Professional Documents

Culture Documents

12MAV24AP001

Uploaded by

Mehroz Khan0 ratings0% found this document useful (0 votes)

21 views14 pagesTest Report

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTest Report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views14 pages12MAV24AP001

Uploaded by

Mehroz KhanTest Report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

SIEMENS

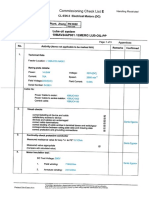

Commissioning Check List E

CL-E06.5 Electrical Motors (DC)

Handling Restricted

126:

PK1022

Powe

3 MW Punjab Power Plant, Jhang

Pt

Part Cse

System: Lube oil system

KKS/ Description: 12MAV24AP001 / EMERGENCY LUB.OIL-PP

Page:tof3 Appendices:

No. Activity (items not applicable to be marked NIA) Remarks | Confirmed

. | |

4. | Technical Data

Feeder Location: +126C02 A001

Rating plato detail:

Power; 12540 Votege: §——220V(00)

Curent 754 Speed. 2900 mi Osman

Field Voltage: 220V(00) Field Curent: 153 0 Powrove

Serial Number: 92920 |

Cable Nor

Power Cable to motor: s2Buct00%

Power Gable to serie resistor: {28UC1002

onto cable 12804100

z Visual checks ~ ~

come abeing of device and cable 3

Satisfactory access to device a 6.

devices and cables are undamaged a sman |

Corest cable terminations a Poturovic

correct sealing of cable ents in terminal boxes and switchgear

correspondence betwoen rating plate data end drawing date a

correc protective and grounding connections a

3 Continuity check protective conductor - 7

Measured resistance vale for loop ‘L+ 0 PE" 9 (him ovmnan

Poturovc

Measured value appropriate a

| Compare wih cate vay

« Motor Insulation test: - ~

DC Test Votage: 500

Osman

1. Fleldwinding: —>990 Moh» Poturove

2 Armature winding: 299 vom

“rraral positon, Seeman nd eng adie or weton cain

Title: CL-E06.5 Electrical Motors (DC)

KS: 42MAV24APO01

| Activity ]

Page: 2 0f3

Remarks | Confirmed

Electrical function tests.

41. DC contro! a

2. Fault signal from plug-in unit a 6

3. On/Off switching manuaytrom local cont a wa | orn,

4. ECO relay (correct function of pressure switch) g

5. External commands (.e. pressure switch) a

6. | Winding resistance test ~

1. Fleldwinding: == 100.2 Ohm Osman

Poturovie

2 Armature winding: 0.7 Ohm

‘Adjustment of Resistors

7.4| Armature series resistor ~

1. According to manufacturers instruction, the resistor(s) shall be adjusted to

R21=0492, 220020

Osman

2. Actual adjustment of resistor(s) Poturovie

R21=0.481 0, R22=0.027 0

Note: in case the values are different, add an appropriate explanation under

“Remarks”

7.2. | _ Field resister (f applicable) 7

1. According to manufacturers instruction, the resistor shall be adjusted

‘e. a Osman

2. Actual adjustment of resistor. 2} NA | poturovic

‘Note: In case the values are different, add an appropriate explanation under

"Remarks"

8. | Timer for switching out Start Up Resistor(s) (if applicable) 7 -

Time Delay 1 (set}=0.88

Time Delay 2 (set)=0.28

Osman

Time Delay 1(measured)=20 is | Poturovic

Time Delay 2(measured)=23' m=

“Tcwcitlproaicton Gteeinton andr oie ofa aaainoy ay wees aoaion

Tith

CL-E06.5 Electrical Motors (DC)

