods D2622, D3120, D5453, or

method sampling, as applicable. D7039. California specifies that compliance with the California

Copyright ASTM International

Provided by IHS Markit under license with ASTM

4Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

sulfur standard for denatured ethanol shall be determined using ethanol volumes) at the time of denaturing. There is no

Test Method D5453 – 93. EPA allows Test Methods standardized test procedure or calculation to directly or indi-

D3120 – 06ε1, D5453 – 08a, or D7039 – 07 for measuring rectly determine the denaturant content in denatured fuel

sulfur in gasoline as long as these alternative test method ethanol.

results are correlated to the EPA designated Test Method

D2622 – 05 when determining compliance with Federal EPA 9. Keywords

sulfur standards.

9.1 acidity; automotive spark-ignition engine fuel; base

8.10 Existent Sulfate—Test Methods D7318, D7319, or gasoline; chloride ion; copper; corrosion inhibitors; denatur-

D7328. ants; denatured fuel ethanol; ethanol; fuel; fuel ethanol; gaso-

8.11 Denaturant—The denaturant content is determined by line; gasoline-ethanol blend; oxygenate; solvent-washed gum

the ratio of (metered denaturant) to (metered denaturant and content; sulfate ion; sulfur; water

APPENDIXES

(Nonmandatory Information)

X1. SIGNIFICANCE OF SPECIFIED PROPERTIES

X1.1 Denatured Fuel Alcohol X1.1.2 Solvent-Washed Gum Content:

X1.1.1 Water—Karl Fischer analysis is generally the only X1.1.2.1 The test for solvent-washed gum content measures

consistently reliable procedure for the determination of water the amount of residue after evaporation of the fuel and

in denatured ethanol. Test Method E203 describes the modifi- following a heptane wash. The heptane wash removes the

cations required to run the test in the presence of alcohols. heptane-soluble, nonvolatile material such as additives, carrier

Relative density or specific gravity is needed to convert the oils used with additives, and diesel fuels. Solvent-washed gum

Karl Fischer water determination from E203 and E1064 from consists of heptane-insoluble gum. The fuel-insoluble portion

a percent by mass to a percent by volume. Methods D1298 and can clog fuel filters. Both can be deposited on surfaces when

D4052 are recommended for determination of relative density. the fuel evaporates.

X1.1.1.1 Methods and tables exist to determine the water X1.1.2.2 Solvent-washed gum can contribute to deposits on

content of ethanol/water mixtures based on the specific gravity the surfaces of carburetors, fuel injectors, and intake

of the mixture. These methods do not work for water determi- manifolds, ports, valves, and valve guides. The impact of

nation after the denaturant has been added. solvent-washed gum from pure alcohols such as ethanol on

malfunctions of modern engines is not known. The test method

X1.1.1.2 Blends of denatured fuel ethanol and gasoline or

is used essentially to detect the presence of high boiling,

similar hydrocarbons have a limited solvency for water. This

heptane-insoluble impurities.

solvency will vary with the ethanol content, the temperature of

the blend, and the aromatic content of the base gasoline. A fuel X1.1.2.3 Because the precision statements for Test Method

made by blending 10 % by volume denatured fuel ethanol with D381 were developed using only data on hydrocarbons, they

a gasoline containing 14 % by volume aromatics and 0.6 % by are not applicable to denatured fuel ethanol.

mass dissolved water (about 0.5 % by volume), will separate X1.1.3 Chloride Ion—Low concentrations of chloride ions

into a lower alcohol-rich aqueous phase and an upper hydro- are corrosive to many metals.

carbon phase if cooled to about 7 °C. As normal spark-ignition

X1.1.4 Copper—Copper is a very active catalyst for the

engines will not run on the aqueous phase material, such a

low-temperature oxidation of hydrocarbons. Experimental

separation is likely to cause serious operating problems. The

work has shown that copper concentrations higher than

phase separation of gasoline-ethanol blends is affected by the

0.012 mg ⁄kg in commercial gasolines can significantly in-

total water content of the mixture. This includes the water

crease the rate of gum formation.

content from the ethanol and gasoline hydrocarbons blended at

the rack and the water adsorbed from the transportation and X1.1.5 Acidity—Very dilute aqueous solutions of low-

storage infrastructure for the blended fuel. All water sources molecular weight organic acids such as acetic acid

should be identified, monitored and controlled to prevent phase (CH3COOH) are highly corrosive to many metals. It is

separation of the blended fuel. Denatured fuel ethanol is therefore necessary to keep such acids at a very low level.

