Professional Documents

Culture Documents

Gps Asco 4800

Uploaded by

Roque Camacho AlfredoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gps Asco 4800

Uploaded by

Roque Camacho AlfredoCopyright:

Available Formats

4000 SERIES

Data Sheet Model 4800

The ASCO Model 4800 are resistive,

AC load banks designed for outdoor

installation when up to 3000 kW of

resistive load is required.

LOAD BANK RATINGS Cooling System

Standard capacity ratings of: Approximately 20,000 CFM cooling per individual vertical frame is provided by

integral TEFC or TEAO motor which is direct coupled to the cooling fan blade.

• 450 kW • 1000 kW • 2000 kW

• 500 kW • 1250 kW • 2500 kW The fan motor is fully protected with fuses, motor starter contractor, and overload relay.

• 600 kW • 1500 kW • 3000 kW Operator Controls

• 750 kW • 1750 kW

The standard load control for the 4800 is a manual 19" rack mount panel. Controls

Standard load step resolution of either include: Power On/Off switch, Blower Start/Stop push buttons, Master Load On/

5 or 50 kW. Off switch, and Individual Load Step switches. Visual indicators include: Power On,

Select from standard three phase Blower On, and Blower/Air Failure.

voltage ratings of: Other control options are available, please consult factory.

• 208-60Hz • 400-50Hz Construction

• 240-60Hz • 240/480-60Hz* The 4800 is constructed using heavy gauge aluminized steel per ASTM A463. It is designed

• 480-60Hz

for continuous outdoor weatherproof operation. Forklift channels are provided in the base

• 600-60Hz *NOTE: available up to for lifting.

1500 kW

All exterior fasteners are stainless steel. The main input bus, load step relays, fuses, and

Please consult factory for non-standard blower/control relays are located in the main enclosure. The 4800 load bank is listed to UL

ratings. standard 508A.

Short Circuit Rating Finish

The 4800 has a high quality baked polyester powder coated finish with a film thickness

Standard at 10kA or 100kA of 2.8 +/- 0.4 mils per coat. The standard color is gray (ANSI 61).

Blower Motor Control Two Year Warranty Included

The blower motor(s) are factory wired to The equipment is covered by an industry exclusive 24-month parts and labor warranty.

the main load bus. If external blower con-

nection is required, the factory installed

wired must be removed. Refer to the load

bank schematic for specific details.

An external 120V, 1 Phase, 60 Hz supply

is required for control circuit operation.

An optional step-down transformer is avail-

able to provide the required control power.

The transformer receives its power from

the blower motor circuit described above.

Model 4800 Specifications

Resistor Elements AIRFLOW

ASCO load banks use helically wound 45.75

[1162.05]

BOLT ON

EXHAUST HOODS

chromium alloy Helidyne elements. Ele- (SHIPPED LOOSE)

ments are fully supported across their

entire length by segmented ceramic

138.00

insulators on stainless steel rods. These [3505.00]

REMOVABLE

BLOWER &

elements are designed to operate at 156.00 CONTROL

92.25

ACCESS PANELS

CONNECTIONS

approximately 1/2 of their maximum [3962.00]

(with

[2343.15]

continuous wire rating. elevating

stand) B

A

C 0.56 [14.00] DIA

Elements are positioned within the cool- SIDE AIR

HOLES

ing airstream for optimal performance. INTAKE A

B

1.75

[44.00]

Changes in resistance due to temperature 18.00

C TYP

are minimized by maintaining conservative FORKLIFT

[457.00] 39.31

[998.54] C

CHANNELS

watt densities. 57.19 ELEVATING STAND 4810: 450-1000 kW

1.75 [44.00]

TYP

[1452.56] (2500 & 3000 kW ONLY)

The overall load tolerance of the 4800 59.00 79.56 [2021.00]

[1499.00]

load bank is -0, +5%. This ensures that (with elevating stand) 4820: 1250-2000 kW

advertised kW is delivered at rated 120.00 [3048.00]

voltage. 4830: 2500-3000 kW

The elements are continuously rated at Model 4810: is a single stack (1 bay) 450 - 1000 kW unit.

the specific voltage. Tests at lower volt-

Model 4820: is a double stack (2 bay) 1250 - 2000 kW unit.

ages, with a corresponding reduction in

overall rating, may be carried out. Model 4830: is a triple stack (3 bay) 2500 - 3000 kW unit,

which includes the elevating stand.

