Professional Documents

Culture Documents

TDS Encoder Belt Tension and Pulley Alignment Procedure

Uploaded by

Carel0 ratings0% found this document useful (0 votes)

40 views1 pageThe document provides a 6 step maintenance procedure for inspecting, aligning, and tensioning encoder belts on TDS 8 SA & TDS 1000A top drives. The procedure involves: 1) visually inspecting belts for wear every 3 months, 2) accessing and replacing belts if damaged, 3) aligning pulleys using an alignment tool, 4) securing pulley grub screws, 5) adjusting tension to 0.5lbs force to deflect the belt 0.10 inches, and 6) reinstalling the encoder cover plate and lockwiring.

Original Description:

TDS Encoder belt tension and pulley alignment procedure

Original Title

TDS Encoder belt tension and pulley alignment procedure

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a 6 step maintenance procedure for inspecting, aligning, and tensioning encoder belts on TDS 8 SA & TDS 1000A top drives. The procedure involves: 1) visually inspecting belts for wear every 3 months, 2) accessing and replacing belts if damaged, 3) aligning pulleys using an alignment tool, 4) securing pulley grub screws, 5) adjusting tension to 0.5lbs force to deflect the belt 0.10 inches, and 6) reinstalling the encoder cover plate and lockwiring.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views1 pageTDS Encoder Belt Tension and Pulley Alignment Procedure

Uploaded by

CarelThe document provides a 6 step maintenance procedure for inspecting, aligning, and tensioning encoder belts on TDS 8 SA & TDS 1000A top drives. The procedure involves: 1) visually inspecting belts for wear every 3 months, 2) accessing and replacing belts if damaged, 3) aligning pulleys using an alignment tool, 4) securing pulley grub screws, 5) adjusting tension to 0.5lbs force to deflect the belt 0.10 inches, and 6) reinstalling the encoder cover plate and lockwiring.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MAINTENANCE TDS 8 SA & TDS 1000A ENCODER BELT TENSION

PROCEDURE & PULLEY ALIGNMENT PROCEDURE 1

1. As per OEM guidance (16534623-PIB), Hohner belt driven

encoder belts are to be visually inspected, pulleys aligned, and 4. Using the alignment tool as illustrated below to align both

belts tensioned 3 monthly. encoder belt pulleys. Once this is complete ensure that the

grub screws are secured with Loctite 243 thread locker or

equivalent

2. Encoder belt is to be visual inspected for wear and/or damage.

To access the belt, remove the cover by removing the bolts and 5. Check the belt tension, which should measure 0.5lbs force to

rotating the cover sideways. As per the below image, this will deflect 0.10”. If required adjust the tension using the jacking

reveal the belt. Replace the belt if any damage or wear witnessed bolt until the tension criteria is met. The images below illustrate

(P/N 120117-1) the tension adjustment to achieve the correct tension

3. Following completion of the belt inspection, ensure that belt 6. Upon completion of belt inspection, tension and pulley

pulleys are aligned using the alignment tool supplied with the alignment, rotate the encoder cover plate into position, secure

TDS. The image below shows the location of the tool. If this is not with bolts and washers as per DS00008 then lockwire as per

available, it can be manufactured as per the drawing or ordered ASP00019 which can be located in the Topdrive user manual

from NOV (P/N 30152073 – 500)

You might also like

- Adjusting Valve Cummins QSBDocument4 pagesAdjusting Valve Cummins QSBMoch Imron100% (1)

- Volvo d12d TimingDocument9 pagesVolvo d12d Timingali100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Valve Adjustment E7Document16 pagesValve Adjustment E7malcolm stewartNo ratings yet

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando NunezNo ratings yet

- Toyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairDocument17 pagesToyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairWenceslao Francisco Mejía EspinozaNo ratings yet

- SM-TOYOTA 5FB10 30-5FB10 5FB14 30-5FB14 5FB15 30-5FB15 5FB18 30-5FB18 5FB20 30-5FB20 - AaaDocument47 pagesSM-TOYOTA 5FB10 30-5FB10 5FB14 30-5FB14 5FB15 30-5FB15 5FB18 30-5FB18 5FB20 30-5FB20 - AaaHushanji100% (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- Model M ManualsDocument6 pagesModel M ManualsdiegoNo ratings yet

- Bucket Elevator ManualDocument12 pagesBucket Elevator ManualKoevoet1No ratings yet

- Bolt TensionDocument2 pagesBolt TensionJayaram GowdaNo ratings yet

- TGN RT 03 Bolting Procedure For Steel Structures Rev 1Document3 pagesTGN RT 03 Bolting Procedure For Steel Structures Rev 1TimNo ratings yet

- Derex AC140 140 Ton Truck CraneDocument102 pagesDerex AC140 140 Ton Truck CraneHarsh Sharma100% (1)

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- Sensor Supply - Test: TroubleshootingDocument18 pagesSensor Supply - Test: TroubleshootingCarel100% (1)

- Tabla Tension Correas GatesDocument4 pagesTabla Tension Correas Gatesvibrador0% (1)

- 1-Stage Pressure Cut-Off (PCO) Adjustment ProcedureDocument4 pages1-Stage Pressure Cut-Off (PCO) Adjustment ProcedurethierrylindoNo ratings yet

- T ISS PX01 Instruction Manual Rev.01Document9 pagesT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Document12 pagesAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNo ratings yet

- Asm 4Document2 pagesAsm 4Ingenieria SIALASNo ratings yet

- Assembly and Tensioning of High Strength Bolts andDocument14 pagesAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNo ratings yet

- 16 August 2021 Vimec E10 EcoVimec Lifting PlatformDocument20 pages16 August 2021 Vimec E10 EcoVimec Lifting Platformmohammed.ranaNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- Asm 8Document2 pagesAsm 8Ingenieria SIALASNo ratings yet

