0% found this document useful (0 votes)

2K views13 pagesCam and Follower

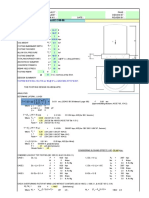

Cam and follower mechanisms are used to convert rotary motion to linear or oscillating motion. They consist of a cam, which is a rotating part that provides reciprocating or oscillating motion to the follower through direct contact. Cams are used in engines to operate valves and other components and can have various shapes depending on the desired motion profile. Common applications include internal combustion engines, machinery timing systems, and automotive fuel pumps.

Uploaded by

JOHN LENNARD DATUINCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views13 pagesCam and Follower

Cam and follower mechanisms are used to convert rotary motion to linear or oscillating motion. They consist of a cam, which is a rotating part that provides reciprocating or oscillating motion to the follower through direct contact. Cams are used in engines to operate valves and other components and can have various shapes depending on the desired motion profile. Common applications include internal combustion engines, machinery timing systems, and automotive fuel pumps.

Uploaded by

JOHN LENNARD DATUINCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd