Professional Documents

Culture Documents

STTH 1 R 02

STTH 1 R 02

Uploaded by

radu nistorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STTH 1 R 02

STTH 1 R 02

Uploaded by

radu nistorCopyright:

Available Formats

STTH1R02

Datasheet

200 V - 1.5 A ultrafast recovery diode

K A Features

• Very low conduction losses

A

A • Negligible switching losses

• Low forward voltage drop

• High junction temperature

K K • ECOPACK®2

SMA SMB

Applications

A • Switching diode

A • LED Lighting

• Auxiliary power supply

K • Flyback diode

K

Description

DO-15 DO-41

The STTH1R02 uses ST's new 200 V planar Pt doping technology, and it is specially

suited for switching mode base drive and transistor circuits.

Packaged in SMA, SMB, DO-41 and DO-15, the STTH1R02 is ideal for use low

voltage, high frequency inverters, free wheeling and polarity protection

Product status

STTH1R02

Product summary

Symbol Value

IF(AV) 1.5 A

VRRM 200 V

T j(max.) 175 °C

VF(typ.) 0.7 V

trr(typ.) 15 ns

DS4743 - Rev 4 - December 2018 www.st.com

For further information contact your local STMicroelectronics sales office.

STTH1R02

Characteristics

1 Characteristics

Table 1. Absolute ratings (limiting values at 25 °C, unless otherwise specified)

Symbol Parameter Value Unit

VRRM Repetitive peak reverse voltage 200 V

SMA, SMB TL = 150 °C

IF(AV) Average forward current δ = 0.5, square wave 1.5 A

DO-41, DO-15 TL = 135 °C

IFSM Surge non repetitive forward current tp = 10 ms sinusoidal 60 A

Tstg Storage temperature range -65 to +175 °C

Tj Operating junction temperature +175 °C

Table 2. Thermal resistance parameter

Symbol Parameter Max. value Unit

Rth(j-l) Junction to lead SMA, SMB 30

°C/W

Rth(j-l) Junction to lead Lead length = 10 mm on infinite heatsink DO-15, DO-41 45

For more information, please refer to the following application note :

• AN5088 : Rectifiers thermal management, handling and mounting recommendations

Table 3. Static electrical characteristics

Symbol Parameter Test conditions Min. Typ. Max. Unit

Tj = 25 °C - 3

IR(1) Reverse leakage current VR = VRRM µA

Tj = 125 °C - 2 20

Tj = 25 °C - 0.89 1.00

VF(2) Forward voltage drop Tj = 100 °C IF = 1.5 A - 0.76 0.85 V

Tj = 150 °C - 0.70 0.80

1. Pulse test: tp = 5 ms, δ < 2%

2. Pulse test: tp = 380 µs, δ < 2%

To evaluate the conduction losses, use the following equation:

P = 0.68 x IF(AV) + 0.08 x IF2(RMS)

For more information, please refer to the following application notes related to the power losses :

• AN604: Calculation of conduction losses in a power rectifier

• AN4021: Calculation of reverse losses on a power diode

DS4743 - Rev 4 page 2/15

STTH1R02

Characteristics

Table 4. Dynamic characteristics (Tj = 25 °C unless otherwise stated)

Symbol Parameters Test conditions Min. Typ. Max. Unit

IF = 1 A, dIF/dt = -50 A/μs,VR = 30 V - 23 30

trr Reverse recovery time ns

IF = 1 A, dIF/dt = -100 A/μs, VR = 30 V - 15 20

IRM Reverse recovery current IF = 1.5 A, dIF/dt = -200 A/μs, VR = 160 V, Tj = 125 °C - 3 4 A

tfr Forward recovery time IF =1.5 A, dIF/dt = 100 A/μs, VFR = 1.1 VF(max.) - 50 ns

VFP Forward recovery voltage IF =1.5 A, dIF/dt = 100 A/μs - 2.1 V

DS4743 - Rev 4 page 3/15

STTH1R02

Characteristics (curves)

1.1 Characteristics (curves)

Figure 2. Forward voltage drop versus forward current

Figure 1. Peak current versus duty cycle

(typical values)

IM(A)

50

IF (A)

T

45 IM 50

40 δd=tp/T tp

40

35

30

30

P = 5W

25

20

20

P = 2W

15 Tj=150°C

P = 1W

Tj=25°C

10 10

5

VF (V)

δ

0 0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 0.0 0.5 1.0 1.5 2.0 2.5

Figure 3. Forward voltage drop versus forward current Figure 4. Relative variation of thermal impedance junction

