Professional Documents

Culture Documents

Lecture 2 - Practice Answer

Uploaded by

Bhunesh KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 2 - Practice Answer

Uploaded by

Bhunesh KumarCopyright:

Available Formats

Answers

CHAPTER 3 - ACCOUNTING FOR OVERHEADS

3.1 OVERHEAD COST PER UNIT

CC1 CC2

Total hours Total hours

Product X 12,000 × 1.5 18,000 12,000 × 2.0 24,000

Product Y 10,000 × 1.2 12,000 10,000 × 2.6 26,000

30,000 50,000

Total overheads Rs.126,000 Rs.180,000

Absorption rate per Rs.4.20 Rs.3.60

hour

Fixed overhead cost/unit Product Product

X Y

Rs. Rs.

CC1 1.5 × Rs.4.20 6.30 1.2 × Rs.4.20 5.04

CC2 2.0 × Rs.3.60 7.20 2.6 × Rs.3.60 9.36

Total 13.50 14.40

3.2 APPORTIONMENT

Tutorial note: The answers to all three parts of the question are shown here, but

are not labelled.

Basis of Total A B C

apportionment

Rs. Rs. Rs. Rs.

Indirect Allocation 23,000 7,000 6,600 9,400

materials

Indirect Allocation 87,000 40,000 27,000 20,000

labour

Rent Floor area 60,000 15,000 20,000 25,000

Depreciation Equipment cost 80,000 16,000 48,000 16,000

Insurance Employee 20,000 8,000 6,400 5,600

numbers

Heating, Volume 18,000 8,000 6,000 4,000

lighting

Total 288,000 94,000 114,000 80,000

Direct labour hours 8,000 6,000 4,000

Absorption (per direct labour hour) Rs. Rs.19 Rs.20

rate 11.75

If a single factory-wide absorption rate is used instead of separate absorption rates

for each department, the absorption rate would be Rs.16 per direct labour hour

(= Rs.288,000/18,000 hours).

© Emile Woolf International 93 The Institute of Chartered Accountants of Pakistan

Cost and management accounting

3.3 SERVICE DEPARTMENTS

(a) Repeated distribution method

C = Canteen

BH = Boiler house

Dept 1 Dept 2 Dept 3 C BH

Rs. Rs. Rs. Rs. Rs.

Initial overheads 700,000 300,000 400,000 78,000 100,000

Apportion:

BH (30:30:20:20) 30,000 30,000 20,000 20,000 (100,000)

98,000

C (40:20:30:10) 39,200 19,600 29,400 (98,000) 9,800

BH (30:30:20:20) 2,940 2,940 1,960 1,960 (9,800)

C (40:20:30:10) 784 392 588 (1,960) 196

BH (30:30:20:20) 59 59 39 39 (196)

C (40:20:30:10) 15 8 12 (39) 4

BH (30:30:20:20) 1 1 1 1 (4)

C (40:20:30:10) 1 0 0 (1) 0

Total overhead 773,000 353,000 452,000

(b) Simultaneous equations method

Let X = the total overheads apportioned from the Canteen

Let Y = the total overheads apportioned from the Boiler House

This gives us the simultaneous equations:

X = 78,000 + 0.2 Y … (1)

Y = 100,000 + 0.1 X … (2)

Re-arrange:

78,000 = X – 0.2 Y … (1)

100,000 = – 0.1 X + Y … (2)

Multiply (2) by 10

1,000,000 = – X + 10Y … (3)

Add (1) and (3)

1,078,000 = 9.8Y

Y = 110,000

Therefore, from (1) and substituting Y = 110,000:

X = 78,000 + 0.2 (110,000) = 100,000.

Dept 1 Dept 2 Dept 3

Rs. Rs. Rs.

