Professional Documents

Culture Documents

Sap QM 1684889366

Sap QM 1684889366

Uploaded by

Alison MartinsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sap QM 1684889366

Sap QM 1684889366

Uploaded by

Alison MartinsCopyright:

Available Formats

Quality Management (QM)

Curriculum: Introduction to S/4HANA using Global Bike

Teaching material - Information

i Teaching material - Version

3.3 (February 2019)

Software used

• SAP S/4HANA 1809

Model

• Global Bike

Prerequisites

• No Prerequisites needed

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 2

Module Information

Authors

Tim Böttcher

Babett Ruß

Target Audience

Beginner

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 3

Module Information

Learning Objectives

You are able to

name functionalities of the QM module.

define the central organizational structures of the QM module.

summarize the master data which is most important for the QM module.

explain a standard QM process.

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 4

Functionality

Quality Planning Control in Logistics

Quality Inspection Archiving

Quality Control Data Transfer

Quality Certificates

Quality Notifications

Test Equipment Management

Inspection Using Multiple Specifications

Stability Study

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 5

Unit Overview

QM Organizational Structure

QM Master Data

QM Processes

What is new in S/4HANA

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 6

QM Organizational Structure

Client

• An independent environment in the system

Company Code

• Smallest org unit for which you can maintain a legal set of books

Plant

• Operating area or branch within a company

Manufacturing, distribution, purchasing or maintenance facility

Storage Location

• An organizational unit allowing differentiation between the various stocks of a material in a plant

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 7

QM Organizational Structure

Purchasing Organization

• The buying activity for a plant takes place at the purchasing organization

• Organization unit responsible for procuring services and materials

• Negotiates conditions of the purchase with the vendors

Purchasing Group

• Key that represents the buyer or group of buyers who are responsible for certain purchasing activities

• Channel of communication for vendors

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 8

Global Bike Structure for Quality Management

Global Bike Client

Company

Global Bike Inc. Global Bike Germany GmbH Code

Dallas San Diego Miami Heidelberg Hamburg Plant

Raw Materials Trading Goods Trading Goods Raw Materials Trading Goods

Storage

Semi-fin. Goods Finished Goods Finished Goods Semi-fin. Goods Finished Goods Location

Finished Goods Miscellaneous Miscellaneous Finished Goods Miscellaneous

Miscellaneous Miscellaneous

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 9

Global Bike Enterprise Structure in SAP ERP (Logistics)

Shipping Point DL00 MI00 SD00 TO00 HD00 HH00 PE00

RM00 TG00 TG00 TG00 RM00 TG00 TG00

Storage SF00 FG00 FG00 FG00 SF00 FG00 FG00

Location

FG00 MI00 MI00 MI00 FG00 MI00 MI00

MI00 MI00

Central Purchasing Organization (global) GL00

Purchasing Org. US00 CA00 PO DE00 AU00

Purchasing Group North America PGr Europe Asia

N00 E00 A00

Dallas Miami S. Diego Toronto Heidelb. Hamburg Perth Plant

DL00 MI00 SD00 TO00 HD00 HH00 PE00

CC US00 CA00 CC DE00 AU00 Company Code

Client Global Bike

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 10

Agenda

QM Organizational Structure

QM Master Data

QM Processes

What is new in S/4HANA

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 11

QM Master Data

Customer Master Data

Material Master Data

Vendor Master Data

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 12

Customer Master Data

Customer Master

• Contains all of the information necessary for processing

orders, deliveries, invoices and customer payment

• Every customer MUST have a master record

Created by Sales Area

• Sales Organization

• Distribution Channel

• Division

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 13

Customer Master Data

The customer master information is divided into 3 areas:

• General Data

• Company Code Data

• Sales Area Data

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 14

Material Master Data

Material Master

• Contains all the information a company needs to manage about a material

• It is used by most components within the SAP system

Sales and Distribution

Materials Management

Production

Plant Maintenance

Accounting/Controlling

Quality Management

• Material master data is stored in functional segments called Views

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 15

Material Master Views

Sales Data

Basic Data Purchasing Data

Mat. Plan. Data

Material Master Forecasting Data

Storage Data

Controlling Data Quality Data

Accounting Data

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 16

Material Master

General Information relevant for the entire organization:

Name

Weight

Client XXX Unit of Measure

Sales specific information: Storage Location specific information:

Delivering Plant Stock Qty

Loading Grp

Sales Org. UW00 Storage Loc. FG00

Sales Org. UE00 Storage Loc. TG00

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 17

Vendor Master Data

Vendor Master

• Contains all the necessary information needed to business with an

external supplier

• Used and maintained primarily by the Purchasing and Accounting

Departments

• Every vendor MUST have a master record

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 18

Vendor Master Views

Client Level

• Address

• Vendor Number

• Preferred Communication

General Data

Company Code Data

• Reconciliation Account

• Terms of Payment Company Code Data

• Bank Account Financial Accounting (FI)

Purchase Org Data

• Purchasing Currency

• Salesman’s Name Purchasing Data

• Vendor Partners Materials Mgmt (MM)

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 19

Vendor Master

General Information relevant for the entire organization:

Name

Address

Client XXX Communication

Company Code specific information: Purch. Organization specific information:

Acc. Mgmt Incoterms

Payment Currency

Company Code US00 Bank

Purch. Org. US00

Company Code DE00 Purch. Org. DE00

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 20

Agenda

QM Organizational Structure

QM Master Data

QM Processes

• Quality Management

• Quality Management in Procurement

• Quality Management in SD

What is new in S/4HANA

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 21

QM Process

Quality

Inspection Inspection Perform Usage

Info.

Plan Lot Inspection Decision

Record

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 22

Quality Information Record

If a quality assurance agreement or vendor release is required for a material, a Quality Info. Record must be

created

Determines how a material can be processed further

when a quotation or purchase order is created, the system checks whether a quality info record is required and

available for the combination of material and vendor

System also checks, whether the vendor and material-vendor combination is blocked or released for quotations,

purchase orders and/or goods receipt

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 23

Inspection Plan

Can be created for different uses as model inspection, carrying out an audit, preliminary series inspection,

goods receipt inspection, goods issue inspection, inspection of stock transfers, inspections in repetitive

manufacturing

Defines which characteristics are to be inspected in each inspection operation and which test equipment is to be

used in the inspection

Several materials can be assigned to an inspection plan

Several inspection plans with different inspection operations or inspection characteristics can be created for a

material or combination of material, vendor and manufacturer, or material and customer

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 24

Inspection Lot

Request to a plant to inspect a specific quantity of material or one or more pieces of equipment or functional

locations

Documented by an inspection lot record

Used to record, process and manage information for a quality inspection

Whenever materials are moved from on place to another under certain conditions, the QM component can

automatically create inspection lots

The system can also create an inspection lot automatically if a delivery is created in the SD component for a

inspection-relevant material

Can be created automatically or manually

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 25

Perform Inspection

Inspection of sample units of the inspection lot

Number of non-conforming sample units entered in the SAP System

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 26

Usage Decision

Confirms that all physical samples have been valuated and the inspection has been completed

Specifies whether the goods in the inspection lot have been accepted or rejected for use

Inspection lot stock can be posted to different stocks

• Unrestricted use

• Scrap

• Sample usage

• Blocked stock

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 27

QM Process in Procurement

Quality

Inspection Purchase Receiving Inspection Perform Usage

Info.

Plan Order Material Lot Inspection Decision

Record

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 28

Quality Management in SD

Quality Perform

Inspection Goods Inspection Usage Goods Sales Outbound

Info Invoice

Plan Issue Lot Inspection Decision Receipt Order Delivery

Record

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 29

SAP QM Module Integration

High integration in other SAP modules including:

• SAP MM

e.g. maintain quality agreements

• SAP SD

e.g. quality information related to customers

• SAP PP

e.g. perform inspection planning

• SAP CO

e.g. integrate SAP QM with controlling process

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 30

Agenda

QM Organizational Structure

QM Master Data

QM Processes

• Quality Management

• Quality Management in Procurement

• Quality Management in SD

What is new in S/4HANA?