hygroscopic and can pick up water from the atmosphere during X1.1.5.1 The acidity method is intended to determine the

long-term storage. Prudent precautions to reduce water expo- concentration of organic acids in ethanol. However, carbon

sure and monitor the product should be considered if long term dioxide gas is very soluble in ethanol, and in the presence of

storage is expected. available water, a small portion of the gas converts to carbonic

X1.1.1.3 Test Method D7923 may be used to measure water acid. In denatured fuel ethanol, the water content is very low

content in denatured fuel ethanol in concentrations 0.05 % to and the ethanol molecules will combine with the water leaving

5.0 % by mass. very little water available for the carbon dioxide molecule. One

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

5Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

step in the test method is to add a significant quantity of water ethanol will vary based on levels of denaturant, water and the

to the sample allowing a greater fraction of the dissolved gas to minor components common to ethanol production.

become carbonic acid. Another step of the test method is the

X1.1.9 Existent Sulfate—The presence of small amounts of

addition of an aqueous base to perform the titration. The base

inorganic sulfates in denatured fuel ethanol under the right

addition will shift the equilibrium from the carbonic acid to the

conditions can contribute to turbine meter deposits and the

carbonate salt resulting in more of the dissolved carbon dioxide

premature plugging of fuel dispensing pump filters in the fuel

being converted into carbonic acid. By the end of the titration

distribution system. The sulfates also have been shown to

all of the dissolved gas will have been converted to the

cause fuel injector sticking resulting in engine misfiring and

carbonate salt.

poor driveability in automobiles.

X1.1.5.2 Dissolved carbon dioxide is a known interference

and can cause a false high reading when using Test Method X1.1.10 Denaturant—Section 5 discusses the denaturants

D1613. Prior to 2018, Test Method D1613 was included in the that are allowed or prohibited and the denaturing levels for

standard. Due to the CO2 interference, a number of false high product meeting this specification. Denaturant is added in the

acidity values were reported causing disruptions in the mar- specified concentration range to comply with TTB and IRS

ketplace. The problems with using Test Method D1613 led to requirements. The content is set by volumetric addition during

the development of Test Method D7795 with a purge step the denaturing process. Standard analytical methods do not

which removed the CO2 interference. Test Method D1613 has exist to directly or indirectly determine the denaturant content

been removed as an appropriate test method for this standard. or acceptability of the denaturant beyond that point.

X1.1.6 pHe—When the pHe of ethanol used as a fuel for X1.1.11 Sulfur—The Federal Tier 2 Motor Vehicle and

automotive spark-ignition engines is below 6.5, fuel pumps can Emissions Standards and Gasoline Sulfur Control Require-

malfunction as a result of film forming between the brushes ments establish sulfur standards for refineries and importers

and commutator, fuel injectors can fail from corrosive wear, producing reformulated gasoline, Reformulated Blendstock for

and excessive engine cylinder wear can occur. When the pHe Oxygenate Blending (RBOB), and conventional gasoline. EPA

is above 9.0, fuel pump plastic parts can fail. has established gasoline sulfur content standards for gasoline

X1.1.7 Appearance—Turbidity or evidence of precipitation and denatured fuel ethanol blended into gasoline. Sulfur

normally indicates contamination. contaminates the catalytic converter necessary for reducing

X1.1.7.1 Fuel components can encounter conditions in the emissions of hydrocarbons (HC), carbon monoxide (CO), and

bulk distribution system that could cause the material to fail a nitrogen oxides (NOx).

workmanship visual evaluation. Some fuel components can X1.1.12 Methanol—Small amounts of methanol can be

contain dirt or rust particles during distribution. Terminals or produced in the ethanol production process. Methanol at high

bulk plants can address these issues with proper operating concentrations can be corrosive to components of the fuel

procedures; for example, by allowing sufficient time for the dirt system and has a greater effect on increasing vapor pressure

or particles to settle in the tank, by filtration or by other means. than does ethanol. The limit is set to prevent methanol

X1.1.8 Ethanol—The ethanol content is important in deter- corrosion and the incremental effect on vapor pressure. The

mining the blend ratios for adding denatured fuel ethanol into limit is also to prevent methanol from being used as a

the finished gasoline. The ethanol content of denatured fuel denaturant.

