Professional Documents

Culture Documents

10MAV24AP001

Uploaded by

Mehroz Khan0 ratings0% found this document useful (0 votes)

13 views11 pagesTest Report

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTest Report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views11 pages10MAV24AP001

Uploaded by

Mehroz KhanTest Report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

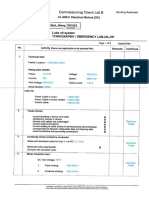

SIEMENS

Commissioning Check List E

CL-E06.5 Electrical Motors (DC)

Handling Restricted

1263 MW Punjab Power Plant, Jh

System: Lube oil system

KKS/ Description: 10MAV24AP001 / EMERG LUB-OIL-PP

Page: 1 of 3 Appendices:

No. Activity (Items not applicable to be marked NIA) Remarks | Confirmed

1. | Technical Data

Feeder Location: +108UC9,NA001

Rating plate details

Power: 14.5iW Voltage: 220\\00)

‘Current: T5A ‘Speed:. 2900 min Denis E

Field Vottage:220V(00) Field Current: 0.644

Serial Number: 542631

‘CableNo; -

Power Cable to motor: toBUCt001

Power Cable to series resistor: 108UC1002

Control cable: 10BUC4100

2 |” Visual checks

correct labeling of device and cable a

‘satisfactory access to device a

devices and cables are undamaged a Denis Egorov

correct cable terminations a

Correct sealing of cable entries in terminal boxes and switchgear

Correspondence between rating plate data and drawing data a

Correct protective and grounding connections a

3. | Continuity check protective conductor

Measured resistanc lue for “L+ to PE*: 0.1 Oh

jeasured resistance value for oop im Denis Egor

‘Measured value appropriate

(Compare with calulated vale)

4 Motor insulation test :

DC Test Voltage: 500V

Denis Egorov

4. Fleld winding: 718G0hm

2. Armature winding: 227G0hm

Proiect Ste Execution iSite commaneaten eae aes mea

Title: CL-E06.5 Electrical Motors (DC)

Page: 2 of 3

KKS: 40MAV24APO01

No. Activity Remarks | Confirmed

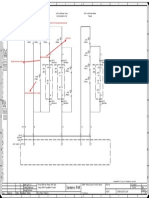

5. | Electrical function tests

41. DC control

2, Fault signal from plug-in unit B

3. On/Off switching manually/rom local control o WA — | Denis Egorov

4, ECO relay (correct function of pressure switch) g

5. Extemal commands (i.e. pressure switch) a

6] Winding resistance test

1. Field winding: = 228.40hm Denis Egorov

2. Armature winding: 6.20%m

7. | Adjustment of Resistors

74 | Armature series resistor

: Were

1. According to manufacturers instruction, the resistor(s) shall be adiusted to a ae

RO=OABY, RZ=VVAT ees

Jon the

2, Actual adjustment of resistor(s) resistor | Denis Egorov

R2I=0.4710, R22-00250 lut=o.471v

u2=0.025v

‘Note: In case the values ere diferent, add an appropriate explanation under

"Remarks".

7.2, | _ Fleld resistor (i appiicabie)

1. According to manufacturers instruction, the resistor shall be adjusted

to. a .

2. Actual adjustment of resistor. NA | Denis Egorov

Note: in case the values are diferent, add an appropriate explanation under

"Remarks"

8. | Timer for switching out Start Up Resistors) (if applicable)

Time Delay 1 (set}=0.88

Time Delay 2 (set)=0.2s

Time Delay 1(measured)=8 16ms Denis Egorov

Time Delay 2(measured)=238ms

‘rare repreicion.Siseriafen adr etng hs dear cowl ca zmion

. i cone a conemnieabon re! ober waka emrcs seoeatones ee.

Project Site Execution ender ibe nodal foray’ of caragee A ighececastr paste

Title: CL-E06.5 Electrical Motors (DC)

Page: 3.0f 3

KKS: 10MAV24APO01

No. Activity Remarks | Confirmed

8 Settings overcurrentiovertoad protection equipment power circuit

1. Overcurrent protection equipment (ie. -Q1) power circuit

‘Type of equipment: Siemens, 3NAS 140

‘Overcurrent setting: > 2008,

High-set overcurrent setting> [>> sue (if applicable) NA

2, Overload protection equipment (ie. -F4) power circuit

Denis Egorov

‘Type of equipment: ‘ABB, TA 200DU-110

Overioad setting: 1 75A (if applicable)

‘Overioad function: tripfaiorm

3. Overcurrentoverioad protection equipment (Le. -F11) control circuit

‘Type of equipment: ‘Siemens, §8Y5203-7

Overcurrent setting: bc

‘10. Rotation / Direction test according to mechanical requirement / Current

1. Carried out with driven machine a

2. Carried out without driven machine o

3. Direction ( view from driven machine to motor )

clockwise Q

‘counterclockwise a

Measurement of current Denis Egorov

1 Start-up current (armature circuit) 338.34

2 Load current (with driven machine, armature circuit. 51.68

07a

Current field circuit (with driven machine),

TT

Remarks:

Department: PG SOGP COMMELEC Nam:

Date: 10.01.2023 Signature:

[SIEMENS ENERGY

[ees

fe ning ‘never!

Yeo rr caerbwien ane ong of i doomen| wa ap anor

crnrurcaion set cher win enrst susie ee on

Project Site Executon Oferrs ibs i abs poynt of anagee Ang eed Epos tee

SIEMENS Commissioning Check List E

Restricted

CL-E03.2 Dischargi

[26s Pajan Power Plt hang: [Beseae

1263 MW Punjab Power Plant, Jhang 1022

Poe Pt

System: ST, Battery Net

Component: 10BTA10

NOTE: Applicable only, if no manufacturer checklist is available Page: 1 of 3

No. Activity Remarks | Confirmed

(ttems not applicable to be marked N/A)

1. Technical data from Manufacturer

Menufacturer, HOPPECKE

Type: A7OSPLHe 1445

No.ofcalis: 108 Desis

Reted voltage per cell: 2.0

vu

Total Rated voltage: 210 Fone

Rated capacity: 4525An

Discharge period: 10h

Final discharge voltage: 194.4

Nomina temparaturet 20°

2. Test data

“Ambient temp. at test begin 20°C .

“Ambient tomp. at end of test 30.1°C Denis

Start of test 08:26 hours &

End of test 18:26 hours Peto

3 | Calculation of discharge current/Final discharge voltage

Discharge current = Rated capacity / Discharge period

Discharge current = 152.54,

Final discharge voltage = Final discharge voltage per coll x No.of cells

Final discharge voltage = 194.4\V

4. | Discharging

table next page.

© Adjust discharge current (item 3) and keep current constant

during discharging.

© Measure battery voltage continuously or at intervals during the

test. Note: the intervals shall be shortened towards the final

discharge voltage.

‘© Connect a recorder to record battery voltage and current or if

available, use application software of test device manufacturer

NOTE: Start charging of battery immediately after completion of tests

‘© Five pilot cells shall be chosen and the numbers entered into the

Tacea pica teneaetetesm arent,

Project Site Execution vn ae eS MA EH aren reo

CL-E03.2 Discharging of Batteries

Commissioning Checklist E ‘System: ST, Battery Net

Component: A0BTA10

rr tesa

Page: 2 of 3

Activity Remarks | Confirmed

(items not applicable to be marked N/A)

Tine [caren] ey, Temperature Desiyh

Cell | Cell | Cell | Cell | Call | Col | Coli | Cell | Cel | Call

21_| 44 | 64 | e9 | 101 | a1 | 44 | 64 | 89 | 101

ozs | 1525 | aia | 270 | 26s | 209 | 273 | 200 | 123 | 120 | 120 bras] 12s |

1420 | a525 210.3 347 | 209 | 286 | 207 | 319 | 116 | 116 | 46 |iss ass]

ENS ENER

SIBENIS EEORO

GY

v

‘Commissioning Specialist

{SIEMENS ENERGY

i SIGMENS EMO.

Project Site Execution

CL-£03.2 Discharging of Batteries

ioning Checklist E Syoter ST, Battery tet

Component: 10BTA10

Page: 3 of 3

No. Activity Remarks | Confirmed

(Items not applicable to be marked N/A)

Remarks: —

‘Test was interrupted for a minute whereas representative person from

NESPAK (Juergen Redder) was in front of operator panel.

Department: PG SO GP COMMELEC Name: Denis Egorov

KoY

Date: 21.01.2023 ome EEE SEY

1

0

{Commissioning Specialist

Project Ste Execution

CL-E03.2 Discharging of Batteries

‘Commissioning Checklist E ‘system: ST, Battory Net

Component: 408TA10

Page: 4 0f 3

No. Activity Remarks | Confirmed

(items not applicable to be marked N/A)

‘aria repodicen, assonnehon sass age

its cones sormincase ere ,

Ge wiioareires ha

Project Site Execution ‘tenders benassi Se tee ea

SIEMENS Commissioning Check List E

Restricted

1263 MW Punjab Power Plant rang

are

System: ST, Battery No2

Component: — 10BTA20

NOTE: Applicabie only, ifno manufacturer checKist is avaliable

No. Activity Remarks | Confirmed

(items not applicable to be marked N/A)

1. | Technical data from Manufacturer

Manufacturer: HOPPECKE

Type: 17 OSPHC 1445 .