Page: 30f 3

KKS: 12MAVZ4APo01

No. Activity Remarks | Confirmed

9. | Settings overcurrentioverioad protection equipment power circult ~

1 Overcurrent protection equipment (i.e. 1) power circuit

Type of equipment ‘Siemens, 3NA3 140

Overcurrent setting: & 200A

High-set overcurrent setting> [>> (fapplicable) NIA

2, Overload protection equipment (.e. -F4) power circuit ‘Osman

Poturovie

‘Type of equipment: ‘ABB, TA 2000U-110 |

‘Overload setting: 1 758 (applicable |

Overload function: tripfalarm

3. Overcurrentiovertoad protection equipment (ie. -F11) contro circuit

Type of equipment: Siemens, 5SY5203-7

Overcurrent setting bm c3

10. | Rotation / Direction test according to mechanical requirement / Current =

1. Carried out with criven machine a

2. Carried out without driven machine Oo

3. Direction (view from driven machine to motor )

clockwise o

‘counterclockwise a

Measurement of current Osman

Poturovie

1 Startup current (armature circuit. 252.8

2. Load current with driven machine, armature circ). 548

3. Current field circuit (with driven machine) ..cueee 16A

| 4.) Remarks: ~ ~

| Department: PG SO GP COMMELEC Name: Osman Poturovie

Date: 04.04.2022. Signature: ag

ERGY |

SENENS EMA |

Commissioning “a8

a ircrarandcrnincson ea ones oes te

ean

ee ores,

SIEMENS

Commissioning Check List E

CL-E03.2 Discharging of Batteries

126:

|

MW Punjab Power Plant, Jhang | PK1022

System:

Component:

‘ST-Battery Ne.1

12BTA10

Restricted

NOTE: Applicable only, if no manufacturer checklist is available. Page:

10f3

No. I

Activity

(Items not applicable to be marked N/A)

Remarks

Confirmed

1

Technical data from Manufacturer

Manufactures HOPPECKE

Type: 15 OSPHC 1275

No. ofcelis: 108

Rated voltage per cell: 2.0

Total Rated voltage: 216V

Rated capacity: 1345 Ah

Discharge period 10h

Final discharge voltage: 2024 V

‘Nominat temperature: 20°C

Test data

‘Ambient temp. attest begin 22°C

“Ambient temp. at end of test 35°C

Start of test 8:40 hours

End of est 18:40 hours |

Calculation of discharge currentFinal discharge voltage

Discharge current = Rated capacity / Discharge period

Discharge current = 134.54

Final discharge voltage = Final discharge voltage per cell x No. of cells

Final discharge vottage = 2024 V

Discharging

Five pilot cells shail be chosen and the numbers entered into the

table next page.

Adjust discharge current (tem 3) and keep current constant

during discharging. i

Measure battery voltage continuously or at intervals during the

‘est. Note: the intervals shall be shortened towards the final

discharge voltage.

Connect a recorder to record battery voltage and current ori

available, use application sofware of test device manufacturer

NOTE: Start charging of battery immediately after completion of tests

Tipit crran ronnie ae eater eam a rlegw

CL-E03.2 Discharging of Batteries

Commissioning Checklist € System: SFBattery NA

‘Component: +1BTAt0

Page: 2 of 3

No. Remarks | Confirmed

| {Items not applicable to be marked N/A)

Battery

Time | Curenua ater TemperatuelC

Cel | Gell Cell) Cell | Ce

ae jo | % | 50 | 7 | 90

caso | 1346 | 2259 | 209 | 266 | 303 | s02 | 200

roan | s048 | tre | 202 | ana | se | 320 | 317

tao | 1948 | ate | 225 | asa | ant | oa | a0

taao | 145 | 2157 | 347 | a70 | 357 | 365 | 364

wea | 1948 | 205 | 67 | 60 | 50 | ova | ose

1440 | 1945 | 2130 | 346 | 372 | 259 | o58 | 967

ssao_| 1345 | 244 ap7 --a86 + aoe] ae) one

t (Tt

teao | 145 | 2007 | 262 | se2 | 67 | soa | ace

wao | ras | 2070 | aes | v0 | 268 | ser | so7 | x12 | ass | 2 [ue] a

te40 | 1945 | 2054 | 973 | a7e | a7 | are | a74 | 140 | a1 | 140 [ato aa1

tea | 1345 | 2024 | 359 | 363 | are | 379 | 350 | 100 | 100 | 100 | 1001 100

q 7 Yt

s | ot te |]