(maximum values) to lead versus pulse duration (SMA)

IFM(A) Zth(j-a) /Rth(j-a)

50 1.0

SMA

0.9 Scu=1cm²

40 0.8

0.7

30 0.6

0.5

20 0.4

Tj=150°C

0.3

Tj=25°C

10 0.2

Single pulse

VFM(V) 0.1 t P(s)

0 0.0

0.0 0.5 1.0 1.5 2.0 2.5 1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

DS4743 - Rev 4 page 4/15

STTH1R02

Characteristics (curves)

Figure 5. Relative variation of thermal impedance junction Figure 6. Relative variation of thermal impedance junction

to lead versus pulse duration (SMB) to lead versus pulse duration (DO-41)

Zth(j-a) /Rth(j-a) Zth(j-a) /Rth(j-a)

1.0 1.0

SM B DO-41

0.9 Scu=1cm² 0.9 Lleads=10mm

0.8 0.8

0.7 0.7

0.6 0.6

0.5 0.5

0.4 0.4

0.3 0.3

0.2 0.2

Single pulse

0.1 t P(s) 0.1 Single pulse t P(s)

0.0 0.0

1.E -02 1.E -01 1.E +00 1.E +01 1.E +02 1.E +03 1.E-03 1.E-02 1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

Figure 7. Relative variation of thermal impedance junction Figure 8. Junction capacitance versus reverse voltage

to lead versus pulse duration (DO-15) applied (typical values)

Zth(j-a) /Rth(j-a) C(pF)

1. 0

100

DO-15

F=1MHz

0. 9 Leads =10mm

Vosc=30mVRMS

Tj=25°C

0. 8

0. 7

0. 6

0. 5 10

0. 4

0. 3

0. 2

0. 1 Single pulse

t P(s) VR(V)

0. 0 1

1. E- 03 1. E- 02 1. E- 01 1. E+ 00 1. E+ 01 1. E+ 02 1. E+ 03 1 10 100 1000

Figure 9. Reverse recovery charges versus dIF/dt (typical Figure 10. Reverse recovery time versus dIF/dt (typical

values) values)

QRR(nC) t RR(ns)

80 80

IF=1.5A IF=1.5A

70 VR=160V VR=160V

70

60 60

50 50

Tj=125°C

40 40

Tj=125°C

30 30

20 20 Tj=25°C

Tj=25°C

10 10

dIF/dt(A/µs) dIF/dt(A/µs)

0 0

10 100 1000 10 100 1000

DS4743 - Rev 4 page 5/15

STTH1R02

Characteristics (curves)

Figure 11. Peak reverse recovery current versus dIF/dt Figure 12. Relative variations of dynamic parameters

(typical values) versus junction temperature

IRM(A) QRR; IRM [T j ] / Q RR; IRM [T j =125°C]

8 1.4

IF=1.5A IF=1.5A

VR=160V VR=160V

7 1.2

6

1.0

5 IRM

0.8

4

0.6

3 QRR

Tj=125°C

0.4

2

Tj=25°C 0.2

1

Tj (°C)

dIF/dt(A/µs)

0 0.0

10 100 1000 25 50 75 100 125 150

Figure 13. Thermal resistance junction to ambient versus Figure 14. Thermal resistance junction to ambient versus

copper surface under each lead (typical values) copper surface under each lead (typical values)

Rth(j-a)(°C/W) Rth(j-a)(°C/W)

200 200

SMA

SMB

150 150

100 100

Epoxy printed board FR4, eCu = 35 µm

Epoxy printed board FR4, eCu = 35 µm

50 50

SCu (cm²) SCu (cm²)

0 0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Figure 15. Thermal resistance junction to ambient versus Figure 16. Thermal resistance junction to ambient versus

lead length (DO-41) lead length (DO-15)

Rth(j-a) (°C/W)

Rth(j-a) (°C/W)

100 100

DO-41

90 DO-15

80 80

70

60 60

50

40 40

30

20 20

10 L leads (mm)

L leads (mm)

0 0

0 1 2 3 4 5 6 7 8 9 10 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

DS4743 - Rev 4 page 6/15

STTH1R02

Package information

2 Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK®

packages, depending on their level of environmental compliance. ECOPACK® specifications, grade definitions

and product status are available at: www.st.com. ECOPACK® is an ST trademark.

