Professional Documents

Culture Documents

15801E09 - Manual Valve

Uploaded by

FAUSTO SAMPIETROOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15801E09 - Manual Valve

Uploaded by

FAUSTO SAMPIETROCopyright:

Available Formats

eni spa

COMPANY TECHNICAL STANDARD

MANUAL VALVES

15801.ENG.PIP.STD

Rev 09 – September 2021

ABSTRACT The scope of this document is to identify requirements for the preparation of

standard and project valves.

Digitally Signed by Digitally Signed

MARCO POZZAN by

01/09/2021 SORIN RUGAN

06/09/2021

13:51:15 11:24:03

Firmato digitalmente da: Fabien Dominique Duclocher

Organizzazione: ENI SPA/00484960588

Unità organizzativa: UPSTREAM DOT

Motivo: Approved

Digitally Signed by Digitally Signed by

Luogo: Milano

Data: 08/09/2021 14:40:59

IRENE ACCIARDI ANDREA

01/09/2021 11:38:40 MARCEGLIA

01/09/2021 18:05:35

09 09/2021 Final Issue Acciardi / M.Pozzan S. Rugan F. Duclocher

A. Marceglia

09B 02/2021 Issued for SPC Puma Acciardi / M.Pozzan Andrea Marceglia Filippo Vailati

implementation

09A 06/2020 Issued for Comments M.Pozzan Andrea Marceglia Giuseppe Ligato

08 06/2015 Final Issue D.Russell/M.Pozzan Andrea Marceglia Enrico Craighero

REV. DATE Reason for issue Prepared Verified Approved

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 2 of 390

REVISION TRACKING

Rev 09: Final Issue

Date: February 2021

Total Number of pages: 390

The document has been reviewed in the following points:

- Implementation of IOGP std

- Change of 600 ASME rating flange connection from RJ to RF

- New valves addition for PCs no. 04, 08, 11, 42/S, 43/S, 44T/ST, 46T/ST, 46 and deletion

of PC no. 44

Further details on reviewed parts include:

- Replacement of A352 LCB Casting material for valves body by LCC to comply with IOGP

MDSs with consequent LTCS PCs p-T rating has been increase.

- New MDSs for Inconel 825 have been created (ref. 05892)

Rev 08: Final Issue

Date June 2015

Total Number of pages: 368 pages.

INFORMATION REQUEST

eni personnel can access company standard repository at:

http://wwweandp.eni.it/TSServices/ITEM/Standards-/Normalizat/Documents-/index.asp

External user shall refer to the Project Engineer Manager.

For information about the content of this standard, please refer to persons mentioned on first

page or to Company Standard Team (mbxc&st@eni.com).

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 3 of 390

INDEX

1 GENERAL ............................................................................................................... 5

1.1 Scope ............................................................................................................. 5

1.2 Reference Standards ...................................................................................... 6

1.2.1 European Union Directives ........................................................................... 6

1.2.2 International Standards .............................................................................. 6

1.2.3 ENI Standards ........................................................................................... 9

1.2.4 Acronyms and Abbreviations ........................................................................ 9

1.3 IOGP SUPPLEMENTARY REQUIREMENTS SPECIFICATIONS .......................... 11

1.3.1 QSL (Quality Specification Level) Selection Criteria for Valves to be Designed

According to IOGP S-562 or IOGP S-611 .................................................................. 11

1.3.2 CAS (Conformity Assessment System) Selection Criteria for Valves to be Designed

According to IOGP S-562 or IOGP S-611 .................................................................. 12

1.3.3 Elastomers types for Valves to be Designed According to IOGP S-562 .............. 13

COMPANY VALVE DESIGNATION ............................................................................... 14

1.4 Standard Valves ........................................................................................... 14

1.5 Project Valves .............................................................................................. 14

2 VALVE DESIGN (FOR NON IOGP VALVES) ........................................................... 17

2.1 Manufacturing requirements ........................................................................ 17

2.2 Dimensional requirements ........................................................................... 18

2.3 requirements FOR MATERIALS ACCORDING TO IOGP S-563......................... 19

2.3.1 Corrosion allowances ................................................................................ 20

2.3.2 Nace requirements ................................................................................... 21

2.3.3 Seals and gaskets .................................................................................... 21

2.3.4 Soft seat ................................................................................................. 21

2.3.5 Packing Materials ..................................................................................... 21

2.4 Gate Valves .................................................................................................. 22

2.5 Globe and Needle Valves .............................................................................. 22

2.6 Check Valves ................................................................................................ 22

2.7 Plug Valves .................................................................................................. 23

2.8 Ball Valves.................................................................................................... 23

2.9 Butterfly Valves............................................................................................ 23

2.10 Triple Offset Butterfly Valves .................................................................... 23

2.11 Compact DBB valves.................................................................................. 24

3 OPERATING DEVICES (FOR NON IOGP VALVES) ................................................. 24

3.1 Manual gear operator for manual valves ...................................................... 26

3.2 Extension for valves ..................................................................................... 27

3.2.1 Designation ............................................................................................. 27

3.2.2 Marking .................................................................................................. 27

3.2.3 Supports for valves extensions under walking level. ...................................... 44

3.2.4 Connection plates to rod ........................................................................... 49

3.2.5 Chain wheel for overelevated valve operation ............................................... 53

4 LUBRICATORS (FOR NON IOGP VALVES) ........................................................... 63

4.1 Lubricated stuffing box valves, detail of connection for lubricator ............... 63

4.2 Valves with lubricated seat, detail of connection for lubricator .................... 65

4.3 Lubricator for valves lubricated at the shutter and the stuffing box ............. 66

5 REPAIRS (FOR NON IOGP VALVES) ..................................................................... 67

6 SPARE PARTS (FOR NON IOGP VALVES) ............................................................. 67

7 PAINTING AND PACKING .................................................................................... 67

8 MARKING OF VALVES (FOR NON IOGP VALVES) ................................................. 67

9 REQUIREMENTS FOR QUALITY MANAGEMENT AND QUALITY ASSURANCE (FOR

NON IOGP VALVES) .................................................................................................. 68

10 ADDITIONAL REQUIREMENTS FOR MANUAL VALVES, INSPECTION AND

DOCUMENTATION DATA SHEETS (FOR NON IOGP VALVES) ...................................... 68

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 4 of 390

11 REQUIREMENTS (FOR NON IOGP VALVES) ....................................................... 68

11.1 Tests ......................................................................................................... 68

11.2 Supplementary tests ................................................................................. 69

11.2.1 Types of supplementary tests .................................................................... 69

11.2.2 Sampling criteria ...................................................................................... 71

11.3 Fugitive Emissions .................................................................................... 73

12 DOCUMENTATION (FOR NON IOGP VALVES) ................................................... 73

12.1 Documentation for approval ...................................................................... 73

12.2 Inspection documentation ........................................................................ 73

12.3 Final documentation.................................................................................. 73

APPENDIX A Pressure Equipment Directive (PED) ................................................ 75

APPENDIX B Valves Types Summary and Standard Valve Data Sheets ................. 75

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 5 of 390

1 GENERAL

1.1 SCOPE

The scope of this document is to identify the minimum design and manufacturing

requirements for standard and project valves. Pipeline block valves are not covered by

this specification.

This specification applies to valves with the following end types:

- threaded or socket welded;

- flanged or butt weld;

- wafer type, butterfly, check and duo-check;

The use of threaded and socket welded ends is restricted to NPS ≤1½”.

For the application of this specification within the European Union, the additional

requirements of Pressure Equipment Directive (P.E.D.) must be applied. See APPENDIX A

Pressure Equipment Directive (PED).

This specification shall be applied to the design of upstream greenfield onshore and

offshore facilities.

Application to brownfield facilities, midstream and downstream installations and other

industrial projects shall be evaluated on project basis.

Drilling and completion facilities, subsea systems and transport facilities (e.g. pipelines)

are out of the scope of this standard.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 6 of 390

1.2 REFERENCE STANDARDS

1.2.1 European Union Directives

Directive 2014/68/EU of the European Parliament and of

the Council of 15 May 2014 on the harmonisation of the

2014/68/EU

laws of the Member States relating to the making available

on the market of pressure equipment.

97/23/EC Pressure Equipment Directive (P.E.D.)

1.2.2 International Standards

API 594 Check Valves: Flanged, Lug, Wafer, and Butt-welding

API 598 Valve Inspection and Testing

API 599 Metal Plug Valves—Flanged, Threaded, and Welding Ends

Steel Gate Valves - Flanged and Butt-welding Ends, Bolted

API 600

Bonnets

Steel Gate, Globe, and Check Valves for Sizes NPS 4 (DN

API 602 100) and Smaller for the Petroleum and Natural Gas

Industries

Fire Test for Quarter-turn Valves and Valves Equipped with

API 607

Nonmetallic Seats

API 608 Metal Ball Valves - Flanged, Threaded, and Welding Ends

API 609 Butterfly Valves: Double-flanged, Lug- and Wafer-type

API 6A / ISO 10423 Specification for Wellhead and Christmas Tree Equipment

API 6D / ISO 14313 Specification for Pipeline and Piping Valves

API 6FA Specification for Fire Test for Valves

API 6FB Specification for Fire Test for End Connections

API 6FD Specification for Fire Test for Check Valves

Recommended Practice for Design and Installation of

API RP 14E

Offshore Production Platform Piping Systems

ASME B1.1 Unified Inch Screw Threads (UN and UNR Thread Form)

ASME B1.5 Acme Screw Threads

ASME B1.20.1 Pipe Threads, General Purpose (Inch)

ASME B16.10 Face-to-Face and End-to-End Dimensions of Valves

ASME B16.11 Forged Fittings, Socket-Welding and Threaded

Metallic Gaskets for Pipe Flanges - Ring-Joint, Spiral-

ASME B16.20

Wound and Jacketed

ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges

ASME B16.24 Cast Copper Alloy Pipe Flanges and Flanged Fittings

ASME B16.34 Valves - Flanged, Threaded, and Welding End

ASME B16.47 Large Diameter Steel Flanges NPS 26 through NPS 60

ASME B16.5 Pipe Flanges and Flanged Fittings NPS ½ through NPS 24

ASME B16.9 Factory-Made Wrought Buttwelding Fittings

Square, Hex, Heavy Hex, and Askew Head Bolts and Hex,

ASME B18.2.1 Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch

Series)

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 7 of 390

Nuts for General Applications - Machine Screw Nuts, Hex,

ASME B18.2.2

Square, Hex Flange, and Coupling Nuts (Inch Series)

ASME B36.10M Welded and Seamless Wrought Steel Pipe

ASME B36.19M Stainless Steel Pipe

ASME B46.1 Surface Texture (Surface Roughness, Waviness, and Lay)

ASME BPVC II – Part D Materials – Part D - Properties

ASME BPVC VIII, Division 1 Rules for Construction of Pressure Vessels - Division 1

ASME BPVC IX Welding, Brazing, and Fusing Qualifications

ASTM A105/A105M Carbon Steel Forgings for Piping Applications

ASTM A153 / A153M Zinc Coating (Hot-Dip) on Iron and Steel Hardware

Forged or Rolled Alloy and Stainless Steel Pipe Flanges,

ASTM A182/A182M Forged Fittings, and Valves and Parts for High-Temperature

Service

Alloy-Steel and Stainless Steel Bolting for High

ASTM A193/A193M Temperature or High Pressure Service and Other Special

Purpose Applications

Carbon and Alloy Steel Nuts for Bolts for High Pressure or

ASTM A194/A194M

High Temperature Service, or Both

Steel Castings, Carbon, Suitable for Fusion Welding, for

ASTM A216/A216M

High-Temperature Service

Standard Practice for Magnetic Particle Examination of

ASTM A275/275M

Steel Forgings

Carbon and Low-Alloy Steel Forgings, Requiring Notch

ASTM A350/A350M

Toughness Testing for Piping Components

ASTM A351/A351M Castings, Austenitic, for Pressure-Containing Parts

Standard Practice for Steel Castings, Welding,

ASTM A488/A488M

Qualifications of Procedures and Personnel

ASTM B148 Standard Specification for Aluminum-Bronze Sand Castings

ASTM B381 Titanium and Titanium Alloy Forgings

ASTM B564 Nickel Alloy Forgings

ASTM E94 Standard Guide for Radiographic Examination

Standard Practice for Liquid Penetrant Examination for

ASTM E165/165M

General Industry

Standard Reference Radiographs for Heavy-Walled (2 to

ASTM E186

41⁄2-in. (50.8 to 114-mm)) Steel Castings

Standard Reference Radiographs for Heavy-Walled (4 1⁄2

ASTM E280

to 12-in. (114 to 305-mm)) Steel Castings

Standard Reference Radiographs for Steel Castings Up to 2

ASTM E446

in. (50.8 mm) in Thickness

ASTM E709 Standard Guide for Magnetic Particle Testing

Standard Test Method for Compressibility and Recovery of

ASTM F36

Gasket Materials

Specification for Surfacing Electrodes for Shielded Metal

AWS A5.13/A5.13M

Arc Welding - 5th Edition

Steel check valves (flanged and butt-welding ends) for the

BS 1868

petroleum, petrochemical and allied industries

Steel globe and globe stop and check valves (flanged and

BS 1873 butt-welding ends) for the petroleum, petrochemical and

allied industries

BS 6364 Valves for cryogenic service

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 8 of 390

BS EN 593 Industrial valves - Metallic butterfly valves

Industrial valves — Testing of metallic valves Part 1:

BS EN 12266-1 Pressure tests, test procedures and acceptance criteria —

Mandatory requirements

Industrial valves — Testing of metallic valves Part 2: Tests,

BS EN 12266-2 test procedures and acceptance criteria — Supplementary

requirements

BS EN 12288 Industrial valves - Copper alloy gate valves

90/10 Copper Nickel Alloy Piping for Offshore Applications

EEMUA PUB 145

Specification: Flanges Composite and Solid

Specification for integral block and bleed valve manifolds

EEMUA PUB 182

for direct connection to pipework

EN 10204 Metallic products - Types of inspection documents

EN 12288 Industrial valves - Copper alloy gate valves

Industrial valves - Face-to-face and centre-to-face

EN 558 dimensions of metal valves for use in flanged pipe systems

- PN and Class designated valves

Supplementary Requirements to API Specification 6D Ball

IOGP S-562

Valves

Information requirements specification (IRS) for IOGP S-

IOGP S-562L 562 supplementary requirements to API Specification 6D

for Pipeline and Piping Valves

Quality requirements specification (QRS) for IOGP S-562

IOGP S-562Q supplementary requirements to API Specification 6D for

Pipeline and Piping Valves

IOGP S-563 Material Data Sheets for Piping and Valve Components

Supplementary Requirements to API 600 Steel Gate Valves

IOGP S-611

and to API 603 CRA Gate Valves

Information requirements (IRS) for Steel and CRA Gate

IOGP S-611L

Valves

IOGP S-611Q Quality requirements (QRS) for Steel and CRA Gate Valves

Bolted bonnet steel gate valves for the petroleum,

ISO 10434

petrochemical and allied industries

ISO 10497 Testing of valves - Fire type-testing requirements

Steel gate, globe and check valves for sizes DN 100 and

ISO 15761

smaller, for the petroleum and natural gas industries

Industrial valves - Measurement, test and qualification

ISO 15848

procedures for fugitive emissions - Part 1, 2 and 3

Metal ball valves for petroleum, petrochemical and allied

ISO 17292

industries

Petroleum and natural gas industries - Compact flanged

ISO 27509

connections with IX seal ring

ISO 5208 Industrial valves - Pressure testing of metallic valves

Metal valves for use in flanged pipe systems - Face-to-face

ISO 5752

and centre-to-face dimensions

MSS SP-44 Steel Pipeline Flanges

MSS SP-80 Bronze Gate, Globe, Angle, and Check Valves

Petroleum and natural gas industries - Materials for use in

NACE MR0175/ISO 15156 H2S-containing environments in oil and gas production -

Parts 1, 2, and 3.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 9 of 390

1.2.3 ENI Standards

05703.ENG.MME.STD Titanium alloy piping welding

05883.COS.GEN.STD Packings for the dispatching of materials and Equipments

05892.ENG.PIP.PRG Pipes and Piping Components for Plants

06732.ENG.PIP.STD Piping Classes

11544.ENG.PIP.STD Cryogenic valve test procedure at -196°C

14365.ENG.PIP.STD Gaskets for Flanged Joints

15722.ENG.PIP.STD Stud Bolts And Nuts For Flanged Joints

29000.ENG.CPI.STD Paintings And Coatings For Offshore And Coastal Structures

20019.ENG.COR.STD Material Selection for Seawater Handling Systems

20198.VAR.LCI.STD Item Numbering

20367.ENG.PIP.STD Weld Code For Welding Procedure And Examination

20367.ENG.MME.STD Carbon steel piping welding

20369.ENG.MME.STD 3,5% Ni steel piping welding

20370.ENG.MME.STD Austenitic stainless steel piping welding

20371.ENG.MME.STD Cr-Mo steel piping welding

20372.ENG.MME.STD 0.5% Mo steel piping welding

20373.ENG.MME.STD Austenitic-ferritic (duplex) stainless steel piping welding

20374.ENG.MME.STD Dissimilar metal piping welding

20375.ENG.MME.STD Nickel alloy piping welding

20376.ENG.MME.STD Carbon steel for low temperature application piping welding

20377.ENG.MME.STD Piping welding examination general requirements

20379.ENG.MME.STD Copper Nickel alloys piping welding

20380.ENG.MME.STD Steel Piping Components

20601.ENG.PIP.STD Elastomer Selection Guidelines

Material Selection for Guidelines in Oil and Gas Processing

20603.ENG.COR.STD

Facilities

MOD.MEC.VLI.001 Additional Requirements For Manual Valves

MOD.MEC.VLI.101 Inspection Data Sheet (Ids)

MOD.MEC.VLI.201 Required Documentation Data Sheet (Dds)

MOD.MEC.VLI.003 Gate Valves - Technical Data Sheet (Tds)

MOD.MEC.VLI.004 Globe Valves - Technical Data Sheet (Tds)

MOD.MEC.VLI.005 Ball Valves - Technical Data Sheet (Tds)

MOD.MEC.VLI.007 Check Valves - Technical Data Sheet (Tds)

MOD.MEC.VLI.009 Butterfly Valves - Technical Data Sheet (Tds)

1.2.4 Acronyms and Abbreviations

The following abbreviations are used in this document:

API American Petroleum Institute

ASME American Society of Mechanical Engineers

ASTM American Society for Testing and Materials

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 10 of 390

BS British Standard

BW Butt-welded (connection)

CE Carbon Equivalent

CS Carbon Steel

CuNi Copper-Nickel Alloy (90/10)

DBB Double Block and Bleed

DN Nominal size

DSS Duplex Stainless Steel (UNS S31803)

EEMUA Engineering Equipment and Material Users Association

EFW Electric Fusion Weld

EN Euro Norm

ENP Electroless Nickel Plating

EPDM Ethylene Propylene Diene Monomer

ERW Electric Resistance Weld

FF Flat Face

GRAPHITE Carbon-Graphite compounds

GRE Glass Reinforced Epoxy

HDPE High Density Polyethylene

IOGP International Association of Oil&Gas Producers

ISO International Standards Organisation

LTCS Low Temperature Carbon Steel

MSS Manufacturers Standardisation Society

NACE National Association of Corrosion Engineers

NB Nominal Bore

NDE Non-Destructive Examination

NPS Nominal Pipe Size

NPT National Pipe Thread

PCTFE Polychlorotrifluoroethylene

PEEK Polyetheretherketone

PMI Positive Material Identification

PTFE Polytetrafluorethilene

PWHT Post Weld Heat Treatment

Average deviation of roughness profile from the mean line

Ra

as defined in ASME B46.1

RF Raised Face

RJ Ring Joint

R-PTFE 15% glass filled reinforced Polytetrafluoroethylene

RTJ Ring Type Joint. See also "RJ"

SBB Single Block and Bleed

SDSS Super Duplex Stainless Steel

SMAW Shielded metal arc welding

SS Stainless Steel

STELL. Welding wire or electrode AWS A5.13 E-Co-Cr-A

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 11 of 390

SW Socket-weld (connection)

THDD Threaded (connection)

TOV Triple Offset Butterfly Valve

UN Unified Inch

UNC Unified Inch Coarse

UNS Unified Numbering System

For gaskets symbols refer to document 14365.ENG.PIP.STD

1.3 IOGP SUPPLEMENTARY REQUIREMENTS SPECIFICATIONS

Requirements of this Company Technical Standard are superseded when IOGP S-562 or

S-611 is specified in the valve data sheet, except for the following:

- paragraph no. 1 GENERAL

- paragraph no. 0 COMPANY VALVE DESIGNATION

- paragraph no. 8 PAINTING AND PACKING

- APPENDIX A PRESSURE EQUIPMENT DIRECTIVE (PED)

- APPENDIX B VALVES TYPES SUMMARY AND STANDARD VALVE DATA SHEETS

When the IOGP S-562 is specified in the valve data sheet, the valve shall be according to

“S-562 Supplementary Requirements to API Specification 6D Ball Valves”, together with

associated documentation and any additional requirements specified in the valve data

sheet. Valve shall be provided with handwheel/gearbox or wrenches/levers for manual

operation.When, in a valve data sheet, the IOGP S-611 is specified, the valve shall be

according to “S-611 Supplementary Requirements to API 600 Steel Gate Valves and to

API 603 CRA Gate Valves”, together with associated documentation and any additional

requirements specified in the valve data sheet. Valve shall be provided with

handwheel/gearbox for manual operation.

1.3.1 QSL (Quality Specification Level) Selection Criteria for Valves to be Designed According to

IOGP S-562 or IOGP S-611

The QSL defines the extent of inspection and testing to be undertaken by the

manufacturer. The QSL is selected on the basis of service risk, with the QSL number

increasing with the extent of inspection and testing required. QSL levels are the

following: QSL-1, QSL-2/2G, QSL-3/3G or QSL-4.

The QSL shall be selected according to the following formula:

QSL = round_up_to_nearest_integer (1+r+s+m+t+f)

where:

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 12 of 390

Valve rating

≤ #600 > #600

r = 0 0,5

Valve Size (DN)

≤ 24" > 24"

s = 0 0,5

Valve body material

CS

All other material,

LTCS

including

SS 304

Cladded valve body

SS 316

m = 0 0,5

Valve design temperature

‐46°C ≤ t ≤ 200°C t < ‐46°C, t > 200°C

t = 0 0,5

fluid

fluid not

flammable, not all other fluids

toxic

f = 0 0,5

A QSL-2 valves to be used in gas service shall be subject to additional inspections and

tests as required by QSL-2G. A QSL-3 valves to be used in gas service shall be subject to

additional inspections and tests as required by QSL-3G.

Higher QSL can be accepted in place of lower QSL. QSL-2G can be accepted also in place

of a QSL-2. QSL-3G can be accepted in place of a QSL-3.

Example:

The QSL for a DN 6”, rating #600, LTCS body material, -29°C ≤ t design ≤ 200°C,

hydrocarbon service trunnion ball valve is:

QSL = round_up_to_nearest_integer (1+0+0+0+0+0,5) = 2

therefore the QSL-2, as minimum, shall be applied to the valve. If the valve is intended

for gas service, the QSL-2G shall be applied.

1.3.2 CAS (Conformity Assessment System) Selection Criteria for Valves to be Designed

According to IOGP S-562 or IOGP S-611

The QRS (Quality Requirements Specification) includes a conformity assessment system

(CAS) which specifies standardized user interventions against quality management

activities at four different levels (A, B, C, D), with the CAS letter increasing with the

decreasing of user intervention.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 13 of 390

If not otherwise specified, the CAS level to be applied shall be the following:

Valve QSL CAS

QSL-4 A

QSL-3/3G B

QSL-2/2G C

QSL-1 D

1.3.3 Elastomers types for Valves to be Designed According to IOGP S-562

IOGP S-562 Version 3.0, “Table 12 – Elastomers Types” shall be replaced with the

following:

Type

Sour Nace

Sweet service

H2S ≤ 20 % (200000 ppm)

Class Tmax design

≤ 150 °C ≤ 150 °C

150 LT FKM LT FKM

300 LT FKM LT FKM

600 LT FKM LT FKM

900 LT FKM +BU LT FKM +BU

1500 LT FKM +BU a

2500 LT FKM +BU a

a Sealing materials in sour service above 250 °F (120 °C) in pressure classes 1500 and 2500

is difficult. The manufacturer shall confirm seal suitability after consultation with seal OEM.

The manufacturer shall confirm to the Company the qualification and certification testing of

elastomers at these pressure classes and max design temperature during bidding phase.

NOTE 1 In sour service peroxide cured FKMs are required.

NOTE 2 Low Temperature - LT grades is standard for FKM. LT grades are available in HNBR.

NOTE 3 +BU means complete with back-up rings.

NOTE 4 HNBRs have limited suitability with aromatic hydrocarbons and steam.

NOTE 5 FKMs have limited suitability with methanol, amines, strong alkalis and some Freons.

NOTE 6 The information given in this table is for guidance only. It is the manufacturer’s

responsibility to confirm seal suitability against specified service conditions with seal

OEM.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 14 of 390

COMPANY VALVE DESIGNATION

Company valve designation shall be as shown below.

1.4 STANDARD VALVES

Standard valves are identified using the Company symbol EN as shown below.

TYPE 5.1

Example of designation VB 5 1 5 EN 1 D 4 RJ 12

Type

Category

Material Group

Rating

Company symbol (EN = eni)

Execution

Body/Bonnet material

progressive number

Valve ends

Nominal diameter

1.5 PROJECT VALVES

Project valves are identified using the company symbol PR as shown below.

TYPE 5.1

Example of designation VB 5 1 5 PR 1 D 9 RJ 12

Type

Category

Material Group

Rating

Company symbol (PR = project)

Execution

Body/Bonnet material

progressive number

Valve ends

Nominal diameter

The valve designation is compiled from the tabulated lists below.

Type:

VS Gate valves

VD Globe, needle or angle valves

VR Plug or 3-way plug valves

VB Ball or 3-way ball valves

VDR Check valves

VF Butterfly valves

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 15 of 390

VM Diaphragm valves

VP Piston valves

CM Compact Modular valves for instrumentation isolation

Category:

1 VS flanged or butt welded

2 VS threaded or socket welded

3 VD flanged or butt welded

4 VD threaded or socket welded

5 VR or VB flanged or butt welded

6 VR or VB threaded or socket welded

7 VDR flanged or butt welded

8 VDR threaded or socket welded

9 Other categories (VF, VM, VP etc.)

C Compact Modular Valves for instrumentation isolation

Material Groups:

0 Cast iron

1 Carbon steel

2 Low alloy steel

3 Stainless steel

5 Copper and its alloys (Bronze, Brass, Copper, Aluminum-Bronze etc.)

7 Metals and special alloys (Hastelloy, Titanium, Monel, Nickel etc.)

8 Non-metallic materials (GRE, HDPE, etc.) and lined body

Rating:

0 Class 125

1 Class 150, PN 10, PN 16, PN 20, PN 25, 16 bar, 20 bar

2 Class 200

3 Class 300 or PN 40

4 Class 400

5 Class 600 or 800

6 Class 900

7 Class 1500

8 Class 2500

9 Other pressure ratings

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 16 of 390

Company Symbol:

EN eni standard

PR Project

Execution and TYPE:

“Execution” is a number 1 ÷ 9 or a capital letter A ÷ Z.

“Category” together with “Execution” (e.g. Category = 5, Execution = 1) allows to find

the constructive form (e.g. TYPE 5.1) as shown in APPENDIX B Valves Types summary.

Body/Bonnet Material:

The letters signify the materials of construction for body and bonnet:

C Carbon Steel

D Low Temperature Carbon Steel

G ASTM A182 F11

J Nickel Alloy 625

N AISI 304

P AISI 304/304L dual certified

R AISI 316

S AISI 316/316L dual certified

T AISI 347

U duplex (forged / casting)

Y Nickel Alloy 20

W Nickel Alloy 825

X Cu-Ni / Aluminum-Bronze

Z Titanium

Valve ends:

BW butt-welded

FF flanged ANSI/ASME: (flat face)

RF flanged ANSI/ASME: (raised face)

RJ flanged ANSI/ASME: (ring joint)

RF125 Ra flanged ANSI/ASME: RF-125 Ra

RF250 Ra flanged ANSI/ASME: RF-250 Ra

THDD threaded BS/DIN/etc.

NPT threaded ASME B1.20.1 NPT

SW socket welded ASME B16.11

SW/THDD one end socket welded, other end threaded

RJ/THDD one end flanged ring joint, other end threaded

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 17 of 390

WAFER RF 125 Ra wafer ANSI/ASME: RF-125 Ra

WAFER RF 250 Ra wafer ANSI/ASME: RF-250 Ra

2 VALVE DESIGN (FOR NON IOGP VALVES)

Note that paragraph 2 (and related subparagraph) are NOT applicable to valves designed in

accordance to IOGP.

The design of standard valves shall consider the following:

- Maintainability, two or three pieces, or top entry

- Fluids aggressiveness (non-corrosive, corrosive, NACE)

- Design temperatures and design pressure

- Fire resistance

- Construction features (ends, materials)

2.1 MANUFACTURING REQUIREMENTS

Standard valves shall be manufactured as per the valve data sheets and be in accordance

with this specification and the following requirements. When the code does not cover a

class rating, size or material the design shall comply with the manufacturer’s standard,

the code mentioned in valve data sheet and ASME B16.34 as far as applicable.

In addition to what is requested in the datasheet the following prescriptions shall be

applied.

- Flanged ends shall be integral with the body.

- The surface finishing of stuffing box and stem shall have a maximum roughness of

63 Ra.

- By-pass valves shall be globe valve type, external screw with yoke and rising

stem.

- Stem yoke nut for valves with an external screw and a non rising stem for valves

DN≥6” pressure rating 600#, 900# and 1500# and for valves DN≥3” pressure

rating 2500# shall be fitted with thrust bearing.

- Gate and globe valves NPS ≥ 2”, in piping classes of rating ≥ 300#, shall be

provided with a lantern ring of the same material as the stem. A plugged NPS ¼”

NPT lubricating point shall be provided at the lantern ring position.

- Unless otherwise specified, the stem of gate and globe valves shall be

manufactured with a back-seat;

- Gate, globe and check valves provided with threaded or expanded seats, are

acceptable with integral seats when specified with the same body material;

- Valves shall incorporate an anti-static feature that ensures electrical continuity

between the stem and body of valves NPS ≤ 2”, and between the ball, stem and

body of larger valves. The anti-static feature shall have electrical continuity across

the discharge path with a resistance not exceeding 10 Ω from a power source not

exceeding 12 V dc. when type tested on a new, dry, as-built valve after pressure

testing and cycling of the valve at least five times.

