Professional Documents

Culture Documents

00 MT June 2023 Advertorial-AAF 1

Uploaded by

American Air Filter0 ratings0% found this document useful (0 votes)

4 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 page00 MT June 2023 Advertorial-AAF 1

Uploaded by

American Air FilterCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ADVERTORIAL

AAF India adapting to the

Japanese PDS system

(Production Daikin System) for Better, Faster

and Cost Effective Manufacturing Facility

innovative solutions that eliminate

redundant resource consumption.

We have initiated the reduction of CO2

emissions by implementing proper energy

consumption monitoring and energy savings

implementations at our factory. Frequently

Industrial Dust Collector we conduct “Tool box talk” with our workers

to create awareness about safety, quality, and

American Air Filter (AAF) is a Daikin group of the company, the No.1 on time delivery to our customers.

air filtration solution and industrial air pollution control equipment (dry & wet

dust collector) provider in India. We are committed to strengthening product Faster Production: Pioneering

manufacturing excellence and rigorous quality aspects by adapting to various Breakthroughs

Japanese technologies, and methodologies. Traditional product fabrication processes PUSHKARAJ

The Kaizen system (a Japanese philosophy that emphasizes continuous often come with inherent time constraints, DIVISIONAL MANAGER –

FACTORY OPERATIONS

improvement) is one of the core principles that we intend to incorporate into our resulting in bottlenecks and reduced

AAF INDIA PVT LTD

manufacturing system. By implementing this system throughout all operations, productivity. However, thanks to

we constantly strive for excellence in every aspect of our operations, from the groundbreaking advancements in technology, our production line is now faster and

production process to skill enhancement in the staff, warehousing, packaging, and more efficient than ever. With this, we have augmented the annual production capacity

transportation. Being a member of the Daikin group, safety is our foremost priority of 2 million filters (former production capacity 1.6 million) and 1,20,000 equipment

and we ensure to abide by all safety guidelines in our manufacturing facility. units (prior capacity 90,000 units). We have implemented a few semi automation

technologies in our process for better productivity and transforming towards industry

Kaizen (Continuous Improvement) Driven System at AAF 5.0 for supporting the large business. Revolutionary HEPA filters, engineered in

Our Kaizen-driven system enables us to stay ahead of the curve, adapt to evolving our upgraded cleanroom environments, are at the forefront of this rapid evolution.

industry demands, and enable us to deliver quality products. These filters are manufactured under ISO9001-2015, ISO 45001-2018 & ISO14001-

On the other hand, our customer-centric approach ensures that we consistently 2015 stringent conditions and tested using EN 1822 compliance autoscan system.

exceed their expectations, providing tailored solutions that address specific With the advent of autoscan we are confident to deliver zero defect products to our

challenges and deliver unparalleled product performance. During the FY23 year, we customers. Apart from this, the technology also enables us to reduce the amount of

aim to build strong connections with our valued customers and vendors by inviting wastage in the factory premises, and the reverse transportation challenges.

them to our manufacturing facility. Furthermore, customer visits will provide us

with an invaluable opportunity to receive direct feedback and insights from those Cost-Effectiveness: The Triple Bottom Line Advantage

who rely on our products. This collaborative approach strengthens the bond between In today's competitive landscape, cost-effectiveness is a key consideration for

us and our customers. businesses that are seeking sustainable solutions. One such breakthrough is the

As a new endeavor, we are actively demonstrating AAF's business goals investment (we have invested 140 million) of industrial automation systems that

(such as quality expectations from the customers) to our vendors and suppliers, offer significant cost savings while maintaining high efficiency are now a reality.

thereby contributing to the enhancement of product quality and meeting customer

requirements. We also train our vendors to follow the PDS system for implementing Future Foolproof Commitment

Daikin culture for producing high quality products with on time delivery. We also place great emphasis on product lifecycle management. From the initial

design phase to product disposal, we consider the environmental impact of our

Environmentally Friendly Solutions: Sustainability at the Core products at every stage. By employing eco-friendly materials, optimizing packaging,

