Professional Documents

Culture Documents

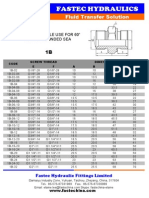

DIN Scuba Fittings

DIN Scuba Fittings

Uploaded by

Rohan KOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN Scuba Fittings

DIN Scuba Fittings

Uploaded by

Rohan KCopyright:

Available Formats

DIN Scuba Fittings

This page was developed for the uk.rec.scuba website here but I will keep this copy current so I can fine tune it. (O-rings) (Threads)

Nigel's home page.

Most scuba divers are familiar with the A-clamp or

International fitting. Originally designed for lower

pressures this has been strengthened for up to

232bar and is still widely used. It has certain

disadvantages and is progressively being

superseded by DIN especially in technical diving

circles.

This is a 300bar DIN regulator. Notice that on the

A-clamp the O-ring was on the cylinder and is

often visible when the regulator is assembled to

the tank valve here it is not only on the regulator

but it ends up buried inside the system and is

hence captive and protected in its working

position. The thread is actually a 5/8" BSP as the

DIN standard is based on what was used and

most dive gear was BSP even my Russian stuff.

232 bar DIN

- 5 thread

Notice 1

inch (25mm)

front to back

outside

dimension

and the

dimple for

the A-

clamp's

screw.

When I

bought

these they

were sold as

A-clamps by

being

supplied

with the slug

(see below)

factory

installed. I

used them

as A-clamps

for my first

couple of

years diving.

If you screw

a 300bar

DIN

regulator in

here it winds

down the 5

threads and

then

compresses

the O-ring

and is ready

to dive. Also

notice the

quite wide

but shallow

hole at the

bottom of

the threaded

section.

300 bar DIN

- 7 thread

Notice 1.4"

(35mm)

depth and

no dimple

so an A-

clamp frame

just will not

fit (Yes I

know the

bull bars are

in the way

too).

If you screw

a 232bar

regulator in

here it is too

deep for the

O-ring to

tighten

against the

bottom and

it will not

seal so

there is no

danger of

blowing your

232bar regs

up on

300bar

pressure.

Also notice

that the hole

at the

bottom of

the threaded

section is

narrower

than the 232

bar DIN -

what is hard

to see in a

picture is

that it is

deeper.

More

differences.

On the left a

232bar end,

notice the

diameter of

the central

piece is

larger then

the 300bar

end on the

right. The

300 will fit

either.

These are

regulator

inputs

coded to

prevent a

232bar only

fitting being

placed on a

300bar tank.

And you remember I pointed out the hole at the

back of the DIN pillar valve? Well this is a 300bar

DIN filling adapter. It has a tube sticking out that

goes into that hole but will not fit the 232bar pillar

valve. This is done to try and stop you overfilling a

tank way beyond its rated pressure.

By using long or short, wide or narrow ends and

setting the number of threads on the fitting you

can include or exclude any combination of fittings

so the two sizes can be used together with safety.

eg: Most regs are usable on 232 or 300 bar so

they have a 7 turn body and a short, narrow core

and fit both. If it was a 232 only reg it would only

have a 5 thread body.

The 232bar

DIN slug to

screw in and

convert DIN

to A-clamp.

It has a

captive DIN

O-ring at the

other end

and this end

has one to

seat the A-

clamp.

If you screw

it into a

300bar DIN

fitting it just

keeps on

going down

before it

seals down

and is lost in

a hole

where the

A-clamp

cannot

reach.

The DIN to

A

adapter wit

h 1.1"

(28mm) max

opening,

this one's by

Apeks.

Um... We don't talk about this one. It's a 300bar

DIN to A-clamp converter and I use it for filling at

places where I can only get on an A-clamp pump.

eg: my club who pump clean air but only 232bar.

It would allow you to put an A-clamp reg on a

300bar tank but if the extra stress broke it we

would all say "What a fool. We do hope he's

alright" as they drag you off to A+E.

This was the

wonderful

Euro Nitrox

valve that

was

supposed to

take over

from DIN for

Nitrox

mixes. I only

ever saw it

in Germany

on Draeger

equipment

but who

knows...

Personally I

didn't like

the external

thread. It

just looked

too

vulnerable.