Safety Features All dimensions are in inches [millimeters].

Specifications subject to change without notice.

A differential pressure switch is inter-

locked with the load application controls

to prevent load from being supplied if Ambient Temperature Weight and Dimensions

cooling air is not present.

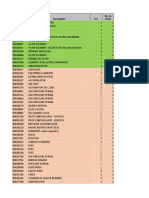

The 4800 load bank is designed for Dimensions (approx. in/mm) Weight

An overtemperature switch is provide to continuous duty cycle with no limi- Capacity (approx.

(kW) Length Width Height

sense the load bank exhaust. The switch is tations. The ambient temperatures lb/kg)

interlocked with the load application con- range is -20°F to 120°F (-28°C to 450- 57/ 40/ 138/ 1500/

trols to disable load from being supplied if 50°C). 1000 1453 999 3505 680

an over-temperature condition is present.

1250- 57/ 80/ 138/ 3000/

The fan motors are protected with fuses

Mounting 2000 1453 2021 3505 1360

and overloads. The 4800 is designed for outdoor 2500- 59/ 120/ 156/ 5500/

installation on a concrete pad or 3000 1499 3048 3962 2495

Major fault protection is provided by

structural base.

branch circuit fuse protection. Fuse

protection is provided on all load steps. Documentation -

Power Terminals and

The exterior of the load bank has appro- Operating Manual

Cable Entry

priate warning and caution statements on A comprehensive operator's manual is

access panels. The power terminals are located behind supplied electronically via a USB drive.

a removable, bolt on access panel. The

Internal access is restricted by bolt on 4800 has a recommended conduit entry Sections include: Safety, Installation,

exterior panels. area underneath the power terminal as- Operation, Maintenance, and Trouble-

The air intake on the 4800 is designed to sembly to facilitate load cable installation. shooting.

prevent objects greater than 0.50" diam-

eter from being ingested into the unit. Optional Accessories Testing and Standards

Vertical air discharge is provided and • Control Power Transformer ASCO load banks comply with NEMA,

exhaust air is directed downward away • NEMA 4 Type Control Panel Enclosure NEC, and ANSI standards. Quality control

from personnel. system is certified to ISO9001 standards.

• Automatic Load Control

• Digital Metering with Data Logging

• SIGMA 2 Digital Controls

• Remote I/O Control

• Pilot Relay Control

• PLC Control

• Arctic Rating (low temperature)

ASCO Power Technologies

6255 Halle Drive, Cleveland, Ohio 44125, U.S.A.

You might also like

- Model 4950: 4000 SERIESDocument2 pagesModel 4950: 4000 SERIESAfzal ImamNo ratings yet

- ASCO-2600 LoadBank-pub5510-revDDocument2 pagesASCO-2600 LoadBank-pub5510-revDAllamNo ratings yet

- Hoja Técnica Asco 2000 - Modelo 2500 - 100 KW - V2Document2 pagesHoja Técnica Asco 2000 - Modelo 2500 - 100 KW - V2Hernán Peñafiel ReaNo ratings yet

- Avtron-K575a DatasheetDocument2 pagesAvtron-K575a DatasheetKarlos Miguel Lopez GomezNo ratings yet

- AVTRON 2705CE Pub5128 RevbDocument2 pagesAVTRON 2705CE Pub5128 Revbzqgjxwcc5wNo ratings yet

- K575a AvtronDocument2 pagesK575a AvtronjithukshajiNo ratings yet

- Hoja Técnica Asco 2905 - 700 KW2905Document2 pagesHoja Técnica Asco 2905 - 700 KW2905Hernán Peñafiel ReaNo ratings yet

- Asc LB Ds 2200Document2 pagesAsc LB Ds 2200JOSE RODRÍGUEZNo ratings yet

- BE Engineering Guide B 50 Model ENG15072 YLAA Scroll Chillers PDFDocument58 pagesBE Engineering Guide B 50 Model ENG15072 YLAA Scroll Chillers PDFMegaHyperMaxNo ratings yet