X2. CALIFORNIA ETHANOL REQUIREMENTS

X2.1 California Ethanol Requirements TABLE X2.1 California Denatured Ethanol Standards

(In Addition to the Performance Requirements in ASTM

X2.1.1 While the following requirements are believed to be D4806 – 99)

accurate at the time of publication, users should consult the Specification

Property Test Method

relevant authority to confirm the current regulations and Limit

requirements. The information provided about the regulations Sulfur, mg/kg, max 10 D5453 – 93

is for information only. In case of conflict, the text of current Benzene, % by volume, max 0.06 D7576 – 10

Olefins, % by volume, max 0.5 D7347 – 071

regulations takes precedence. Aromatics, % by volume, max 1.7 D7576 – 10

X2.1.2 The California Air Resources Board has approved

standards for denatured ethanol to be field-blended with

California Reformulated Gasoline Blendstock for Oxygenate

Blending (CARBOB) to make California Phase 3 Reformu- X2.1.3 The California standards for denatured ethanol set

lated Gasoline (CaRFG3). Standards also have been specified maximum limits on sulfur, benzene, olefins, and aromatics

for the denaturant. These California standards for denatured contents as shown in Table X2.1, and also require the dena-

ethanol and denaturant became effective Dec. 31, 2003, and tured ethanol to comply with the performance requirements in

were amended on Aug. 29, 2008. Specification D4806 – 99.

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

6Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

TABLE X2.2 California Denaturant Standards the test results are multiplied by the decimal fraction repre-

Property

Specification

Test Method

senting the percent denaturant.

Limit

Benzene, % by volume, 1.10 D5580 – 02 (2007) X2.1.5 California allows an exception to the limits shown in

max Table X2.1 where the denatured ethanol supplier takes reason-

Olefins, % by volume, max 10.0 D6550 – 10

Aromatics,% by volume, 35.0 D5580 – 02 (2007)

ably prudent precautions to ensure the denatured ethanol that

max exceeds these limits will only be added to a specially designed

CARBOB which has been designated to be blended with such

denatured ethanol. Documentation is required to support the

X2.1.4 California specifies that compliance with the sulfur transfer of denatured ethanol. All CaRFG3 requirements for the

standard shall be determined by testing the denatured ethanol final blend shall be met.

using Test Method D5453 – 93. California specifies that com-

X2.1.6 California specifies the standards for the denaturant

pliance with the standards for benzene, olefins, and aromatics

used in denatured ethanol as shown in Table X2.2. Also shown

contents shall be determined by direct analysis of the denatured

are the test methods required to determine compliance.

fuel ethanol (Table X2.1) or by testing a sample of the

denaturant using the test methods specified for CARB gasoline X2.1.7 California standards allow higher amounts of

(Table X2.2), and then calculating the content of those com- benzene, olefins, and aromatics in the denaturant if the supplier

pounds in the denatured ethanol, multiplying the test value by takes necessary precautions to ensure that when added to the

0.0500. However, where it is demonstrated that the denatured ethanol, the level is less than 5.00 % by volume and the limits

ethanol contains less than 5.00 % by volume denaturant, then in Table X2.1 are met.

X3. U.S. FEDERAL REQUIREMENTS FOR DENATURED FUEL ETHANOL

X3.1 While the following requirements are believed to be with the rounding method described in the ASTM standard

accurate at the time of publication, users should consult the practice, ASTM E29 – 02ε1, entitled, ‘Standard Practice for

relevant authority to confirm the current regulations and Using Significant Digits in Test Data to Determine Confor-

requirements. The information provided about the regulations mance with Specifications’”. The denaturant concentration in

is for information only. In case of conflict, the text of current the denatured fuel ethanol is not determined by an analytical

regulations takes precedence. test method but is calculated from the metered volumes by the

denaturer.

X3.2 U.S. EPA Requirements for Denaturant in Dena-

tured Fuel Ethanol X3.2.1.3 The following portions of Practice E29 – 13 ad-

dress the EPA denaturant limit.

X3.2.1 There are two EPA regulations impacting the dena-

6.4 Rounding Procedure—The actual rounding procedure shall be as follows:

turant concentration in denatured fuel ethanol. 6.4.1 When the digit next beyond the last place to be retained is less than 5,

X3.2.1.1 In the definition for Renewable Fuel (40 CFR § retain unchanged the digit in the last place retained.

6.4.2 When the digit next beyond the last place to be retained is greater than 5,

80.1401) the EPA states “(2) Ethanol covered by this definition increase by 1 the digit in the last place retained.

shall be denatured as required and defined in 27 CFR parts 19 6.4.3 When the digit next beyond the last place to be retained is 5, and there

through 21. Any volume of denaturant added to the undena- are no digits beyond this 5, or only zeros, increase by 1 the digit in the last

place retained if it is odd, leave the digit unchanged if it is even. Increase by 1

tured ethanol by a producer or importer in excess of 2 volume the digit in the last place retained, if there are non-zero digits beyond this 5.

percent shall not be included in the volume of ethanol for

purposes of determining compliance with the requirements X3.2.1.4 For rounding purposes only, if the records from the

under this subpart.” The U.S. Environmental Protection denaturant addition system indicate the denaturant concentra-

Agency regulations stipulate that denaturant added in excess of tion is between 1.5 % by volume to 2.5 % by volume, then

2 % by volume shall not be considered when determining using the rounding method in Practice E29 – 02ε1, the dena-

volumes for the purposes of compliance with the Renewable tured fuel ethanol is deemed to contain 2 % by volume

Fuel Standard. This absolute limitation includes volumes for denaturant for EPA purposes only.