As a leading manufacturing company, we understand the importance of minimizing and implementing recycling initiatives, we ensure that our products have a minimal

our ecological footprint while delivering high-quality products to our customers. As impact on the environment throughout their lifecycle.

part of this commitment, we as a team have tailored to Poka-Yoke lean manufacturing AAF has been awarded several certifications and eco-labels that demonstrate our

system throughout our operations. commitment to sustainability. In order to expand business activities in tier 1 & 2

The key factor behind choosing this Poka-Yoke Mistake proof system in cities, we even planning to transform our manufacturing facilities in Noida.

our production aspects is waste reduction. At AAF India, we have anticipated These achievements not only validate our efforts but also inspire us to push the

implementing a comprehensive waste management system that minimizes waste boundaries of what is possible, further solidifying AAF’s position as a leader in

generation at every stage of our manufacturing process. By accurately analyzing sustainable manufacturing practices.

our production lines and identifying areas of waste, we have been able to implement info@aafindia.net

www.manufacturingtodayindia.com Manufacturing Today JULY2023 25

You might also like

- Presentation CorrectDocument1 pagePresentation CorrectkevinvohraNo ratings yet

- A Shop - Oor Kaizen Breakthrough Approach To Improve Working Environment and Productivity of A Sewing Oor in RMG IndustryDocument13 pagesA Shop - Oor Kaizen Breakthrough Approach To Improve Working Environment and Productivity of A Sewing Oor in RMG Industryabhilekh sarkarNo ratings yet

- Strategy Map - Everpia - Group 12Document2 pagesStrategy Map - Everpia - Group 12Minh Tâm TrầnNo ratings yet

- 58IJMPERDFEB201958Document12 pages58IJMPERDFEB201958TJPRC PublicationsNo ratings yet

- Ford - Aligned Business Framework (ABF) - SajalDocument11 pagesFord - Aligned Business Framework (ABF) - SajalSajal GuptaNo ratings yet

- Overview On Kanban Methodology and Its ImplementationDocument4 pagesOverview On Kanban Methodology and Its Implementationlaukik_rautNo ratings yet

- Catálogo Coval - PneumáticoDocument280 pagesCatálogo Coval - PneumáticoEliezér UhlmannNo ratings yet

- Group 4 JIT ReportDocument22 pagesGroup 4 JIT ReportNUR SHAHIRA ISANo ratings yet

- KANBANDocument4 pagesKANBANMarija IlievskaNo ratings yet

- CCCCCCCCCCCCCCCCCCCCCCCCC CCC: Ôc" C Ôc C C C C C CC Ôcc C C C C C Ôc C C CC C C C C C C C C C C C C C CDocument21 pagesCCCCCCCCCCCCCCCCCCCCCCCCC CCC: Ôc" C Ôc C C C C C CC Ôcc C C C C C Ôc C C CC C C C C C C C C C C C C C CAnjesh KumarNo ratings yet

- Turnaround at Preston Plant Through Quality PrinciplesDocument5 pagesTurnaround at Preston Plant Through Quality Principlesmelinda fahrianiNo ratings yet

- journalsresaim,+IJRESM V3 I8 89Document3 pagesjournalsresaim,+IJRESM V3 I8 89Soumiya BishtNo ratings yet

- journalsresaim,+IJRESM V3 I8 89Document3 pagesjournalsresaim,+IJRESM V3 I8 89Soumiya BishtNo ratings yet

- 5S Implementation in Textile IndustryDocument3 pages5S Implementation in Textile Industryaqsa imranNo ratings yet

- Bài 2Document11 pagesBài 2ttkphuong2001094No ratings yet

- Kaizen Costing: Group-1 Akanksha Bhatnagar-102 Himanshu Kamat-22 Sandeep Singh-12Document19 pagesKaizen Costing: Group-1 Akanksha Bhatnagar-102 Himanshu Kamat-22 Sandeep Singh-12Sandeep SinghNo ratings yet

