Professional Documents

Culture Documents

PEEK

Uploaded by

Hugorong WongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PEEK

Uploaded by

Hugorong WongCopyright:

Available Formats

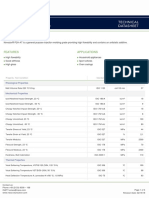

VICTREX® PEEKTM 450CA40

Product Description:

High performance thermoplastic material, 40% carbon fibre reinforced PolyEtherEtherKetone (PEEK), semi crystalline, granules for

injection moulding and extrusion, standard flow, FDA food contact compliant, colour black.

Typical Application Areas:

Applications for higher strength and stiffness in a static or dynamic system. Excellent wear resistance, low coefficient of friction, low

coefficient of thermal expansion. Chemically resistant to aggressive environments.

Material Properties

CONDITIONS TEST METHOD UNITS TYPICAL VALUE

Mechanical Data

Tensile Strength Break, 23°C ISO 527 MPa 250

Tensile Elongation Break, 23°C ISO 527 % 1.5

Tensile Modulus 23°C ISO 527 GPa 32

Flexural Strength 23°C ISO 178 MPa 380

Flexural Modulus 23°C ISO 178 GPa 28

-2

Izod Impact Strength Notched, 23°C ISO 180/A kJ m 8.5

Unnotched, 23°C ISO 180/U 40

Thermal Data

Melting Point ISO 11357 °C 343

Glass Transition (Tg) Onset ISO 11357 °C 143

-1 -1

Specific Heat Capacity 23ºC DSC kJ kg °C 1.8

-1

Coefficient of Thermal Expansion Along flow below Tg ISO 11359 ppm °C 5

Average below Tg 35

Along flow above Tg 8

Average above Tg 90

Flow

Melt Viscosity 400°C ISO 11443 Pa.s 850

Miscellaneous

-3

Density Crystalline ISO 1183 g cm 1.44

Water Absorption (3.2mm thick Tensile bar) 24h, 23°C ISO 62-1 % 0.03

(by immersion) Equilibrium, 23°C 0.3

Fire Smoke Toxicity

Flammability Rating UL94 n/a V-0 @ 0.5 mm

Glow Wire Test 2mm thickness IEC 60695-2-12 ºC 960 *

Toxicity Index CO content NES 713 n/a 0.05 *

CO2 content 0.12 *

Total gases 0.17 *

* Result based on 450CA30

VICTREX® PEEK™ high performance polymers ©Victrex plc Revision Jun 09 1

Recommended Processing Conditions

Drying Temperature / Time 150°C / 3h or 120°C / 5h

Temperature settings 380 / 390 / 395 / 400 / 405°C (Nozzle)

Hopper Temperature Not greater than 100°C

Mould Temperature 190°C - 210°C (max 250°C)

Runner Die / nozzle >3mm, manifold >3.5mm

Gate >2mm or 0.5 x part thickness

Mould Shrinkage and Spiral Flow

Spiral Flow 405°C nozzle, 200°C tool 1mm thick section Victrex mm 65

Mould Shrinkage 405°C nozzle, 200°C tool Along flow ISO 294-4 % 0.1

Across flow 0.5

Detailed data available on our website www.victrex.com or upon request

World Headquarters

Victrex plc, Hillhouse International, Thornton Cleveleys, Lancashire FY5 4QD United Kingdom

Tel: + (44) 1253 897700 Fax: + (44) 1253 897701 Email: victrexplc@victrex.com

VICTREX PLC BELIEVES THAT THE INFORMATION CONTAINED HEREIN IS AN ACCURATE DESCRIPTION OF THE TYPICAL CHARACTERISTICS AND/OR USES OF THE PRODUCT

OR PRODUCTS, BUT IT IS THE CUSTOMER'S RESPONSIBILITY TO THOROUGHLY TEST THE PRODUCT IN EACH SPECIFIC APPLICATION TO DETERMINE ITS PERFORMANCE,

EFFICACY AND SAFETY FOR EACH END-USE PRODUCT, DEVICE OR OTHER APPLICATION. SUGGESTIONS OF USES SHOULD NOT BE TAKEN AS INDUCEMENTS TO INFRINGE

ANY PARTICULAR PATENT. THE INFORMATION AND DATA CONTAINED HEREIN ARE BASED ON INFORMATION WE BELIEVE RELIABLE. MENTION OF A PRODUCT IN THIS

DOCUMENTATION IS NOT A GUARANTEE OF AVAILABILITY. VICTREX PLC RESERVES THE RIGHT TO MODIFY PRODUCTS, SPECIFICATIONS AND/OR PACKAGING AS PART OF A

CONTINUOUS PROGRAM OF PRODUCT DEVELOPMENT. VICTREX® IS A REGISTERED TRADEMARK OF VICTREX MANUFACTURING LIMITED. PEEK™, APTIV™, PEEK-ESD™, T-

SERIES™, PEEK-HT™ ARE TRADEMARKS OF VICTREX PLC. VICOTE® IS A REGISTERED TRADEMARK OF VICTREX PLC.