Renewable Identification Number (RIN) generation. The limits X3.2.2 Beginning January 1, 2017, under the U.S. EPA Tier

for the denaturant addition are shown in Table X3.1. 3 fuel program, “the concentration of all denaturants used in

X3.2.1.2 The EPA also has a procedure to follow when DFE [denatured fuel ethanol] is limited to a maximum of 3.0

determining compliance with this regulation. Regulation 40

volume percent” (40 CFR 80.1610(a)(4)).

CFR § 80.9, “Rounding a test result for determining confor-

mance with a fuels standard,” states “for purposes of determin- X3.2.3 Denatured fuel ethanol “must be composed solely of

ing compliance with the fuel standards of 40 CFR Part 80, a carbon, hydrogen, nitrogen, oxygen and sulfur” (40 CFR

test result will be rounded to the nearest unit of significant 80.1610(a)(2)), and “only previously certified gasoline (includ-

digits specified in the applicable fuel standard in accordance ing previously certified blendstocks for oxygenate blending),

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

7Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

TABLE X3.1 U.S. Federal Limits on Denaturants and Denatured Fuel Ethanol

Limits on Denaturant Content of Denatured Fuel Ethanol

Limit, volume % Source Requirement

1.96 minA TTBB TTB Formulas require a minimum of two parts of approved denaturant to 100 parts of

ethanol with a minimum of 195 proof ethanol.

2 maxC,D EPAD The maximum amount of denaturant the EPA allows for RIN generation in denatured fuel

ethanol under the national Renewable Fuels Standard Program.

3.0 maxC EPAE The maximum amount of denaturant the EPA allows in denatured fuel ethanol for use as a

gasoline blendstock.

Chemical Limits on Denatured Fuel Ethanol

Property Specification Limit Test Method

Sulfur, mg/kg, max 10F D2622, D3120, D5453, D7039

A

For purposes of determining conformance with this limit, the Absolute Method in Practice E29 should be used.

B

See X3.4 for information on this TTB limit.

C

For purposes of determining conformance with this limit, the Rounding Method in Practice E29 should be used.

D

See X3.2.1.1 for additional information on this EPA limit.

E

See X3.2.2 for additional information on this EPA limit.

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

F

See X3.3.1 for additional information on this EPA limit.

gasoline blendstocks, or natural gas liquids may be used as are published in the United States Code of Federal Regulations,

denaturants” (40 CFR 80.1610(a)(3)). Title 27, Parts 19, 20, and 21. The denatured fuel ethanol

allowed by this specification shall contain a minimum of 1.96

X3.3 U.S. EPA Requirements for Sulfur in Denatured % by volume denaturant.

Fuel Ethanol

X3.3.1 Beginning January 1, 2017, under the U.S. EPA Tier X3.4.2 To avoid imposition of the beverage excise tax, TTB

3 fuel program, “the sulfur content must not be greater than 10 regulations require the denaturer to add specific quantities of

ppm” (10 mg/kg) (40 CFR 80.1610(a)(1)). approved denaturants to the ethanol prior to shipping. The

denaturant content is determined by the ratio of metered

X3.3.2 There are additional EPA federal requirements for denaturant and ethanol volumes at the time of denaturing. The

producers and importers of certified denaturant to be used for

TTB regulations stipulate the record keeping requirements for

the manufacture of denatured fuel ethanol: The sulfur content

the denaturer. These regulations include records of the quanti-

of the denaturant for use in the manufacture of denatured fuel

ties of ethanol and denaturant added in the denaturing process.

ethanol “must not be greater than 330 ppm” (40 CFR

The TTB periodically audits the denaturing facilities and

80.1611(a)(1)). “The ethanol denaturant “must be composed

solely of carbon, hydrogen, nitrogen, oxygen and sulfur” (40 associated records for compliance with these regulations. The

CFR 80.1611(a)(2)). “Only previously certified gasoline (in- regulations do not require the receiver to analytically verify

cluding previously certified blendstocks for oxygenate that the material added was an approved denaturant or that it

blending), gasoline blendstocks, or natural gas liquids may be was added within the necessary concentration range. Approved

used as denaturants” (40 CFR 80.1611(a)(3)). analytical methods or calculations do not exist to permit any

the following: (1) to confirm compliance with this section of

X3.4 U.S. Alcohol and Tobacco Tax and Trade Bureau the specification after the denaturing process, (2) to determine

