Professional Documents

Culture Documents

PBA Therm Clad Brochure

Uploaded by

James Dickinson0 ratings0% found this document useful (0 votes)

10 views2 pagesThis document provides technical specifications for No-Clad hot and cold pipe insulation. It is made of physically crosslinked closed cell polyolefin foam with a reinforced aluminum foil facing to prevent mechanical damage. It has low thermal conductivity and water vapor permeability, is fire resistant, puncture resistant, and durable against UV light, weathering, fungi, and ozone. It is designed to insulate pipes from -80°C to 100°C.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides technical specifications for No-Clad hot and cold pipe insulation. It is made of physically crosslinked closed cell polyolefin foam with a reinforced aluminum foil facing to prevent mechanical damage. It has low thermal conductivity and water vapor permeability, is fire resistant, puncture resistant, and durable against UV light, weathering, fungi, and ozone. It is designed to insulate pipes from -80°C to 100°C.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesPBA Therm Clad Brochure

Uploaded by

James DickinsonThis document provides technical specifications for No-Clad hot and cold pipe insulation. It is made of physically crosslinked closed cell polyolefin foam with a reinforced aluminum foil facing to prevent mechanical damage. It has low thermal conductivity and water vapor permeability, is fire resistant, puncture resistant, and durable against UV light, weathering, fungi, and ozone. It is designed to insulate pipes from -80°C to 100°C.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

No-Clad

HOT & COLD PIPE INSULATION

Closed cell, physically crosslinked polyolefin foam insulation with ultra

tough foil facing to prevent mechanical damage in high risk areas.

VICTORIA: (03) 9464 4155 - QUEENSLAND: (07) 3889 8844 - NSW: (02) 6040 3888

FREE CALL: 1800 444 022 - FREEFAX: 1800 444 024

www.pbasafety.com.au

Technical Specifications

HOT & COLD PIPE INSULATION

PHYSICAL PROPERTIES FIRE AND SMOKE BEHAVIOUR

Material: Physically (irradiation) crosslinked closed BS476 Parts 6 & 7: CLASS 0

cell polyolefin foam with factor

y applied Technical Data

reinforced aluminium foil and acrylic AS1530 Part 3 Physically

Material: Ignitability Index:crosslinked

(irridation) 0 closed cell polyolefin

adhesive backing foam with factory applied,

Spread heavy

of Flame duty

Index:0 multilayer composite with a

specially developed UV and weather

Heat Evolved Index: 0

durable coating.

Density: 25 kg/m3 (foam core only)

Density: Smoke Developed25kg/m

0-1 3 (foam core only)

Index:

Thermal Conductivity: 0.032 W/m/°K (@ 23°C mean temp.) Thermal Conductivity: 0.032 W/mK (@ 23° C mean

(ASTM C518) 0.036 W/m/°K (@ 36°C mean temp.) ASTM E84: C518) COMPLIES (NFPA 90A & B)

(ASTM temperature)

Flame Spread Index: <25

Water Vapour Permeability: 8.19 x 10-15 kg/Pa.s.m Puncture Resistance >400 N

Smoke Developed Index:

<50

(ASTM E96) (0.029 mg.m/N.h) (ASTM D4833)

Product Description Tear

ASTM Testing

C411: > 60COMPLIES

N MD (NFPA 90A & B)

Water Vapour Permeance: 3.3 x 10-4 g/MN.s (ASTM D751) > 50 N CD

A cost effective alternative to cladding of pipe and duct FM 4924

Tensile Testing Thermobreak Sheet APPROVED

> 1000 N MD

insulation

Water toby

absorption prevent

volume: mechanical

<0.1% v/v damage. It differs from

(ASTM D751) > 900 N CD

Up to 25mm thickness

standard

(JIS K6767) insulation in that the aluminium

(0.00038 g/cm2) foil is a

puncture resistant multilayer consisting of: MD = Machine Direction, CD = Cross Direction

Permeability Resistance Factor: µ > 20,000

• A salt-water resistant, UV and weather durable coating. UV & Weathering Excellent

AS 3837

(3000 hr QUV BCA Group Number:

exposure) 1

No change in performance

• The aluminium

Resistance to fungi: foil isZero

reinforced

Growth with a ultra tough,

Smoke Index: or appearance

≤250

(ASTMclose

G21) weave scrim.