However in

the couple

of years

since I first

put this

page

together

(04/2003) I

only ever

came

across one

of them and

that was

being

swapped

out. Sadly

the EU

came up

with the

M26 body

which looks

like a

standard

DIN but is

slightly

bigger

thread as

the new Nitr

ox standard.

This is only

a

recomendati

on but some

places are

trying to

force it on

us. I'm not

impressed

as I see it as

fixing a

problem that

does not

exist.

Finally two

specials. On

the left:

Hands up

the guy who

said you

could

probably

convert

anything. It

is a 232 bar

tank but a 7

turn 300bar

fitting. Put a

slug in that

and fit an A-

clamp.

On the

right....

Well... What

do you think

that is for?

Threads and O-rings

I wanted to list the thread names we use on Scuba gear as I can never remember them.

O-rings are identified by their 'dash number' and ID/CS dimensions. (Internal Diameter/Cross Section)

Notice that the DIN and A-clamp O-rings are listed as different but a DIN ring seems to work in every A-clamp reg I

see. This is not true the other way round. They seem to seal OK but fall out at every possible opportunity. I think

everybody uses the DIN size and thinks they are the same.

What I call it What it is O-ring

Standard low pressure port 3/8” UNF -011 .301” .070”

The Apeks bigger version 1/2” UNF -013 .426” .070”

Standard high pressure port 7/16” UNF -012 .364” .070”

Standard 'DIN' thread 5/8” 14TPI BSP -112 .487” .103”

New funny EU nitrox thing M26x2 Apparantly as DIN

A clamp -014 .489” .070”

HP swivels -003 .056” .060”

2nd stage connection 9/16” UNF -010 .239” .070”

Compressed air pipe fittings

G: Series British Standard Pipe - Parallel (Straight) BSP or BSPF

Also referred to as British Gas, British Pipe Parallel or Parallel Fastening thread.

Rc: Series British Standard Pipe - Taper- BSPT

Also referred to as British Standard Taper Pipe or Pipe Taper, or Conical Thread.

Taper is 3/4” taper per foot (1 in 16 on the diameter)

Of course the size refers to the o/d of pipe so the fittings are much bigger.

The pictures are of a 1/4” thread. The major and minor diameters are close enough to get an identification - well -

provided you're sure it can't be the American NTP which is horribly similar.

Nominal Size (inches) TPI Major Diameter (inches) Minor Diameter (inches)

1/16” 28 0.304 0.2583

1/8” 28 0.383 0.3372

1/4” 19 0.518 0.4546

3/8” 19 0.656 0.5886

1/2” 14 0.825 0.7336

5/8” (DIN) 14 0.902 0.8106

3/4” 14 1.041 0.9496

7/8” 14 1.189 1.0976

1” 11 1.309 1.1926

Spotting the taper, to know if it's BSP or BSPT, can be problematic but the calipers can help.

Comments/complaints/pointing out obvious errors to nigelh@nigelhewitt co uk

by Nigel Hewitt

You might also like

- 102 Engine SeriesDocument781 pages102 Engine SeriesRaed Mahyoub100% (2)

- ASME B1.13M - 2005 (Reaffirmed 2010) PDFDocument84 pagesASME B1.13M - 2005 (Reaffirmed 2010) PDFKristin JonesNo ratings yet

- Asme b1.20.1 NPT ThreadsDocument1 pageAsme b1.20.1 NPT ThreadsGabriel Arghiriade100% (1)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingSun Rise100% (1)

- Basic Rigging Work BookDocument45 pagesBasic Rigging Work BookJohn Henry Sinurat100% (1)

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionRating: 5 out of 5 stars5/5 (2)

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinFrom EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinNo ratings yet

- Dial String Guide DC-3Document95 pagesDial String Guide DC-3Edd Whatley100% (1)

- 9mm PistolDocument24 pages9mm PistolGeorg WolfNo ratings yet

- Asme B5.38-1958Document14 pagesAsme B5.38-1958vijay pawarNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- Tubulars and Tubular Services Catalog: DrilcoDocument29 pagesTubulars and Tubular Services Catalog: DrilcoDoni KurniawanNo ratings yet

