Professional Documents

Culture Documents

York 10 Manual de Usuario

York 10 Manual de Usuario

Uploaded by

FaustoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

York 10 Manual de Usuario

York 10 Manual de Usuario

Uploaded by

FaustoCopyright:

Available Formats

INSTALLATION OUTDOOR SPLIT-SYSTEM

INSTRUCTION AIR CONDITIONER

MODELS: 10, 12, 13 AND 14 SEER

1 PHASE - 1.5 TO 5 TONS

TABLE OF CONTENTS

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . 2

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHECK ELECTRICAL POWER SUPPLY . . . . . . . . . 2

SELECTING EQUIPMENT LOCATION . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OUTDOOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INDOOR UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REFRIGERANT LINE (SWEAT FIT) . . . . . . . . . . . . . 4

INSULATION OF VAPOR LINE . . . . . . . . . . . . . . . . 4

RE-ASSEMBLING, BRAZING AND CLEANING OF

JOINT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . 5

REFRIGERANT LINE SUPPORT . . . . . . . . . . . . . . . 5

CHARGING AND LEAK TESTING . . . . . . . . . . . . . . 5

TOTAL LINE LENGTH . . . . . . . . . . . . . . . . . . . . . . . 5

ORIFICE SELECTION (ON SWEAT FIT COILS) . . . 5

REFRIGERANT VALVE OPERATION . . . . . . . . . . . 6

OIL TRAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SYSTEM CHARGE . . . . . . . . . . . . . . . . . . . . . . . 8

MEASUREMENT METHOD . . . . . . . . . . . . . . . . . . . 8

SUPERHEAT CHARGING METHOD . . . . . . . . . . . . 8

CHECKOUT PROCEDURE . . . . . . . . . . . . . . . . . . 10

SYSTEM OPERATION CHECKOUT . . . . . . . . . . . 10

CAUTION:READ ALL SAFETY GUIDES BEFORE

YOU START TO INSTALL YOUR UNIT.

SAVE THIS MANUAL

035-13606-003 Rev. A (202)

035-13606-003 Rev. A (202)

GENERAL INFORMATION

These outdoor units are designed to be connected to a

matching UPG indoor coil with sweat connection lines. These

units are factory charged with refrigerant for a matching The manufacturer is not responsible for the per-

indoor coil plus 15 feet of field supplied line. The outside unit formance of a mismatched system. The outdoor

is designed to be placed alongside or at the back of the unit must be installed with a compatible indoor

home, remote from the indoor coil. The outdoor unit has been unit as designated in the specification data or in

factory run-tested and all components of the system are the Directory of Certified Unitary Heat Pumps

ready for easy, immediate installation. published by the Air Conditioning and Refrigera-

tion Institute. Using unmatched components may

INSPECTION not only affect the performance of the system, but

Check the unit thoroughly for shipping damage, Unusually may also void the warranty of the equipment.

rough handling during shipment may loosen fan motors, com- Do not install any coil in a furnace which is to be

pressors, or other components. Be sure that the unit is ready operated during the heating season without

to operate before installing it. If there is damage, file a claim attaching the refrigerant lines to the coil. Allowing

with the shipper. See Form 50.15-NM for more information. the coil charge to enter the refrigerant lines pre-

vents excessive refrigerant pressure build-up and

REFERENCE possible coil damage.

Use this instruction in conjunction with the instructions for the

appropriate indoor unit, air moving system and accessories. Table 1: APPLICATION LIMITATIONS

Installer should pay particular attention to the words NOTE, Ambient Air Temperature Air Temperature on

CAUTION and WARNING. on Outdoor Coil Indoor Coil

NOTES are intended to clarify or make the installation easier. Min. °DB Max. °DB Min. Max.

50 120 57 72

CAUTIONS identify procedures which, if not followed care-

fully, could result in personal injury, property damage or CHECK ELECTRICAL POWER SUPPLY

equipment damage. The electrical power should be checked to determine if ade-

WARNINGS are given to alert the installer that severe per- quate power is available, and near constant voltage can be

sonal injury, death or equipment damage may result if instal- maintained. If there is any question concerning the power

lation procedures are not followed properly. supply, contact the local power company for corrections; oth-

erwise, unsatisfactory performance may result.