- Implementation of Lean Manufacturing Operation in RMG Industry of BangladeshDocument26 pagesImplementation of Lean Manufacturing Operation in RMG Industry of BangladeshSayeef Zimran KhanNo ratings yet

- Anufacturing Perations Anagement: Enterprise Sof T Ware ForDocument7 pagesAnufacturing Perations Anagement: Enterprise Sof T Ware ForPedroNo ratings yet

- Forming IS Machine: Proportional Valves, 26 Lines Valve Block, AFE SystemDocument28 pagesForming IS Machine: Proportional Valves, 26 Lines Valve Block, AFE SystemJohn Paul EspanoNo ratings yet

- Rolling Shutters: Quality Engineered SafetyDocument36 pagesRolling Shutters: Quality Engineered SafetyAbin MathewNo ratings yet

- V VV VVV VDocument28 pagesV VV VVV VFlavia GomesNo ratings yet

- Upgradation - PLC Modernization - GMA - Ebrochure - XA1Document22 pagesUpgradation - PLC Modernization - GMA - Ebrochure - XA1Nageswar MakalaNo ratings yet

- ISO System - TQM FinalDocument19 pagesISO System - TQM FinalRambo ThomasNo ratings yet

- SPHERA-GaBi Life Cycle EngineeringDocument4 pagesSPHERA-GaBi Life Cycle EngineeringnayancoepmechNo ratings yet

- Maintenance Evaluation & Benchmarking: Carlos Henrique ArrudaDocument45 pagesMaintenance Evaluation & Benchmarking: Carlos Henrique ArrudaShilpin BhadaniaNo ratings yet

- Developing a Performance Measurement System for Lean ManufacturingDocument5 pagesDeveloping a Performance Measurement System for Lean ManufacturingJuan JacksonNo ratings yet

- Lean Management: Case Study On Gokaldas Exports Ltd. (Gex)Document16 pagesLean Management: Case Study On Gokaldas Exports Ltd. (Gex)Siddharth JhaNo ratings yet

- Lean Manufacturing A1Document14 pagesLean Manufacturing A1Ankita SinhaNo ratings yet

- Operational Excellence in Textile Industry Case Study: East AfricaDocument3 pagesOperational Excellence in Textile Industry Case Study: East AfricafarooquintuNo ratings yet

- Operational Excellence Week-2-17.02.2024 fvDocument38 pagesOperational Excellence Week-2-17.02.2024 fvleondashie143No ratings yet

- Reliability Management at Asian Paints - Team 3Document40 pagesReliability Management at Asian Paints - Team 3nith28No ratings yet

- 58IJMPERDFEB201958 With Cover Page v2Document13 pages58IJMPERDFEB201958 With Cover Page v2allissonNo ratings yet

- AT-07404 AFPM Whitepaper - FinalDocument15 pagesAT-07404 AFPM Whitepaper - FinalZeeshan AlamNo ratings yet

- Lean Case Study - LeatherDocument9 pagesLean Case Study - LeatherSk Mosaib AhamedNo ratings yet

- Inter 1Document8 pagesInter 136Zuhalwah Yuliah IlhamKelas ANo ratings yet

- MainDocument7 pagesMainGabriel Anderson Ceballos OlmosNo ratings yet

- Overview On Kan Ban Sdsdmethodology and Its ImplementationDocument5 pagesOverview On Kan Ban Sdsdmethodology and Its ImplementationyirgaNo ratings yet

- OM Unit IIDocument25 pagesOM Unit IIshabeena ShahNo ratings yet

- Screenshot 2023-12-13 at 12.16.03 PMDocument124 pagesScreenshot 2023-12-13 at 12.16.03 PMhellrider22No ratings yet