- 3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsFrom Everand3D Photography Slide-Bars, How to Make 3D Camera Slide-Bars and Twin-Cam Mounting BarsNo ratings yet

- The Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoFrom EverandThe Marmo Method Modelbuilding Guide #6: Building The Williams Bros. 1/72 scale Curtiss C-46A CommandoNo ratings yet

- Geometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsFrom EverandGeometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsRating: 5 out of 5 stars5/5 (2)

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C Membersmanumeet100% (2)

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C MembersAmey ShettiNo ratings yet

- Cameron SurfaceDocument25 pagesCameron SurfaceRazvan BaicanNo ratings yet

- Dulmison RRG 2003Document263 pagesDulmison RRG 2003Nestor100% (1)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Logan Standard Releasing Spear ManualDocument37 pagesLogan Standard Releasing Spear ManualSamuel Arévalo GNo ratings yet

- CHANGHE Freedom Service Manual PDFDocument341 pagesCHANGHE Freedom Service Manual PDFFabian Carrasco Naula100% (10)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- DC-3 SAMS Dial Cord PDFDocument95 pagesDC-3 SAMS Dial Cord PDFKrocodyne RádioNo ratings yet

- Practical Guide to the Operational Use of the Beretta 92F/M9 PistolFrom EverandPractical Guide to the Operational Use of the Beretta 92F/M9 PistolNo ratings yet

- Tubulars Tubular Services Catalog PDFDocument29 pagesTubulars Tubular Services Catalog PDFHERNANDO CASTILLO100% (1)

- Engineering Drawing by Sakthi PDFDocument238 pagesEngineering Drawing by Sakthi PDFSakthi RoyalhunterNo ratings yet

- Anwendung: ApplicationDocument2 pagesAnwendung: ApplicationAditya Putra PanjaitanNo ratings yet

- General - Tooling: ContentDocument38 pagesGeneral - Tooling: ContentKaiser46Li206No ratings yet

- Reinforcing Detailing of R.C.C Members - K.kaviTHADocument47 pagesReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaNo ratings yet

- E6102 Schnellverschlussk PDFDocument10 pagesE6102 Schnellverschlussk PDFZool HilmiNo ratings yet

- EN6102 SchnellverschlusskDocument10 pagesEN6102 SchnellverschlusskaNKURNo ratings yet

- Cam & Groove Couplings: Standard Federal Mil A-A-59326ADocument42 pagesCam & Groove Couplings: Standard Federal Mil A-A-59326ADar FallNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهSwift WardNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهBen ÂmarNo ratings yet

- Scott CylinderDocument5 pagesScott CylinderMashur Al Junaibi100% (1)

- 1 2 2 System Description 2 3 Material and Identification 4 4 Load Capacity 4 5 Production 4 6 Installation 7 7 Quality Assurance 7 8 Applications 8Document8 pages1 2 2 System Description 2 3 Material and Identification 4 4 Load Capacity 4 5 Production 4 6 Installation 7 7 Quality Assurance 7 8 Applications 8Vagany7No ratings yet

- BLK18-S-4065-S03100-SBMG-B-003 Rev 1 IFR End Fitting Closed Socket General Arrangement DrawingDocument2 pagesBLK18-S-4065-S03100-SBMG-B-003 Rev 1 IFR End Fitting Closed Socket General Arrangement DrawingKaoutar KaddouriNo ratings yet

- Vsd35 3 AzDocument8 pagesVsd35 3 AzUpendra Priyanka KumaraNo ratings yet

- Salberg A4 Catalogue RevisedDocument28 pagesSalberg A4 Catalogue RevisedSinenhlanhlaNo ratings yet

- GTS-65 (2-Layer) : Global Transmission Sleeve (Application Without Epoxy Primer)Document2 pagesGTS-65 (2-Layer) : Global Transmission Sleeve (Application Without Epoxy Primer)Carlos MtzNo ratings yet

- Guy-Grip Dead-End: NomenclatureDocument8 pagesGuy-Grip Dead-End: NomenclatureTurinto MarjonoNo ratings yet