- PR.F-01 - PR.F-02Document3 pagesPR.F-01 - PR.F-02Gwenn AsprerNo ratings yet

- BE EngGuide YLUACompressingCondenser50HzDocument52 pagesBE EngGuide YLUACompressingCondenser50HzJo PastorNo ratings yet

- Be - Eng - Guide - Ylaa 60 HZDocument64 pagesBe - Eng - Guide - Ylaa 60 HZCharles FalcaoNo ratings yet

- 150 72-Eg6Document68 pages150 72-Eg6ks aksNo ratings yet

- Cat 350 KW Gen SetDocument4 pagesCat 350 KW Gen SetMuhammad Sabir ImtiazNo ratings yet

- Hoja Técnica Load Bank Avtron K490Document2 pagesHoja Técnica Load Bank Avtron K490Hernán Peñafiel ReaNo ratings yet

- BE YLAA Spec Engineering Guide B50HzDocument54 pagesBE YLAA Spec Engineering Guide B50HzPrestoneKNo ratings yet

- Banco de Carga ResistivaDocument2 pagesBanco de Carga ResistivaEDDY ZEA UMIÑANo ratings yet

- YLAA Spec EngineeringGuideDocument64 pagesYLAA Spec EngineeringGuideAnonymous 7FXutrGNo ratings yet

- He-321a PDS 146565-000Document2 pagesHe-321a PDS 146565-000413666436qq.comNo ratings yet

- Avents (Kruger Make Fans)Document12 pagesAvents (Kruger Make Fans)Ateeq KhanNo ratings yet

- TSK II Series: In-Line Centrifugal Duct FanDocument4 pagesTSK II Series: In-Line Centrifugal Duct FancoollineNo ratings yet

- TSK II Series - In-Line Centrifugal Duct Fan - Product CatalogueDocument4 pagesTSK II Series - In-Line Centrifugal Duct Fan - Product CatalogueMuthu SelvarajNo ratings yet

- Type FEC Epoxy Encapsulated, Copper-Wound Industrial Control TransformersDocument12 pagesType FEC Epoxy Encapsulated, Copper-Wound Industrial Control TransformersTOLENTINONo ratings yet

- Service Manual 38cvur13!16!42cvur13 16Document104 pagesService Manual 38cvur13!16!42cvur13 16Leo De ocampoNo ratings yet

- Patriot 700 Ficha TecnicaDocument2 pagesPatriot 700 Ficha Tecnicasoldadores motoresNo ratings yet

- VSKT106 16S90P VishayDocument9 pagesVSKT106 16S90P VishayjoseNo ratings yet

- Air Circuit Breakers For The 21st Century: Catalogue No.'00-P55EDocument4 pagesAir Circuit Breakers For The 21st Century: Catalogue No.'00-P55EAsif ShahNo ratings yet

- BE YLAA Scroll ChillerDocument68 pagesBE YLAA Scroll ChillerEnrique Mejia Gamarra100% (1)

- YLAA Engineering GuideDocument64 pagesYLAA Engineering GuideJoe YoungNo ratings yet

- Emax-Air Circuit Breakers: E3 3200A Fixed and DrawoutDocument2 pagesEmax-Air Circuit Breakers: E3 3200A Fixed and DrawoutAishNo ratings yet

- 3 - Cooper 24040 Fuse HolderDocument6 pages3 - Cooper 24040 Fuse Holderheri fauziNo ratings yet

- Medium Voltage Motor Brochure - 1621Document8 pagesMedium Voltage Motor Brochure - 1621Edimar SilvaNo ratings yet

- Selección de CondensadorasDocument64 pagesSelección de CondensadorasAntonio Osante LeyvaNo ratings yet

- 410 Ycal-1099Document90 pages410 Ycal-1099Al Dizdar NazarNo ratings yet

- Ficha Tecnica Panel Solar Jinko280WpDocument2 pagesFicha Tecnica Panel Solar Jinko280WpJair SaavedraNo ratings yet

- CAT XQ125 350 BrochureDocument4 pagesCAT XQ125 350 BrochureArturo SánchezNo ratings yet