Initial overheads 700,000 300,000 400,000

Apportion:

BH (30%, 30% and 20% of 110,000) 33,000 33,000 22,000

C (40%, 20% and 30% of 100,000) 40,000 20,000 30,000

Total overhead apportionment 773,000 353,000 452,000

© Emile Woolf International 94 The Institute of Chartered Accountants of Pakistan

Answers

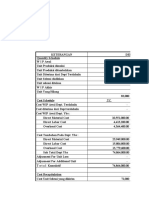

3.4 ZIA TEXTILE MILLS

(a) The under or over applied overhead may be:

treated as period cost by closing it to Cost of Goods Sold Account or

directly to Income Statement.

apportioned between inventories and cost of goods sold.

Reasons for Under/ Over applied Factory Overhead

(i) The actual hours worked may be more or less than the estimated

hours.

(ii) The estimates may not be accurate.

(iii) Actual overhead costs and actual activity levels are different from

budgeted costs and activity levels.

(iv) Changes in the methods of production.

(v) Abnormal changes in the component prices of factory overheads.

(vi) Extraordinary expenses might have been incurred during the

accounting period.

(vii) Major changes might have taken place. For example, replacement of

general purpose machine with automatic high speed machines.

(b) Calculation of Annual Charges of New Machine

Rupees

Total budgeted costs of existing five

machines (Rs. 390 x (12,500 - 900)) 4,524,000

Add: Costs of new machines

(i) Depreciation (1,300,000 – 100,000)/10 x 11/12 110,000

(ii) Electricity (2,600 x 10 x Rs. 8.5) 221,000

(iii) Cost of maintenance (Rs. 25,000 x 11) 275,000

(iv) Part replacement (Rs. 10,000 x 11) 110,000

(v) Operator Wages (Rs. 9,000 x 11) 99,000

(vi) Departmental expenses (Rs. 5,000 x 11) 55,000

5,394,000

Productive Budgeted hours (12,500 + 2,600 - 900 - 120 - 80) 14,000

Adjusted machine hours rate 385.29

Say 385.00

© Emile Woolf International 95 The Institute of Chartered Accountants of Pakistan

Cost and management accounting

3.5 TERNARY ENGINEERING LIMITED

(a) Rs. (000)

Production departments

Variable overhead 370

Fixed overhead 660

Service department

Inspection 210

Maintenance 300

1,540

Estimated direct labour hours (DLH)

Fabrication 24,000

Phosphate 9,600

Painting 12,000

Total estimated direct labour hours 45,600

Estimated Total Overheads

Single overhead absorption rate =

Estimated Direct Labour Hours

Rs.1,540,000 = Rs. 33.77 per

=

45,600 hours direct labour hour

(b) Production Service

Fabrication

Maintenance

Phosphate

Inspection

Painting

Rupees in thousand

Variable Overhead 200 70 100 60 90

Fixed Overhead 480 65 115 150 210

Allocation of Maintenance

Department Costs on the basis of

labour hours

630 ÷ 1,050 x 300 180 (180)

273 ÷ 1,050 x 300 78 (78)

147 ÷ 1,050 x 300 42 (42)

Allocation of Inspection Department

Costs on the basis of Inspection

hours

1,000 ÷ 3,000 x 210 70 (70)

500 ÷ 3,000 x 210 35 (35)

1,500 ÷ 3,000 x 210 105 (105)

930 248 362 - -

Base Machine hours Direct labour hours

number of hours 9,000 9,600 12,000

Departmental Overhead Rate (Rs.) 103.33 25.83 30.17

© Emile Woolf International 96 The Institute of Chartered Accountants of Pakistan

Answers

3.6 PRODUCTION AND SERVICE

(a) Service department expenses allocation by repeated distribution

method:

Production Service

Department Department

A B X Y

Total expenses as given 500 400 100 60

Allocation of X department cost 50 30 (100) 20

Allocation of Y department cost 32 40 8 (80)

Allocation of X department cost 4 2 (8) 2

Allocation of Y department cost 1 1 - (2)

587 473 - -

(b) Service department expenses allocation by simultaneous equation

method:

Let total expenses of department X inclusive of expenses allocated from

department Y = x

Let total expenses of department Y inclusive of expenses allocated from

department X = y

Then according to question x = 100 + 0.1 y ------------ eq (1)

y = 60 + 0.2 x -------------- eq (2)

Putting the value of y from eq(1) in eq(2)

x = 100 + 0.1 (60 + 0.2x)

= 100 + 6 + 0.02 x

x – 0.02 x = 106

x = 108

y = 60 + 0.2x

= 60 + 22 = 82

ALLOCATIONS

Production

Description Department

A B

Product department costs 500 400

Distribution of X department cost

(108 50%) & (108 30% ) 54 32

Distribution of Y department cost

(82 40%) & (82 50% ) 33 41

587 473

© Emile Woolf International 97 The Institute of Chartered Accountants of Pakistan

Cost and management accounting

3.7 RT LIMITED

RT LIMITED

Allocation of overheads

(a) Allocation of Service dept. cost to production dept. - Repeated

distribution method:

Production Dept. Service Dept.

P1 P2 P3 S1 S2

Rupees in thousand

S1 overheads allocation % 20% 30% 40% 10%

S2 overheads allocation % 30% 40% 20% 10%

Actual overheads as given 1,250 2,000 1,800 500 750

Allocation of S2 cost

30:40:20:10 225 300 150 75 (750)

Allocation of S1 cost

20:30:40:10 115 172 230 (575) 58

Allocation of S2 cost

30:40:20:10 17 23 11 6 (58)

Allocation of S1 cost

20:30:40:10 1 2 3 (6)

Allocation from service dept. 358 497 394

TOTAL 1,608 2,497 2,194

(b) Over / under applied overheads:

P1 P2 P3

Actual overheads after allocation from service dept. 1,608 2,497 2,194

Application of overheads to production:

P1 Machine hours basis{(1,200/60,000)*60,500} 1,210

P2 Labour hours basis {(2,000/200,000*190,000} 1,900

P3 75% of material cost (3,200*75%) 2,400

Overheads applied 1,210 1,900 2,400

Overheads under / (over) applied 398 597 (206)

© Emile Woolf International 98 The Institute of Chartered Accountants of Pakistan

Answers

3.8 AHSAN ENTERPRISES

(a) Factory overheads cost per unit based on direct labour hours used:

Alpha Beta Gamma Total

Production (no. of units) A 12,000 20,000 45,000 77,000

Direct labour hours per unit 20 5 4

Total direct labour hours B 240,000 100,000 180,000 520,000

Allocation of overheads

(9,488,000/520,000 ×B) Rs. C 4,379,077 1,824,615 3,284,308 9,488,000

(C /

Cost per unit Rs. A) 364.92 91.23 72.98

(b) Factory overheads cost per unit based on utilisation of facilities:

Allocation basis Alpha Beta Gamma Total

Production (no. of

units) A 12,000 20,000 45,000 77,000

Machine hours per

unit 6 8 10

Total machine hours *1 72,000 160,000 450,000 682,000

Units inspected 600 400 1,350 2,350

Per unit inspection

hours 2 3 4

Total no. of hrs for

units inspected *2 1,200 1,200 5,400 7,800

Overhead allocation:

Indirect wages:

Machine

maintenance Machine hours 63,343 140,763 395,894 600,000

Stores Store

consumption 144,000 54,000 162,000 360,000

Quality control Inspected hours 72,000 72,000 324,000 468,000

Cleaning and related Factory space

services utilisation 160,000 140,000 100,000 400,000

Fuel and power Machine hours 295,601 656,892 1,847,507 2,800,000

Depreciation on

plant and machinery Machinery cost 600,000 400,000 300,000 1,300,000

Depreciation on

building

(1,560,000- Factory space

1,300,000) utilisation 104,000 91,000 65,000 260,000

Insurance on plant

and machinery Cost of Machinery 110,769 73,846 55,385 240,000

Insurance on Factory space

building utilisation 24,000 21,000 15,000 60,000

Stores, spares and

supplies consumed Actual 720,000 270,000 810,000 1,800,000

Rent, rates and Factory space

taxes utilisation 480,000 420,000 300,000 1,200,000

Total overheads B Rs. 2,773,714 2,339,500 4,374,786 9,488,000

Cost per unit (B/A) Rs. 231.14 116.98 97.22

© Emile Woolf International 99 The Institute of Chartered Accountants of Pakistan