Requirements on Denatured Fuel Ethanol that the denaturant used was approved by the TTB or allowed

X3.4.1 In the United States, ethanol is rendered unfit for in this specification, (3) to quantify the ratio of denaturant

beverage use by the addition of denaturants under formulas added during the denaturing process, or (4) to distinguish

approved by the Alcohol and Tobacco Tax and Trade Bureau between the hydrocarbons added as part of the denaturing

(TTB) of the U.S. Treasury Department that allow the dena- process and those absorbed later in the distribution system.

tured alcohol to ship from the denaturer free of beverage excise There is no ASTM approved test method for determining

tax and to be distributed and used as a fuel component without denaturant concentration in denatured fuel ethanol, although

TTB permits. TTB regulations concerning the preparation, regulatory agencies may use non-ASTM methods for investi-

handling, distribution and use of denatured ethanol formulas gative purposes.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

8Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

D4806 − 19a

SUMMARY OF CHANGES

Subcommittee D02.A0 has identified the location of selected changes to this standard since the last issue

(D4806 – 19) that may impact the use of this standard. (Approved Sept. 15, 2019.)

(1) Revised subsection 3.2.9; moved term from “Definitions of

Terms Specific to this Standard” to “Definitions.”

Subcommittee D02.A0 has identified the location of selected changes to this standard since the last issue

(D4806 – 18a) that may impact the use of this standard. (Approved March 1, 2019.)

(1) Revised Table 1.

Subcommittee D02.A0 has identified the location of selected changes to this standard since the last issue

(D4806 – 18) that may impact the use of this standard. (Approved Dec. 1, 2018.)

(1) Revised subsections 3.2.3 and 3.2.4.

(2) Added new subsection 5.1.2 to Section 5, Denaturant,

under subsection 5.1, General Requirements, to include warn-

ings about using additive materials that are not compatible with

ethanol blends.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

--``,``,,,,,`,``,`,`,``,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

9Licensee=Repsol Sites 1-16 - Madrid Spain EAA/5982486001, User=Malasquez, Maria

No reproduction or networking permitted without license from IHS Not for Resale, 02/26/2020 17:15:01 MST

You might also like

- Pre-Qualification Docs ListDocument11 pagesPre-Qualification Docs ListNikhil RajuNo ratings yet

- Phosphate Ester Based Fluids For Turbine Lubrication and Steam Turbine Electro-Hydraulic Control (EHC) ApplicationsDocument5 pagesPhosphate Ester Based Fluids For Turbine Lubrication and Steam Turbine Electro-Hydraulic Control (EHC) ApplicationsJicheng PiaoNo ratings yet

- Design Guide For Roadways PDFDocument219 pagesDesign Guide For Roadways PDFBart Lucena Jr.No ratings yet

- D86 - 19 PDFDocument29 pagesD86 - 19 PDFGuillermo ZapataNo ratings yet

- Microbial Contamination in Fuels and Fuel Systems: Standard Guide ForDocument12 pagesMicrobial Contamination in Fuels and Fuel Systems: Standard Guide ForAlabbas FadhelNo ratings yet

- CBLM Implementing Plant Nutrition ProgramDocument64 pagesCBLM Implementing Plant Nutrition Programmarlene a. dinlayanNo ratings yet

- Astm D2700-19Document60 pagesAstm D2700-19Angel Murillo100% (2)

- Biomedical Engineering Technical - Applications in Medicine PDFDocument431 pagesBiomedical Engineering Technical - Applications in Medicine PDFThiagoNo ratings yet

- Astm D86 - 17Document29 pagesAstm D86 - 17Esteban Calderón NavarroNo ratings yet

- ChE Day 1 Mock Board 2.0Document6 pagesChE Day 1 Mock Board 2.0zzrot1100% (1)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Astm D86Document29 pagesAstm D86Difany tsabitaNo ratings yet

- Astm D4378-22Document19 pagesAstm D4378-22Hani YilmazNo ratings yet

- Astm D2414-21Document9 pagesAstm D2414-21Rajdeep MalNo ratings yet

- ASTM D-6224-9 Aux Oil Analysis Power PlantDocument15 pagesASTM D-6224-9 Aux Oil Analysis Power Plantridhal fauzanNo ratings yet

- D 7343 - 18Document7 pagesD 7343 - 18Saro H100% (1)

- Van Meerbeek (2001) Adhesives and Cements To Promote Preservation DenitistryDocument26 pagesVan Meerbeek (2001) Adhesives and Cements To Promote Preservation DenitistryAnderson Chamblas100% (1)

- Chemical Agents COP 2016Document56 pagesChemical Agents COP 2016James McloughlinNo ratings yet

