Professional Documents

Culture Documents

EDRO MoldMax-XL ENG

Uploaded by

KalpeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EDRO MoldMax-XL ENG

Uploaded by

KalpeshCopyright:

Available Formats

MoldMax XL®

MoldMax XL is a high strength copper mold alloy with good thermal conductivity, which is free of beryllium. The alloy’s hardness

is comparable with AISI P-20 tool steel, but its thermal conductivity is two to three times higher. MoldMax XL is used as injection

mold cores and cavities. The alloy provides excellent toughness, wear resista nce and surface finish. MoldMax XL Alloy typically

machines faster than tool steels, and with appropriate machine tools, metal removal rates several times higher can be obtained.

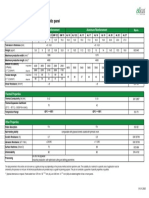

CHEMICAL COMPOSITION (weight-- %)

Alloy Nickel Tin Copper

MoldMax XL 8,5 – 9,5 5,5 – 6,5 Balance

PHYSICAL PROPERTIES

Melting Heat

E- Thermal Thermal Capacity

Point Density Expansion Conductivity

Modulus (Solidus ) (100 °C)

117 GPa 925 °C 8,91 g/cm3 16,2 x 10 -6 /°C 70 W/mK 0,39 J/gK

TYPICAL MECHANICAL PROPERTIES*

0.2% Offset Ultimate

Fatigue Strength Impact

Yield Strength Tensile Elongation Härte

107 Cycles (R = -1)

(nominal) Strength Strength

725 MPa 795 MPa 240 MPa 6% 13 J 30 HRC

* Properties may vary by shape and thickness

AVAILABLE DIMENSIONS

MoldMax XL is available in plate condition with different thicknesses ex stock in Appenweier (GER).

RELATED INFORMATION

Further technical information on our MoldMax® Products can be found on our webpage www.edro.com or by calling +49 7805

915790. For pricing and availability information, please feel free to contact us.

EDRO Specialty Steels GmbH

Industriestraße 5c

DE-77767 Appenweier

+49 7805 915790

info@edro-gmbh.de

You might also like

- VSL Tech Data PDFDocument29 pagesVSL Tech Data PDFhythamNo ratings yet

- Rgf33 Natural New - Nominal PropDocument1 pageRgf33 Natural New - Nominal PropRanjan GnanaoliNo ratings yet

- PV3347Document12 pagesPV3347Orbán NorbertNo ratings yet

- SLA Accura BluestoneDocument2 pagesSLA Accura BluestoneclevercogNo ratings yet

- SRF Limited: Typical Properties of Tufnyl Rms 1 Steel GreyDocument1 pageSRF Limited: Typical Properties of Tufnyl Rms 1 Steel Greyரஞ்சன் ஞானயோளிNo ratings yet

- GAMMA-GERMAN PLT-PE-4mmDocument2 pagesGAMMA-GERMAN PLT-PE-4mmEgyp XsNo ratings yet

- Product Brochure of Speciality-ProductsDocument13 pagesProduct Brochure of Speciality-ProductsMADDI MADHAV.No ratings yet

- Rain Sheds Rightangle Boots Straight BootsDocument2 pagesRain Sheds Rightangle Boots Straight BootsEhab Abd-allaNo ratings yet

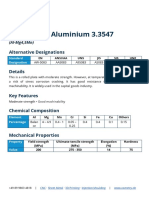

- Data Sheet: Aluminium 3.3547: Alternative DesignationsDocument2 pagesData Sheet: Aluminium 3.3547: Alternative DesignationsMemkNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Domex 700 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 700 MC Hot Rolled, Extra High Strength, Cold Forming Steelflorin_iacob2001No ratings yet

- SH8900-H (White) EngDocument4 pagesSH8900-H (White) EngKollinNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Inflon Ptfe Gasket Sheet: Inmarco Type 600Document1 pageInflon Ptfe Gasket Sheet: Inmarco Type 600ArunNo ratings yet

- Stellite 12Document2 pagesStellite 12xy2zjgNo ratings yet

- Strands Area and Their Specifications PDFDocument2 pagesStrands Area and Their Specifications PDFLamin AungNo ratings yet

- Stellite 6Document2 pagesStellite 6백승훈No ratings yet

- 20160331070853-5122 37MnSi5 PDFDocument2 pages20160331070853-5122 37MnSi5 PDFAnonymous yNuNE1iMW3No ratings yet

- Material Specification Sheet Saarstahl - 37mnsi5: 1.5122 Vms 135 BS: Afnor: Sae: Material Group: Chemical CompositionDocument2 pagesMaterial Specification Sheet Saarstahl - 37mnsi5: 1.5122 Vms 135 BS: Afnor: Sae: Material Group: Chemical CompositionAnonymous upAbzZNo ratings yet