Cost and management accounting

3.9 AMBER LIMITED

(a) Budgeted overhead rate for department-A Rs. in million

Budgeted Overhead rate per machine hour

(OHD/MH Rs.5m/400,000) Rs. 12.5

Budgeted overhead rate for department-B

Budgeted labour cost (Rs. 120 × 500,000) 60

Budgeted overhead (Rs. 60 m × 15%) 9

Budgeted overhead rate per labour hour (Rs. 9 m/0.5 m) 18

Budgeted overhead rate for department-C

Budgeted overhead as a % of Prime Cost (Rs.7.5 m /150 m) 5%

(b) Computation of actual cost of producing one unit of product:

Departments

Rupees in million

A B C

Material cost 80.00 150.00 120.00

Labour cost

(0.22 m × Rs. 120) 26.40

(0.53 m × Rs. 120) 63.60

(0.24 m × Rs. 120) 28.80

Actual overhead cost 5.35 8.90 7.45

Total Cost 111.75 222.50 156.25

Unit cost (Cost/3.57 m. units) (Rs.) 31.30 62.32 43.77

Total Actual Cost per unit (Rs.) 137.39

(c) Applied Overhead Cost

(0.34 m × 12.5) 4.25

(0.53 m × Rs. 18) 9.54

(Rs. 148.8 m × 5%) 7.44

Actual Overhead Cost 5.35 8.90 7.45

Under applied / (over applied) 1.10 (0.64) 0.01

© Emile Woolf International 100 The Institute of Chartered Accountants of Pakistan

Answers

3.10 SPARROW (PVT) LIMITED

Allocation of

Machine Machine

costs to cost Basis Inspection Packing Total

M1 M2

centres

Area 5,500 4,800 12,000 15,000

Occupied 37,300

Allocation of Area 330,000 288,000 720,000 900,000 2,238,000

Electricity

Allocation of Area 220,000 192,000 480,000 600,000 1,492,000

rent

Operational 5,500,000 3,200,000 - - 8,700,000

cost

6,050,000 3,680,000 1,200,000 1,500,000 12,430,000

ALLOCATION OF COST TO PRODUCTS

Basis of Cost Allocation A B TOTAL

Units produced 5,600 7,500

Inspection time (hrs.) 1,400 1,500 2,900

(5,600 x 15 min /60) &

(7,500 x 12 min /60)

Packing time (hrs.) 1,120 1,250 2,370

(5,600 x 12 min /60) &

(7,500 x 10 min /60)

Units produced on Machine M1 2,800 4,875 7,675

(50% A and 65% B)

Units produced on Machine M2 2,800 2,625 5,425

(50% A and 35% B)

Cost Allocated

Machine M1 cost 2,207,166 3,842,834 6,050,000

Machine M2 cost 1,899,355 1,780,645 3,680,000

Inspection department cost 579,310 620,690 1,200,000

Packing department cost 708,861 791,139 1,500,000

5,394,692 7,035,308 12,430,000

© Emile Woolf International 101 The Institute of Chartered Accountants of Pakistan

You might also like

- Fin420.540 Jan 2018 Q2-5Document8 pagesFin420.540 Jan 2018 Q2-5Amar AzuanNo ratings yet

- Absorbing Overhead CostsDocument9 pagesAbsorbing Overhead CostssikshaNo ratings yet

- Assignment - Service Cost AllocationDocument4 pagesAssignment - Service Cost AllocationRoselyn LumbaoNo ratings yet

- Kuis Akun No 1Document10 pagesKuis Akun No 1Daveli NatanaelNo ratings yet

- Redesigning Cost Systems: Is Standard Costing Obsolete?Document10 pagesRedesigning Cost Systems: Is Standard Costing Obsolete?SillyBee1205No ratings yet