- The specified finishing for the housing surface of body-cover gaskets shall be:

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 18 of 390

a) For FF coupling: flat face type with roughness 500 Ra in accordance with ASME

B46.1.

b) For MF coupling: male-female type smooth, finished with roughness 125 Ra in

accordance with ASME B46.1.

c) For RJ coupling: ring joint type, in accordance with ASME B16.20.

- The body/ bonnet gasket seat of valves NPS ≤ 2” shall be designed to completely

surround the gasket (confined gasket type).

- Bodies of all valves with NPS ≥ 2”, except butterfly and diaphragm valves, shall

be fitted with bosses for purge connection, by-passes with dimensions and locations

in accordance with the manufacturing codes of the valves.

- With the exception of plug or ball valves and valves with class rating 800#; the

body to bonnet joint for standard valves shall be of RJ type when:

a) the end connection to the line of Class ≥ 900# is RJ

b) the end connection to the line of Class ≥ 900# is BW

- Globe and check valves shall have a cast or forged raised arrow on the valve body

indicating direction of flow.

- When body seats and backseat are to be welded, welded threaded joints are not

acceptable.

- Threaded seat bushings shall be fixed by tack welds.

- Carbon and low alloy steel trunnion ball valves with C.A. ≥ 3mm shall have the

seat housings ENP according to EDS IH0004 or stainless steel overlayed.

- Carbon and low alloy steel trunnion ball valves with C.A. ≥ 6 mm shall have the

seat housing with CRA weld overlay.

- The min. hardness and thickness of nickel overlay on stem, ball and seat rings

shall be as follows:

a) carbon and alloy steel: min. 67 HRC. Thickness min. 50 microns for Mildly

Corrosion severity and min. 75 microns for Highly Corrosion severity and

NACE service.

b) stainless steel: min 60 HRC. Thickness min. 25 microns.

- Valves in cryogenic service shall be designed, manufactured and tested according

“BS 6364 Valves for cryogenic service” and “11544.ENG.PIP.STD Cryogenic valve

test procedure at -196°C”.

- Gate valves for cryogenic service shall have a bleed in the wedge to equalize

pressure in the body cavity with the upstream side pressure.

- Manufacturer shall provide a procedure for welding BW and SW valve ends to the

piping in order to prevent seats damage.

2.2 DIMENSIONAL REQUIREMENTS

Valves are quoted in NPS inch sizes as per codes ANSI/ASME B16.5, ASME B16.47 and

MSS SP 44. The flanged ends of valves shall be designed as follows:

Valves of other materials: ANSI/ASME B16.5 for NPS up to 24” included; ASME

B16.47 Series “A” for NPS of 26” to60”,

MSS SP 44 for NPS of 22”;

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 19 of 390

“Wafer”-type valves shall be designed in such a way to allow their assembly

between flanges ANSI/ASME B16.5 up to 24”, ASME B16.47 Series “A” from 26” to

60” and MSS SP 44 for NPS of 22”.

Bronze, Cu-Ni, Aluminum-Bronze and lined body valves end flanges shall match

with flanges manufactured according to EEMUA Specification no. 145 and ASME

B16.5 Class 150#.

The types of facing specified for flanged valves are:

FF (Flat Face) ANSI/ASME B16.5 for valves class rating 150#;

RF (Raised Face) ANSI/ASME B16.5 for valves class rating 150#, 300# and 600#

RJ (Ring Joint) ANSI/ASME B16.5 for valves class rating 900#, 1500# and 2500#

The ends of butt-welded (BW) valves shall be profiled as per ASME B16.25 to suit the

specified Piping Class NPS and pipe wall thickness.

When the thickness of the valve end is 1,5 times, or more, of the pipe wall thickness, the

Contractor shall supply a transition piece, the design of which shall be submitted to

Company for approval.

The socket welded (SW) and threaded (THDD) valve ends shall comply with ASME

B16.11. The thread of the threaded joints (NPT) shall comply with ASME B1.20.1.

Only valves threaded or socket welded or wafer type may be accepted with end-to-end

dimensions not conforming to the standard specified in the data sheet providing the

deviation is clearly indicated in the bid.

2.3 REQUIREMENTS FOR MATERIALS ACCORDING TO IOGP S-563

When the IOGP MDS (Material Data Sheet) code (e.g. IC004) is specified in the valve

data sheet, the material shall comply with the “IOGP S-563 Material Data Sheets for

Piping and Valve Components”.Material requirements (FOR NON IOGP S-563 MATERIALS)

Additional requirements shall comply with “Particular Requirements for Materials” (e.g.

for sour service, toughness test) defined by “06732.ENG.PIP.STD Piping Classes” and

“05892.ENG.PIP.PRG Pipes and Piping Components for Plants”.

For Inconel 825 MDS no. EIN204S and EIN205S refer to 05892.ENG.PIP.PRG.

The data sheets for standard valves in this specification define the materials of

manufacture for each component. Alternative materials of equal or better suitability may

be offered for Company approval; the proposal shall be justified and documented.

- Cladded carbon steel valves may be submitted for Company approval instead of

materials specified on data sheets providing they are suitable for use in the

conditions of the project.

- The yoke, if separated from the bonnet, shall be manufactured using the same

material as the bonnet.

- Disc and seats of gate, globe and check valves, shall be manufactured either

integrally with the requested material or with the same material as the body and

with sealing surfaces consisting of a welded overlay of the requested material.

- The sealing surfaces of disc may be either integral, manufactured by means of a

welded overlay, or welded rings, or hardened by weld overlay of Cobalt alloy E-Co-

Cr-A” AWS 5.13 (wire or electrode)

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 20 of 390

- When seats and backseat are requested with sealing surfaces of austenitic steel or

hardened by means of a weld overlay of Cobalt alloy “E or Cr-A” AWS 5.13 (wire or

electrode), the requested material may be deposited directly on the separated rings

or on the body/bonnet.

- Direct deposits of 13Cr material on the body or bonnet are not allowed.

- The thickness of the overlay material shall be minimum 1.6 mm after machining.

For valves API 602/ISO15761 the thickness shall be minimum 0.8 mm.

- Cobalt alloys “E-Co-Cr-A” AWS 5.13 used for weld overlay shall be deposited in

accordance with paragraphs QW 216 and 281 of ASME Sect. IX.

- All other welded overlays shall be carried out in accordance with ASME Sect. IX.

- Unless specified in the data sheets, API 6D/ISO 14313 chemical composition limits

shall be fulfilled for valves manufactured according to these standards and in

particular for carbon steel butt welded valves ends the following carbon equivalent

limits shall not be exceeded:

Mn V Cr Mo Ni Cu

CE C

6 5 15

CE ≤ 0,43

- All SS valves with BW, SW ends and/or welded body shall adopt dual certified

marked 316/316L (304/304L) for body material in order to:

• reach higher pressure/ temperature rating of 316 (304)

• ensure the better weldability of 316L (304L);

• harmonize the procurement activities;

• simplify maintenance and repairs.

- All alloy steel bolting for body/bonnet joints up to 210°C shall be hot-galvanized

according to ASTM F2329 or ISO 10684 as per IOGP S-563. .

- Materials and ASTM B564 UNS N06625 shall be supplied according to IOGP S-563.

- Materials ASTM B564 UNS N08825 shall be supplied according to relevant MDS

included in 05892.ENG.PIP.PRG.

2.3.1 Corrosion allowances

Two different corrosion allowances have been defined for carbon and low alloy steel

standard valves based on corrosion severity, as shown below:

Corrosion severity Corrosion Allowance

Mildly Corrosive 3 mm

Highly / Severely Corrosive 6 mm

For 1,5mm CA Piping Classes, 3mm CA valve body can be used.