- ASTM D4929-Organic ChlorideDocument16 pagesASTM D4929-Organic Chlorideismaegsrj.gwta2No ratings yet

- Lab Manual AsphaltDocument100 pagesLab Manual AsphaltmuhanadNo ratings yet

- ASTM D 86 - 07b PDFDocument27 pagesASTM D 86 - 07b PDFJulian Felipe Noguera Cruz100% (1)

- Exp.4-Biological Oxygen Demand (BOD) PDFDocument10 pagesExp.4-Biological Oxygen Demand (BOD) PDFaoi_chiepNo ratings yet

- Membrane Contactor Technology - Water Treatment, Food Processing, Gas Separation, and Carbon Capture PDFDocument363 pagesMembrane Contactor Technology - Water Treatment, Food Processing, Gas Separation, and Carbon Capture PDF小菜包No ratings yet

- CPVC ModelDocument1 pageCPVC ModelZhu Chen ChuanNo ratings yet

- Chapter 10 Respiration - WorksheetDocument4 pagesChapter 10 Respiration - Worksheetapi-3728508100% (4)

- ASTM D86 - 20b STANDARD TEST METHOD FOR DISTILLATION PDFDocument29 pagesASTM D86 - 20b STANDARD TEST METHOD FOR DISTILLATION PDFAndy Calcaño LopezNo ratings yet

- Astm 2017-D7344 PDFDocument20 pagesAstm 2017-D7344 PDFsunaryo putra jayaNo ratings yet

- In-Service Monitoring of Lubricating Oil For Auxiliary Power Plant EquipmentDocument20 pagesIn-Service Monitoring of Lubricating Oil For Auxiliary Power Plant Equipmentمحمد نصیریNo ratings yet

- Astm D381-19 PDFDocument6 pagesAstm D381-19 PDFHoàng Thuý TrangNo ratings yet

- Astmd1655 22Document20 pagesAstmd1655 22Muneeb100% (2)

- Field Determination of In-Service Fluid Properties Using IR SpectrosDocument8 pagesField Determination of In-Service Fluid Properties Using IR SpectroshemberNo ratings yet

- Astm D 86-2020Document29 pagesAstm D 86-2020Mohammed AliNo ratings yet

- Denatured Fuel Ethanol For Blending With Gasolines For Use As Automotive Spark-Ignition Engine FuelDocument9 pagesDenatured Fuel Ethanol For Blending With Gasolines For Use As Automotive Spark-Ignition Engine FuelAchintya SamantaNo ratings yet

- Standard Test Method For Water in Ethanol and Hydrocarbon Blends by Karl Fischer TitrationDocument9 pagesStandard Test Method For Water in Ethanol and Hydrocarbon Blends by Karl Fischer Titrationjhalays7574No ratings yet

- ASTM D7547 For AVGAS UL91Document7 pagesASTM D7547 For AVGAS UL91tan kevinNo ratings yet

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument27 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForGuillermo ZapataNo ratings yet

- Determination of Organic Chloride Content in Crude Oil by Distillation Followed by Detection Using Combustion Ion ChromatographyDocument10 pagesDetermination of Organic Chloride Content in Crude Oil by Distillation Followed by Detection Using Combustion Ion ChromatographyTsogtsaihan MyahlaiNo ratings yet

- Aviation Turbine Fuels: Standard Specification ForDocument19 pagesAviation Turbine Fuels: Standard Specification ForAhmad Mu'tasimNo ratings yet

- Water in Ethanol and Hydrocarbon Blends by Karl Fischer TitrationDocument9 pagesWater in Ethanol and Hydrocarbon Blends by Karl Fischer TitrationEugene GudimaNo ratings yet

- Astm D4857 - 12Document10 pagesAstm D4857 - 12mancjaNo ratings yet

- ASTM D86-19 Distillation of Petroleum ProductsDocument29 pagesASTM D86-19 Distillation of Petroleum Productsrgveda18No ratings yet

- Cold Filter Plugging Point of Diesel and Heating Fuels: Standard Test Method ForDocument10 pagesCold Filter Plugging Point of Diesel and Heating Fuels: Standard Test Method ForPablo Fabian Del RossoNo ratings yet

- Aviation Turbine Fuels: Standard Specification ForDocument21 pagesAviation Turbine Fuels: Standard Specification ForzakariazelmatmecNo ratings yet

- Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDocument29 pagesDistillation of Petroleum Products and Liquid Fuels at Atmospheric Pressurenjarac1972No ratings yet

- Calibration Requirements For Elemental Analysis of Petroleum Products and LubricantsDocument13 pagesCalibration Requirements For Elemental Analysis of Petroleum Products and LubricantsChulaka PitigalaNo ratings yet