- Snake Farm Income AnalysisDocument3 pagesSnake Farm Income Analysisboerd77No ratings yet

- RadheDocument11 pagesRadheApoorv GUPTANo ratings yet

- ABC COSTING TITLEDocument6 pagesABC COSTING TITLEDominic E. BoticarioNo ratings yet

- SINGH007 Ans Homework Lec 14 To 21Document47 pagesSINGH007 Ans Homework Lec 14 To 21Lau Chun GuiNo ratings yet

- Alba, Camille Joy M. MGT211: Total Cost 240,000.00Document4 pagesAlba, Camille Joy M. MGT211: Total Cost 240,000.00Camille Joy AlbaNo ratings yet

- Unit and Batch Homework SolutionsDocument2 pagesUnit and Batch Homework Solutionsnikhilcoke7No ratings yet

- Book 1Document12 pagesBook 1Vincent Luigil AlceraNo ratings yet

- Budgetory Control Flexible Budget With SolutionsDocument6 pagesBudgetory Control Flexible Budget With SolutionsJash SanghviNo ratings yet

- UntitledDocument13 pagesUntitledAbhinav SharmaNo ratings yet

- Afar SolutionDocument8 pagesAfar SolutionAsnifah AlinorNo ratings yet

- Joint Products & by Products: Solutions To Assignment ProblemsDocument5 pagesJoint Products & by Products: Solutions To Assignment ProblemsXNo ratings yet

- Cañas Alexia V Pa1Document4 pagesCañas Alexia V Pa1Joshua BangiNo ratings yet

- Exercise 1 and 2Document7 pagesExercise 1 and 2Nigussie BerhanuNo ratings yet

- Ast Chapter 1 MCPDocument14 pagesAst Chapter 1 MCPElleNo ratings yet

- Group2 PPEDocument2 pagesGroup2 PPELeane MarcoletaNo ratings yet

- Umipig AbbyMarileth Interim2Document3 pagesUmipig AbbyMarileth Interim2abbyyyyy.mariNo ratings yet

- Incremental Analysis InsightsDocument11 pagesIncremental Analysis InsightsannarheaNo ratings yet

- 24GK0065Document12 pages24GK0065bernardorasimo26No ratings yet

- CPA review exam solutions for management advisory servicesDocument6 pagesCPA review exam solutions for management advisory servicesMark Anthony Casupang100% (1)

- CA-Inter-Costing-A-MTP-2-May 2023Document13 pagesCA-Inter-Costing-A-MTP-2-May 2023karnimasoni12No ratings yet

- Chapter 4 ExercisesDocument23 pagesChapter 4 ExercisesLiza Mae MirandaNo ratings yet

- W14 - As8 Maranan, A2aDocument3 pagesW14 - As8 Maranan, A2aJere Mae MarananNo ratings yet

- Complete Investment Appraisal - 2Document7 pagesComplete Investment Appraisal - 2Reagan SsebbaaleNo ratings yet

- MTP 3 16 Answers 1681098469Document13 pagesMTP 3 16 Answers 1681098469Umar MalikNo ratings yet

- Ch05 Traditional Overheads Versus Activity-Based CostingDocument15 pagesCh05 Traditional Overheads Versus Activity-Based CostingAndrew ChongNo ratings yet

- cost-management-accounting-test-2-ch-4-5-6-may-2024-Solution-1702883162Document15 pagescost-management-accounting-test-2-ch-4-5-6-may-2024-Solution-1702883162jin031543No ratings yet

- BA 117 SolutionsDocument19 pagesBA 117 SolutionsAlaine Milka GosycoNo ratings yet

- Project Formworks and Steel Structure Cost EstimationDocument34 pagesProject Formworks and Steel Structure Cost EstimationCiscy TorcinoNo ratings yet