LIMITATIONS

SELECTING EQUIPMENT LOCATION

The unit should be installed in accordance with all national

Several important factors must be considered before select-

and local codes and regulations which govern the installation

ing the site for the outdoor unit:

of this type of equipment. In lieu of local codes, the equip-

ment should be installed in accordance with National Electric • Distance to indoor coil

Code, and in accordance with the recommendations made by • Proximity to the structure

the National Board of Fire Underwriters. • Proximity to vents and exhaust systems

Limitations for the indoor unit, coil and appropriate accesso- • Ability to service

ries must also be observed. • Sound transmission

The outdoor unit must not be installed with any duct work in • Air circulation

the air stream. The outdoor fan is the propeller type and is not • Wind direction

designed to operate against any additional external static • Relationship between structure, sun, and unit

pressure. • Distance from power source

The maximum and minimum conditions for operation must be • Water drainage

observed to assure a system that will give maximum perfor- • Local codes

mance with minimum service. Locate the outdoor unit near enough to the indoor coil vicinity

to eliminate lengthy refrigerant line runs. Do not locate the

outdoor unit so it discharges air under eaves or gutters. Rain

or snow melt-off should not be able to run off a roof and down

upon the unit. Be sure vents are not located upwind from the

outdoor unit.

2 Unitary Products Group

035-13606-003 Rev. A (202)

A minimum clearance of 18 inches is required for service at Provide ample clearance from shrubs to allow adequate air to

the control panel and compressor compartments access. A pass across the outdoor coil without leaves or branches

10 inch clearance is required for the air inlet to the outdoor being pulled into the coil.

coil around the perimeter of the unit. The air discharge of the Consideration should be given to the distance and routing of

unit requires a 60 inch clearance between the top of the unit electrical service that would have to be run to connect the

and any obstruction. See Figure 1. outdoor unit.

The length of the refrigerant tubing, between the outdoor unit The unit must be located outdoors and must not be con-

and indoor coil, should be as short as possible to avoid nected to duct work. It is recommended the outdoor unit be

capacity and efficiency loss. Excessive spacing of the out- mounted upon a solid base that will not shift or settle. Top of

door unit from the home can lead to the refrigerant lines base should be two inches above grade. Thought should be

being restricted by trampling or by being punctured by lawn given to water drainage away from the outdoor unit. Drain

mowers. Locate the outdoor unit away from bedroom win- holes in the base pan must be kept clear.

dows or other rooms where sound might be objectionable.

Adverse effects of prevailing winds, blowing snow or sleet

onto the outdoor coil can be eliminated by placing the outdoor

unit where the wind does not blow across the unit. Trees,

shrubs, corners of buildings and fences standing off from the

coil can reduce capacity loss due to wind chill effect.

MINIMUM 24” SERVICE ACCESS

CLEARANCE ON ONE SIDE THERMOSTAT TO FURNACE OR

60” OVERHEAD

CLEARANCE AIR HANDLER

WEATHERPROOF

TERMINAL BLOCK

DISCONNECT

SWITCH NEC CLASS 1 WIRING

NEC CLASS 2 WIRING

10” CLEARANCE

COIL AREA TO INDOOR COIL

SEAL OPENING(S) WITH

NOTE: ALL OUTDOOR WIRING PERMAGUM OR EQUIVALENT

MUST BE WEATHERPROOF.

CONTROL ACCESS PANEL

FIGURE 1 : TYPICAL RESIDENTIAL OUTDOOR UNIT LOCATION

Unitary Products Group 3

035-13606-003 Rev. A (202)

INSTALLATION Use only ACR grade copper tubing and keep ends sealed

until joints are made.

OUTDOOR UNIT

The correct diameters of the refrigerant lines are listed in the

After the site has been selected, a solid base pad that will not

Tabular Data Sheet.

shift or settle should be provided. The base pad should not

come in contact with the foundation or side of the structure For best performance, select routing of refrigerant lines for

because sound may be transmitted to the residence. The pad minimum distance and fewest number of bends.

should be located far enough away from the structure so the Determine the path that the refrigerant lines will follow.

outdoor unit is not closer than its minimum distances. See

Starting at either the indoor coil or the outdoor unit refrigerant

Figure 1. Set the outdoor unit upon the pad with care to avoid

line connections, carefully measure, cut, de-burr and fit cop-

damage..

per refrigerant lines along the path previously determined.

NOTE: If it is necessary for bends to be formed in the vapor

line, the radius should not be less than 12 inches.