- In-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesDocument19 pagesIn-Service Monitoring of Mineral Turbine Oils For Steam, Gas, and Combined Cycle TurbinesEhsan ZiaeiNo ratings yet

- E - Norma Astm 86 - 12 DestilacionDocument28 pagesE - Norma Astm 86 - 12 DestilacionAlejandro CordobaNo ratings yet

- Mineral and Synthetic Lubricating Oil Used in Steam or Gas TurbinesDocument8 pagesMineral and Synthetic Lubricating Oil Used in Steam or Gas TurbinesJicheng PiaoNo ratings yet

- D86 1112553-1Document28 pagesD86 1112553-1Luis Enrique Tarón PinedaNo ratings yet

- Para Consulta: Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDocument29 pagesPara Consulta: Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureJUAN CARLOSNo ratings yet

- Standard Specification For Fuel OilsDocument13 pagesStandard Specification For Fuel OilsVedang Bhagwat0% (1)

- ASTM D 86 - 16aDocument28 pagesASTM D 86 - 16aDiana L PérezNo ratings yet

- ASTM D664-18e2 No. ÁcidoDocument11 pagesASTM D664-18e2 No. ÁcidoAngel MurilloNo ratings yet

- Astm D86 - DestilacionDocument28 pagesAstm D86 - Destilacionpaul_garcia_uNo ratings yet

- Gas Turbine Fuel Oils: Standard Specification ForDocument8 pagesGas Turbine Fuel Oils: Standard Specification ForAshokNo ratings yet

- D86-15 Standard Test Method For Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDocument28 pagesD86-15 Standard Test Method For Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureMASTER SOURCENo ratings yet

- Astm Contaminacion de Hidrocarburo Con MicroorganismosDocument11 pagesAstm Contaminacion de Hidrocarburo Con Microorganismosfbetzabeth07No ratings yet

- Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDocument28 pagesDistillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDan MatNo ratings yet

- Distillation of Petroleum Products and Liquid Fuels at Atmospheric PressureDocument28 pagesDistillation of Petroleum Products and Liquid Fuels at Atmospheric PressureCK CkkouNo ratings yet

- D 8045 - 17e1Document7 pagesD 8045 - 17e1Fanambinantsoa Eddy RAKOTONDRAZAFYNo ratings yet

- Research Octane Number of Spark-Ignition Engine Fuel: Standard Test Method ForDocument45 pagesResearch Octane Number of Spark-Ignition Engine Fuel: Standard Test Method ForAMANDA BARRERANo ratings yet

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument28 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method Forchandra usmarianNo ratings yet

- Density, Relative Density, and API Gravity of Liquids by Digital Density MeterDocument9 pagesDensity, Relative Density, and API Gravity of Liquids by Digital Density MeterAbidin SyakirinNo ratings yet

- Leaded Aviation Gasolines: Standard Specification ForDocument9 pagesLeaded Aviation Gasolines: Standard Specification Fordmvaldes21No ratings yet

- Pour Point of Petroleum Products: Standard Test Method ForDocument7 pagesPour Point of Petroleum Products: Standard Test Method ForKafka SetiadiNo ratings yet

- Astm D86-15 Distillation of Petroleum ProductsDocument28 pagesAstm D86-15 Distillation of Petroleum ProductsLito Saul Fernandez QuispeNo ratings yet

- Distillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForDocument27 pagesDistillation of Petroleum Products at Atmospheric Pressure: Standard Test Method ForAcácio AlvesNo ratings yet

- Astm D613Document19 pagesAstm D613Eder Fajardo ValenciaNo ratings yet

- ASTM D86-20b Destilación A Presión AtmDocument29 pagesASTM D86-20b Destilación A Presión AtmRodrigo De la BarreraNo ratings yet

- Standard Test Method For Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-Ray Fluorescence SpectrometryDocument9 pagesStandard Test Method For Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-Ray Fluorescence SpectrometryalexanderNo ratings yet

- Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (And The Calculation of Kinematic Viscosity)Document14 pagesDynamic Viscosity and Density of Liquids by Stabinger Viscometer (And The Calculation of Kinematic Viscosity)Eder Fajardo ValenciaNo ratings yet

- D664 - Standard Test Method For Acid Number of Petroleum Products by Potentiometric TitrationDocument11 pagesD664 - Standard Test Method For Acid Number of Petroleum Products by Potentiometric TitrationEhsan ZiaeiNo ratings yet

- Gas TQ 10D1 - CorregidDocument2 pagesGas TQ 10D1 - CorregidMaryNo ratings yet

- PS CH EPA Orion Drinking Water Wastewater Compliance ENDocument8 pagesPS CH EPA Orion Drinking Water Wastewater Compliance ENMaryNo ratings yet