- Question 4Document8 pagesQuestion 4Jeremiah NcubeNo ratings yet

- Activity Cost BehaviorDocument28 pagesActivity Cost Behaviorangel caoNo ratings yet

- Chapter - 1 Cost Sheet - Problems - & - Solution - 3-9Document12 pagesChapter - 1 Cost Sheet - Problems - & - Solution - 3-9Legends CreationNo ratings yet

- Problem 6 - Partnership OperationDocument5 pagesProblem 6 - Partnership OperationShaira UntalanNo ratings yet

- UCD MOLAVE Expansion 3-LguDocument6 pagesUCD MOLAVE Expansion 3-LgutontonNo ratings yet

- FManAcc Teaching Week 11 Seminar Answers Part 1 2023 - 2024 - TaggedDocument5 pagesFManAcc Teaching Week 11 Seminar Answers Part 1 2023 - 2024 - Taggedredwaanmo19No ratings yet

- Siddhi Test Series: Q.1) SolutionDocument3 pagesSiddhi Test Series: Q.1) SolutionAkki GalaNo ratings yet

- Costing English Answer 14.07.2020Document12 pagesCosting English Answer 14.07.2020Prathmesh JambhulkarNo ratings yet

- Property, Plant and Equipment DepreciationDocument13 pagesProperty, Plant and Equipment DepreciationJannelle SalacNo ratings yet

- MAS First Preboard SolutionsDocument3 pagesMAS First Preboard SolutionslorenzNo ratings yet

- Joint Cost Allocation MethodsDocument29 pagesJoint Cost Allocation MethodsInanda MeitasariNo ratings yet

- Umipig AbbyMarileth CE1Document4 pagesUmipig AbbyMarileth CE1abbyyyyy.mariNo ratings yet

- Bajaj Finserv Investor Presentation - Q2 FY2018-19Document19 pagesBajaj Finserv Investor Presentation - Q2 FY2018-19AmarNo ratings yet

- Akt Biaya 2Document14 pagesAkt Biaya 2Yesica Ratna PutriNo ratings yet

- Dalaon Water System 1mDocument6 pagesDalaon Water System 1mtontonNo ratings yet

- 12914sugg_pe2_gp2_1Document33 pages12914sugg_pe2_gp2_1harshrathore17579No ratings yet

- 2) Solution To Problem No 2 On Flexible BudgetDocument7 pages2) Solution To Problem No 2 On Flexible BudgetVikas guptaNo ratings yet

- Drury ADocument77 pagesDrury ATauraab50% (2)

- Solution To The Problem Set On "Treatment of Overheads"Document6 pagesSolution To The Problem Set On "Treatment of Overheads"Saloni MalhotraNo ratings yet

- CH 10 SolDocument7 pagesCH 10 SolNotty SingerNo ratings yet

- (Jennifer / 1901469555 / LA53) : GSLC Assignment Profit PlanningDocument5 pages(Jennifer / 1901469555 / LA53) : GSLC Assignment Profit PlanningJennifer GunawanNo ratings yet

- Cost accounting solutionsDocument6 pagesCost accounting solutionsShehrozSTNo ratings yet

- SS Process Ac Jun19 Dec16jun16Document8 pagesSS Process Ac Jun19 Dec16jun16anis izzatiNo ratings yet

- Audit Probs 4 (Final Exam)Document6 pagesAudit Probs 4 (Final Exam)YameteKudasaiNo ratings yet

- Cost Accounting: C S F EOQDocument6 pagesCost Accounting: C S F EOQShehrozSTNo ratings yet

- Manabat - Problem 5 & Problem 8Document5 pagesManabat - Problem 5 & Problem 8Reugi ManabatNo ratings yet

- Problem 1: Change Variable Factory Overhead Change Machine Hours $ 1,875,000 $ 1,250,000) $ 625,000Document6 pagesProblem 1: Change Variable Factory Overhead Change Machine Hours $ 1,875,000 $ 1,250,000) $ 625,000AJ OrtegaNo ratings yet

- Visual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsFrom EverandVisual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsNo ratings yet