No. ofcals: 108, Denis

Rated voltage per col Egorov

Tota Rated votage

Rated capacity

Discharge period:

Final cischarge vo

_ Nominal. temperature:

2 | Test data Dens

ne

Ambiont temp. attest begin 198" Eporon}

“Ambient temp. at ond of ost sarc

Start oftest, 08:32 hours

End oftest 18:32 hours

3. | Calculation of discharge currentFinal discharge voltage

Discharge current = Rated capacity / Discharge period

Discharge current = 152.54, Denis

Final clacharge voltage = Fina discharge vollage pr oll No.of calls Fpoee

Final echarge voltage = 194.4

4. | Discharging

© Five plot cols sha be chosen and the numbers entered into the

table noxt page Dons

© Adjust discharge curent (tem 3) and koop curent constant "

during isenarsing. Fors.

© Measure battery vltage continuously o at intvals during the

test Note: the intervals shal be shortened towards the fal

charge voage,

© Connect reorder to record batery voltage and curent or

avalable, use application sofware of test device manufacturer

NOTE: Start charging of battery immediately after completion of tests

“erecta roroducton, dierinten onal eng oe conan os wal as acai

iis carson comurcaten et won ech eres ronan tees,

Project Site Execution ‘Sten one ron Wa Ae a ee

CL-E03.2 Discharging of Batteries

Commissioning Checklist E system: ST, Battory 2

Component: 408TA20

Page: 2 of 3

No. ‘Activity Remarks | Confirmed

{items not applicable to be marked N/A)

Baltery

Time | curenua| Sener, Temperature/C Densiyrkg

Gall | Cell | Call | Cel [Call | Cal | Gall] Cel! | Cal | coi

a| 4s |e | a9 | sor | 21 | 44 | 64 | 60 | 01

cose | 126 | 2255 | 208 | 286 | 201 | 204 | aoa | 124 | 1.26 | 1.24 [1.24] 1.24

oosz | 125 | 2176 | 206 | sia | a15 | 320 | 31.9 | 129 | 123 | 123 [129 | 128

tose | 1525 | 2165 | 326 | 357 | 341 | o4¢] 38 | 122 | 422 | 122 |i21| 12

‘192 | 1825 | 2152 | 346 | 379 | 358 | 365 | asa | 121 | 121 | 120 | 4.49 | 120

tage | 25 | 2138 | 367 | 390 | 355 | 374 | 66 | 120 | 10 | x10 [128 | 110

tsa2 | 1825 | 2125 | 346 | 372 | 359 | 958 | 357 | sar | saz | aa [rae | 110

tae | 1825 | 2107 | 340 | s66 | 369 | 364 | 303 | 16 | te | aie fase | aie

toa2_ | 1525 | 2089 | 360 | 302 | 367 | 968 | 50 | 115 | ats | ata [1aa | 14

1525 | 2067 | 965 | 369 | 267 | 267 | 357 | ata | 443 | a2 fata | a9

trae | 1825 | 2039 | 374 | 304 | 34 | a73 | za | sat | at | ta0 [140 | a4

tesa | 1825 | 1993 | 350 | 366 | 378 | 389 | 355 | 1.09 | 109 | 1.00 | 109 | 110

Commissioning

St

BEEN R AvtMooO

Cominissioning Specialist

Project Site Execution

‘aroun dearigen ar eg Fs dora we natn

eet rs wih ores nutans

j ones

(Grannies Se ean ON

CL-E03.2 Discharging of Batteries

Commissioning Checklist System: ST, Battory 2

Component: 10BTA20

Page: 3 of 3

No. Activity Remarks | Confirmed

(Items not applicable to be marked N/A)

"Remarks: - ~

Department: PG SO GP COMMELEC Name:

Dato: 19.01.2023 Signa

ine Suecialist

‘Commission

“ene rpadscion,dosenahon ardor ang dts doce ns wa asson

cits cnt sa corarcaen rections wie eress eantate ae chee

Project Site Execution ‘Gtenan st taba nares see pss

CL-E03.2 Discharging of Batteries

Commissioning Checklist E System: ST, Battory te2

Component: 108TA20

Page: 4 of 3

No. Activity Remarks | Confirmed

(tems not applicable to be marked N/A)

Project Site Execution

You might also like

- 12MAV24AP001Document14 pages12MAV24AP001Mehroz KhanNo ratings yet

- 11MAV24AP001Document14 pages11MAV24AP001Mehroz KhanNo ratings yet

- Pack LDocument1 pagePack LMehroz KhanNo ratings yet

- Sop MaintenanceDocument55 pagesSop MaintenanceMehroz KhanNo ratings yet

- Map Audit 1 RajputEDocument1 pageMap Audit 1 RajputEMehroz KhanNo ratings yet

- Pack ListDocument1 pagePack ListMehroz KhanNo ratings yet

- Siemens PAK: Change Contacts Q12 To Q3 and Add Terminals DetailsDocument1 pageSiemens PAK: Change Contacts Q12 To Q3 and Add Terminals DetailsMehroz KhanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)