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 31

Innovations in S/4HANA in QM

Integrated QM capabilties

Challenge: mass personalization while ensuring consistent quality in every product

Manufacturers require flexible and intergrated QM processes from design to final delivery

With S/4HANA, Quality management becomes fully integrated in the entire quality process

• Improves the Segment of One process

Streamlined and exceptional end user experience together with new functionalities

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 32

Innovations in S/4HANA in QM

Integrated QM capabilties

SAP S/4 HANA Standardization of issue

Manufacturing Cloud resolution procedures

Simplified inspection

planning process

Predictive quality Third-party collaboration

management

Preconfigured QM

scenarios Streamlined test equipment

Machine – Learning management

capabilities

Comprehensive analysis

Advanced closed loop of quality management

inspection planning

Integrated QM capabilities

IoT connectivity Digital Core

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 33

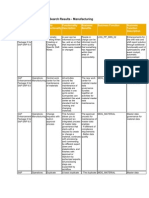

Innovations in S/4HANA in QM

Preconfigured core processes

Quality Management

Quality management in procurement

Procurement Regular quality inspection process at goods receipt

Quality inspection process with dynamic modification

Quality inspection process with material-supplier release

Inventory Quality management in stock handling

Management

Post unrestricted or blocked stock to quality inspection stock

Post quality inspection stock to different storage location

Production Quality management in discrete manufacturing

Goods receipt from production

Within production process

Sales Quality management in sales

Goods issue only with accepted quality

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 34

Innovations in S/4HANA in QM

Role-specific Fiori launchpads

Core QM processes supported by new roles

New personalized Fiori launchpads for the following roles:

Quality planner Quality technician Quality engineer

• Creating QM data

• Execute quality inspections • Monitoring quality inspections

• Manage plans

• Record the results • Analysis of test results

• Provide basis for inspection

Calibration

Quality manager Quality auditor

technician

• Establishing quality • Check products based • make sure that testing

standards/ procedures on specific inspection devices are calibrated

• Set up of controls plans correctly

Typical transactions/ apps are combined in business catalogs and assigned to the different roles

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 35

Innovations in S/4HANA in QM

New Fiori apps

New Fiori apps with exceptional end user experience together with new functionalities

For example: App for recording results of quality inspections

Quality technicians can record the results of their quality inspection easily and efficiently

In order to achieve this the app provides flexible and state-of-the-art worklists

© 2019 SAP SE / SAP UCC Magdeburg. All rights reserved. 36

You might also like

- 2017 Aaron and Hur Paper On Protocol and Ushers MinistryDocument18 pages2017 Aaron and Hur Paper On Protocol and Ushers MinistryIsaac Abayomi Oshin100% (1)

- Subcontracting (BMY) - Process DiagramsDocument1 pageSubcontracting (BMY) - Process DiagramsAnonymous s1zWy06ZDNo ratings yet

- Rule 60 CasesDocument28 pagesRule 60 CasesMaria Cristina MartinezNo ratings yet

- Sap Bom TablesDocument14 pagesSap Bom TablesthakkardhNo ratings yet

- SAP S 4HANA IS Mill Solutions - The Way Forward PDFDocument5 pagesSAP S 4HANA IS Mill Solutions - The Way Forward PDFyulius sugianto100% (1)

- PPDS Process Flowv.2Document7 pagesPPDS Process Flowv.2Jagannadh BirakayalaNo ratings yet

- Sap Co PaDocument13 pagesSap Co PazenarbeNo ratings yet

- Sap Rollout Project - Co: November 2018, Juan Pablo García Vargas Sika Colombia / Sap Local Team (Co)Document18 pagesSap Rollout Project - Co: November 2018, Juan Pablo García Vargas Sika Colombia / Sap Local Team (Co)Alex GarzonNo ratings yet

- Intro - S4HANA - Using - Global - Bike - Case - Study - PP - Fiori - en - v3.3 (Step 10)Document5 pagesIntro - S4HANA - Using - Global - Bike - Case - Study - PP - Fiori - en - v3.3 (Step 10)Rodrigo Alonso Rios AlcantaraNo ratings yet