- Hydac Acoplamientos CampanaDocument4 pagesHydac Acoplamientos CampanaDavid MejidoNo ratings yet

- RAS-13N3KCV Service ManualDocument102 pagesRAS-13N3KCV Service ManualRiyo SaputraNo ratings yet

- (Steam Trap - Thermo) Yoshitake TD-10 NADocument2 pages(Steam Trap - Thermo) Yoshitake TD-10 NAAldeline SungahidNo ratings yet

- Crydom HD4850 10 DatasheetDocument4 pagesCrydom HD4850 10 DatasheetOscar PelcastreNo ratings yet

- Kohler KK16 - 0519Document5 pagesKohler KK16 - 0519Nguyen Vu Hoang ThachNo ratings yet

- EH2500 Series Enclosure: Product SpecificationDocument2 pagesEH2500 Series Enclosure: Product SpecificationdenfertNo ratings yet

- Catálogo Generadores Ultra Silenciosos KIPORDocument16 pagesCatálogo Generadores Ultra Silenciosos KIPORPacho SantacruzNo ratings yet

- 80 1143 03 Rev. 07.1 11 430 Man. Opt. 9 PDFDocument68 pages80 1143 03 Rev. 07.1 11 430 Man. Opt. 9 PDFCristi MarianNo ratings yet

- D D D D D D D: A7800 SERIES Positive-Voltage RegulatorsDocument18 pagesD D D D D D D: A7800 SERIES Positive-Voltage RegulatorsAmanda BentoNo ratings yet

- YLAA Air-Cooled Scroll Chiller SpecsDocument70 pagesYLAA Air-Cooled Scroll Chiller SpecsoribataNo ratings yet

- Industrial Diesel Generator Set - 50 HZ: General SpecificationsDocument6 pagesIndustrial Diesel Generator Set - 50 HZ: General Specificationsnguyenbinh20No ratings yet

- 0hulgldq &rqwuro 6/Vwhpv 'HvfulswlrqDocument2 pages0hulgldq &rqwuro 6/Vwhpv 'Hvfulswlrqrichr49No ratings yet

- Industrial Diesel Generator Set - 50 HZ: Benefits & Features KOHLER SDMO Premium QualityDocument6 pagesIndustrial Diesel Generator Set - 50 HZ: Benefits & Features KOHLER SDMO Premium Qualitynguyenbinh20No ratings yet

- Izn Two Stage CompressorDocument2 pagesIzn Two Stage CompressorLhexter Mhervin CoNo ratings yet

- Stick, TIG, Flux-Cored, Gouging: ProcessesDocument4 pagesStick, TIG, Flux-Cored, Gouging: ProcessesMostafa ElabdNo ratings yet

- HVAC Bard S3502 (2018 09)Document28 pagesHVAC Bard S3502 (2018 09)nisaelNo ratings yet

- ACRU-B Upblast Centrifugal Exhaust Ventilator Roof Mounted/Belt DriveDocument1 pageACRU-B Upblast Centrifugal Exhaust Ventilator Roof Mounted/Belt DriveJose MaciasNo ratings yet

- Turbo Electromechanical Irreversible Key Automation Catalogue 2013Document1 pageTurbo Electromechanical Irreversible Key Automation Catalogue 2013galih santosoNo ratings yet

- ASCO 7000 Operator ManualDocument12 pagesASCO 7000 Operator ManualJason29No ratings yet

- KATKO Load Break and Changeover Switches - Rating - TablesDocument4 pagesKATKO Load Break and Changeover Switches - Rating - TablesVildanNo ratings yet

- Vents Ov Vents Ovk Vents VKF: Series Series SeriesDocument9 pagesVents Ov Vents Ovk Vents VKF: Series Series SeriesValentin MalihinNo ratings yet

- BCI184FDocument8 pagesBCI184F3efooNo ratings yet

- Industrial Diesel Generator Set - 50 HZ: KOHLER SDMO Premium QualityDocument7 pagesIndustrial Diesel Generator Set - 50 HZ: KOHLER SDMO Premium QualityJoanCarlesLLopysNo ratings yet

