Professional Documents

Culture Documents

PEEK

Uploaded by

Hugorong WongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PEEK

Uploaded by

Hugorong WongCopyright:

Available Formats

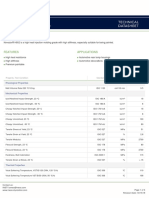

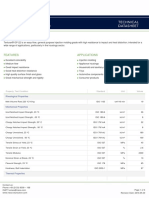

VICTREX® PEEKTM 450FC30

Product Description:

High performance thermoplastic material, 30% reinforced with carbon fibre / graphite / PTFE PolyEtherEtherKetone (PEEK), semi

crystalline, granules for injection moulding and extrusion, standard flow, colour black.

Typical Application Areas:

Tribological applications for high strength. Excellent wear resistance, very low coefficient of friction, low coefficient of thermal

expansion. Chemically resistant to aggressive environments.

Material Properties

CONDITIONS TEST METHOD UNITS TYPICAL VALUE

Mechanical Data

Tensile Strength Break, 23°C ISO 527 MPa 140

Break, 125°C 95

Break, 175°C 55

Break, 225°C 45

Break, 275°C 35

Tensile Elongation Break, 23°C ISO 527 % 2.2

Tensile Modulus 23°C ISO 527 GPa 12.5

Flexural Strength 23°C ISO 178 MPa 230

Flexural Modulus 23°C ISO 178 GPa 11.5

Compressive Strength 23°C ISO 604 MPa 170

120°C 110

-2

Charpy Impact Strength Notched, 23°C ISO 179/1eA kJ m 5.0

-2

Unnotched, 23°C ISO 179/1U kJ m 35

-2

Izod Impact Strength Notched, 23°C ISO 180/A kJ m 6.0

Unnotched, 23°C ISO 180/U 35

Thermal Data

Melting Point ISO 11357 °C 343

Glass Transition (Tg) Onset ISO 11357 °C 143

-1 -1

Specific Heat Capacity 23ºC DSC kJ kg °C 1.8

-1

Coefficient of Thermal Expansion Along flow below Tg ISO 11359 ppm °C 15

Average below Tg 45

Along flow above Tg 20

Average above Tg 115

Heat Deflection Temperature 1.8 MPa ISO 75-f °C 315

-1 -1

Thermal Conductivity 23ºC ISO/CD 22007-4 W m °C 0.87

Continuous Use Temperature Mechanical w/o impact UL 746B °C 240

Mechanical w/impact 180

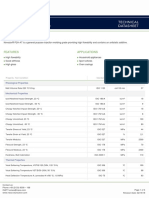

Flow

Melt Viscosity 400°C ISO 11443 Pa.s 550

VICTREX® PEEK™ high performance polymers ©Victrex plc Revision Jun 09 1

Miscellaneous

-3

Density Crystalline ISO 1183 g cm 1.45

Shore D hardness 23°C ISO 868 85

Water Absorption (3.2mm thick Tensile bar) 24h, 23°C ISO 62-1 % 0.04

(by immersion) Equilibrium, 23°C 0.3

Fire Smoke Toxicity

Flammability Rating UL94 n/a V-0 @ 0.75 mm

Glow Wire Test 2mm thickness IEC 60695-2-12 ºC 960

Limiting Oxygen Index ISO 4289 %O2 43

Recommended Processing Conditions

Drying Temperature / Time 150°C / 3h or 120°C / 5h

Temperature settings 365 / 370 / 375 / 380 / 385°C (Nozzle)

Hopper Temperature Not greater than 100°C

Mould Temperature 170°C - 200°C (max 250°C)

Runner Die / nozzle >3mm, manifold >3.5mm

Gate >2mm or 0.5 x part thickness

Mould Shrinkage and Spiral Flow

Spiral Flow 385°C nozzle, 200°C tool 1mm thick section Victrex mm 80

3mm thick section 380

Mould Shrinkage 385°C nozzle, 200°C tool Along flow ISO 294-4 % 0.3

Across flow 0.7

Detailed data available on our website www.victrex.com or upon request

World Headquarters

Victrex plc, Hillhouse International, Thornton Cleveleys, Lancashire FY5 4QD United Kingdom

Tel: + (44) 1253 897700 Fax: + (44) 1253 897701 Email: victrexplc@victrex.com

VICTREX PLC BELIEVES THAT THE INFORMATION CONTAINED HEREIN IS AN ACCURATE DESCRIPTION OF THE TYPICAL CHARACTERISTICS AND/OR USES OF THE PRODUCT

OR PRODUCTS, BUT IT IS THE CUSTOMER'S RESPONSIBILITY TO THOROUGHLY TEST THE PRODUCT IN EACH SPECIFIC APPLICATION TO DETERMINE ITS PERFORMANCE,

EFFICACY AND SAFETY FOR EACH END-USE PRODUCT, DEVICE OR OTHER APPLICATION. SUGGESTIONS OF USES SHOULD NOT BE TAKEN AS INDUCEMENTS TO INFRINGE