- Business Analysis Chapter 1Document70 pagesBusiness Analysis Chapter 1Bob MarshellNo ratings yet

- ++++ Fin Analysis Chapter4Document59 pages++++ Fin Analysis Chapter4Bhunesh KumarNo ratings yet

- Cash Budget AdvanceDocument6 pagesCash Budget AdvanceBhunesh KumarNo ratings yet

- Ratio Questions For Fall 2018 Only Do The Red OnesDocument3 pagesRatio Questions For Fall 2018 Only Do The Red OnesBhunesh KumarNo ratings yet

- End of Chapter Exercises: SolutionsDocument4 pagesEnd of Chapter Exercises: SolutionsMichelle LeeNo ratings yet

- Presentation 4 - Cost & Management Accounting - March 10, 209 - 3pm To 6pmDocument45 pagesPresentation 4 - Cost & Management Accounting - March 10, 209 - 3pm To 6pmBhunesh KumarNo ratings yet

- Lecture 4 - Practice AnswerDocument10 pagesLecture 4 - Practice AnswerBhunesh KumarNo ratings yet

- Lecture 6 - Practice Question 2 - March 24, 2019 - 3pm To 6pmDocument1 pageLecture 6 - Practice Question 2 - March 24, 2019 - 3pm To 6pmBhunesh KumarNo ratings yet

- Case Ratios and Cash BudgetDocument2 pagesCase Ratios and Cash BudgetBhunesh KumarNo ratings yet

- Course Outline - Cost & Management AccountingDocument2 pagesCourse Outline - Cost & Management AccountingBhunesh KumarNo ratings yet

- Lecture 4 - Practice QuestionDocument8 pagesLecture 4 - Practice QuestionBhunesh KumarNo ratings yet

- Lecture 6 - Practice Question - March 24, 2019 - 3pm To 6pmDocument2 pagesLecture 6 - Practice Question - March 24, 2019 - 3pm To 6pmBhunesh KumarNo ratings yet

- ObjectGrouping Lecture4Document24 pagesObjectGrouping Lecture4Bhunesh KumarNo ratings yet

- Lecture 3 - Practice QuestionDocument6 pagesLecture 3 - Practice QuestionBhunesh KumarNo ratings yet

- Handout 1 - Cost & Management Accounting - Feb 17, 2019 - 3pm To 6pmDocument3 pagesHandout 1 - Cost & Management Accounting - Feb 17, 2019 - 3pm To 6pmBhunesh KumarNo ratings yet

- Part One: Introduction To Management and Cost Accounting Chapter One: Introduction To Management AccountingDocument19 pagesPart One: Introduction To Management and Cost Accounting Chapter One: Introduction To Management AccountingRajesh DantinaNo ratings yet

- Lecture 2 - Practice QuestionDocument8 pagesLecture 2 - Practice QuestionBhunesh KumarNo ratings yet

- Module 2-2 Basic ASA Firewall ConfigurationsDocument37 pagesModule 2-2 Basic ASA Firewall Configurationsvitalsign75No ratings yet

- Cost AccountingDocument61 pagesCost AccountingyoihkbsNo ratings yet

- Modular Policy Framework-7Document14 pagesModular Policy Framework-7Bhunesh KumarNo ratings yet

- Lecture 01Document27 pagesLecture 01Ali Raza RahmaniNo ratings yet

- قومي ۽ انقلابي جدوجهد ۾ ادب ۽ فن جو ڪردارDocument45 pagesقومي ۽ انقلابي جدوجهد ۾ ادب ۽ فن جو ڪردارBhunesh KumarNo ratings yet

- Basic Threat Detection-8Document7 pagesBasic Threat Detection-8Bhunesh KumarNo ratings yet

- Exploration Accessing WAN Chapter2Document23 pagesExploration Accessing WAN Chapter2Bhunesh KumarNo ratings yet