—| a :— 1 ~

+ { | -

| {

mi | bo J. 7

| \ 1 |

engot he dame a wala iin

CL-E03.2 Discharging of Batteries

Commissioning Checklist © ‘System: “SF Battery Net

Component: 11BTA10

Page: 3 0of3

No. Activity. Remarks | Confirmed

(Items not applicable to be marked N/A)

Remarks: —

| Department: PG SOGP COMM ELEC Name: Dubravko Poljak

Date: 15.01.2022. Signature: aa

a

Tt ein isn ae etgat ones wi

SIEME NS Commissioning Check List E pesticted

03.2 Discharging of Batteries

1263 MW Punjab Power Plant, Jhang | PK1022

Power Pa ne eae

Component: 12BTA10

NOTE: Applicable only, if no manufacturer checklist is available

No. Activity Remarks | Confirmed

{items not applicable to be marked N/A)

a Technical data from Manufacturer

Manufacturer, HOPPECKE

Type: 18 OSP.HC 1275

No. ofcelis: 08

Rated voltage perce: 2.0

Total Rated voltage: 216

Rated capacity: 1945 An

| Discharge period: 10h

Final discharge voltage: 203.0 V

Nominal temperature: 20°C

2 | Testdata

‘Ambient temp. attest begin 22°C

‘Ambient temp. at end of test 36°C

Start of test 8:20 hours

End of test 18:30 hours |

3. | Calculation of discharge current/Final discharge voltage

Discharge curent = Rated cepacty / Discharge period

Discharge current = (34.54.

| Fina discharge voltage = Final discharge voltage per cellx No of cls

Final discharge voltage = 203.0

4. Discharging

© Five pilot ces shall be chosen and the numbers entered into the

table next page.

© Adjust discharge current item 3) and keep current constant

during discharging

© Measure battery voltage continuously or at intervals during the

test. Note: the intervals shall be shortened towards the final

discharge voltage.

© Connect a recorder to record battery voltage and current or if

available, use application software of test device manufacturer

‘arent eed, garnet rr ean a Soares ve tenon

CL-E03.2 Discharging of Batteries

‘Commissioning Checklist E ‘System: (GF=Battery N2

Component: +18TA20

Page: 2 of 3

No. Activity Remarks | Confirmed

(ltems not applicable to be marked N/A)

Bat |

Time Cuenta | en TempertuelG | Densiykgh

— "| Gell | Cell | Cell! Cel | Celi | Cel | Ce | Cell | Cet

_| 10 30 | 60 | 70 | 90 40 | 30 | 50 | 70

vaso | 1945 | 2005 | 04 | 205 | 301 | 207 | 298 | 123 | 124 | 124 [1.24

| 0230 | 1945 | 2170 | 322 | at7 | 926) a12 | 202 | 122 | 123 | 128 123 123

1030 | 1345 zee | 343 | sa7 | a2 | s27 | sar [tar | a22 | sae [121 | 120

| 1" 1

130 | 1945 | 2168 362 | 353 | 348 | 969 | 120 | 121 | 120 [1201 120

1230 | 145 | 2147 | 373 | 266 119 | 1.19 | 1.19

1330 | 1345 | 2133 | 268 | 367 | 264

| saz fitz | a.17

1430; 1345 | 2146 _{ 36.01 a64-| a6.

i EIST TTS

1530 | 1348 2099 | 269 | 365 | 267 | 36.2 | 374

v4] 446 | ta | 113 | a6

1630 | 1345 208.1 | 370 ses | 365 | 369

192 | 1.43 | 412 | 412 | 1.13

1730 | 1345 2058 | 376 375 | 368

an | ato fatto} ast

18:30 | 1348 2030 | 379 378 | 370] 363

4.09 | 1.09 | 4.09 | 1.09 | 4.10

Temi pice, daemon etna

SIEME NS Commissioning Check List E

CL-E03.2 Discharging of Batteries

1263 MW Puniab Power Plant, Jhang | PK1022

System: ‘ST, Battery No.1

Component: 12BTA10

NOTE: Applicable only, if no manufacturer checklist is available

Page: 1 of 3

Restricted

No. | Activity

{Items not applicable to be marked N/A)