• The flexible closed cell physically crosslinked polyolefin Salt Resistance No visible change in appearance

BS 6853 Annex B Smoke Toxicity COMPLIES (R < 1.0)

Ozonefoam

Resistance: Excellent

underneath allows for distribution of impact (Internal test) (2 week immersion in 5 % salt solution)

force so inhibiting mechanical damage to the IMOWater Vapour

MSC 61(67) Part Permeability

2 Smoke Toxicity 2.3 XCOMPLIES

10-15 kg/P a.s.m

UV Resistance: Excellent

insulation. (ASTM E96)

ISO 5659 Part 2 Smoke Density COMPLIES (IMO MSC 61(67) Part 2)

Noise Reduction Coefficient: 0.20 (12mm foam thickness) Water Vapour Permeance: 0.000195 µg/N.s

Although

(ISO 354) designed to be resistant

0.30 to mechanical

(25mm foam thickness) damage 12mm thickness Dm < 200

this type of insulation has been designed for easy Satisfies max allowable

Permeability Resistance Factor: µ > 80,000

Operating Temperature Range: -80 °C ~ +100 °C (no adhesive) concentrations for the

fabrication using sharp knives.

Water Absorption by Volume: 0.03% v/v (0.00038g/cm²)

following combustion gases:

GreenStar Rating: Low VOC Emitting (JIS K6767)

System Accessories x, SO2

CO, HCl, HBr, HF, HCN, NO

(ASTM D5116)

Resistance to Fungi: Zero Growth

No Clad Foil Tape UL 94

(ASTM G21) Horizontal Burn APPROVED (HF-1)

Physical Property Requirements:COMPLIES (Type II - Sheet)

A specially developed UV and salt-water resistant

(ASTM C1427) Ozone Resistance: Excellent

reinforced aluminium foil tape is available to ensure

SIZE AVAILABILITY

Operating Temperature: - 80° C to 100° C

system

REACH integrity.

Directives: COMPLIES

(1907/2006/EC)

Fire and Smoke Behaviour:

8-mm 50m X 1200 mm rolls

Size Availability

Product Certification may be plant specific. Please consult with your local representative.

BS 476 Part 6&7 Class 0

Available in a range of sizes for pipes and ducts. 10-mm 20m X 1200 mm rolls

AS1530.3(1999)

Distributed by Ignitability index

12-mm 0 rolls

20m X 1200 mm

Tube: Standard pipe OD’s from 25mm to 273mm, with Spread of Flame Index 0

wall thicknesses of 25mm and 50mm. Heat

15-mm evolved Index 0 rolls

20m X 1200 mm

Smoke Develop Index 0-1

20-mm 20m X 1200 mm rolls

Sheets: Available in sheets FM 4924 Approved (up to 8” IPS &

1200mm X 2400mm in Thicknesses of 25mm to 50mm (130546)

25~50-mm 50mm sheets

2300mm X 1200mm wall thickness)

Other sizes available on request.

Softlon and Thermobreak - Registered trademarks of

Sekisui Chemical Co. Ltd or its subsidiaries

Australian Plant Thailand Plant

1-5 Parraweena Rd, PO BOX 2898, 700/329 Moo 6, Amata Nakorn Industrial Estate,

Taren Point NSW 2229 Australia Tumbol Donhua-Ioh, Amphur Muang Chonburi 20000

Tel: +61 2 9525 9880 Tel: +66 38 213219-26

Email: info@sekisuifoam.com.au Email: info@thaisekisui.co.th

Australian Distributor: PBA Safety Pty Ltd

Web: www.sekisuifoam.com.au Web: www.thaisekisui.co.th

ACN 080 532 896 ABN 13 080 532 896

VICTORIA: (03) 9464 4155 - QUEENSLAND: (07) 3889 8844 - NSW: (02) 6040 3888

FREE CALL: 1800 444 022 - FREEFAX: 1800 444 024

SPC011_Thermobreak 8pp_concept_FA.indd 8 28/04/14 3:24 PM

www.pbasafety.com.au

You might also like

- C95500 ASTM - Nickel Aluminum BronzeDocument2 pagesC95500 ASTM - Nickel Aluminum BronzethuykvNo ratings yet

- Types of MaterialsDocument13 pagesTypes of MaterialsHaider ManzoorNo ratings yet

- Polymer Processing TechniquesDocument9 pagesPolymer Processing TechniquesShalini VirdiNo ratings yet

- Nynas Nytro LibraDocument2 pagesNynas Nytro Librap m yadavNo ratings yet

- Chemistry Grade 10 States of MatterDocument40 pagesChemistry Grade 10 States of MatterTrudy- Ann CaineNo ratings yet

- Ib PPT 9 SL PDFDocument38 pagesIb PPT 9 SL PDFzarna nirmal rawalNo ratings yet

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- Atomic Structure and Quantum Theory POGILDocument20 pagesAtomic Structure and Quantum Theory POGILmagiclcj100% (1)

- Pe1000 PDFDocument2 pagesPe1000 PDFrohitdakngNo ratings yet

- Thermobreak Tube BrochureDocument4 pagesThermobreak Tube BrochureTamNo ratings yet

- Sekisui Thermobreak Thermaloc 2017 Brochure - OptDocument4 pagesSekisui Thermobreak Thermaloc 2017 Brochure - OptengineerhamzehNo ratings yet

- 2019 - Sekisui No-Clad International BrochureDocument4 pages2019 - Sekisui No-Clad International BrochureengineerhamzehNo ratings yet

- Sekisui AcoustiPlus 2018 Brochure - WEBDocument4 pagesSekisui AcoustiPlus 2018 Brochure - WEBĐặng Văn SiêuNo ratings yet

- Bao On AmazonDocument4 pagesBao On AmazonTrần ChâuNo ratings yet

- 2017 - 06 - Armaflex FRV PDFDocument8 pages2017 - 06 - Armaflex FRV PDFNaqqash SajidNo ratings yet

- Foam Glass Data SheetDocument2 pagesFoam Glass Data SheetMohamed KareemNo ratings yet

- Specs of PU FoamDocument3 pagesSpecs of PU FoamJuan ValdiviesoNo ratings yet

- Akfix Eng Technical Catalog 2022 Rev16Document211 pagesAkfix Eng Technical Catalog 2022 Rev16ahmed.serefNo ratings yet

- Datasheet - Oil PDFDocument1 pageDatasheet - Oil PDFVijay KumarNo ratings yet

- Roxul Comfortboard 80: Insulated SheathingDocument1 pageRoxul Comfortboard 80: Insulated SheathingMark RauNo ratings yet

- Halene - P: Technical Data Sheet F103Document1 pageHalene - P: Technical Data Sheet F103Dharmendrasinh ZalaNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- tds12 19 2019 - 10 49 12Document1 pagetds12 19 2019 - 10 49 12Camilo DazaNo ratings yet

- Modulatus Ornans Abstract Technical Brochure 2021 Rev00 IntlDocument48 pagesModulatus Ornans Abstract Technical Brochure 2021 Rev00 IntlRamses TorrealbaNo ratings yet

- Nexans XT Medium Voltage Single Core...Document15 pagesNexans XT Medium Voltage Single Core...Mathias CanalesNo ratings yet

- Rti Prorox WM 940 Es ExpDocument1 pageRti Prorox WM 940 Es ExpMadiaw NajaNo ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- PVC Insulating Tape PREMIUMDocument1 pagePVC Insulating Tape PREMIUMengman2121No ratings yet

- Ficha Técnica - 24mar2010 - Nytro LibraDocument2 pagesFicha Técnica - 24mar2010 - Nytro LibraAnonymous Oj2n5Ot7cNo ratings yet

- Datasheet Wesgo Ceramics Al500Document2 pagesDatasheet Wesgo Ceramics Al500hemanth_85No ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Metal Detectable PE1000 Data SheetDocument2 pagesMetal Detectable PE1000 Data SheetPrashant MalikNo ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- 5000W ABS Taita TaiwanDocument1 page5000W ABS Taita TaiwanPhạm Thanh TùngNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- Curtainrock 40 Curtain Wall Thermal Insulation TechdataDocument2 pagesCurtainrock 40 Curtain Wall Thermal Insulation TechdataBrian MabenNo ratings yet

- Able UCT S: Wiring ChannelsDocument8 pagesAble UCT S: Wiring ChannelsberdinsonNo ratings yet

- Nynas TR DT 11 I Iec enDocument1 pageNynas TR DT 11 I Iec enLee RoNo ratings yet

- Cavityrock Cavity Wall and Rainscreen Applications TechdataDocument2 pagesCavityrock Cavity Wall and Rainscreen Applications TechdatadeepscubNo ratings yet

- Searox SL 328: Technical InsulationDocument1 pageSearox SL 328: Technical InsulationAnh Le NgocNo ratings yet

- UK NatureFlex NPFDocument2 pagesUK NatureFlex NPFHavir GhteuNo ratings yet

- LTK Ul 1430 #26Document1 pageLTK Ul 1430 #26Enzo AscañoNo ratings yet

- PK605DMDocument2 pagesPK605DMKan Sang MokNo ratings yet

- Polybetol 40aDocument2 pagesPolybetol 40ahazelNo ratings yet

- Iig - ENERWRAP - MA - 960DataSheetDocument1 pageIig - ENERWRAP - MA - 960DataSheettmp_rootsNo ratings yet

- Halene - P: Technical Data Sheet B200Document1 pageHalene - P: Technical Data Sheet B200Dharmendrasinh ZalaNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Description Application: Advanced EngineeringDocument5 pagesDescription Application: Advanced EngineeringGregory BrownNo ratings yet

- Neoram Super 70 (Ramming Plastic Castable)Document1 pageNeoram Super 70 (Ramming Plastic Castable)muhammad abidinNo ratings yet

- Humiseal 1B31 English TdsDocument2 pagesHumiseal 1B31 English TdsLee HitchensNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Shellsol A150 q7493 Eu 18042016Document3 pagesShellsol A150 q7493 Eu 18042016Henry FloresNo ratings yet

- 002DP48 PDFDocument2 pages002DP48 PDFDiadam SharmaNo ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- Humiseal 1R32 Conformal Coating English TdsDocument2 pagesHumiseal 1R32 Conformal Coating English TdsLee HitchensNo ratings yet

- Shell Diala InglesDocument2 pagesShell Diala InglesdetresgeNo ratings yet

- Standoff Insulator BMC DataDocument1 pageStandoff Insulator BMC DataSwapnil KiniNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- Opal - Hdpe - 4Document2 pagesOpal - Hdpe - 4Piyush A JoshiNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

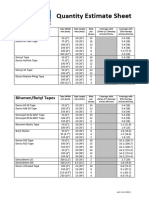

- Denso Quantity Estimate SheetDocument3 pagesDenso Quantity Estimate SheetJames DickinsonNo ratings yet

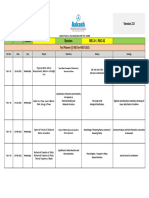

- EN Supplementary Instructions Mounting Brackets KV 31 Pipes Ø 50 200 MM Horizontal Sensor MountingDocument20 pagesEN Supplementary Instructions Mounting Brackets KV 31 Pipes Ø 50 200 MM Horizontal Sensor MountingJames DickinsonNo ratings yet

- Franna MAC 25 Load Chart 3B6Document36 pagesFranna MAC 25 Load Chart 3B6James DickinsonNo ratings yet

- Duo Wafer Cast enDocument2 pagesDuo Wafer Cast enJames DickinsonNo ratings yet

- Cable Supports Catalogue Complete 20131003Document124 pagesCable Supports Catalogue Complete 20131003James DickinsonNo ratings yet