2.1 SMB package information

• Epoxy meets UL94, V0

• Lead-free package

Figure 17. SMB package outline

E1

A1

C A2

L b

DS4743 - Rev 4 page 7/15

STTH1R02

SMB package information

Table 5. SMB package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Max. Min. Max.

A1 1.90 2.45 0.074 0.097

A2 0.05 0.20 0.001 0.008

b 1.95 2.20 0.076 0.087

c 0.15 0.40 0.005 0.016

D 3.30 3.95 0.129 0.156

E 5.10 5.60 0.200 0.221

E1 4.05 4.60 0.159 0.182

L 0.75 1.50 0.029 0.060

Figure 18. SMB recommended footprint

1.62 2.60 1.62

(0.064) (0.102) (0.064)

2.18

(0.086)

5.84

(0.230)

DS4743 - Rev 4 page 8/15

STTH1R02

SMA package information

2.2 SMA package information

• Epoxy meets UL94, V0

• Cooling method : by conduction (C)

Figure 19. SMA package outline

E1

A1

C A2

L b

Table 6. SMA package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Max. Min. Max.

A1 1.90 2.45 0.074 0.097

A2 0.05 0.20 0.001 0.008

b 1.25 1.65 0.049 0.065

c 0.15 0.40 0.005 0.016

D 2.25 2.90 0.088 0.115

E 4.80 5.35 0.188 0.211

E1 3.95 4.60 0.155 0.182

L 0.75 1.50 0.029 0.060

DS4743 - Rev 4 page 9/15

STTH1R02

SMA package information

Figure 20. SMA recommended footprint in mm (inches)

1.4 2.63 1.4

(0.055) (0.104) (0.055)

1.64

(0.065)

5.43

(0.214)

DS4743 - Rev 4 page 10/15

STTH1R02

DO-41 package information

2.3 DO-41 package information

• Epoxy meets UL 94, V0

Figure 21. DO-41 package outline

C A C

ØD

ØB

Table 7. DO-41 package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Typ. Max. Min. Typ. Max.

A 4.07 - 5.20 0.160 - 0.205

B 2.04 - 2.71 0.080 - 0.107

C 25.40 - 1.000 -

D 0.71 - 0.86 0.028 - 0.0034

DS4743 - Rev 4 page 11/15

STTH1R02

DO-15 package information

2.4 DO-15 package information

• Epoxy meets UL 94, V0

Figure 22. DO-15 package outline

C A C

ØD

ØB

Table 8. DO-15 package mechanical data

Dimensions

Ref. Millimeters Inches (for reference only)

Min. Typ. Max. Min. Typ. Max.

A 6.05 - 6.75 0.238 - 0.266

B 2.95 - 3.53 0.116 - 0.139

C 26.00 - 31.00 1.024 - 1.220

D 0.71 - 0.88 0.028 - 0.0035

DS4743 - Rev 4 page 12/15

STTH1R02

Ordering information

3 Ordering information

Table 9. Ordering information

Order code Marking Package Weight Base qty. Delivery mode

STTH1R02A R1A SMA 0.068 g 5000 Tape and reel

STTH1R02U 1R2S SMB 0.107 g 2500 Tape and reel

STTH1R02 STTH1R02 DO-41 0.34 g 2000 Ammopack

STTH1R02RL STTH1R02 DO-41 0.34 g 5000 Tape and reel

STTH1R02Q STTH1R02Q DO-15 0.40 g 1000 Ammopack

STTH1R02QRL STTH1R02Q DO-15 0.40 g 6000 Tape and reel

DS4743 - Rev 4 page 13/15

STTH1R02

Revision history

Table 10. Document revision history

Date Revision Changes

03-May-2006 1 First issue.

13-Oct-2006 2 Added DO-15 and SMB packages.

08-Mar-2007 3 Replaced Figure 8. Replaced ecu with copper thickness.

05-Dec-2018 4 Updated Section Applications. Minor text changes.

DS4743 - Rev 4 page 14/15

STTH1R02

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2018 STMicroelectronics – All rights reserved

DS4743 - Rev 4 page 15/15

You might also like

- PC200-8 Sen00084-03 PDFDocument1,009 pagesPC200-8 Sen00084-03 PDFandra94% (35)

- 26jul2010094254 - Immobilizer Reg (Fortuner, Hilux&Innova)Document8 pages26jul2010094254 - Immobilizer Reg (Fortuner, Hilux&Innova)mikaelarikuntoNo ratings yet

- Automation Specn - 220kVDocument88 pagesAutomation Specn - 220kVkiran100% (1)

- Informações Gerais Loco SD 40Document8 pagesInformações Gerais Loco SD 40Justin Hernandez100% (1)

- EcotecDocument2 pagesEcotecSebastian Aravena AravenaNo ratings yet

- Platina 100ES KS - ComforTec - REV03 - SEPT 16 1Document70 pagesPlatina 100ES KS - ComforTec - REV03 - SEPT 16 1sanjika luckruwan100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- RMT (3-Cycle Open-Transition) Single-Operator Transfer Switch BrochureDocument8 pagesRMT (3-Cycle Open-Transition) Single-Operator Transfer Switch Brochurehenryvargas238565No ratings yet

- STM32 Tutorial 04 - I2C Module (Pca9685) Using HAL (And FreeRTOS)Document6 pagesSTM32 Tutorial 04 - I2C Module (Pca9685) Using HAL (And FreeRTOS)Quocdt Ngoc100% (1)

- STTH1R02 200V 1.5A U-FastDocument15 pagesSTTH1R02 200V 1.5A U-Fastrara221122raraNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- Stps 2 H 100Document19 pagesStps 2 H 100WAN MOZESNo ratings yet

- STTH 110Document11 pagesSTTH 110Mohamed IsmailNo ratings yet

- R1A Mark STTH1R02A 200V 1.5A UfastDocument10 pagesR1A Mark STTH1R02A 200V 1.5A Ufastrara221122raraNo ratings yet

- STTH212: DescriptionDocument11 pagesSTTH212: DescriptionPablo Gonzalez RivielloNo ratings yet

- STTH812Document11 pagesSTTH812rolando ojedaNo ratings yet

- Bat 41Document11 pagesBat 41Tanko SuleNo ratings yet

- Stps 10120 CDocument9 pagesStps 10120 CLEWIS RODRIGUEZNo ratings yet

- Media 3323329Document6 pagesMedia 3323329Daniel MesiNo ratings yet

- STPS1045D Eng TdsDocument8 pagesSTPS1045D Eng Tdsjohn9999_502754No ratings yet

- STPS3150 STMicroelectronicsDocument16 pagesSTPS3150 STMicroelectronicssegundo zapataNo ratings yet

- Stps 340Document19 pagesStps 340Mariusz KaźmierczakNo ratings yet

- STPS2L40: 40 V, 2 A Low Drop Power Schottky RectifierDocument17 pagesSTPS2L40: 40 V, 2 A Low Drop Power Schottky RectifierNirmal NepalNo ratings yet

- STTH3002CDocument8 pagesSTTH3002Celad kotlovskiNo ratings yet

- STPS30H100C: 100 V Power Schottky RectifierDocument12 pagesSTPS30H100C: 100 V Power Schottky RectifierPablo AllosiaNo ratings yet

- TBR3516 Three Phase Bridge Rectifiers: FeaturesDocument3 pagesTBR3516 Three Phase Bridge Rectifiers: FeaturesGabriel MassiminoNo ratings yet

- Bta 25Document10 pagesBta 25ingservicioddmNo ratings yet

- TS1117BDocument8 pagesTS1117BImonkNo ratings yet

- Stps 30100 STDocument9 pagesStps 30100 STDerkis MarcanoNo ratings yet

- 28N50F FairchildSemiconductorDocument8 pages28N50F FairchildSemiconductorgabosakrNo ratings yet

- STPS80H100CY Schottky RectifierDocument10 pagesSTPS80H100CY Schottky RectifierAnonymous oyUAtpKNo ratings yet

- Igbt 40N60 - 600V, 40aDocument10 pagesIgbt 40N60 - 600V, 40aLuis HuanqqueNo ratings yet

- STPS640C: Power Schottky RectifierDocument8 pagesSTPS640C: Power Schottky RectifierMax TeleNo ratings yet

- Stps 40170 CDocument15 pagesStps 40170 CotnielsaririNo ratings yet

- 20N60M2EP Mark STP20N60M2-EP 600V 13A FETDocument14 pages20N60M2EP Mark STP20N60M2-EP 600V 13A FETRuslanNo ratings yet

- Fga25n120 IgbtDocument9 pagesFga25n120 IgbtpserednickiNo ratings yet

- STTH5R06: Turbo 2 Ultrafast High Voltage RectifierDocument17 pagesSTTH5R06: Turbo 2 Ultrafast High Voltage RectifierGoran NovakovNo ratings yet

- Unisonic Technologies Co., LTD: Description 1Document5 pagesUnisonic Technologies Co., LTD: Description 1alexjcc10No ratings yet