- 01 - SWG - Tecs - MCB - (1.01 - 1.02)Document2 pages01 - SWG - Tecs - MCB - (1.01 - 1.02)ThilinaNo ratings yet

- Behringer B2030a Manual 42697Document10 pagesBehringer B2030a Manual 42697robyx71No ratings yet

- Siemens LiteratureDocument92 pagesSiemens LiteratureMuhammad Noman AslamNo ratings yet

- Earthing DesignDocument90 pagesEarthing Designabdulkadhir83% (6)

- Westinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsDocument28 pagesWestinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsRodney PimentaNo ratings yet

- Atasheet en 201508 T58I-E-02 Rev3 2Document17 pagesAtasheet en 201508 T58I-E-02 Rev3 2deri mardiNo ratings yet

- Technics SC Eh560 Users Manual 359448Document44 pagesTechnics SC Eh560 Users Manual 359448josean_mNo ratings yet

- (MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDocument500 pages(MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDaniel Reconco88% (8)

- Bhelfeed O&m D1Document70 pagesBhelfeed O&m D1Rajesh Sirsath100% (3)

- JP 33 ManualDocument111 pagesJP 33 ManualKiên Sơn NguyễnNo ratings yet

- Audiolab 8000TE AM/FM Stereo Tuner User InstructionsDocument4 pagesAudiolab 8000TE AM/FM Stereo Tuner User Instructionsgorankontic1_4459869No ratings yet

- Elektro RadoviDocument197 pagesElektro RadovigamasistemNo ratings yet

- 240-56227516 LV Switchgear and Control Gear Assemblies and ... Standard Rev 2Document48 pages240-56227516 LV Switchgear and Control Gear Assemblies and ... Standard Rev 2iabhua100% (1)

- Automatic Manual ChargersDocument46 pagesAutomatic Manual ChargersfoxastNo ratings yet

- Ghc140 RPLDocument6 pagesGhc140 RPLDecomaderas SanchezNo ratings yet

- Manual de Partes Motrec Tittan E-330Document58 pagesManual de Partes Motrec Tittan E-330Antonio GonzálezNo ratings yet

- Lesson Plan 5 Electrical Installation and Maintenance I. ObjectivesDocument5 pagesLesson Plan 5 Electrical Installation and Maintenance I. Objectivescecille mañacapNo ratings yet

- © Siemens AG 2007Document24 pages© Siemens AG 2007angeljavier9No ratings yet

- Siemens Low Voltage Switch Gear Price ListDocument67 pagesSiemens Low Voltage Switch Gear Price ListDheeraj YadavNo ratings yet

- Operation Manual for Daikin FDY and FD Ducted Air ConditionersDocument12 pagesOperation Manual for Daikin FDY and FD Ducted Air ConditionersJustiniano Martel67% (3)

- Kat XEnergy 143171 enDocument850 pagesKat XEnergy 143171 enhuy phạmNo ratings yet

- PowerTips - Motor Starting and Running Currents and Rating GuideDocument14 pagesPowerTips - Motor Starting and Running Currents and Rating Guideankur yadavNo ratings yet

- HC 150 Dew 150 ManualDocument47 pagesHC 150 Dew 150 Manualpburks254647No ratings yet

- Arc Flash Training PresentationDocument106 pagesArc Flash Training Presentationalaa_saq100% (1)

- XAP Series Busduct Storage, Installation, and Maintenance: Instruction Booklet IBDocument9 pagesXAP Series Busduct Storage, Installation, and Maintenance: Instruction Booklet IBUmerNo ratings yet

- 3RV20110JA15 Datasheet enDocument9 pages3RV20110JA15 Datasheet enXuân Kiên VũNo ratings yet

- Kia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aDocument48 pagesKia-Carnival 2008 en Manual de Mantenimiento C6b3ec5b7aAmelia Sofía Sanhueza GrandónNo ratings yet

- Presentation 1Document17 pagesPresentation 1Saket AgarwalNo ratings yet

- Automatic Transfer Switch Panel Operation GuideDocument23 pagesAutomatic Transfer Switch Panel Operation Guideyorgo7002100% (2)

- Micom C264/C264C: Bay ComputerDocument732 pagesMicom C264/C264C: Bay ComputerBimMariusNo ratings yet