- Indoor Vaccum Circuit Breaker - 11kV & 33kV: EVB-1225/ EVB-3625Document10 pagesIndoor Vaccum Circuit Breaker - 11kV & 33kV: EVB-1225/ EVB-3625Kannan SreekumarNo ratings yet

- Metastream TSC Coupling IOMDocument4 pagesMetastream TSC Coupling IOMthanhphamNo ratings yet

- Blower Belt Drive Tension: WarningDocument2 pagesBlower Belt Drive Tension: WarningAryo WicaksonoNo ratings yet

- Chip Conveyor Manual (Direct Drive)Document10 pagesChip Conveyor Manual (Direct Drive)Roberto RamírezNo ratings yet

- Chip Conveyor Manual (Direct Drive)Document10 pagesChip Conveyor Manual (Direct Drive)Roberto RamírezNo ratings yet

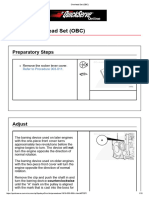

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- 7 +brakesDocument143 pages7 +brakesLuis Daniel RodriguezNo ratings yet

- MN16016 - 0322 (W)Document2 pagesMN16016 - 0322 (W)Julio Cesar Madero MartinezNo ratings yet

- TGN-RT-03 - Bolting Procedure For Steel Structures Rev 1Document3 pagesTGN-RT-03 - Bolting Procedure For Steel Structures Rev 1mostafamaroc0% (1)

- Sewage Treatment Plant AOP (OPERATION MANUAL DRESSING PLANT) 04-15-23Document30 pagesSewage Treatment Plant AOP (OPERATION MANUAL DRESSING PLANT) 04-15-23Bcdecs InfoNo ratings yet

- Para-Flex Couplings Dodge: Installation Instructions Manual ForDocument4 pagesPara-Flex Couplings Dodge: Installation Instructions Manual ForAdrian CantaragiuNo ratings yet

- Skidmore Instructions Model MS ManualsDocument15 pagesSkidmore Instructions Model MS ManualsbwbrockNo ratings yet

- Syncro Trak Service ManualDocument26 pagesSyncro Trak Service ManualMelina SbhNo ratings yet

- Valve Adjustment PDFDocument34 pagesValve Adjustment PDFlilo6romeroNo ratings yet

- How It Works - PDF RotaBoltDocument5 pagesHow It Works - PDF RotaBoltaop10468No ratings yet

- Instruction Manual-Smc 33KVDocument9 pagesInstruction Manual-Smc 33KVRAKESH CHANDRA PATRANo ratings yet

- Para-Flex Couplings: Includes ATEX Certified Couplings Instruction ManualDocument4 pagesPara-Flex Couplings: Includes ATEX Certified Couplings Instruction Manualrrobles011No ratings yet

- Standard Practices Tubing, Hoses and Fittings Maintenance PracticesDocument12 pagesStandard Practices Tubing, Hoses and Fittings Maintenance PracticesWalter TorenaNo ratings yet

- Null MOTORDocument215 pagesNull MOTORAditya JoglekarNo ratings yet

- DODGE® GRIP TIGHT Adapter Mount Ball BearingsDocument4 pagesDODGE® GRIP TIGHT Adapter Mount Ball BearingsDaNnIe09No ratings yet

- MM01001 enDocument32 pagesMM01001 enmahmoud yarahmadiNo ratings yet

- Dezurik Mastergear Manual Actuators: Instruction August 2012Document9 pagesDezurik Mastergear Manual Actuators: Instruction August 2012Charles MutetwaNo ratings yet

- 35-590096 - Section 7Document31 pages35-590096 - Section 7Fábio FariaNo ratings yet

- wp1142II XMLDocument1 pagewp1142II XMLaugustinhodjNo ratings yet

- Belt & Bucket Elevator: Installation, Maintenance & Spare Parts ManualDocument13 pagesBelt & Bucket Elevator: Installation, Maintenance & Spare Parts ManualratheeshNo ratings yet

- Operation Maintenance Service Manual: Heavy Duty Suspension SystemDocument18 pagesOperation Maintenance Service Manual: Heavy Duty Suspension SystemWilliam RoarkNo ratings yet

- 3gr-Fse-Em6-Drive BeltDocument3 pages3gr-Fse-Em6-Drive BeltHuỳnh Minh ĐứcNo ratings yet

- InstrukcijaDocument12 pagesInstrukcijaBaltija MechanikasNo ratings yet

- Hoist Drum Brake Maintenance: Inspection, Adjustment, Testing and ReplacementDocument6 pagesHoist Drum Brake Maintenance: Inspection, Adjustment, Testing and ReplacementDaniel TostaNo ratings yet

- Model MS ManualsDocument15 pagesModel MS ManualsbarrettshawnNo ratings yet

- BMC CalibrationADocument10 pagesBMC CalibrationAAngel DlsgNo ratings yet

- QuickServe Online - (4021499) K19 Service ManualDocument10 pagesQuickServe Online - (4021499) K19 Service Manualengmohsen.ramadanhotmail.com100% (1)

- Normativa Técnica Salvadoreña de AccesibilidadDocument2 pagesNormativa Técnica Salvadoreña de AccesibilidadmattkidoNo ratings yet

- Alignment Cylinder 30174224-ASMDocument1 pageAlignment Cylinder 30174224-ASMCarelNo ratings yet

- Spectrum Master 10580-00328LDocument92 pagesSpectrum Master 10580-00328LCarelNo ratings yet

- Engine Overspeed Alarm VeriDocument1 pageEngine Overspeed Alarm VeriCarelNo ratings yet

- Jura x8 User ManualDocument48 pagesJura x8 User ManualCarelNo ratings yet