- Features: Transil™Document9 pagesFeatures: Transil™m.furqan.q.tsNo ratings yet

- btw69 1200Document9 pagesbtw69 1200Kumar ShresthaNo ratings yet

- AP4501AGM DatasheetDocument8 pagesAP4501AGM DatasheetguvenelktNo ratings yet

- STTH12R06: Turbo 2 Ultrafast High Voltage RectifierDocument11 pagesSTTH12R06: Turbo 2 Ultrafast High Voltage RectifierNitish kumarNo ratings yet

- FDP 150 N 10Document8 pagesFDP 150 N 10Luka BaracNo ratings yet

- 249NQ135-150 (R) - 1 N1208, Dioda 890Document5 pages249NQ135-150 (R) - 1 N1208, Dioda 890diesmirnovNo ratings yet

- Datasheet PDFDocument10 pagesDatasheet PDFShikamaru MendozaNo ratings yet

- STTH 602 CDocument9 pagesSTTH 602 COmar MelchorNo ratings yet

- Stps 20 S 100 CDocument12 pagesStps 20 S 100 CEnrico RotaNo ratings yet

- DatasheetDocument10 pagesDatasheetKENDY CAMACHO VELOZNo ratings yet

- STPS3045CT/CG/CR/CP/CPI/CW/CFP: Power Schottky RectifierDocument9 pagesSTPS3045CT/CG/CR/CP/CPI/CW/CFP: Power Schottky Rectifierигорь федотовNo ratings yet

- STPS10L25: Low Drop Power Schottky RectifierDocument12 pagesSTPS10L25: Low Drop Power Schottky Rectifierjohn9999_502754No ratings yet

- STTH 100 W 06 CDocument8 pagesSTTH 100 W 06 CSandro SachserNo ratings yet

- Standard 1 A Triacs: FeaturesDocument16 pagesStandard 1 A Triacs: Featuresamir.yousefi7813No ratings yet

- Features: Transil™Document10 pagesFeatures: Transil™Tirwanda EdhoNo ratings yet

- STPS80170C: 170 V Power Schottky RectifierDocument9 pagesSTPS80170C: 170 V Power Schottky Rectifiern tanevarNo ratings yet

- DatasheetDocument8 pagesDatasheetRegisk8 OliveiraNo ratings yet

- stth60rq06 M2yDocument12 pagesstth60rq06 M2yRahul SinghNo ratings yet

- TN6050-12PI: 60 A, 1200 V Standard SCRDocument11 pagesTN6050-12PI: 60 A, 1200 V Standard SCRluis lopezNo ratings yet

- FFP08S60S 8 A, 600 V, Stealth II Diode: Features DescriptionDocument6 pagesFFP08S60S 8 A, 600 V, Stealth II Diode: Features DescriptionSenoara SusanNo ratings yet

- BT169D LDocument12 pagesBT169D Lأبو أنس المسلمNo ratings yet

- T1235T-8FP: 12 A Snubberless™ TriacDocument9 pagesT1235T-8FP: 12 A Snubberless™ TriacArguetaManuelNo ratings yet

- Fagor FT0109MN00RB DatasheetDocument6 pagesFagor FT0109MN00RB DatasheetJose BenavidesNo ratings yet

- Littelfuse Thyristor C106 D Datasheet - pdf-1372503Document6 pagesLittelfuse Thyristor C106 D Datasheet - pdf-1372503Juan PintoNo ratings yet

- NGTB25N120FL2WAG IGBT - Field Stop II / 4 Lead: 25 A, 1200 V V 2.0 V E 0.99 MJDocument12 pagesNGTB25N120FL2WAG IGBT - Field Stop II / 4 Lead: 25 A, 1200 V V 2.0 V E 0.99 MJJuan Carlos SrafanNo ratings yet

- Features: Small Signal Schottky DiodeDocument8 pagesFeatures: Small Signal Schottky DiodemariopilarNo ratings yet

- AB01B Data Sheet: V 800 V, I 0.5 A, T 200 Ns Fast Recovery DiodeDocument5 pagesAB01B Data Sheet: V 800 V, I 0.5 A, T 200 Ns Fast Recovery DiodeytnateNo ratings yet

- ACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilyDocument10 pagesACS110-7SN/SB2: Ac Line Switch Asd™ AC Switch FamilySamerNo ratings yet