Do not remove the protective caps or plugs from Cut ends of the copper tubing square.

the unit refrigerant connections until the refriger- Remove all burrs from tubing with a reamer, file or de-burring

ant lines are run and ready for final connection. If tool.

this procedure is not observed, dirt and other par-

ticles will get into the system and plug various ori- When the indoor coil is above the outdoor unit, the vapor line

fices and small tubes. should be sloped toward the outdoor unit with a fall of at least

1/4 inch per 5 feet.

INDOOR UNITS

When the outdoor unit is above the indoor coil the horizontal

Install the indoor coil in the furnace or air handler according to runs should be sloped toward the outdoor unit as described

the installation instructions packed with each component. above.

REFRIGERANT LINE (SWEAT FIT) INSULATION OF VAPOR LINE

The following steps are very important when setting up a Insulate vapor line with 3/8" (or that required by local code)

refrigeration system and need to be followed completely to closed cell insulation.

insure that a strong, flexible and leak tight system is obtained.

Slide tubing insulation onto the vapor line so that it is covered

The installation of the copper refrigerant tubing must be done completely from the indoor coil to the outdoor unit. Be sure

with care to obtain reliable, trouble-free operation. that the tubing is capped before sliding on insulation.

1. Selection of proper refrigerant tubing grade and size. It is not necessary to insulate the liquid line, unless it is sub-

2. Refrigerant line routing, cutting and fitting. ject to excess heat in an uninsulated area.

3. Insulating the vapor line.

NOTE: In areas of extreme temperatures and humidity,

4. Connecting the refrigerant lines to the indoor coil and additional insulation may be required to prevent excessive

outdoor unit. condensation and loss of capacity.

5. Proper preparation of joint connections.

Do not insulate liquid line and vapor line together. Liquid line

6. Reassembling, cleaning and brazing the joint connec- should not be in contact with the vapor line. See Figure 2.

tions.

7. Pressure leak test all joints. Tape

8. Evacuate refrigerant lines and indoor coil. Liquid

Line

9. Charging refrigeration system (If the line length is other

than 15 feet). See Table 2. Incorrect

Table 2: REFRIGERANT LINE CHARGE

LIQUID OD VAPOR OD R-22 CHARGE, OZ/FT

3/8" 5/8" 0.66 Sheet Metal Hanger

3/8" 3/4" 0.68 Correct

3/8" 7/8" 0.70 Insulated Vapor Line

3/8" 1-1/8" 0.76

FIGURE 2 : INSULATION OF VAPOR LINE

4 Unitary Products Group

035-13606-003 Rev. A (202)

RE-ASSEMBLING, BRAZING AND CLEANING OF When recovering refrigerant from a system, with a burnout,

JOINT CONNECTIONS follow a safe procedure due to possible contamination.

When using hard solder, an inert gas such as dry Avoid getting the refrigerant in the eyes or on the

nitrogen must be introduced and permitted to skin.

flow through tubing during brazing to displace air

and prevent oxidation. Contaminated refrigerant must be recovered and returned to

the local refrigeration supply house for proper disposition.

Remove the Schrader Valve cores from the service valves.

Remove the plugs from the service valve field tubing connec- TOTAL LINE LENGTH

tions. Clean the joints to be brazed. Units should be installed only with approved system combina-

tion (indoor/outdoor) as specified in the Technical Guide.

NOTE: Do not overheat the connection to be brazed as this

can cause improper flow of solder, resulting in a weak and For systems with total line length exceeding 50 feet, see

leaking joint. Never apply heat directly to face of fitting. Do APPLICATION DATA and work sheet "General Piping Rec-

not heat solder by direct contact with flame of the torch. ommendations and Refrigerant Line Length" for vapor and

liquid line sizing, calibration of liquid line pressure loss or

When brazing copper tubing it is very important to preheat

gain, determination of vapor line velocity, elevation limita-

the entire joint before applying the solder. This is done by

tions, orifice connections, system charging, traps, etc.

sweeping the flame steadily and evenly around the fitting, to

bring both fitting and tubing up to equal temperature before Systems with liquid line pressure loss or gain greater than 11

applying the solder. psi must be provided with corrected orifice size as noted in

.APPLICATION DATA.

Reassemble groups of tubing and fittings, brazing several

joints instead of one joint at a time. This reduces the chance ORIFICE SELECTION (ON SWEAT FIT COILS)

for error in the alignment of the assembly. Replace Schrader

Valve cores. DO NOT OPEN SERVICE VALVES AT THIS NOTE: The proper orifice must be installed in the indoor coil

liquid line connection prior to the connection of the refrigerant

TIME.

lines.

Clean joint connection immediately after brazing with wet rag.

REFRIGERANT LINE SUPPORT

Refrigerant lines should be supported in a way that no dips or

sags occur. We recommend four feet between supports. If Coil is under 30 to 35 psig (inert gas) pressure.

refrigerant lines are to be attached to the home structure, Each coil has an orifice installed in the fitting

care should be taken to eliminate the transmission of vibra- between the liquid line connection and distributor.

tions. Attach the refrigerant lines to the indoor coil first. The orifice is identified on a label next to the liq-

Remove plugs from the indoor coil, then clean joints to be uid line connection.

brazed. Braze refrigerant lines to the indoor coil. Attach refrig-

The orifice shipped with the outdoor unit is based on the

erant lines to the outdoor unit.

“most sold” combination, but it may be changed, depending

CHARGING AND LEAK TESTING on the capacity and efficiency of the outdoor unit, elevation

On systems with or without service valves the refrigerant differences, and/or long total line lengths. An additional ori-

should be recovered or recycled in accordance with EPA reg- fice(s) is shipped with most outdoor units for the most com-

ulations. In some cases this may require putting piercing monly required replacement combinations. Other sizes must

valves on both the high and low sides of the system. be ordered from Source 1 Parts if required.

See the appropriate Tabular Data Sheet for the correct orifice

size and charge adder. If the orifice size matches, nothing fur-

ther is required and the refrigerant lines may be connected

per the outdoor unit instruction. However, if another orifice

DO NOT vent refrigerant to the outdoors. should be used, see the coil instruction for details to change

the orifice in the coil.

Unitary Products Group 5

035-13606-003 Rev. A (202)

REFRIGERANT VALVE OPERATION ELECTRICAL WIRING

All outdoor units are shipped with the service To prevent electrical shock, open remote discon-

valves in the closed position. After installation of nect so electrical supply to outdoor unit is shut

the refrigerant and proper evacuation, make sure off. Contactor does not open both sides of the

that all valves are in the open position and that 208/230 volt electrical circuit.

the caps are securely tightened before turning

POWER SUPPLY

ON the electrical power to the outdoor unit.

All wiring must comply with N.E.C. and local codes. See rat-

All models in this series have brass service valves. These ing plate and product data sheet for volts, frequency, phase,

valves are not back seating. Opening or closing valve does maximum fuse size and minimum branch circuit ampacity.

not close service port. Service ports have Schrader valves for

Refer to the wiring diagram inside the unit control box cover

gauge connections. Use back-up wrench on valve body when

before connecting to power supply.

removing cap to open or close the valve. To open, insert hex

wrench into stem and back out counter clockwise until stem 1. The 208/230 volt single phase line voltage service wiring

just touches retaining ring. for the outdoor unit must include a disconnect switch

located within sight of the outdoor unit.

2. Use the correct size fuse or circuit breaker as listed on

the unit rating plate and data sheet. If using nonmetallic-

sheathed cable (NM or NM-B) ampacities shall be that of

If the valve stem is backed out beyond the retain- 60° C conductors per N.E.C 336-26.

ing ring, system pressure could force the stem 3. Wiring connections. - Two are provided in the control

out of the valve body and possibly cause per- box:

sonal injury. In the event that the retaining ring is a. One for low voltage wiring.

missing do not attempt to open the valve.

b. One entrance for high voltage L1 and L2.

Some units may have factory installed 1-1/8" ball valves. To

The adjustable High Voltage Conduit Plate is factory installed

open the valve, remove the brass valve stem cap, located on

for 1/2" conduit connections. For 3/4" conduit, remove the

the side of the valve, with an adjustable wrench. Next, turn

screw holding the plate in place and adjust the location of the

the valve stem 1/4 turn CCW (away from unit).

holes. For 1" conduit, remove the conduit plate and discard.

All caps must be replaced to prevent leaks. Re-install screw to maintain the integrity of the unit structure,

Replace valve cap finger tight, then tighten an additional 1/6 regardless of the conduit being used. See Figures 9, 10 & 11.

of a turn with a wrench, using a back-up wrench on the valve 4. Power connection to the unit is facilitated by screw termi-

body. nals, L1 and L2 on the outdoor unit contactor. See Fig-

ures 9, 10 & 11.

OIL TRAPPING

5. Ground the outdoor unit using the ground lug provided.

When the outdoor unit is above the indoor coil oil trapping is Unless the outdoor unit is grounded through proper wir-

necessary. Please refer to APPLICATION DATA, 690.01- ing to the service entrance ground, a suitable separate

AD1V (1296) and worksheet 690.01-AD1.1V (791) “General ground should be provided at the outdoor unit.

Piping Recommendations and Refrigerant Line length".

6. Use copper conductors only.

Check the system for correct charge after all components of

the system have been installed, connected and wired cor-

rectly.

Connect service gauges to low pressure port and discharge

service ports. Casing or cabinet must be permanently grounded

Allow unit to operate until system pressures and tempera- in accordance with National Electric Code or

other applicable local codes.

tures have stabilized, making sure that the pressure and tem-

perature align with unit service data. If not, check system

charge and adjust if necessary.

6 Unitary Products Group

035-13606-003 Rev. A (202)

LOW VOLTAGE 1. Route the low voltage cable through the fingered bush-

Control wiring may vary depending upon the type of thermo- ing in the low voltage junction box. See Figures 9, 10 &

11.

stat and furnace being connected.

2. Using wire nuts, connect the low voltage wiring within the

Low voltage wiring diagrams can be found with the furnace or low voltage box.

air conditioning blower package installation instructions.

3. A minimum of 19 AWG wire must be used in connecting

Pig-tail connector wires (2 blue or 1 blue, 1 brown) are pro- the low voltage control wiring between the outdoor unit,

vided from the low voltage pull-in coil on the contactor to a air handler thermostat, and outdoor thermostat. For

section of the control box (See Figure 12). A “Fingered” bush- longer low voltage control wiring lengths, consult the

ing is provided in the low voltage knockout hole. If 1/2" con- N.E.C.

duit is used for the low voltage wiring, the bushing is to be Connect thermostat and control package wiring as shown in

removed. Figure 12 and per the instructions packed with those pieces.

START RELAY CONTACTOR

(Not on all Models)

DUAL

RUN/FAN

CAPACITOR FAN

MOTOR

PLUG

START

CAPACITOR

(Not on all Models) LOW

VOLTAGE

BOX

GROUND “FINGERED”

LUG BUSHING

REVERSIBLE HIGH VOLTAGE

CONDUIT PLATE

FIGURE 3 : Typical Condensing Unit Control Box (Start Components Shown)

START RELAY

CONTACTOR

DUAL

RUN/FAN

CAPACITOR

LOW

VOLTAGE

BOX FAN

MOTOR

PLUG

“FINGERED”

BUSHING

GROUND LUG ADJUSTABLE HIGH VOLTAGE

CONDUIT PLATE

FIGURE 4 : Typical Condensing Unit Control Box (Start Components Shown)

Unitary Products Group 7

035-13606-003 Rev. A (202)

ALL FIELD WIRING TO BE IN ACCORDANCE WITH ELECTRIC CODE (NEC) AND/OR LOCAL CODES

POWER WIRING POWER WIRING

208/230-1-60 CONTROL WIRING

230 - 1 - 50 24 VOLT CONTROL WIRING

MINIMUM 18 GA. WIRE FACTORY WIRING

(NEC CLASS 2)

FURNACE OR AIR HANDLER TERMINAL BLOCK

C Y R G W

* TERMINAL W IS ONLY

CONTACTOR REQUIRED ON SYSTEMS

TERMINALS WITH HEAT.

GND. COIL *

LUG Y R G W

CONDENSING UNIT ROOM THERMOSTAT

ALL OUTDOOR WIRING MUST BE WEATHERPROOF. USE COPPER CONDUCTORS ONLY.

FIGURE 5 : TYPICAL FIELD WIRING

SYSTEM CHARGE

The factory charge in the outdoor unit includes enough

charge for the unit and a most sold matched evaporator.

Some indoor coil matches may require some additional Refrigerant charging should only be carried out

charge. See Tabular Data sheet provided in unit literature by a qualified air conditioning contractor.

packet.

MEASUREMENT METHOD

Sweat connect units also include sufficient charge for 15 feet

If a calibrated charging cylinder or accurate weighing device

of lines. Pre-charged line lengths are factory charged with the

is available, add refrigerant accordingly.

correct amount of refrigerant required. Table 2 lists the refrig-

erant line charges.

The “TOTAL SYSTEM CHARGE” must be permanently

stamped on the unit data plate.

Compressor damage will occur if system is

Total system charge is determined as follows:

improperly charged. On new system installations

1. Determine outdoor unit charge from tabular data sheet. charge system per R-22 charge information label

2. Determine indoor coil adjustment from tabular data and follow guidelines in this instruction.

sheet. Check flare caps on service ports to be sure they

3. Calculate the line charge using Table 2 factors. Calculate are leak tight. DO NOT OVER TIGHTEN

over 15 feet of sweat lines for sweat connect units. (between 40 and 60 inch - lbs. maximum).

NOTE: For sweat connect lines, the line charge over 15 feet SUPERHEAT CHARGING METHOD

should be included on the data plate and must be added to

NOTE: Use this method only during system maintenace

the system.

and repair.

4. Total system charge = item 1 + item 2 + item 3.

1. Operate system until temperatures and pressures stabi-

5. Permanently stamp the unit data plate with the total lize (minimum of 10 minutes).

amount of refrigerant in the system.

2. Measure and record indoor wet bulb (WB) temperature

Use one of the following charging methods whenever addi- using a sling psychrometer and the outdoor dry bulb

tional refrigerant is required for the system charge. (DB) temperature using a thermometer.

8 Unitary Products Group

035-13606-003 Rev. A (202)

Table 3: SUPERHEAT VALUE

INDOOR WB OUTDOOR DB°F

°F1 55 60 65 70 75 80 85 90 95 100 105 110 115

50 9 7

52 12 10 6

54 14 12 10 7

56 17 15 14 10 6

58 20 18 16 13 9 5

60 23 21 19 16 12 8 6

62 26 24 22 19 16 12 8 5

64 29 27 24 21 18 15 11 9 6

66 32 31 30 24 23 18 15 11 9 6

68 35 33 30 27 24 21 19 16 14 12 9 6

70 35 33 30 28 25 22 20 18 15 13 11 8

72 35 33 30 28 26 24 20 20 17 15 14

74 34 31 30 27 25 23 22 20 18

76 35 33 31 29 27 26 25 23

1.

Evaporator Entering Air °F

Table 4: TEMPERATURE AND PRESSURE

SUCTION SUCTION SERVICE VALVE SUPERHEAT

PRESSURE

PSIG 01 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34

(Service Port)

61.5 35 37 39 41 43 45 47 49 51 53 55 57 59 61 63 65 67 69

64.2 37 39 41 43 45 47 49 51 53 55 57 59 61 63 65 67 69 71

67.1 39 41 43 45 47 49 51 53 55 57 59 61 63 65 67 69 71 73

70.0 41 43 45 47 49 51 53 55 57 59 61 63 65 67 69 71 73 75

73.0 43 45 47 49 51 53 55 57 59 61 63 63 67 69 71 73 75 77

76.0 45 47 49 51 53 55 57 59 61 63 65 67 69 71 73 75 77 79

79.2 47 49 51 53 55 57 59 61 63 65 67 69 71 73 75 77 79 81

82.4 49 51 53 55 57 59 61 63 65 67 69 71 73 75 77 79 81 83

1.

Saturation Temperature

Table 5: R-22 SATURATION PROPERTIES

TEMP. PRESSURE TEMP. PRESSURE TEMP. PRESSURE TEMP. PRESSURE TEMP. PRESSURE

°F PSIG °F PSIG °F PSIG °F PSIG °F PSIG

45 76.02 60 101.62 75 132.22 90 168.40 105 210.75

46 77.58 61 103.49 76 134.45 91 171.02 106 213.81

47 79.17 62 105.39 77 136.71 92 173.67 107 216.90

48 80.77 63 107.32 78 138.99 93 176.35 108 220.02

49 82.39 64 109.26 79 141.30 94 179.06 109 223.17

50 84.03 65 111.23 80 143.63 95 181.80 110 226.35

51 85.69 66 113.22 81 145.99 96 184,56 111 229.56

52 87.38 67 115.24 82 148.37 97 187.36 112 232.80

53 89.08 68 117.28 83 150.78 98 190.18 113 236.08

54 90.81 69 119.34 84 153.22 99 193.03 114 239.38

55 92.56 70 121.43 85 155.68 100 195.91 115 242.72

56 94.32 71 123.54 86 158.17 101 198.82 116 246.10

57 96.11 72 125.67 87 160.69 102 201.76 117 249.50

58 97.93 73 127.83 88 163.23 103 204.72 118 252.94

59 99.76 74 130.01 89 165.80 104 207.72 119 256.41

Unitary Products Group 9

035-13606-003 Rev. A (202)

3. Measure and record the suction pressure at the suction 6. Is air filter installed and clean?

service valve port. 7. Is the blower motor speed set correctly?

4. Using Table 4, note the superheat value corresponding

IMPORTANT - Installer should place unit data sheet and

to the intersection of the indoor wet bulb and the outdoor

installation instructions in customer packet and give to home

dry bulb.

owner after installation is complete.

5. With the superheat value obtained in step 4 and the suc-

tion pressure value from step 3, find the intersection of SYSTEM OPERATION CHECKOUT

the values in Table 5. This is the required suction tube 1. With thermostat set to the OFF position, close discon-

temperature at the suction service valve. nect switch or switches to complete circuits to condens-

6. To bring the tube temperature in line with the required ing unit and furnace. Set thermostat to call for cooling.

value from Table 5, add refrigerant to the service port to 2. After the system starts, check the voltage and amperage

cause the tube temperature to fall and reclaim refrigerant at the condensing unit contactor.

to cause the temperature to rise.

3. If voltage is not within 10% of rated voltage, or amperage

CHECKOUT PROCEDURE greatly exceeds nameplate amperage, shut down the

system and contact the local power company for correc-

Use the following list to see that nothing was over looked:

tions; otherwise unsatisfactory performance may result.

1. Have all braze joints on refrigerant lines been leak 4. With the system in operation, check the condensing unit

checked? (Sweat Fit Units) for unusual noise and undue vibration.

2. Line set fittings leak checked? (Quick Connect Units) 5. Allow the system to operate until it is balanced or stabi-

3. Have base valves been opened? (Sweat Fit Units only) lized (approximately 30 minutes), before making further

4. Have all refrigerant lines been secured and isolated checks.

properly? 6. Remove manifold gages hoses, and install cap on

5. Is the indoor coil drain hooked up and draining freely? Schrader valves.

Pour water in drain pan.

10 Unitary Products Group

035-13606-003 Rev. A (202)

SERVICE RECORDS

Unitary Products Group 11

Subject to change without notice. Printed in U.S.A. 035-13606-003 Rev. A (202)

Copyright © by York International Corp. 2002. All rights reserved. Supersedes: 035-13606-002, 550.46-N1Y (199)

Unitary 5005 Norman

Products York OK

Group Drive 73069

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Plan de Manejo Ambiental Instalación de Paneles SolaresDocument45 pagesPlan de Manejo Ambiental Instalación de Paneles Solaresefgene50% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Electronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesFrom EverandElectronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- Industrial Process Control: Advances and ApplicationsFrom EverandIndustrial Process Control: Advances and ApplicationsRating: 2 out of 5 stars2/5 (1)

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- UntitledDocument1 pageUntitledFaustoNo ratings yet

- Tarea de Flip Flop, Contadores y Registros de Desplazamiento.Document10 pagesTarea de Flip Flop, Contadores y Registros de Desplazamiento.FaustoNo ratings yet

- M9F11316 DATASHEET WW en-WWDocument3 pagesM9F11316 DATASHEET WW en-WWFaustoNo ratings yet

- UntitledDocument1 pageUntitledFaustoNo ratings yet

- Instituto Ecuatoriano de Seguridad Social: Certificado de AfiliaciónDocument1 pageInstituto Ecuatoriano de Seguridad Social: Certificado de AfiliaciónFaustoNo ratings yet

- Pproyecto de Aula Numeros Complejos 3rosDocument6 pagesPproyecto de Aula Numeros Complejos 3rosFaustoNo ratings yet

- Arrobo - Vélez - Murillo - Práctica 7 - CPEfc EnergéticaDocument1 pageArrobo - Vélez - Murillo - Práctica 7 - CPEfc EnergéticaFaustoNo ratings yet

- UntitledDocument1 pageUntitledFaustoNo ratings yet

- Specification: Constant Current Discharge Characteristics: A (25)Document6 pagesSpecification: Constant Current Discharge Characteristics: A (25)FaustoNo ratings yet

- Arrobo Preparatorio15 TEMR454CPDocument5 pagesArrobo Preparatorio15 TEMR454CPFaustoNo ratings yet

- Cálculo Ejercicio 2Document4 pagesCálculo Ejercicio 2FaustoNo ratings yet

- PDF Cap Vii CompressDocument45 pagesPDF Cap Vii CompressJoShUa PrONo ratings yet

- MEC Company Profile 202211Document36 pagesMEC Company Profile 202211wahyudiNo ratings yet