- Polycarbonate Data SheetDocument1 pagePolycarbonate Data SheetJoseph Cloyd Lamberte100% (1)

- Hydro en Aw 1050aDocument1 pageHydro en Aw 1050aManoranjan MohapatraNo ratings yet

- 9700 Protector: Thermal Protector For Motor/Fluorescent Ballasts and Temperature Sensing ControlsDocument4 pages9700 Protector: Thermal Protector For Motor/Fluorescent Ballasts and Temperature Sensing ControlsRuben RodriguezNo ratings yet

- PB Unimax English160604152107Document12 pagesPB Unimax English160604152107filipeNo ratings yet

- Thin-Wall, Semirigid, Fluoropolymer Heat-Shrinkable Tubing: Temperature RatingDocument3 pagesThin-Wall, Semirigid, Fluoropolymer Heat-Shrinkable Tubing: Temperature RatingPabloNo ratings yet

- Hoist Chains: For Manual and Motor-Driven HoistsDocument12 pagesHoist Chains: For Manual and Motor-Driven HoistsjoosuasinagaNo ratings yet

- Z Marc 4Document1 pageZ Marc 4Brad SmolekNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- Pds Tial m80Document2 pagesPds Tial m80Yan FerizalNo ratings yet

- Dimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) With ABS PlusDocument8 pagesDimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) With ABS PlusChris BurgerNo ratings yet

- Extrusora Geomembranas Pro XDocument2 pagesExtrusora Geomembranas Pro XPaul Alex Quiroz BarrionuevoNo ratings yet

- Renk Tds Floating Labyrinth Seal enDocument2 pagesRenk Tds Floating Labyrinth Seal enJaime Vanegas IriarteNo ratings yet

- Stellite 6Document2 pagesStellite 6Shreenivas ThakurNo ratings yet

- Durolon HFR 1910Document2 pagesDurolon HFR 1910elrolo3000No ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- PB Elastoseal Tanking ENGDocument5 pagesPB Elastoseal Tanking ENGdan ivan100% (1)

- STC White Paper Zta Zirconia Toughened Alumina 01062021Document4 pagesSTC White Paper Zta Zirconia Toughened Alumina 01062021王柏昆No ratings yet

- Stellite 12 Technical DataDocument2 pagesStellite 12 Technical DataJakeTheSnake69No ratings yet

- Stellite 6 DS01-21708 (S R0808)Document2 pagesStellite 6 DS01-21708 (S R0808)bwv1006No ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Rexolite 2200 Spec SheetDocument1 pageRexolite 2200 Spec SheetTimothée Le gallNo ratings yet

- X-Tract Electrical Submersible Pump CableDocument2 pagesX-Tract Electrical Submersible Pump CableHarry RincónNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- CatalogueDocument6 pagesCatalogueFawwazNo ratings yet

- SentryGlas Technische BrochureDocument40 pagesSentryGlas Technische BrochureMarco CervioNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Silicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeDocument2 pagesSilicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeTran Tuan anhNo ratings yet

- O Ring Data SheetDocument3 pagesO Ring Data Sheetandri putrantoNo ratings yet

- Technical Data Sheet - Nylong: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylong: 3D Printing FilamentSteven DonosoNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- Pancake Geiger-Mueller Tubes: Gas-Filled Radiation DetectorsDocument2 pagesPancake Geiger-Mueller Tubes: Gas-Filled Radiation DetectorsmvpgmNo ratings yet

- FDM Nylon FamilyDocument6 pagesFDM Nylon FamilykaledioskoppNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- 2512 Thick Film Chip Resistor: Standard Grade, WraparoundDocument1 page2512 Thick Film Chip Resistor: Standard Grade, WraparoundasdfasdfsafdasfsaNo ratings yet

- Plexiglas G P 95 DP 95 FinalDocument3 pagesPlexiglas G P 95 DP 95 Finalyezer.coramNo ratings yet

- RHRB & RHSB: Material SpecificationsDocument1 pageRHRB & RHSB: Material SpecificationsHKC EQUIPEMENTSNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- Radiator Flush Rev 0.1 0816Document9 pagesRadiator Flush Rev 0.1 0816KalpeshNo ratings yet

- TDS Phosphonate HEDP 60Document2 pagesTDS Phosphonate HEDP 60KalpeshNo ratings yet

- Motor Medic 100063218 SdsDocument9 pagesMotor Medic 100063218 SdsKalpeshNo ratings yet