ANY PARTICULAR PATENT. THE INFORMATION AND DATA CONTAINED HEREIN ARE BASED ON INFORMATION WE BELIEVE RELIABLE. MENTION OF A PRODUCT IN THIS

DOCUMENTATION IS NOT A GUARANTEE OF AVAILABILITY. VICTREX PLC RESERVES THE RIGHT TO MODIFY PRODUCTS, SPECIFICATIONS AND/OR PACKAGING AS PART OF A

CONTINUOUS PROGRAM OF PRODUCT DEVELOPMENT. VICTREX® IS A REGISTERED TRADEMARK OF VICTREX MANUFACTURING LIMITED. PEEK™, APTIV™, PEEK-ESD™, T-

SERIES™, PEEK-HT™ ARE TRADEMARKS OF VICTREX PLC. VICOTE® IS A REGISTERED TRADEMARK OF VICTREX PLC.

VICTREX PLC MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, A WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR OF INTELLECTUAL PROPERTY NON-

INFRINGEMENT, INCLUDING, BUT NOT LIMITED TO PATENT NON-INFRINGEMENT, WHICH ARE EXPRESSLY DISCLAIMED, WHETHER EXPRESS OR IMPLIED, IN FACT OR BY LAW. FURTHER, VICTREX

PLC MAKES NO WARRANTY TO YOUR CUSTOMERS OR AGENTS, AND HAS NOT AUTHORIZED ANYONE TO MAKE ANY REPRESENTATION OR WARRANTY OTHER THAN AS PROVIDED ABOVE.

VICTREX PLC SHALL IN NO EVENT BE LIABLE FOR ANY GENERAL, INDIRECT, SPECIAL, CONSEQUENTIAL, PUNITIVE, INCIDENTAL OR SIMILAR DAMAGES, INCLUDING WITHOUT LIMITATION, DAMAGES

FOR HARM TO BUSINESS, LOST PROFITS OR LOST SAVINGS, EVEN IF VICTREX HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, REGARDLESS

® ™ OF THE FORM OF ACTION. 2

VICTREX PEEK high performance polymers ©Victrex plc 062007

You might also like

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Victrex - Peek Data SheetDocument2 pagesVictrex - Peek Data SheetM J VoraNo ratings yet

- VictrexTDS150G 151GDocument2 pagesVictrexTDS150G 151GKumaar RanjanNo ratings yet

- Victrex ST 45CA30: Conditions Test Method Units Typical ValueDocument2 pagesVictrex ST 45CA30: Conditions Test Method Units Typical ValuenomeNo ratings yet

- Victrex TDS WG101Document2 pagesVictrex TDS WG101matteo.gaggioliNo ratings yet

- Victrex PEEK 450FE20: Conditions Test Method Units Typical ValueDocument2 pagesVictrex PEEK 450FE20: Conditions Test Method Units Typical ValueRohan KulkarniNo ratings yet

- Victrex TDS 650GDocument2 pagesVictrex TDS 650GKumaar RanjanNo ratings yet

- Victrex™ Peek 450G™: Product DescriptionDocument2 pagesVictrex™ Peek 450G™: Product DescriptionBerkant CangalNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Victrex TDS 450GDocument3 pagesVictrex TDS 450GPRAMOD KUMARNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- TDS - Tecomid NB40 GR30 NLDocument1 pageTDS - Tecomid NB40 GR30 NLilkerNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- 4lex® 10F10000Document3 pages4lex® 10F10000srinivasaNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Styro Lution Tds 401200140448Document3 pagesStyro Lution Tds 401200140448scribdNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Evonik Corporation Vestamid X7293 Plasticized Nylon 12Document3 pagesEvonik Corporation Vestamid X7293 Plasticized Nylon 12Prabhu MohanNo ratings yet

- B70 S Natural S1: Badamid®Document2 pagesB70 S Natural S1: Badamid®hocineNo ratings yet

- Styrolution TDS401000260275Document3 pagesStyrolution TDS401000260275vicenteNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Delrin® 100 NC010-enDocument14 pagesDelrin® 100 NC010-enshahin_723No ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- Grivory GVX 5h Nat - Mds - enDocument5 pagesGrivory GVX 5h Nat - Mds - enJohn KingNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Dupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinDocument11 pagesDupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinTomGaliciaNo ratings yet

- Crastin S600 F40 NC010Document11 pagesCrastin S600 F40 NC010TomGaliciaNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDocument1 pageSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- Technical Data Sheet - Rilsanclear - G350 (Polyamide PA 12)Document2 pagesTechnical Data Sheet - Rilsanclear - G350 (Polyamide PA 12)Alan TsaiNo ratings yet