VICTREX PLC MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, A WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR OF INTELLECTUAL PROPERTY NON-

INFRINGEMENT, INCLUDING, BUT NOT LIMITED TO PATENT NON-INFRINGEMENT, WHICH ARE EXPRESSLY DISCLAIMED, WHETHER EXPRESS OR IMPLIED, IN FACT OR BY LAW. FURTHER, VICTREX

PLC MAKES NO WARRANTY TO YOUR CUSTOMERS OR AGENTS, AND HAS NOT AUTHORIZED ANYONE TO MAKE ANY REPRESENTATION OR WARRANTY OTHER THAN AS PROVIDED ABOVE.

VICTREX PLC SHALL IN NO EVENT BE LIABLE FOR ANY GENERAL, INDIRECT, SPECIAL, CONSEQUENTIAL, PUNITIVE, INCIDENTAL OR SIMILAR DAMAGES, INCLUDING WITHOUT LIMITATION, DAMAGES

FOR HARM TO BUSINESS, LOST PROFITS OR LOST SAVINGS, EVEN IF VICTREX HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, REGARDLESS

® ™ OF THE FORM OF ACTION. 2

VICTREX PEEK high performance polymers ©Victrex plc 062007

You might also like

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Victrex - Peek Data SheetDocument2 pagesVictrex - Peek Data SheetM J VoraNo ratings yet

- VictrexTDS150G 151GDocument2 pagesVictrexTDS150G 151GKumaar RanjanNo ratings yet

- Victrex TDS 650GDocument2 pagesVictrex TDS 650GKumaar RanjanNo ratings yet

- Victrex™ Peek 450G™: Product DescriptionDocument2 pagesVictrex™ Peek 450G™: Product DescriptionBerkant CangalNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Victrex TDS WG101Document2 pagesVictrex TDS WG101matteo.gaggioliNo ratings yet

- Victrex PEEK 450FE20: Conditions Test Method Units Typical ValueDocument2 pagesVictrex PEEK 450FE20: Conditions Test Method Units Typical ValueRohan KulkarniNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Victrex ST 45CA30: Conditions Test Method Units Typical ValueDocument2 pagesVictrex ST 45CA30: Conditions Test Method Units Typical ValuenomeNo ratings yet

- Main Characteristics Value Unit Test Method: ( ) Samples Conditioned 15 Days at 23°C - 50 % R.H. (C) Complete BreakDocument1 pageMain Characteristics Value Unit Test Method: ( ) Samples Conditioned 15 Days at 23°C - 50 % R.H. (C) Complete BreakAlan TsaiNo ratings yet

- Arkema PEKK kKepstan 8001 TDSDocument3 pagesArkema PEKK kKepstan 8001 TDSstartionlilNo ratings yet

- Victrex TDS 450GDocument3 pagesVictrex TDS 450GPRAMOD KUMARNo ratings yet

- TDS - Tecomid NB40 GR30 NLDocument1 pageTDS - Tecomid NB40 GR30 NLilkerNo ratings yet

- Evonik Corporation Vestamid X7293 Plasticized Nylon 12Document3 pagesEvonik Corporation Vestamid X7293 Plasticized Nylon 12Prabhu MohanNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Grand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsDocument1 pageGrand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsPhuoc Thinh TruongNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Hdpe Bl3-MarunDocument1 pageHdpe Bl3-MarunChetan PandyaNo ratings yet

- PP TDSDocument2 pagesPP TDSsribachaNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Seriola K 3120Document2 pagesSeriola K 3120WWTP SerafoodNo ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- Daicel PP: Properties PG2N1Document1 pageDaicel PP: Properties PG2N1Chentouf MohammedNo ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Styrolution TDS401000260275Document3 pagesStyrolution TDS401000260275vicenteNo ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- Epovia Optimum® KRF 1051: Technical Data SheetDocument1 pageEpovia Optimum® KRF 1051: Technical Data SheetsidsaleemNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Total 3645Document1 pageTotal 3645M. Kürşad ArslanNo ratings yet

- Arkema Kepstan PEKK 8002 TDSDocument3 pagesArkema Kepstan PEKK 8002 TDSstartionlilNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Polimax P901BKDocument1 pagePolimax P901BKLe Minh TuanNo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- Apc-2 Peek 031912-01Document6 pagesApc-2 Peek 031912-01Angel LagrañaNo ratings yet

- Dupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinDocument11 pagesDupont™ Crastin S600F40 Nc010: Thermoplastic Polyester ResinTomGaliciaNo ratings yet

- TASNEE 100 Black PE Resin for Pressure PipesDocument2 pagesTASNEE 100 Black PE Resin for Pressure PipesHassanNo ratings yet

- Crastin S600 F40 NC010Document11 pagesCrastin S600 F40 NC010TomGaliciaNo ratings yet

- TDS Mafill CRHT6344Document1 pageTDS Mafill CRHT6344marcohang00No ratings yet

- BESN Noir P20 TLDocument2 pagesBESN Noir P20 TLjuliushasan2No ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNo ratings yet

- Design of A Tuned Intake Manifold - H. W. Engelman (ASME Paper 73-WA/DGP-2)Document9 pagesDesign of A Tuned Intake Manifold - H. W. Engelman (ASME Paper 73-WA/DGP-2)david_luzNo ratings yet

- Understanding The Nature of ReligionDocument41 pagesUnderstanding The Nature of Religioneden l. abadNo ratings yet

- Bentley Bentayga BrochureDocument9 pagesBentley Bentayga BrochureGerry CalàNo ratings yet

- PSUTIL Documentation for Monitoring System ResourcesDocument77 pagesPSUTIL Documentation for Monitoring System ResourcesImam RiadiNo ratings yet

- A Thing of Beauty Analysis by Sharvaree S. ChavanDocument12 pagesA Thing of Beauty Analysis by Sharvaree S. Chavansharu11No ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- Memories of HomeDocument14 pagesMemories of HomeMary Francis Edmer SayconNo ratings yet

- SGDJ PDFDocument334 pagesSGDJ PDFDouglas Rogério de CastroNo ratings yet

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet

- 5 Variable K-MapDocument15 pages5 Variable K-MapBen SewellNo ratings yet

- Oxford Reading Tree: The Pet ShopDocument12 pagesOxford Reading Tree: The Pet ShopKanjaNo ratings yet

- Chapter-1: Introduction of The StudyDocument21 pagesChapter-1: Introduction of The StudyViswanathanNo ratings yet

- G5 C11 TestDocument6 pagesG5 C11 TestvictoriaNo ratings yet

- Acute Severe Asthma Hospital ManagementDocument1 pageAcute Severe Asthma Hospital ManagementItharshan IndreswaranNo ratings yet

- Erasmus Rotterdam University MCDocument24 pagesErasmus Rotterdam University MCAndreea CroitoruNo ratings yet

- Computations on a waiters bill pad and conversations in the mistDocument3 pagesComputations on a waiters bill pad and conversations in the mistRavishu NagarwalNo ratings yet

- The Nature of Substance - Rudolf Hauschka PDFDocument250 pagesThe Nature of Substance - Rudolf Hauschka PDFBruno Morin100% (5)

- Thermal Performance of Air-Cooled Condensing Units by CFD SimulationDocument2 pagesThermal Performance of Air-Cooled Condensing Units by CFD SimulationFauziah JeraiNo ratings yet

- Zenopus ClassicDocument32 pagesZenopus Classicserenity42No ratings yet

- Legend of Nueva VizcayaDocument10 pagesLegend of Nueva VizcayaAndreanna Maria100% (1)

- Essay - DnaDocument2 pagesEssay - Dnaapi-243852896No ratings yet

- Hearing Aid InformationDocument22 pagesHearing Aid InformationDeepakRodeyNo ratings yet

- Life Time Prediction of GRP Piping SystemsDocument15 pagesLife Time Prediction of GRP Piping SystemsRamon FrenchNo ratings yet

- Cell Structure ActivityDocument4 pagesCell Structure ActivitysharksiedNo ratings yet

- S2 Papers FinalizedDocument149 pagesS2 Papers FinalizedRaffles HolmesNo ratings yet

- Circuits Review P2Document44 pagesCircuits Review P2José CastilloNo ratings yet

- Normal Distribution PortfolioDocument6 pagesNormal Distribution Portfoliosophia harris100% (1)

- F825 - Hotcakes Baby Cardigan FinalDocument2 pagesF825 - Hotcakes Baby Cardigan Finaladina100% (1)

- Mohair FiberDocument33 pagesMohair FiberMuhammad Ahsan AftabNo ratings yet

- Let Us Discover: Hairdressing-Grade 11Document5 pagesLet Us Discover: Hairdressing-Grade 11cherry d.bandolaNo ratings yet