- Batch Derivation Overview With Example - SAP BlogsDocument7 pagesBatch Derivation Overview With Example - SAP Blogsharshad05No ratings yet

- SAP Note BookDocument8 pagesSAP Note Bookమనోహర్ రెడ్డిNo ratings yet

- Managing An Information Security and Privacy Awareness and Training Program by Rebecca Herold PDFDocument546 pagesManaging An Information Security and Privacy Awareness and Training Program by Rebecca Herold PDFMaury M MarquesNo ratings yet

- School Emergency Response Plan TemplateDocument24 pagesSchool Emergency Response Plan Templatehridya dasNo ratings yet

- EHP5 Enhancements in PP ModuleDocument8 pagesEHP5 Enhancements in PP ModulekiranmagarNo ratings yet

- Global Bike: Curriculum: Introduction To S/4HANA Using Global BikeDocument21 pagesGlobal Bike: Curriculum: Introduction To S/4HANA Using Global Bikejohn pNo ratings yet

- PP MRPDocument4 pagesPP MRPManoj BholaNo ratings yet

- 17.1 Diesel - Hydro PowerDocument11 pages17.1 Diesel - Hydro PowerJim Lester AmodiaNo ratings yet

- S/4 HANA Manufacturing For Planning and SchedulingDocument9 pagesS/4 HANA Manufacturing For Planning and SchedulingG LINo ratings yet

- SAP Integrated Business Planning - Jun 2021Document9 pagesSAP Integrated Business Planning - Jun 2021Vitor Camargo da SilvaNo ratings yet

- CLMM - Mass Change & Update New Characteristic Values For Set of Materials - SAP BlogsDocument14 pagesCLMM - Mass Change & Update New Characteristic Values For Set of Materials - SAP BlogsAli CukkaNo ratings yet

- SAP Ariba Scope DocumentDocument8 pagesSAP Ariba Scope DocumentDarren OsoreNo ratings yet

- COGI-Correcting Failed Goods Movementduring Backflush-Ecc6Document8 pagesCOGI-Correcting Failed Goods Movementduring Backflush-Ecc6Bhaskar BiswasNo ratings yet

- Determination of The Order PriorityDocument2 pagesDetermination of The Order PriorityvikashdhimanNo ratings yet

- Control Plan FmeaDocument105 pagesControl Plan FmeaOSITORONo ratings yet

- Materials Management (MM) : Curriculum: Introduction To ERP Using Global BikeDocument46 pagesMaterials Management (MM) : Curriculum: Introduction To ERP Using Global BikePeter LeeNo ratings yet

- Intro S4HANA Using Global Bike Slides PP en v3.3Document66 pagesIntro S4HANA Using Global Bike Slides PP en v3.3Arles BernalNo ratings yet

- QMDocument69 pagesQMKristine Jhoy Nolasco Secopito100% (1)

- SD Module - Lecture SlidesDocument53 pagesSD Module - Lecture SlidesChinmayee Choudhury100% (1)

- AID OTC Sale Order Processing 1Document25 pagesAID OTC Sale Order Processing 1SUBHOJIT BANERJEENo ratings yet

- DP and PPDS Without SNPDocument14 pagesDP and PPDS Without SNPJagannadh BirakayalaNo ratings yet

- SAP Batch DefinitionDocument10 pagesSAP Batch DefinitionPramod ShettyNo ratings yet

- S4HANA Extended Production Engineering and Operations (PEO) Part 1 - Configuration SettingsDocument26 pagesS4HANA Extended Production Engineering and Operations (PEO) Part 1 - Configuration Settingsshishir174No ratings yet

- 5 Introduction To Global BikeDocument15 pages5 Introduction To Global Bikegandalf thegreyNo ratings yet

- Best Practices For Mill Products and Min PDFDocument21 pagesBest Practices For Mill Products and Min PDFSandeep Mahindra0% (1)

- Co NT Rol S: Er Vic eDocument35 pagesCo NT Rol S: Er Vic eAbdel Malek100% (1)

- Configuration Rationale Document - Personnel StructureDocument11 pagesConfiguration Rationale Document - Personnel Structurepkank09100% (1)

- Can MRP Be Carried Out For One Particular Level of A BomDocument10 pagesCan MRP Be Carried Out For One Particular Level of A BomVipul ShuklaNo ratings yet

- Day 1 PPDS Master OverviewDocument10 pagesDay 1 PPDS Master Overviewakshay KumarNo ratings yet

- Release Available Delta Functionality Key Capability / Application AreaDocument51 pagesRelease Available Delta Functionality Key Capability / Application AreaAnonymous y11YsHNo ratings yet

- Sap MM Creating ExpertsDocument4 pagesSap MM Creating Expertstrishul100% (1)

- SCM210 - Core Interface (CIF) - SAP TrainingDocument5 pagesSCM210 - Core Interface (CIF) - SAP TrainingfiestamixNo ratings yet

- Automatic Batch Determination in Inventory Management (Fefo, Fifo, Fifo)Document30 pagesAutomatic Batch Determination in Inventory Management (Fefo, Fifo, Fifo)Seren Sökmen100% (1)

- QM OverviewDocument16 pagesQM Overviewrvk386No ratings yet

- Sap IbpDocument1 pageSap Ibpvenkataravin100% (1)

- Transaction Codes For MRP (PP-MRP) - Material Requirements Planning (PP-MRP) - SAP LibraryDocument3 pagesTransaction Codes For MRP (PP-MRP) - Material Requirements Planning (PP-MRP) - SAP LibraryPavilionNo ratings yet

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- SCM2015 Shetty SapapoversussapintegratedDocument42 pagesSCM2015 Shetty SapapoversussapintegratedMumbai WallstreetNo ratings yet

- 02.1 APO SNP ConfigurationDocument15 pages02.1 APO SNP Configurationsankarlikesu100% (2)

- Apo10 PDFDocument227 pagesApo10 PDFashahmednNo ratings yet

- Intro S4HANA Using Global Bike SAP Slides en v.4.1Document39 pagesIntro S4HANA Using Global Bike SAP Slides en v.4.1Nguyen Hoang Son (K16HL)No ratings yet

- Vishal Mudgal: Executive ProfileDocument2 pagesVishal Mudgal: Executive ProfileVishal MudgalNo ratings yet

- Sap PP Interview QuestionDocument55 pagesSap PP Interview QuestionkumarNo ratings yet

- CIF Monitoring Error Handling SCMDocument64 pagesCIF Monitoring Error Handling SCMdmk100% (1)

- Badi PPDocument2 pagesBadi PPSatheesh kumarNo ratings yet

- Sap MM: Course: Materials Management Type: Instructor-Led Training Duration: 60 HrsDocument3 pagesSap MM: Course: Materials Management Type: Instructor-Led Training Duration: 60 Hrsmysticguy99No ratings yet

- S4HANA1909 Availability Dependencies en XXDocument52 pagesS4HANA1909 Availability Dependencies en XXgobashaNo ratings yet

- PP - Master Data-Sap PPDocument16 pagesPP - Master Data-Sap PPratnesh_xpNo ratings yet

- SKYPE:itmentors121: Configuration Having 4 ModulesDocument1 pageSKYPE:itmentors121: Configuration Having 4 ModulesGLOBAL TEQNo ratings yet

- Intro - S4HANA - Using - Global - Bike - Slides - MM - en - v3.3 MODDocument45 pagesIntro - S4HANA - Using - Global - Bike - Slides - MM - en - v3.3 MODMrThedjalexNo ratings yet

- Materials Management (MM) : Curriculum: Introduction To ERP Using Global BikeDocument46 pagesMaterials Management (MM) : Curriculum: Introduction To ERP Using Global BikeToño Gomez BarredaNo ratings yet

- Lecture5 - Production PlanningDocument81 pagesLecture5 - Production PlanningNgoc Khanh Linh NguyenNo ratings yet

- Intro S4HANA Using Global Bike Slides PP en v4.1Document61 pagesIntro S4HANA Using Global Bike Slides PP en v4.1upeshcp059No ratings yet

- Intro S4HANA Using Global Bike Slides EAM en v3.3Document35 pagesIntro S4HANA Using Global Bike Slides EAM en v3.3Bayu SetyawanNo ratings yet

- 06 Mod 4 GBI IntroductionDocument10 pages06 Mod 4 GBI IntroductionOuerfelli MahjoubNo ratings yet

- Akinola Damilola .VDocument3 pagesAkinola Damilola .VAbdulkabir Olatunji YesufuNo ratings yet

- ACBA Admission NoticeDocument1 pageACBA Admission NoticerifatNo ratings yet

- The War Service of The 1/4 Royal Berkshire Regiment (T. F.) by Cruttwell, Charles Robert Mowbray FraserDocument81 pagesThe War Service of The 1/4 Royal Berkshire Regiment (T. F.) by Cruttwell, Charles Robert Mowbray FraserGutenberg.orgNo ratings yet

- Berthier Rifles and Carbines (France)Document4 pagesBerthier Rifles and Carbines (France)blowmeasshole1911No ratings yet

- De Giua Ky 1 Tieng Anh 12 Nam 2022 2023 Truong THPT Nui Thanh Quang NamDocument3 pagesDe Giua Ky 1 Tieng Anh 12 Nam 2022 2023 Truong THPT Nui Thanh Quang NamHuy Tạ QuangNo ratings yet

- ProjectDocument2 pagesProjectYash YashNo ratings yet

- 1519545495372Document6 pages1519545495372sumit malikNo ratings yet

- Mil M8Document5 pagesMil M8Eya Kayte C. ReblandoNo ratings yet

- Famous Celebrity Portfolio by SlidesgoDocument40 pagesFamous Celebrity Portfolio by SlidesgoMDW PutraNo ratings yet

- Full Download Test Bank For Western Civilization Ideas Politics and Society Volume II From 1600 11th Edition PDF Full ChapterDocument35 pagesFull Download Test Bank For Western Civilization Ideas Politics and Society Volume II From 1600 11th Edition PDF Full Chaptergladdenbugler.uy6kz100% (20)

- BSP Circular No. 918-16Document4 pagesBSP Circular No. 918-16Helena HerreraNo ratings yet

- SITA CORP Profile HighlightsDocument12 pagesSITA CORP Profile Highlightsgovind1040No ratings yet

- Advertising Budgeting, Media, and Media PlanningDocument45 pagesAdvertising Budgeting, Media, and Media PlanningAbesheik HalduraiNo ratings yet

- Amit ManochaDocument3 pagesAmit Manochapeter samuelNo ratings yet

- 6 Reasons To Use The Term "Community Benefit Organization": HildyDocument3 pages6 Reasons To Use The Term "Community Benefit Organization": HildyKelvin F. AlfaroNo ratings yet

- Language and Social Media: Joan Nicole P. BalugayDocument6 pagesLanguage and Social Media: Joan Nicole P. BalugayBalongNo ratings yet

- Company Profile PT Samiaji Putra MandiriDocument19 pagesCompany Profile PT Samiaji Putra MandiriSkandinavia ApartmentNo ratings yet

- 5-Day Trip To Georgia - A Customizable 5 Day ItineraryDocument4 pages5-Day Trip To Georgia - A Customizable 5 Day Itineraryjavvaji nikhilNo ratings yet

- HLF 10-10 ResearchDocument13 pagesHLF 10-10 ResearchZerohedgeNo ratings yet

- 20th Century's Greatest Hits 100 English-Language Books of FictDocument5 pages20th Century's Greatest Hits 100 English-Language Books of FictIain CowieNo ratings yet

- 1 PBDocument16 pages1 PBAdipati DiwaNo ratings yet

- Dependence of Earth's Thermal Radiation On Five Most Abundant Greenhouse GasesDocument38 pagesDependence of Earth's Thermal Radiation On Five Most Abundant Greenhouse GasesMaycon Rogers Ribeiro AlvesNo ratings yet

- Simple Service InvoiceDocument2 pagesSimple Service InvoiceFaisalNo ratings yet

- Banking ProjectDocument24 pagesBanking ProjectHaseeb ParachaNo ratings yet