- Electricidad 2003Document7 pagesElectricidad 2003Roxana Cueva VenturaNo ratings yet

- Abi - Gestion Ambiental - Leime SantiagoDocument6 pagesAbi - Gestion Ambiental - Leime SantiagoSanty AlexanderNo ratings yet

- Rev C - Manual Exportação Mshower Mbanho Lbello RelaxDocument1 pageRev C - Manual Exportação Mshower Mbanho Lbello RelaxDiego PerezNo ratings yet

- Accu-217 FormatoalumnotrabajofinalDocument7 pagesAccu-217 FormatoalumnotrabajofinalAngel CosavalenteNo ratings yet

- Pack Size: Jamuna Oil Company Limited SL Products ListDocument7 pagesPack Size: Jamuna Oil Company Limited SL Products ListtonjyNo ratings yet

- 4H TM P5 Laboratorio de Física IIDocument8 pages4H TM P5 Laboratorio de Física IIFajardo De La Cruz DanielaNo ratings yet

- Petrojet Commercial PricedDocument5 pagesPetrojet Commercial PricedAbdulrahman Ezzat AlkhogaNo ratings yet

- Datasheet JSP36Document2 pagesDatasheet JSP36Ben BenNo ratings yet

- Rapport de Staage SontrachDocument16 pagesRapport de Staage Sontrachsaad taibiNo ratings yet

- Blank Sticker Tabs TemplateDocument2 pagesBlank Sticker Tabs TemplateJobelle De Vera TayagNo ratings yet

- Despiece de DispensadorDocument4 pagesDespiece de DispensadorReinel Damian Orrego Quintero100% (1)

- ModasaDocument2 pagesModasaAldo PabloNo ratings yet

- K45603, K45604, K45703, K45704 - ADA5000 - Technical DatasheetDocument2 pagesK45603, K45604, K45703, K45704 - ADA5000 - Technical DatasheetSales Technical PetrolabindoNo ratings yet

- Catalogo Rack OutdoorDocument15 pagesCatalogo Rack OutdooreduardoNo ratings yet

- 400CFM To 600CFM QXD - ENDocument2 pages400CFM To 600CFM QXD - ENJamal Habbas100% (1)

- EQUIPO7 Actividad3 PDFDocument3 pagesEQUIPO7 Actividad3 PDFVladimir RGNo ratings yet

- TRITON2Document2 pagesTRITON2Augustine File StudyNo ratings yet

- 10 - Beaver600c Dredger Technical DataDocument2 pages10 - Beaver600c Dredger Technical Datahanisry baseriNo ratings yet

- BI-10-09004-0004 Marjan Increment Program Jubail Area-Pipeline Projact PKG#18 DC System Sizing CalculationDocument32 pagesBI-10-09004-0004 Marjan Increment Program Jubail Area-Pipeline Projact PKG#18 DC System Sizing CalculationAfzal AsifNo ratings yet

- HR10SS 1 - L1 - MAHR10SS-E003-02 - JUL10 - SAL - Festo - DDtype - Sensor - PT - ESPDocument51 pagesHR10SS 1 - L1 - MAHR10SS-E003-02 - JUL10 - SAL - Festo - DDtype - Sensor - PT - ESPLuis GuerraNo ratings yet

- Adecuación Tienda LocatelDocument32 pagesAdecuación Tienda LocatelgerardorodriguezNo ratings yet

- ISG CM2880 - 05 - SCR System - CN - 20170227Document71 pagesISG CM2880 - 05 - SCR System - CN - 20170227cx zNo ratings yet

- Lista de Exercícios de Movimento Harmônico Amortecido e Forçado (MHA) e (MHF) - (Resolução Comentada)Document8 pagesLista de Exercícios de Movimento Harmônico Amortecido e Forçado (MHA) e (MHF) - (Resolução Comentada)Pedro Silva100% (1)

- Ingegneria Dei Pozzi PetroliferiDocument487 pagesIngegneria Dei Pozzi PetroliferiAymenNo ratings yet

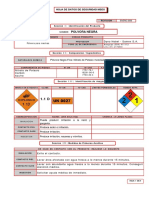

- 19polvora NegraDocument4 pages19polvora NegraLiliana BeruNo ratings yet

- Dipole RCDocument4 pagesDipole RCbechir sidialyNo ratings yet

- 2 Trimestre Ciencias, PlaneacionesDocument22 pages2 Trimestre Ciencias, PlaneacionesBaruch LaraNo ratings yet