Remarks

1. | Technical data from Manufacturer

Manufacturer, HOPPECKE

Type: 15 OSP.HC 1275

No. ofcells: 108,

Rated voltage per cel; = 2.0

Total Rated voltage: 216

Rated capacity: 1345 An

Discharge period: 10h

Final discharge voltage: 209.8 V

Nominal temperature: 20°C

2 Test data

Ambient temp. at test begin 27°C

Ambient temp. at end of test 45°C

Star of test 10:44 hours

End of test 20:50 hours

3. Calculation of discharge current/Final discharge voltage

Discharge current = Rated capacity / Discharge period

Discharge current = 134.54

Final discharge voltage = Final discharge voltage per cell x No. of cells,

Final discharge voltage = 203.8 V

4. | Discharging

‘© Five pilet cells shall be chosen and the number

table next page.

tered

during discharging.

discharge voltage.

‘© Connect a recorder to record battery voltage and current.

“Trait edison, deveined ding of doarer wet on

‘© Adjust discharge current (tem 3) and keep current constant

© Measure battery voltage continuously or a intervals during the

test. Note: the intervals shall be shortened towards the final

available, use application software of test device manufacturer

__NOTE: Start charging of battery immodiately after completion of tests

into the

orif

CL-E03.2 Discharging of Batteries

‘Commissioning Checklist & Systom: -SFeBattery 01

‘Component: $2BTA10

Page: 2 of 3

No. Activity Remarks | Confirmed

(tems not applicable to be marked N/A)

time | Curenva volanely Temperature/C Densityrkgi

- nie | Cell | Cell | cel | Cell | Cott | Cel | Ce | Cer T cen

im | 27 | 6 | toe | 4+ {tt | 27 | 86 | 108

soma | 1348 2366 | 308 | 308 | 314 | 307 | 204 | 1.24 | 124 | 124 | 1.24] 4.24

1444 | 1365 279 | 337 | 333 | a24 | s24 | a26 | 1.23 | 1.23 | 123 | 1.231 129

- ——= { i :

was | 145 | 2172 | a0 | 98 | a0 | o53 | a3 122 |1.21 | 122

1944 | 1365 2161 | 341 | 340 | 933 | 337] 335 121 [1.20] 121

| | et

1404 | 134.8 2150 | 342 | 340 | 341 | 338 | 337

18:44 | 1945 2138 | 343 | 341 | 348 | 339 | 339

194.5 223 | 359 | 350) 36.4 rears

waa | 1345 2107 | 350 | 352 | s68 | one | asa

1844 | 134.5 209.0 36.1 | 365 | 37.0 | 35.0 | 356

1944 | 1945 2068 | 364 | 257 | 373 | 257 | 957

zoso | 1245 | 2038 | a70 | 361 | 381 | a61 | 968 | 1.09 | 109 | 1.00 | 100] 100

( \

(

| {oo

{ ] |}

= | a == r

“Terao rproascten deren andr ange ta conmer a we icaion

fis crton se onan Brett ober who eltess adnan oind

CL-E03.2 Discharging of Batteries

‘Commissioning Checklist E ‘System:

Component: 128TA10

Page: 3 0f3

[ No. Activity Remarks | Confirmed

{Items not applicable to be marked N/A)

Department: PG SO GP COMMELEC Name: Osman Poturovié

Dato: 01.04.2022 Signature: Dood

SIEME NS Commissioning Check List E

Restricted

1263 MW Pun er Plant, Jhang_|PK1022

System: ‘ST, Battery No.2

Component: 12BTA20

NOTE: Applicable only, ifno manufacturer checklist is available Page: 1 of 3

No, I - - Activity Remarks | Confirmed |

{Items not applicable to be marked N/A)