- Safety Data Sheet: Section 1 Product and Company InformationDocument3 pagesSafety Data Sheet: Section 1 Product and Company InformationKalpeshNo ratings yet

- SDS00153000270-01 PIKAL Liquid Metal PolishDocument12 pagesSDS00153000270-01 PIKAL Liquid Metal PolishKalpeshNo ratings yet

- Igcc Power Plants: (A New Technology To Answer Global Warming)Document16 pagesIgcc Power Plants: (A New Technology To Answer Global Warming)venky123456789No ratings yet

- Silo - Tips 2 Write The Chemical Formulas of The Products and Balance The Following Spontaneous ReactionsDocument40 pagesSilo - Tips 2 Write The Chemical Formulas of The Products and Balance The Following Spontaneous ReactionsAkash BhoiNo ratings yet

- Experimental Investigations Into Electrical Discharge Machining With A Rotating Disk ElectrodeDocument10 pagesExperimental Investigations Into Electrical Discharge Machining With A Rotating Disk ElectrodeENRIQUE RAMOSNo ratings yet

- HosesDocument1 pageHosesMazin KCNo ratings yet

- Open Ended QuestionsDocument2 pagesOpen Ended QuestionsMuriani Nur HayatiNo ratings yet

- 3 Impact LoadingDocument42 pages3 Impact Loadingsri kiran100% (1)

- SM AppSlidesDocument12 pagesSM AppSlidesrajrjNo ratings yet

- Furnace CGL#4 Micro Planning - Rev2Document138 pagesFurnace CGL#4 Micro Planning - Rev2PA PROJECTS PVT LTDNo ratings yet

- MoRTH - Standard Data BookDocument342 pagesMoRTH - Standard Data BookNo OneNo ratings yet

- Z&s Finishing CottonDocument12 pagesZ&s Finishing Cottonguven440% (1)

- BAroda BOQDocument16 pagesBAroda BOQTomNo ratings yet

- BASIC CIVIL - MODULE 2 - CementDocument75 pagesBASIC CIVIL - MODULE 2 - CementSEKHAR JNo ratings yet

- Engineering Materials and Metallurgy 2 Marks PDFDocument21 pagesEngineering Materials and Metallurgy 2 Marks PDFranjithNo ratings yet

- Ce133p 2 A74 HW1 DaguipaDocument13 pagesCe133p 2 A74 HW1 DaguipaColin Dwight M. DaguipaNo ratings yet

- Operation & Maintenance Guideline For Bio-Digesters: 6 Economics 11Document13 pagesOperation & Maintenance Guideline For Bio-Digesters: 6 Economics 11myco samNo ratings yet

- Material Safety Data SheetDocument11 pagesMaterial Safety Data SheetsystemNo ratings yet

- 4.5 Concentrations of SolutionsDocument4 pages4.5 Concentrations of Solutionsjunkhead254No ratings yet

- ROCKWOOL Technical Insulation ENG 06.2015 PDFDocument32 pagesROCKWOOL Technical Insulation ENG 06.2015 PDFSelvakumar PalaniandavarNo ratings yet

- Damage MechanismDocument10 pagesDamage MechanismAndiappan PillaiNo ratings yet

- Practical Lab ReportDocument5 pagesPractical Lab ReportAmirul Adli RozaimyNo ratings yet

- Procedure For Calculation of Efficiency-1Document7 pagesProcedure For Calculation of Efficiency-1JAY PARIKHNo ratings yet

- Ce Aim-JeDocument64 pagesCe Aim-JeKutty DhanushNo ratings yet

- GPCDOC GTDS Shell Irus C (En) TDSDocument2 pagesGPCDOC GTDS Shell Irus C (En) TDSDenny BayuajiNo ratings yet

- Review QuestionsDocument29 pagesReview QuestionsJjammppong AcostaNo ratings yet

- Anchor Bolt Design Using Anchor ReinforcementDocument8 pagesAnchor Bolt Design Using Anchor Reinforcementtiger_lxfNo ratings yet

- ChemistryQB Topic4c SQ eDocument22 pagesChemistryQB Topic4c SQ eNg Swee Loong StevenNo ratings yet

- HSS Canusa PDFDocument2 pagesHSS Canusa PDFresp-ectNo ratings yet

- Hs2-Hs2-Cv-Spe-000-011700 (P03)Document28 pagesHs2-Hs2-Cv-Spe-000-011700 (P03)Ciucan StefanNo ratings yet

- Experimental Study On Properties of Polymer-Modified Cement Mortars With Silica FumeDocument5 pagesExperimental Study On Properties of Polymer-Modified Cement Mortars With Silica FumeZarko LazicNo ratings yet