- AusPress Press Fit Technical CatalogueDocument10 pagesAusPress Press Fit Technical CatalogueJames DickinsonNo ratings yet

- Scald Valve Installation KitDocument1 pageScald Valve Installation KitJames DickinsonNo ratings yet

- 17.HB158 Welding Manual301 V30713Document38 pages17.HB158 Welding Manual301 V30713James DickinsonNo ratings yet

- A2 Ch.13 QuestionsDocument13 pagesA2 Ch.13 QuestionsDigola WillsNo ratings yet

- Soal Bird PGDocument2 pagesSoal Bird PGI Gusti Ngurah Widiantara0% (1)

- Sample Paper FMDCDocument7 pagesSample Paper FMDCTanzeel UR RehmanNo ratings yet

- RBC Test Planner Phase 1 Full Till Test 08Document2 pagesRBC Test Planner Phase 1 Full Till Test 08Soumyanshu Shekhar PandaNo ratings yet

- Cathodic Protection Installation DetailsDocument12 pagesCathodic Protection Installation Detailsaldeto71No ratings yet

- Research ArticleDocument10 pagesResearch ArticleSoussou PerlaNo ratings yet

- Fluidized Beds and Fixed BedsDocument121 pagesFluidized Beds and Fixed BedstucameaNo ratings yet

- Class 12 Chemistry Project Report On Diffusion of Solids in LiquidsDocument11 pagesClass 12 Chemistry Project Report On Diffusion of Solids in LiquidsASHWIN KUMAR KANNIYAPPANNo ratings yet

- Fuel CellDocument12 pagesFuel CellsaisenthNo ratings yet

- HMT Assignment 1Document6 pagesHMT Assignment 1Mahmed EdNo ratings yet

- Heat Transfer Study GuideDocument9 pagesHeat Transfer Study GuideSadikielNo ratings yet

- An Introduction To Gamess: Mark S. Gordon Iowa State UniversityDocument24 pagesAn Introduction To Gamess: Mark S. Gordon Iowa State UniversityMauricio PerezNo ratings yet

- Microsco PE: Maria Belinda P. Castaneda, MAN, RN Faculty, College of NursingDocument22 pagesMicrosco PE: Maria Belinda P. Castaneda, MAN, RN Faculty, College of NursingMaria Jenina CervantesNo ratings yet

- Construction and Building Materials: Mohammad Tahersima, Paul TikalskyDocument12 pagesConstruction and Building Materials: Mohammad Tahersima, Paul TikalskyalejandroNo ratings yet

- Physical Chemistry 55par Per AnnumDocument3 pagesPhysical Chemistry 55par Per AnnumfredNo ratings yet

- DPD-1 ThermodynamicDocument2 pagesDPD-1 ThermodynamicDeepNo ratings yet

- Lecture 1 of Mass TransferDocument36 pagesLecture 1 of Mass TransferShifaz SikkanderNo ratings yet

- Fundamentals of Analytical Chemistry Skoog Douglas A West CompressDocument1 pageFundamentals of Analytical Chemistry Skoog Douglas A West Compressmhmdgbaren261No ratings yet

- Determinacion de SulfuroDocument7 pagesDeterminacion de SulfuroJose Luis Gonzales QuinoNo ratings yet

- Properties of LiquidDocument2 pagesProperties of LiquidMlcndNo ratings yet

- Flownex Applications On CCSDocument8 pagesFlownex Applications On CCSSanthosh LingappaNo ratings yet

- PolymersDocument13 pagesPolymersVaibhav ShrivastavaNo ratings yet

- A'level Modern Physics NotesDocument64 pagesA'level Modern Physics NotesLubangula UthumanNo ratings yet

- Chemistry 9th Long QuestionDocument4 pagesChemistry 9th Long QuestionMohammad AshfaqNo ratings yet

- 9701 m16 QP 52Document8 pages9701 m16 QP 52SanthiKalyanaGrantNo ratings yet