- Saylordotorg Github Io Text Managerial Accounting s07 03 Using Activity Based CoDocument18 pagesSaylordotorg Github Io Text Managerial Accounting s07 03 Using Activity Based CoRezer JohnNo ratings yet

- How To Write The Best Business Plan - 2021 Complete GuideDocument5 pagesHow To Write The Best Business Plan - 2021 Complete GuideRandy Bayu TrisnandiNo ratings yet

- BAB 2024 CH09 - Budgetary PlanningDocument79 pagesBAB 2024 CH09 - Budgetary Planningmini3110100% (1)

- Yasir ProjectDocument58 pagesYasir Projectaminullah muslimNo ratings yet

- QuizDocument13 pagesQuizErlyNo ratings yet

- EcstasticDocument82 pagesEcstasticCristian D. BaldozNo ratings yet

- Finance AssignmentDocument7 pagesFinance AssignmentMeshack MateNo ratings yet

- Consignment Sales - Advacc 1 Lupisan-BaysaDocument15 pagesConsignment Sales - Advacc 1 Lupisan-BaysaAlvin Francis Padecio100% (1)

- Inventory Valuation and Cost Flow MethodsDocument34 pagesInventory Valuation and Cost Flow MethodsChris Tian FlorendoNo ratings yet

- Folk Exam Janitorial Costs Shipping ExpensesDocument3 pagesFolk Exam Janitorial Costs Shipping ExpensesabeeralkhawaldehNo ratings yet

- Stock Level of MaterialsDocument18 pagesStock Level of MaterialsSabin ParajuliNo ratings yet

- CH9 - Inventory Costing and Capacity AnalysisDocument51 pagesCH9 - Inventory Costing and Capacity AnalysisKatsuhira KizunaNo ratings yet

- Small Business Cash Flow Projection1Document5 pagesSmall Business Cash Flow Projection1ziggyNo ratings yet

- Ca 5107 - Cost Accounting & Control Quizzer - Standard CostingDocument13 pagesCa 5107 - Cost Accounting & Control Quizzer - Standard CostingAlexandra CruzNo ratings yet

- 11 Statement of Cash FlowDocument15 pages11 Statement of Cash FlowLlyod Francis LaylayNo ratings yet

- Standard Costing and Variance AnalysisDocument39 pagesStandard Costing and Variance Analysiskindergarten tutorialNo ratings yet

- General Journal: Date Account Titles and Explanation PR Debit CreditDocument14 pagesGeneral Journal: Date Account Titles and Explanation PR Debit CreditFred WilsonNo ratings yet

- Managerial AccountingDocument21 pagesManagerial AccountingRam KnowlesNo ratings yet

- PDF Rq1 With AnswersDocument9 pagesPDF Rq1 With AnswersCaleb GetubigNo ratings yet

- Income Statement Template For WebsiteDocument5 pagesIncome Statement Template For WebsiteKelly CantuNo ratings yet

- Budgetary As A Planning ToolDocument60 pagesBudgetary As A Planning ToolVaisal AmirNo ratings yet

- Chapter 18—Tactical Decision Making Using Relevant CostsDocument41 pagesChapter 18—Tactical Decision Making Using Relevant CostsKemerutNo ratings yet

- Cfas Inventories QuizletDocument2 pagesCfas Inventories Quizletagm25No ratings yet

- Chlorobenzene Cost 2520Estimation&EconomicsDocument5 pagesChlorobenzene Cost 2520Estimation&EconomicsMaribel ArcaniNo ratings yet

- 0450 Paper 1 - 2016-2021Document396 pages0450 Paper 1 - 2016-2021Ifra HassanNo ratings yet

- CIMA Old P1 May 2005 QP and ANSDocument35 pagesCIMA Old P1 May 2005 QP and ANSHarktheDark0% (1)

- Saint Mary's University: Chapter FiveDocument63 pagesSaint Mary's University: Chapter FivehenockNo ratings yet

- Week 11 Cost Concept RevDocument48 pagesWeek 11 Cost Concept RevMefilzahalwa AlyayouwanNo ratings yet