The valve manufacturer is responsible of the final selection of valve design and processes

such as weld overlay, metal deposit, cladding, surface plating, Electroless Nickel Plating

(ENP according to EDS IH0004), chromium plating (non exhaustive list) to guarantee the

requested valve corrosion allowance for use in the conditions of the project.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 21 of 390

2.3.2 Nace requirements

Valve materials used in sour service piping classes shall meet the requirements of NACE

MR0175/ISO 15156 and IOGP S-563 Material Data Sheets for Piping and Valve

Components”.

2.3.3 Seals and gaskets

When “MFR'S STD” is specified in the datasheet, the valve manufacturer is responsible of

the final selection of the seals and gaskets for the valve, including verification of the

compatibility with fluid and service conditions. At minimum the manufacturer shall take

into account:

- the valve datasheet

- the piping class (design pressure, temperature, service)

- the fluid composition

- the specification “20601.ENG.PIP.STD Elastomer Selection Guidelines”

2.3.4 Soft seat

Soft-seat materials provide good sealing ability, however they shall not be used in dirty

services.

Materials used in standard valves for soft seat are listed below.

PTFE Polytetrafluoroethylene

R-PTFE Reinforced Polytetrafluoroethylene

PCTFE Polychlorotrifluoroethene

PEEK + Graphite Polyetheretherketone Graphite filled

Alternative materials, to manufacturer’s standard, of equivalent or better suitability shall

be submitted to Company for approval before acceptance.

The manufacturing of a soft seat is performed by placing a non-metallic sealing rings in

the plug or in the seats in order to guarantee a perfect tightness.

Valve design, in case non-metallic inserts are destroyed (e.g. in case of fire), shall have a

secondary metal-to-metal seal to prevent an internal leakage and shall ensure that the

ball can be operated with a torque/force value similar to a valve with a primary metal-to-

metal sealing.

The soft seat shall be capable of withstanding a minimum of 2000 opening and closing

cycles at valve operating pressure without suffering damages or permanent deformations

on the soft ring due to friction occurring between the two seals in contact with each

other.

Unless otherwise specified, the soft sealing ring shall protrude out of the metal surface

from min. 0,08 mm to max. 0,25 mm.

The width of the sealing ring shall be maintained in the range from 2,5 mm to 6,5 mm.

2.3.5 Packing Materials

When “MFR'S STD” is specified in the datasheet, packing material shall be specified by

manufacturer in order to guarantee the tightness, adequate torque and force to operate

the valve, ability to withstand wear, fire resistance, compatibility with fluid and suitability

for use in the conditions of the project.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 22 of 390

Packing included in this specification is made of strands of organic, mineral or synthetic

material weaved by square section diagonal intertwining.

An analysis certificate issued by the manufacturer shall guarantee the characteristics of

the material used for the basic weaving or tapes.

In presence of high pressure and high temperature fluids, a metallic reinforcement line

can be added to the basic weaving. During manufacture, such line shall be entirely

wrapped by the fibres that make up the basic weaving.

During manufacture packing are soaked line by line with additives and/or lubricants in

order to give the same special characteristics such as low friction factor, good heat

conductibility, compactness. Soaked or pure graphite packing can be provided by coils of

market length or by pre-compressed rings.

Since a higher number of lines result in better mechanical characteristics, not only the

weaving type and spindles number but also the minimum number of lines that are

necessary for their manufacturing shall be indicated.

Soaking with lubricating, protective, etc. substances shall be implemented line by line.

Alternative packing materials, to manufacturer’s standard, of equivalent or better

suitability shall be submitted to Company for approval.

2.4 GATE VALVES

Gate valves shall be manufactured according to IOGP S-611, ISO 10434/API 600, ISO

15761/API 602, ISO 14313/API 6D and EN 12288 (copper alloy gate valves).

Gate valves can be used with applications that do not require flow control, i.e.:

- interception;

- release valves by-pass of diameter larger than 8";

- when access by clean-up valve is requested;

- purges and pressure gauges.

2.5 GLOBE AND NEEDLE VALVES

Globe valves shall be manufactured according to BS 1873, ISO 15761/API 602 and

MSS SP-80 (copper alloy gate valves).

Globe valves are typically used for DN from 2” to 8” with the following application:

- when regulation is required;

- purges and vents conveying steam;

- regulating choke valve by-pass DN 8” and less.

Needle valves shall be used for DN ≤ 1” ½ when an accurate regulation is required and

as a substitute for globe valve.

2.6 CHECK VALVES

Check valves shall be manufactured according to API 594, ISO 14313/API 6D, ISO

15761/API 602 and BS 1868.

Check valves with DN ≤ 2” are typically of ball or spring piston type.

Swing, Dual Plate Tilting disc check valves can be used on nominal diameters ≥ 2” for

non-pulsating applications. Non slam Nozzle check valves shall be selected in case of

pumps and alternative compressors.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 23 of 390

Dual plate check valves shall have each of the plates will its own spring, or springs which

provides independent closing action.

2.7 PLUG VALVES

Plug valves shall be manufactured according to API 599 and ISO 14313/API 6D.

Lubricated Plug valves can be used when the transported fluid does not risk to be

contaminated by part of seal grease.

Plug valves are typically used with the following applications:

- when clogging might occur;

- when coke formation might occur;

- when quick and efficient closure is crucial;

- lubricating oils;

- fuel gas.

2.8 BALL VALVES

Ball valves shall be manufactured according to IOGP S-562, ISO 14313/API 6D and API

608/ISO 17292.

Ball valves designed according to 14313/API 6D and API 608/ISO 17292:

- shall be “fire safe” certificated according to API 6FA/ISO 10497 and provided with

antistatic device;

- for metal-seated ball valves the leakage rate shall not exceed ISO 5208, Rate B.

2.9 BUTTERFLY VALVES

Butterfly valves shall be manufactured according to API 609 and BS EN 593.

It is difficult to accomplish a leak-tight seal with a regular (non-high performance)

Butterfly valve.

Concentric Butterfly valves wafer lug type with elastomeric liner are normally used in

water service class 150# only.

All butterfly valves with metallic seal shall be certified as fire safe according to

specifications API 607.

Butterfly valves with coupling seal can be used on lines conveying water for approximate

regulation and where defective seal does not result into inefficiency. For offshore

platforms, the use of butterfly valves shall anyway comply with API RP 14E regulation.

All butterfly valves shall be provided with antistatic device.

Disk-to-pipe clearance (see e.g. API 609 ANNEX D) shall be taken into account especially

when valves shall be mounted between EEMUA (16 or 20 bar) flanges or ANSI 150#

flanges.

2.10 TRIPLE OFFSET BUTTERFLY VALVES

Following factors shall be considered in selection and design of Triple Offset Butterfly

Valves:

a) TOVs shall be rate A as per ISO 5208.

b) TOVs are torque seated i.e. operator dismounting with delta pressure is not

possible because TOVs require positive torque to guarantee closure tightness.

Depending on manufacturer design, typically TOVs have preferred installation

(uni-direction) with the shaft to the high pressure side. Shut-off performance is

more reliable in this direction, since pressure is pushing the disc in to the seat.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 24 of 390

In “fail to open” application, the pressure pushing the disc in to the seat could

be a disadvantage.

c) Metal seated TOV containing elastomer or polymer seals, stem seals, etc. that

are used in fire risk area in which they could be subjected to fire should be of a

fire type tested design (ISO 10497) and may be qualified by a test on a

comparable soft seated valve where other seals and materials are the same.