- Grapa de Anclaje PDFDocument8 pagesGrapa de Anclaje PDFdiux96No ratings yet

- DiffuseresDocument24 pagesDiffuseresHakeem AdDarNo ratings yet

- Fuseclips For A480r5r-1 and A480t2eDocument2 pagesFuseclips For A480r5r-1 and A480t2eM. Taufik HidayatNo ratings yet

- A100K11254 Turbine Compact IP Mounting Manual VSDocument4 pagesA100K11254 Turbine Compact IP Mounting Manual VSPano de PiaNo ratings yet

- 4 Prong Universal Heat InstallationDocument1 page4 Prong Universal Heat InstallationdrsurferNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingLimar SetstraNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument21 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesEliel AbadNo ratings yet

- V Ring PDFDocument26 pagesV Ring PDFAnonymous D5QForitcNo ratings yet

- DownloadDocument47 pagesDownloadGajanVashishth100% (1)

- Quality Screw Conveyor Unit Modules: Catalog No. 298ADocument8 pagesQuality Screw Conveyor Unit Modules: Catalog No. 298AAnonymous K3FaYFlNo ratings yet

- UK Katalog 4.udgaveDocument189 pagesUK Katalog 4.udgavefarmi84No ratings yet

- Dokumen - Tips 9mm-PistolDocument24 pagesDokumen - Tips 9mm-PistolRoberto SchreinerNo ratings yet

- Keystone 322Document4 pagesKeystone 322Angel BarrantesNo ratings yet

- JosamDocument274 pagesJosamdavid0775No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Iso 9974 4 2016Document9 pagesIso 9974 4 2016Дмитрий ШурпачNo ratings yet

- StucchiDocument132 pagesStucchiCentral Hydraulics100% (1)

- Dywidag Rock BoltsDocument8 pagesDywidag Rock Boltsjudid rojas huanayNo ratings yet

- Sprocket-Catalog eDocument102 pagesSprocket-Catalog eDesmondKrugerNo ratings yet

- Fastec Pipe Fittings Iso Standard FOR SAAB SCANIADocument18 pagesFastec Pipe Fittings Iso Standard FOR SAAB SCANIALakshitha Dx AmalNo ratings yet

- Accessories: Fields of Application Professional Ground ScrewsDocument18 pagesAccessories: Fields of Application Professional Ground ScrewsMarta GameiroNo ratings yet

- 501/453 UNIVERSAL Hazardous Area Cable GlandDocument1 page501/453 UNIVERSAL Hazardous Area Cable Glandhashmin karuvathilNo ratings yet

- L404F, T, V Pressuretrol Controllers: FeaturesDocument8 pagesL404F, T, V Pressuretrol Controllers: FeaturesGabriel BustamanteNo ratings yet

- Guidelines For Use of HSFG Bolts On Bridges FinalDocument23 pagesGuidelines For Use of HSFG Bolts On Bridges Finalradhakrishnang100% (1)

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- Iso 6157 2 1995Document9 pagesIso 6157 2 1995Gustavo FelipeNo ratings yet

- Home Sitemap About Us Technical Data Privacy & Security Terms & Conditions Basket ContactDocument2 pagesHome Sitemap About Us Technical Data Privacy & Security Terms & Conditions Basket Contactninatena100% (1)

- EML2322L - Tap & Drill ChartDocument2 pagesEML2322L - Tap & Drill ChartKris GonzalezNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- Geometric Constructions: Prepared By: MARIFA S. TORRALBADocument8 pagesGeometric Constructions: Prepared By: MARIFA S. TORRALBABen TenederoNo ratings yet

- Installation, Operation & Maintenance Manual For Series 480 Lineshaft Turbine PumpsDocument36 pagesInstallation, Operation & Maintenance Manual For Series 480 Lineshaft Turbine PumpsAngel De La Torre CollNo ratings yet

- Action JacDocument0 pagesAction Jacswoo323No ratings yet

- Criticality of High Speed Separable AlignmentDocument27 pagesCriticality of High Speed Separable AlignmentJose Luis RattiaNo ratings yet

- Koc MP 030 Part 1Document14 pagesKoc MP 030 Part 1Ravi MahetoNo ratings yet

- Astm A490Document7 pagesAstm A490vu hungNo ratings yet

- Navoji - PodatciDocument88 pagesNavoji - PodatciNikolat84No ratings yet