- Total 3645Document1 pageTotal 3645M. Kürşad ArslanNo ratings yet

- LANXESS_Durethan_BKV35H2.0_901510_ISO_ENDocument3 pagesLANXESS_Durethan_BKV35H2.0_901510_ISO_ENcristinamss33No ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- Daicel PP: Properties PG2N1Document1 pageDaicel PP: Properties PG2N1Chentouf MohammedNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- Tds Carbon enDocument1 pageTds Carbon engegacolucNo ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- Arkema PEKK kKepstan 8001 TDSDocument3 pagesArkema PEKK kKepstan 8001 TDSstartionlilNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- CELANEX® 1600a-EnDocument4 pagesCELANEX® 1600a-EnleftpowtaNo ratings yet

- Pa 12Document1 pagePa 12pava16230.meNo ratings yet

- Zytel® 73G15L NC010-gbDocument12 pagesZytel® 73G15L NC010-gbzoxxxnNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Waterproof Planiseal 288Document3 pagesWaterproof Planiseal 288Chezy629No ratings yet

- Mechanical Engineer-Syed Zain AliDocument5 pagesMechanical Engineer-Syed Zain AliSyedZainAliNo ratings yet

- Soil Stabilization ProjectDocument53 pagesSoil Stabilization Projectrohit attri100% (2)

- Ad428 Gumallaoi Judelle v. RSW MT No.2 4aDocument21 pagesAd428 Gumallaoi Judelle v. RSW MT No.2 4aLuwella GumallaoiNo ratings yet

- Grout - Estogrout UW - Data Sheet - 120404Document2 pagesGrout - Estogrout UW - Data Sheet - 120404Dana IrmawanNo ratings yet

- KOWA Diagnosis Sheet - Engine - 99127Document2 pagesKOWA Diagnosis Sheet - Engine - 99127Rahmat WiraNo ratings yet

- Underground StructuresDocument2 pagesUnderground StructuresvictorNo ratings yet

- MOR and Modes of Failure of BeamsDocument9 pagesMOR and Modes of Failure of Beamsward dhapakhelNo ratings yet

- bs7671 Iee On Site GuideDocument184 pagesbs7671 Iee On Site Guidemigzx95% (19)

- Hydraulic Bottle JackDocument36 pagesHydraulic Bottle JackGebeyaw DemekeNo ratings yet

- 02070-GEN-PNG-SPE-004 - 04 Soportes PDFDocument234 pages02070-GEN-PNG-SPE-004 - 04 Soportes PDFJose C. MelendezNo ratings yet

- Tackling The Shortage of Construction Skills in NigeriaDocument27 pagesTackling The Shortage of Construction Skills in NigeriaJoshua Tanimowo100% (3)

- Tank Manual2 Of2Document195 pagesTank Manual2 Of2AlbertNo ratings yet

- CR 0701 CH 10Document13 pagesCR 0701 CH 10Rıfat BingülNo ratings yet

- Compresor 5120Document32 pagesCompresor 5120Cesar GongoraNo ratings yet

- 'Docslide - Us - General Catalogue MZT Pumpi PDFDocument24 pages'Docslide - Us - General Catalogue MZT Pumpi PDFIvkraNo ratings yet

- Steam Tapping Point-1Document4 pagesSteam Tapping Point-1DangolNo ratings yet

- NBC 105.2020Document111 pagesNBC 105.2020Debendra Dev KhanalNo ratings yet

- Structural ReviewerDocument23 pagesStructural ReviewerrogggNo ratings yet

- Final PDFDocument16 pagesFinal PDFpratiksha ghayalNo ratings yet

- Bearing Pad "A" Bearing Pad "B": Bd-Id1EDocument11 pagesBearing Pad "A" Bearing Pad "B": Bd-Id1EJUAN RULFONo ratings yet

- Peb Kbsil Rev 1Document57 pagesPeb Kbsil Rev 1prabhakarsunku100% (2)

- 450╦«┴·═╖╦╡├≈╩Θ003ok engDocument27 pages450╦«┴·═╖╦╡├≈╩Θ003ok engGabriel IbarraNo ratings yet

- (CQHP) Guidelines For ArchitectureDocument23 pages(CQHP) Guidelines For ArchitectureZEC LIMITEDNo ratings yet

- Problem 9 - Column Interaction DiagramDocument9 pagesProblem 9 - Column Interaction DiagramRey Joseph IglesiaNo ratings yet

- Manual Hoist GA DetailsDocument18 pagesManual Hoist GA Detailsdattasudipto4339No ratings yet

- Risk Assessment For Existing Asphalt Cutting For Laying Utilities Reinstatement Rev1 0Document30 pagesRisk Assessment For Existing Asphalt Cutting For Laying Utilities Reinstatement Rev1 0nagaaNo ratings yet

- OIL & GAS Maintenance Guide - VALVEDocument24 pagesOIL & GAS Maintenance Guide - VALVENouredine Looki100% (1)

- Tall Buildings PDFDocument92 pagesTall Buildings PDFngodangquangNo ratings yet

- Self Compacting ConcreteDocument101 pagesSelf Compacting ConcreteMOHAMMED RAYYAN N100% (1)