Metal seated TOVs to be avoided in gas services where bubble tightness is a

mandatory requirement.

d) Triple offset butterfly valve should not be specified in small sizes or for high

pressures (> Cl 600#) and should be used in clean services for isolation

purposes. In particular, it shall not be used in services carrying large suspended

solid or services which may solidify.

e) Triple offset butterfly valve results in considerable pressure drop and are not

piggable, therefore, their use should be limited to lines/section where pressure

drop is not a concern and pigging of lines or full bore capability is not required.

f) Triple offset butterfly valve Top entry design shall be selected when used in

place of a ball valve top entry design.

g) Double flanged valves should be preferred in process applications for

maintenance reasons.

2.11 COMPACT DBB VALVES

For sizes ½” to 3” the use of DBB Compact Valves is allowed with project data sheet.

3 OPERATING DEVICES (FOR NON IOGP VALVES)

Valves shall be supplied with an operating device, wrench or manual gear, in accordance

with para. 3.1.

Unless otherwise indicated in the valve data sheet, all operating devices shall be

designed in such a way that the manual torque does not exceed 220 N (22 kg) when

opening and closing the valve at the maximum differential pressure.

Butterfly, ball and plug valves, specified without gear operator, shall be supplied with an

operating wrench. Its dimension shall not exceed 450mm.

The operating wrench of ball valves shall be of the replaceable type, with open and

closed stops and be lockable in the open and closed positions. The operating wrench shall

be along the axis of the line in the open position and perpendicular to the line axis in the

closed position. It shall be designed in such a way as to prevent erroneous positioning

and shall be manufactured using carbon steel protected against rusting.

Hand wheels shall be of the crown type, with notches or protrusions for manual

operations, shall have an arrow to indicate the position and marked OPENED - CLOSED

(valves NPS ≤ 2” excluded) and they shall be manufactured in malleable iron or carbon

steel and protected against rusting. Their diameter shall not exceed 750 mm.

Gate valves with a non-rising stem shall be supplied with a T-socket wrench and shall be

equipped with a protective cap.

All valves, except check valves, shall be equipped with a position indicator OPEN -

CLOSED showing intermediate position for the throttling valves.

The range for manual gear operators is as follows:

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 25 of 390

Full Bore Reduced

Class Gate Globe Plug Butterfly

Ball Bore ball

150# ≥ DN 16 " ≥ DN 8" ≥ DN 6" ≥ DN 8" ≥ DN 8"

300# ≥ DN 12 " ≥ DN 8" ≥ DN 6" ≥ DN 8" All sizes

600# ≥ DN 12 " ≥ DN 8" ≥ DN 4" ≥ DN 6" All sizes

900# ≥ DN 8 " ≥ DN 6" ≥ DN 8" ≥ DN 3" ≥ DN 4"

1500# ≥ DN 6 " ≥ DN 4" ≥ DN 6" ≥ DN 3" ≥ DN 4"

2500# ≥ DN 6 " ≥ DN 4" ≥ DN 3" All sizes

All valves shown in the table above shall be equipped with manual gear operator.

Motorized operator may be required for closing assistance of larger valves, not for the

automatic system.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 26 of 390

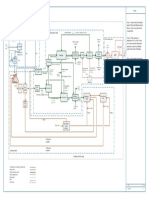

3.1 MANUAL GEAR OPERATOR FOR MANUAL VALVES

Unless otherwise specified, the manufacturer shall supply the "Type A" (see Fig. 1 -

Operator types)

Fig.1 – Operator types

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 27 of 390

The gear operator shall have the following characteristics :

a) Handwheel to be capable to rotate by 90°

b) Thoroughly tight gear box and protected stem

c) Position indicator OPEN - CLOSED

d) The force applied at periphery of operator handwheel shall not exceed 150 N (15

kg) when the operation is started, and 220 N (22 kg) at start-up.

e) Cast iron gear operator is acceptable only if it is mounted on cast iron valves.

Manufacturer shall attach to his tender the mechanical characteristics and the assembly

drawing with description of parts and materials used.

3.2 EXTENSION FOR VALVES

Extensions are forecast for the following valves:

- Globe valves

- Gate valves

- Plug, butterfly and ball valves

- Valves with reduction gear

3.2.1 Designation

Criteria necessary for the complete identification of the materials indicated below for

purchase, storage and usage are the following:

a) type of valve

b) type of extension

c) nominal diameter and rating

d) lengths “L” and “L1” (see fig. 2 e 3)

e) type of steel

f) reference to present document

3.2.2 Marking

Each piece shall be provided with a mark reporting the following criteria:

- type of extension-valve:

PD for globe valves without reduction gear

PS for gate valves without reduction gear

PV for plug, butterfly or ball valves without reduction gear

PRM for valves with reduction gear

- type of extension (see tables)

- DN

- rating

- lengths “L” and “L1”

- type of steel

- relevant company standard document

Example (see note 2): PD / V / 4 - 300 / 1500 - 500 / C / 15801

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 28 of 390

Fig. 2 – Extension assembling layout - Globe valves

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 29 of 390

Fig. 3 – Extension - Globe valves

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 30 of 390

Fig. 4 – Details X and Y

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 31 of 390

VARIABLE DIMENSIONS DEPENDING ON GLOBE VALVE DN AND RATING

VALVE DN

HANDWHEEL

TYPE OF EXTENSION DEFINITION N (equally spaced slotted holes) L L1 M (**) 150 ÷ 600 900 ÷ 2500

N1 N1

150 ÷ 150 ÷ P Q R P Q R

150 300 600 900 1500 2500 150 300 600 900 1500 2500 Arms Arms

2500 2500

1½ - - - V - - - 4 180 300

V 4 ≥ 200 26 17 5

2 V - 4 - 21 15 220 4 400

Z 8

3 V V Z 4 4 8 250 550

V 4 33 22 7

4 Z 8 ≥ 350 300 600

6 SEE 26 17 400 5

NOTE(3)

8 460

Z Valves are fitted 8 Valves are fitted ≥ 450 Valves are fitted with

10 Z 8 510

Z with reduction gear 8 with reduction gear reduction gear

12 33 22 610 7

≥ 500

14 680

TYPE OF C +0,1

DN1 DN2 DN3 S1 S2 S3 A A1 A2 B D D1 E F G H T (*)

Extension thread +0,2

V 4" 2" 1" 6,02 3,91 3,38 130 80 37 33 M32 102 52,0 45 112 31 120

110

Z 6" 3" 1 1/2" 7,11 5,49 3,68 170 105 42 48 M45 154 78 65 152 46 160

NOTES

1) DN = Nominal size (inches).

2) All components of the EXTENSION group must bear the marking in the

positions indicated.

3) The lengths “L” and “L1” will be defined by the Designer each time and will be

indicated in the order.

*) The EXTENSION support guide will be placed in workshop and will be used as

OPEN and CLOSE valve position index.

**) Minimum permitted dimensions in accordance with the various DN to assure

that the exterior box completes the RUN resulting for the travel of the spindle

when the valve is fully open without hitting the guide.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 32 of 390

Fig. 5 – Extension assembling layout –Gate valve

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 33 of 390

Fig. 6 – Extension – Gate Valve

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 34 of 390

Fig. 7 – Details X and Y

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 35 of 390

VARIABLE DIMENSIONS DEPENDING ON GATE VALVE DN AND RATING

VALVE DN

HANDWHEEL

TYPE OF EXTENSION DEFINITION N (equally spaced slotted holes) L L1 M (**) 150 ÷ 600 900 ÷ 2500

N1 N1

150 ÷ 150 ÷ P Q R P Q R

150 300 600 900 1500 2500 150 300 600 900 1500 2500 Arms Arms

2500 2500

1

- - - V - - - 4 ≥ 250 180 300

1/2 V 4 26 17 5

2 V - 4 - 21 15 220 4 400

8 ≥ 350

3 V V Z 4 4 8 250 550

V Z 4 33 22 7

4 ≥ 400 300 600

Z 8 SEE

6 26 17 400 5

Z 8 NOTE(3) ≥ 500

8 Z 8 460

Valves are fitted with

10 ≥ 600 510

Z 8 reduction gear

12 33 22 610 7

≥ 700

14 Valves are fitted with Valves are fitted with 680

16 reduction gear reduction gear - - - - -

18 - - - - - -

TYPE OF C +0,1

DN1 DN2 DN3 S1 S2 S3 A A1 A2 B D D1 E F G H T (*)

Extension thread +0,2

V 4" 2" 1" 6,02 3,91 3,38 130 80 37 33 M32 102 52,0 48 112 31 120

~140

Z 6" 3" 1 1/2" 7,11 5,49 3,68 170 105 42 48 M45 154 78 74 152 46 160

NOTES

1) DN = Nominal size (inches).

2) All components of the EXTENSION group must bear the marking in the

positions indicated.

3) The lengths “L”, “L1” and “L2” will be defined by the Designer each time and

will be indicated in the order.

*) The “extension” support rail shall be positioned in yard.

**) Minimum dimensions accepted for the different DN in order to restrain the

“TRAVEL” of the guide globe resulting from the run of the rod with the valve

in the entirely open position.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 36 of 390

Fig. 8 – Extension assembling layout – Plug, butterfly and ball valves

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 37 of 390

Fig. 9 – Extension – Plug, butterfly and ball valves

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 38 of 390

Fig. 10 – Details X, Y and T

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 39 of 390

VARIABLE DIMENSIONS DEPENDING ON VALVE DN AND RATING

VALVE DN

HANDWHEEL

TYPE OF EXTENSION DEFINITION L L1 M (*) 150 ÷ 600 900 ÷ 2500

N1 N1

150 ÷ 150 ÷ P Q R P Q R

150 300 600 900 1500 2500 Arms Arms

2500 2500

1 V -

21 15 180 4 300

1 1/2 - 26 17 5

2 - See note 300 400

Z ≥ 400 26 17 5

3 - (3) 460 550

33 22 7

4 - 510 600

33 22 7

6 Z - 610

8 Valves are fitted with reduction -

Valves are fitted with reduction gear

10 gear -

TYPE OF C

DN1 DN2 S1 S2 A A1 A2 B D1 E G

Extension thread

V 2" 1" 3,91 3,38 130 80 37 33 M32 52,0 45 31

Z 3" 1 1/2" 5,49 3,68 170 105 42 48 M45 78 65 46

NOTES

1) DN = Nominal size (inches).

2) All components of the EXTENSION group must bear the marking in the

positions indicated.

3) The lengths “L” and “L1” will be defined by the Designer each time and will be

indicated in the order.

4) In yard two longitudinal arrows shall be marked (by painting) on the

extension at the level of the reference indent in the rail support plate, one

with the valve in “CLOSED” position and the other with the valve in “OPEN”

position. The two rotation directions shall be indicated by a double arrow.

5) The extension can be installed both on “VERTICAL” and “HORIZONTAL” valves.

*) Minimum dimensions accepted for the different DN

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 40 of 390

Fig. 11 – Extension assembling layout – Valves with reduction gear

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 41 of 390

Fig. 12 – Extension – Valves with reduction gear

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 42 of 390

Fig. 13 – Details X and Y

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 43 of 390

VARIABLE DIMENSIONS DEPENDING ON GATE VALVE DN AND RATING - WITH OPERATING GEAR

VALVE DN

HANDWHEEL

TYPE OF EXTENSION DEFINITION N (equally spaced slotted holes) L L1 M (**) 150 ÷ 600 900 ÷ 2500

N1 N1

150 ÷ 150 ÷ P Q R Arm P Q R Arm

150 300 600 900 1500 2500 150 300 600 900 1500 2500

2500 2500 s s

4 - - - - - - - - - - - - 300

6 - - 2 1

V 4 300 400 5

8 6 7

2 1

10 V 4 ≥ 350 5 460

6 7 400

12 V 4

See note 550

14 V 4 (3) 460

16÷1 3 2

Z 8 510 600 7

8 3 2

20÷2 3 2

Z 8 610 7 650

2 3 2

Z 8 ≥ 450

> 24 Z 8 680 750

TYPE OF C +0,1

DN1 DN2 DN3 S1 S2 S3 A A1 A2 B D D1 E F G H T (*)

Extension thread +0,2

V 4" 2" 1" 6,02 3,91 3,38 130 80 37 33 M32 102 52,0 45 112 31 120 160 ~

Z 6" 3" 1 ½" 7,11 5,49 3,68 170 105 42 48 M45 154 78 65 152 46 160 210 ~

NOTES

1) DN = Nominal size (inches).

2) Each component of the “EXTENSION” whole shall be marked by the common

mark in the indicated positions.

3) The lengths “L” and “L1” will be defined by the Designer each time and will be

indicated in the order.

4) The extension does not have the reference index for “CLOSED” and “OPEN”

valve.

5) In case of horizontally controlled reducers the valve shall be rotated by 90° in

order to vertically assemble the extension. In special cases the extension can

be horizontally assembled.

*) The “EXTENSION” support rail shall be positioned in yard.

**) Minimum dimensions accepted in the different DN.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 44 of 390

3.2.3 Supports for valves extensions under walking level.

Definition

The criteria necessary for the complete identification of the materials listed below

for supply, storage and use are as follows:

a) support type

b) valve type

c) type of extension

d) type of steel

e) reference to this document.

Marking

Each piece shall be provided with a mark reporting the following criteria:

- type of valve :

o S / PD for globe valves without reduction gear

o S / PS for gate valves without reduction gear

o S / PV for plug, butterfly or ball valves without reduction gear

o S / PRM for valves with reduction gear

- type of extension

- steel

- pertinent internal normalization document

Example: S / PD / V / C / 15801

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 45 of 390

Fig. 14 – Extension Assembling Layout - Globe and gate valves

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 46 of 390

Fig. 15

TYPE OF DNP S A B C D E F G L1 ØP Q L T

Extension

V 8" 8,18 150 350 290 155 220 120 160 162 170 See

Z 10" 9,27 177 410 340 185 270 150 190 174 230 Note (2)

DIMENSION: As reported in table.

MATERIAL: carbon steel.

NOTES

1) Each piece shall be provided with its mark

2) "Q" dimension shall be defined case by case by the designer

NOTE FOR ORDER

- The support shall be ordered together with the valve operation extension type it

refers to and provided with 4 anchorage bolts Ø 5/8" whose lengths shall be

defined by the designer and indicated in the purchase order.

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 47 of 390

Fig. 16 – Extension Assembling Layout - Plug, butterfly and ball valves

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 48 of 390

Fig. 17

TYPE OF

DN S A B C L1 ØP Q L T

Extension

V 4" 6,02 117 230 170 129 110

For valves

Z

6" 7,11 144 270 210 156 160 SEE NOTE(4)

For reduction V

gear Z 8" 8,18 170 300 240 167 210

DIMENSIONS: As indicated in table.

MATERIAL: carbon steel.

NOTES

1) DN = Nominal size (inches).

2) Each piece shall be provided with its mark

3) Specify if “Plug”, “butterfly” or “ball”

4) “Q" dimension shall be defined case by case by the designer

NOTE FOR ORDER

‐ The support shall be ordered together with the valve operation extension type

it refers to and provided with 4 anchor bolts Ø 5/8" whose lengths shall be

defined by the Designer and indicated in the purchase order

ENGINEERING COMPANY STANDARD

This document is property of eni spa. It shall neither be shown to third parties not used for purposes other than those for which it has been sent.

eni spa 15801.ENG.PIP.STD

Rev 09 – September 2021 Pag 49 of 390

3.2.4 Connection plates to rod

Definition

The criteria necessary for the complete identification of the materials listed below

for supply, storage and use are as follows:

a) plate type

b) nominal diameter (inches)