Technical data from Manufacturer

Manufacturer: HOPPECKE

Type: 15 OSP.HC 1275

No. ofcells: 108

Rated voltage per cell: 2.0

Total Rated voltage: 216V

Rated capacity: 1945 Ah

Discharge period: ton

| Final discharge voltage: 202.6 V

Nominal temperature: 20°C

2 Test data

) 4 Ambient temp. at test begin 25°C

| Ambient temp. at end of test 46°C

Star of test 08:20 hours

End of test 18:50 hours,

3 Calculation of discharge current/Final discharge voltage

Discharge current = Reted capacity / Discharge petiod

Discharge current = 134.54

Final discharge voltage = Final discharge voltage per cell x No.of cells

Final discharge voltage = 202.5 V

4. | Discharging

‘© Five pilot cells shall be chosen and the numbers entered into the

table next page.

© Adjust discharge current (tem 3) and keep current constant |

during discharging.

| © Measure battery voltage continuously or at intervals during the

test. Note the intervals shall be shortened towards the fina

discharge votiage

© Connect a recorder to record battery voltage and current or if

availabe, use application software of test device manufacturer

NOTE: Start charging of battery immediately after completion of tests

CL-E03.2 Discharging of Batteries

‘Commissioning Checklist E system: STrtatery M2

Component: 12BTA20

$$ cerns taprazg

Page: 2 0f3

No. Activity Remarks | Confirmed

(toms not applicable to be marked N/A)

Baton

Time | Curenua | Seton, Temperatures ] Densityrkg

Cell | Cel | Cell | Cell ~ Cell | Cet | Cell | Cell | Gell | Cell

1 | 16 | 27 | e108 | 4 | 16 | 27 | as | 108

owzo [seas | cats | 202 | 290 | aoa | 209 | 208 | 124 | 124 | 126 [128] 426

wa [ss | airs |e | a7 | aa | mo | ona [ozs | ts | 49 jas ize

wm \aoas | avo | eso | o57 | m0 | m2 | war [ae fam | 1a [izle

War] sas | atso {asa | ava [ara | ava | coz | tan f 120 [4.20 | 120 |

1220" [rms | 248 [oe | ara | ors | avs | oo | 120] 110 | 110 [18 | 10 |

402) 37.4 365 | 1.18 | 1.47 | 1.47 | 1.16 | 1.18

ost ora $8718 tee IS TT

405 | 373 | 376 | 375 | 367

4o6 | 374 | 376 | 376 | 268

407 | 376 | 37.7 | 377 | 268

woo | a7e | v7 | aa | 90

“Tansnialprcicton,sasanraton ane erg of fe ooze twat te can

CL-E03.2 Discharging of Batteries

Commissioning Checklist E ‘System: ‘SErBattery W2

Component: 12BTA20_

Page: 3 of3

No. Activity Remarks | Confirmed

{items not applicable to be marked N/A)

Remarks:

Department: PG SOGPCOMMELEC Name: Osman Poturovié

Date: 02.04.2022 Signature:

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sop MaintenanceDocument55 pagesSop MaintenanceMehroz KhanNo ratings yet

- 10MAV24AP001Document11 pages10MAV24AP001Mehroz KhanNo ratings yet

- 11MAV24AP001Document14 pages11MAV24AP001Mehroz KhanNo ratings yet

- Pack LDocument1 pagePack LMehroz KhanNo ratings yet

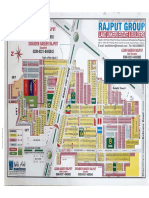

- Map Audit 1 RajputEDocument1 pageMap Audit 1 RajputEMehroz KhanNo ratings yet

- Pack ListDocument1 pagePack ListMehroz KhanNo ratings yet

- Siemens PAK: Change Contacts Q12 To Q3 and Add Terminals DetailsDocument1 pageSiemens PAK: Change Contacts Q12 To Q3 and Add Terminals DetailsMehroz KhanNo ratings yet