- 10 1108 - Ijppm 02 2017 0037 PDFDocument22 pages10 1108 - Ijppm 02 2017 0037 PDFJennyfer ValenzuelaNo ratings yet

- Orion Pharma Project Report.Document9 pagesOrion Pharma Project Report.Doli Singh0% (1)

- Modern AluminiumDocument2 pagesModern AluminiumhamzaNo ratings yet

- Vehicle Control SystemsDocument74 pagesVehicle Control Systemsananth ajith100% (1)

- Overview On Kanban Methodology and Its Implementation: July 2015Document5 pagesOverview On Kanban Methodology and Its Implementation: July 2015prajwal upadhyayNo ratings yet

- 5972-Article Text-23845-1-10-20221031Document10 pages5972-Article Text-23845-1-10-20221031Nur AzlinaNo ratings yet

- BCG Manufacturing Analytics Offering Tcm9 196530Document12 pagesBCG Manufacturing Analytics Offering Tcm9 196530riky123No ratings yet

- Company Profile: Scrap ManegementDocument29 pagesCompany Profile: Scrap ManegementAjay KaushikNo ratings yet

- Process ApproachDocument18 pagesProcess ApproachVincent VicenteNo ratings yet

- Improve Your Business Through Kaizen: Boost your results with continuous improvementFrom EverandImprove Your Business Through Kaizen: Boost your results with continuous improvementRating: 3.5 out of 5 stars3.5/5 (2)

- MCL751: Industrial Engineering System /laboratory Lab 6: Lean Manufacturing 6 SigmaDocument13 pagesMCL751: Industrial Engineering System /laboratory Lab 6: Lean Manufacturing 6 SigmaSURAJ GAVITNo ratings yet

- Emerging Trends in Lean Operation and Sustainability AT Ashok LeylandDocument9 pagesEmerging Trends in Lean Operation and Sustainability AT Ashok Leylandvarun goelNo ratings yet

- Simulation of Lean Assembly Line for High Volume ManufacturingDocument6 pagesSimulation of Lean Assembly Line for High Volume Manufacturingkarthik_avadiNo ratings yet

- Productivity Improvement Using Lean Manufacturing '" A Case Study at Muththamizh IndustriesDocument9 pagesProductivity Improvement Using Lean Manufacturing '" A Case Study at Muththamizh IndustriesEditor IJTSRDNo ratings yet

- The Anand Heijunka Production SystemDocument2 pagesThe Anand Heijunka Production SystemBiswadip BanerjeeNo ratings yet

- Total Quality Management (TQM)Document9 pagesTotal Quality Management (TQM)grace1217No ratings yet

- Introduction To Operations Management: Dr. Erlita C. Guerra, Mba, MpaDocument30 pagesIntroduction To Operations Management: Dr. Erlita C. Guerra, Mba, MpaJessa BasadreNo ratings yet

- Hitachi V RFDocument23 pagesHitachi V RFGallo TicoNo ratings yet

- Hiren - Resure For DhirajDocument4 pagesHiren - Resure For Dhirajsinha_ravikant11No ratings yet

- GaBi Life Cycle Engineering Suite 15Document4 pagesGaBi Life Cycle Engineering Suite 15ochee2toneNo ratings yet

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionFrom EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNo ratings yet

- Non Faculty Application FormDocument6 pagesNon Faculty Application FormBharat KumarNo ratings yet

- Faizan Ur Rehman CVDocument3 pagesFaizan Ur Rehman CVHawabaz AwanNo ratings yet

- Reliance Jio's Internal ResourcesDocument17 pagesReliance Jio's Internal ResourcesBatch 2020-22100% (1)

- A Project Report On Knowledge ManagementDocument6 pagesA Project Report On Knowledge ManagementBharati KudambalNo ratings yet