- btw69 1200nDocument9 pagesbtw69 1200nYou LookNo ratings yet

- STPS3045CT/CG/CP/CPI/CW: Power Schottky RectifierDocument9 pagesSTPS3045CT/CG/CP/CPI/CW: Power Schottky RectifierLed EngNo ratings yet

- Package Information: March 2017Document5 pagesPackage Information: March 2017Alex Nicole SanchezNo ratings yet

- DSAEDA000101305Document15 pagesDSAEDA000101305Alex Nicole SanchezNo ratings yet

- Description Appearance: Voidless-Hermetically-Sealed 5 Watt Glass Zener DiodesDocument5 pagesDescription Appearance: Voidless-Hermetically-Sealed 5 Watt Glass Zener DiodesAlex Nicole SanchezNo ratings yet

- PLZ Series: Vishay SemiconductorsDocument10 pagesPLZ Series: Vishay SemiconductorsAlex Nicole SanchezNo ratings yet

- Blazer Vista 400 - 600 - 800Document12 pagesBlazer Vista 400 - 600 - 800Petrica Luka KerempuhNo ratings yet

- Ficha Metre Eater BQDocument1 pageFicha Metre Eater BQcfr242No ratings yet

- Various Addressing Modes of 8086 - 8088Document3 pagesVarious Addressing Modes of 8086 - 8088NeelmaniNo ratings yet

- E-Hsls HEBETEC Sync Lifting System PDFDocument8 pagesE-Hsls HEBETEC Sync Lifting System PDFBudhi Purnama UtomoNo ratings yet

- Winbond MonitorDocument45 pagesWinbond MonitorAlexNo ratings yet

- DP-440 430 340 330 Service ManualDocument311 pagesDP-440 430 340 330 Service Manuallaitang100% (2)

- OMRON NT620S NT620C Operation ManualDocument338 pagesOMRON NT620S NT620C Operation Manualordense0% (1)

- Screw ConveyorsDocument16 pagesScrew Conveyorsazeez bashaNo ratings yet

- General Notes:: Checklist For Inspection of Electric ElevatorsDocument2 pagesGeneral Notes:: Checklist For Inspection of Electric ElevatorsAli IbrahimNo ratings yet

- Esslinger CatalogDocument48 pagesEsslinger Catalogcircleline0% (4)

- 5253 XX Software ManDocument105 pages5253 XX Software Manjose miguel nuñezNo ratings yet

- PSD - 07 - 2015 - 30RBM - 30RBP - 160 - 520 - LRDocument26 pagesPSD - 07 - 2015 - 30RBM - 30RBP - 160 - 520 - LRAhmadNo ratings yet

- Tucson 2022 CatalogDocument8 pagesTucson 2022 CatalogHyundai CambodiaNo ratings yet

- I Flex Eca Surface Probe Specifications SheetDocument2 pagesI Flex Eca Surface Probe Specifications SheetMarioNo ratings yet

- Sharp LC-32A47E PDFDocument142 pagesSharp LC-32A47E PDFboroda2410100% (1)

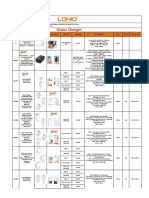

- Add:LDNIO offline experience store,Plaza on the 1st Floor of New Asia,No2.Xidi Road GZ ,China. 广州市荔湾区西堤二马路 53号新亚洲一楼广场 LDNIO体验店Document23 pagesAdd:LDNIO offline experience store,Plaza on the 1st Floor of New Asia,No2.Xidi Road GZ ,China. 广州市荔湾区西堤二马路 53号新亚洲一楼广场 LDNIO体验店Rania EllesNo ratings yet

- 13 Overhead PowerlineDocument1 page13 Overhead PowerlineFlancer SauNo ratings yet

- TCSRDocument16 pagesTCSRscottsawNo ratings yet

- Bảng mã lỗi module Fanuc - Cung cấp giải pháp tự động hóaDocument1 pageBảng mã lỗi module Fanuc - Cung cấp giải pháp tự động hóaQuang Nguyễn đứcNo ratings yet

- Electrical Safety Form Formula Bharat 2019: Car # Team Name Institution NameDocument30 pagesElectrical Safety Form Formula Bharat 2019: Car # Team Name Institution NameGamin' with skeleboneNo ratings yet

- Bateria Eaton - 12V120WDocument2 pagesBateria Eaton - 12V120WAndré Luiz Fraga de OliveiraNo ratings yet

- Ime72410s DS50Document66 pagesIme72410s DS50Georgios MariolisNo ratings yet