- Performances and Durability of Asphalt Mixtures Made With Reclaimed Asphalt PavementDocument283 pagesPerformances and Durability of Asphalt Mixtures Made With Reclaimed Asphalt PavementMaryNo ratings yet

- Orion Meters Brochure B-ORIONMETERS-E RevD 0419 WebDocument24 pagesOrion Meters Brochure B-ORIONMETERS-E RevD 0419 WebMaryNo ratings yet

- Potentiometric Determination of Hydrogen Sulfide, Carbonyl Sulfide and Mercaptans in Petroleum Products Liquid SamplesDocument7 pagesPotentiometric Determination of Hydrogen Sulfide, Carbonyl Sulfide and Mercaptans in Petroleum Products Liquid Sampleskir223No ratings yet

- GasStandards 15Document66 pagesGasStandards 15MaryNo ratings yet

- SD 33-35 Brand GLJ09-1013Document3 pagesSD 33-35 Brand GLJ09-1013MaryNo ratings yet

- Spectro Xepos Brochure 2016Document8 pagesSpectro Xepos Brochure 2016Mary100% (1)

- Brigth Stock HVIDocument1 pageBrigth Stock HVIMaryNo ratings yet

- Oxalate LabDocument5 pagesOxalate LabtylerNo ratings yet

- The Bulk Modulus of RubberDocument5 pagesThe Bulk Modulus of Rubberjjhw2002303No ratings yet

- Effective Nuclear ChargeDocument3 pagesEffective Nuclear Chargekalloli100% (1)

- Soldering (S) : Widely Used Joining MethodDocument9 pagesSoldering (S) : Widely Used Joining MethodAhmed Shaban KotbNo ratings yet

- Core-Level X-Ray Photoemission and Raman Spectroscopy Studies On Electronic Structures in Mott-Hubbard Type Nickelate Oxide NdnioDocument8 pagesCore-Level X-Ray Photoemission and Raman Spectroscopy Studies On Electronic Structures in Mott-Hubbard Type Nickelate Oxide NdnioMehak MughalNo ratings yet

- Industrial Hazards and Safety Management in Pharmaceutical IndustryDocument7 pagesIndustrial Hazards and Safety Management in Pharmaceutical IndustryShmmon AhmadNo ratings yet

- Vapor Pressure of Petroleum Products (Mini Method) : Standard Test Method ForDocument9 pagesVapor Pressure of Petroleum Products (Mini Method) : Standard Test Method ForahmedNo ratings yet

- LO - A Review of Decarbonization Options For The Glass IndustryDocument31 pagesLO - A Review of Decarbonization Options For The Glass IndustryRaulNo ratings yet

- Ultra C6 fabric provides advanced flame resistanceDocument1 pageUltra C6 fabric provides advanced flame resistancedaniel garcia cortesNo ratings yet

- F5 Chapter 1 Rate of ReactionDocument18 pagesF5 Chapter 1 Rate of ReactionSiti Aishah ZolkanainNo ratings yet

- Tribology International: Rongping Yun, Peter Filip, Yafei LuDocument10 pagesTribology International: Rongping Yun, Peter Filip, Yafei LuRajiv Gandhi Rajiv GandhiNo ratings yet

- Huntsmann EU ELECTRONICS-Selector-GuideDocument24 pagesHuntsmann EU ELECTRONICS-Selector-GuideXavierNo ratings yet

- Argan Oil MSDSDocument10 pagesArgan Oil MSDSCrina BanuNo ratings yet

- IsomerismDocument61 pagesIsomerismSaket DubeyNo ratings yet

- Roller Conveyor Chain AttachmentsDocument19 pagesRoller Conveyor Chain AttachmentsRichard VachonNo ratings yet

- Hydrostatic test results and stresses analysisDocument1 pageHydrostatic test results and stresses analysisToniNo ratings yet

- Review Paper JLT Distributed Fiber Optic Sensing For The Oil Gas Industry1Document24 pagesReview Paper JLT Distributed Fiber Optic Sensing For The Oil Gas Industry1heqinghai heNo ratings yet

- Annual Report - 2008-HelsinkiDocument121 pagesAnnual Report - 2008-HelsinkiTran Quang NguyenNo ratings yet

- Byk-9076 TDS (En) PDFDocument4 pagesByk-9076 TDS (En) PDFABHIJIT chowdhuryNo ratings yet

- Cambridge Assessment International Education: Environmental Management 0680/22 May/June 2018Document10 pagesCambridge Assessment International Education: Environmental Management 0680/22 May/June 2018Suyathi MugunthanNo ratings yet