- EC-Council Certification Path Senior Security Forensics Advanced Disaster Recovery Secure Programmer LawyersDocument1 pageEC-Council Certification Path Senior Security Forensics Advanced Disaster Recovery Secure Programmer Lawyersrusty rawatNo ratings yet

- Soil Mechanics I Cee 305: 2.0 Consistency Limit (Atterberge Limit)Document6 pagesSoil Mechanics I Cee 305: 2.0 Consistency Limit (Atterberge Limit)ABUBAKAR SANI HABIBUNo ratings yet

- Mechanical Flotation Equipment Selection GuideDocument13 pagesMechanical Flotation Equipment Selection Guidelouza8No ratings yet

- Sample - Table - Literature ReviewDocument11 pagesSample - Table - Literature ReviewKeyur KevadiyaNo ratings yet

- Standard Operating Procedure For Customer CreationDocument3 pagesStandard Operating Procedure For Customer CreationMRL AccountsNo ratings yet

- اسئلة مكائن كهربائيةDocument2 pagesاسئلة مكائن كهربائيةAhmed JamalNo ratings yet

- of AbbuDocument10 pagesof AbbuMohan VeerabomalaNo ratings yet

- Process Analysis - VariabilityDocument26 pagesProcess Analysis - VariabilityJerry LeeNo ratings yet

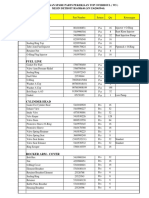

- Even 1819 Result - Results at IET LucknowDocument1 pageEven 1819 Result - Results at IET LucknowDurgesh MauryaNo ratings yet

- Consultancy Dossier 1Document4 pagesConsultancy Dossier 1Ghita NaaimyNo ratings yet

- css12 m2Document7 pagescss12 m2ONHS J MejiaNo ratings yet

- Mrs J's Resource Creations ©Document7 pagesMrs J's Resource Creations ©syddysNo ratings yet

- Control Valves PDFDocument21 pagesControl Valves PDFRiyadh DaoudiNo ratings yet

- Ayvaz Steam Traps BookDocument79 pagesAyvaz Steam Traps BookgideonolinyoNo ratings yet

- All Motor, &electrical Equipment in StorDocument8 pagesAll Motor, &electrical Equipment in StorMd. Saddam HossainNo ratings yet

- Synchrometer STEDocument6 pagesSynchrometer STErcmNo ratings yet

- 16V2000 Detroit W5Document2 pages16V2000 Detroit W5Rendy Chavez LesmanaNo ratings yet

- Redwan Ahmed Miazee - HW - 1Document3 pagesRedwan Ahmed Miazee - HW - 1REDWAN AHMED MIAZEENo ratings yet

- Name Synopsis Description: Curl (Options) (URL... )Document35 pagesName Synopsis Description: Curl (Options) (URL... )yo goloNo ratings yet

- Properties of The Operations On IntegersDocument23 pagesProperties of The Operations On Integersimee marayagNo ratings yet

- Basic Firefighting LectureDocument88 pagesBasic Firefighting LectureBfp Region Vii SanJoseNo ratings yet

- Bess-Sm-3q90041-Qams-003 Method of Statement - Cable Termination PDFDocument5 pagesBess-Sm-3q90041-Qams-003 Method of Statement - Cable Termination PDFChristian BulaongNo ratings yet

- Ekiti Subeb Past Questions and AnswersDocument41 pagesEkiti Subeb Past Questions and AnswersSandra Gkbchall0% (1)

- Civil/Structural Calculation SheetDocument19 pagesCivil/Structural Calculation Sheetfbaxter22No ratings yet

- MATH 103 - Thinking Mathematically I: Gesen @bilkent - Edu.trDocument2 pagesMATH 103 - Thinking Mathematically I: Gesen @bilkent - Edu.trVitto e Leo FerragniNo ratings yet

- High-Impact Talent Analytics PDFDocument2 pagesHigh-Impact Talent Analytics PDFvaibhavjssNo ratings yet